Chemical Resistance Chart.pdf - Aetna Plastics Corp.

Chemical Resistance Chart.pdf - Aetna Plastics Corp.

Chemical Resistance Chart.pdf - Aetna Plastics Corp.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

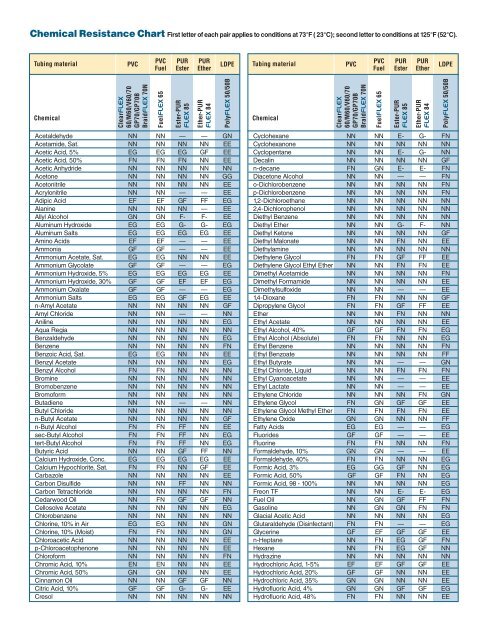

<strong>Chemical</strong> <strong>Resistance</strong> <strong>Chart</strong> First letter of each pair applies to conditions at 73°F ( 23°C); second letter to conditions at 125°F (52°C).<br />

Tubing material<br />

PVC<br />

PVC<br />

Fuel<br />

PUR<br />

Ester<br />

PUR<br />

Ether<br />

LDPE<br />

Tubing material<br />

PVC<br />

PVC<br />

Fuel<br />

PUR<br />

Ester<br />

PUR<br />

Ether<br />

LDPE<br />

<strong>Chemical</strong><br />

ClearFLEX<br />

60/M60/V60/70<br />

GP70/GP70B<br />

BraidFLEX 70N<br />

FuelFLEX 65<br />

Ester-PUR<br />

FLEX 85<br />

Ether-PUR<br />

FLEX 84<br />

PolyFLEX 50/50B<br />

<strong>Chemical</strong><br />

ClearFLEX<br />

60/M60/V60/70<br />

GP70/GP70B<br />

BraidFLEX 70N<br />

FuelFLEX 65<br />

Ester-PUR<br />

FLEX 85<br />

Ether-PUR<br />

FLEX 84<br />

PolyFLEX 50/50B<br />

Acetaldehyde NN NN — — GN<br />

Acetamide, Sat. NN NN NN NN EE<br />

Acetic Acid, 5% EG EG EG GF EE<br />

Acetic Acid, 50% FN FN FN NN EE<br />

Acetic Anhydride NN NN NN NN NN<br />

Acetone NN NN NN NN GG<br />

Acetonitrile NN NN NN NN EE<br />

Acrylonitrile NN NN — — EE<br />

Adipic Acid EF EF GF FF EG<br />

Alanine NN NN NN — EE<br />

Allyl Alcohol GN GN F- F- EE<br />

Aluminum Hydroxide EG EG G- G- EG<br />

Aluminum Salts EG EG EG EG EE<br />

Amino Acids EF EF — — EE<br />

Ammonia GF GF — — EE<br />

Ammonium Acetate, Sat. EG EG NN NN EE<br />

Ammonium Glycolate GF GF — — EG<br />

Ammonium Hydroxide, 5% EG EG EG EG EE<br />

Ammonium Hydroxide, 30% GF GF EF EF EG<br />

Ammonium Oxalate GF GF — — EG<br />

Ammonium Salts EG EG GF EG EE<br />

n-Amyl Acetate NN NN NN NN GF<br />

Amyl Chloride NN NN — — NN<br />

Aniline NN NN NN NN EG<br />

Aqua Regia NN NN NN NN NN<br />

Benzaldehyde NN NN NN NN EG<br />

Benzene NN NN NN NN FN<br />

Benzoic Acid, Sat. EG EG NN NN EE<br />

Benzyl Acetate NN NN NN NN EG<br />

Benzyl Alcohol FN FN NN NN NN<br />

Bromine NN NN NN NN NN<br />

Bromobenzene NN NN NN NN NN<br />

Bromoform NN NN NN NN NN<br />

Butadiene NN NN — — NN<br />

Butyl Chloride NN NN NN NN NN<br />

n-Butyl Acetate NN NN NN NN GF<br />

n-Butyl Alcohol FN FN FF NN EE<br />

sec-Butyl Alcohol FN FN FF NN EG<br />

tert-Butyl Alcohol FN FN FF NN EG<br />

Butyric Acid NN NN GF FF NN<br />

Calcium Hydroxide, Conc. EG EG EG EG EE<br />

Calcium Hypochlorite, Sat. FN FN NN GF EE<br />

Carbazole NN NN NN NN EE<br />

Carbon Disulfide NN NN FF NN NN<br />

Carbon Tetrachloride NN NN NN NN FN<br />

Cedarwood Oil NN FN GF GF NN<br />

Cellosolve Acetate NN NN NN NN EG<br />

Chlorobenzene NN NN NN NN NN<br />

Chlorine, 10% in Air EG EG NN NN GN<br />

Chlorine, 10% (Moist) FN FN NN NN GN<br />

Chloroacetic Acid NN NN NN NN EE<br />

p-Chloroacetophenone NN NN NN NN EE<br />

Chloroform NN NN NN NN FN<br />

Chromic Acid, 10% EN EN NN NN EE<br />

Chromic Acid, 50% GN GN NN NN EE<br />

Cinnamon Oil NN NN GF GF NN<br />

Citric Acid, 10% GF GF G- G- EE<br />

Cresol NN NN NN NN NN<br />

Cyclohexane NN NN E- G- FN<br />

Cyclohexanone NN NN NN NN NN<br />

Cyclopentane NN NN E- G- NN<br />

Decalin NN NN NN NN GF<br />

n-decane FN GN E- E- FN<br />

Diacetone Alcohol NN NN — — FN<br />

o-Dichlorobenzene NN NN NN NN FN<br />

p-Dichlorobenzene NN NN NN NN FN<br />

1,2-Dichloroethane NN NN NN NN NN<br />

2,4-Dichlorophenol NN NN NN NN NN<br />

Diethyl Benzene NN NN NN NN NN<br />

Diethyl Ether NN NN G- F- NN<br />

Diethyl Ketone NN NN NN NN GF<br />

Diethyl Malonate NN NN FN NN EE<br />

Diethylamine NN NN NN NN NN<br />

Diethylene Glycol FN FN GF FF EE<br />

Diethylene Glycol Ethyl Ether NN NN FN FN EE<br />

Dimethyl Acetamide NN NN NN NN FN<br />

Dimethyl Formamide NN NN NN NN EE<br />

Dimethylsulfoxide NN NN — — EE<br />

1,4-Dioxane FN FN NN NN GF<br />

Dipropylene Glycol FN FN GF FF EE<br />

Ether NN NN FN NN NN<br />

Ethyl Acetate NN NN NN NN EE<br />

Ethyl Alcohol, 40% GF GF FN FN EG<br />

Ethyl Alcohol (Absolute) FN FN NN NN EG<br />

Ethyl Benzene NN NN NN NN FN<br />

Ethyl Benzoate NN NN NN NN FF<br />

Ethyl Butyrate NN NN — — GN<br />

Ethyl Chloride, Liquid NN NN FN FN FN<br />

Ethyl Cyanoacetate NN NN — — EE<br />

Ethyl Lactate NN NN — — EE<br />

Ethylene Chloride NN NN NN FN GN<br />

Ethylene Glycol FN GN GF GF EE<br />

Ethylene Glycol Methyl Ether FN FN FN FN EE<br />

Ethylene Oxide GN GN NN NN FF<br />

Fatty Acids EG EG — — EG<br />

Fluorides GF GF — — EE<br />

Fluorine FN FN NN NN FN<br />

Formaldehyde, 10% GN GN — — EE<br />

Formaldehyde, 40% FN FN NN NN EG<br />

Formic Acid, 3% EG GG GF NN EG<br />

Formic Acid, 50% GF GF FN NN EG<br />

Formic Acid, 98 - 100% NN NN NN NN EG<br />

Freon TF NN NN E- E- EG<br />

Fuel Oil NN GN GF FF FN<br />

Gasoline NN GN GN FN FN<br />

Glacial Acetic Acid NN NN NN NN EG<br />

Glutaraldehyde (Disinfectant) FN FN — — EG<br />

Glycerine GF EF GF GF EE<br />

n-Heptane NN FN EG GF FN<br />

Hexane NN FN EG GF NN<br />

Hydrazine NN NN NN NN NN<br />

Hydrochloric Acid, 1-5% EF EF GF GF EE<br />

Hydrochloric Acid, 20% GF GF NN NN EE<br />

Hydrochloric Acid, 35% GN GN NN NN EE<br />

Hydrofluoric Acid, 4% GN GN GF GF EG<br />

Hydrofluoric Acid, 48% FN FN NN NN EE

Tubing material<br />

PVC<br />

PVC<br />

Fuel<br />

PUR<br />

Ester<br />

PUR<br />

Ether<br />

LDPE<br />

Tubing material<br />

PVC<br />

PVC<br />

Fuel<br />

PUR<br />

Ester<br />

PUR<br />

Ether<br />

LDPE<br />

<strong>Chemical</strong><br />

ClearFLEX<br />

60/M60/V60/70<br />

GP70/GP70B<br />

BraidFLEX 70N<br />

FuelFLEX 65<br />

Ester-PUR<br />

FLEX 85<br />

Ether-PUR<br />

FLEX 84<br />

PolyFLEX 50/50B<br />

<strong>Chemical</strong><br />

ClearFLEX<br />

60/M60/V60/70<br />

GP70/GP70B<br />

BraidFLEX 70N<br />

FuelFLEX 65<br />

Ester-PUR<br />

FLEX 85<br />

Ether-PUR<br />

FLEX 84<br />

PolyFLEX 50/50B<br />

Hydrogen Peroxide, 3% EG EG EG EG EE<br />

Hydrogen Peroxide, 30% GN GN GG GG EG<br />

Hydrogen Peroxide, 90% NN NN — — EG<br />

Iodine Crystals NN NN NN NN NN<br />

Isobutyl Alcohol GN GN FF FF EE<br />

Isopropyl Acetate NN NN NN NN GF<br />

Isopropyl Alcohol GN GN GF GF EE<br />

Isopropyl Benzene NN NN NN NN FN<br />

Isopropyl Ether NN NN GF FN NN<br />

Jet Fuel NN FN — — FN<br />

Kerosene NN GN GF FF FN<br />

Lacquer Thinner NN NN FN FN NN<br />

Lactic Acid, 3% EG EG EG EG EG<br />

Lactic Acid, 85% GF GF GF FF EE<br />

Mercury* GN GN EG EG EE<br />

2-Methoxyethanol GN GN G- G- EG<br />

Methoxyethyl Oleate NN NN GF FF EG<br />

Methyl Acetate NN NN NN NN FN<br />

Methyl Alcohol FN FN FN FN EE<br />

Methyl Ethyl Ketone NN NN NN NN EG<br />

Methyl Isobutyl Ketone NN NN NN NN GF<br />

Methyl Propyl Ketone NN NN NN NN GF<br />

Methyl-t-butyl Ether NN NN — — NN<br />

Methylene Chloride NN NN NN NN FN<br />

Mineral Oil (Petroleum) NN GN EG GF GN<br />

Mineral Spirits NN GN GN FN FN<br />

Nitric Acid, 1-10% EF EF NN FN EE<br />

Nitric Acid, 50% GN GN NN NN GN<br />

Nitric Acid, 70% NN NN NN NN FN<br />

Nitrobenzene NN NN NN NN NN<br />

Nitromethane NN NN NN NN NN<br />

n-Octane NN GN EG GF EE<br />

Orange Oil NN FN GF GF FN<br />

Ozone GF GF G- G- EG<br />

Perchloric Acid NN NN NN NN GN<br />

Perchloroethylene NN NN NN NN NN<br />

Phenol, Crystals FN FN NN NN GN<br />

Phenol, Liquid FN FN NN NN NN<br />

Phosphoric Acid, 1-5% EG EG NN NN EE<br />

Phosphoric Acid, 85% GF GF NN NN EE<br />

Picric Acid NN NN FN FN NN<br />

Pine Oil NN FN FN FN GN<br />

Potassium Hydroxide, 1% EG EG E- E- EE<br />

Potassium Hydroxide, conc. GF GF G- G- EE<br />

Propane Gas FN GN GF FF NN<br />

Propionic Acid FN FN GF FF FN<br />

Propylene Glycol GN GN G- G- EE<br />

Propylene Oxide FN FN — — EG<br />

Resorcinol, Sat. NN NN NN NN EE<br />

Resorcinol, 5% NN NN NN NN EE<br />

Salicylaldehyde NN NN — — EG<br />

Salicylic Acid, Powder GF GF — — EE<br />

Salicylic Acid, Sat. GF GF — — EE<br />

Salt Solutions, Metallic EG EG G- G- EE<br />

Silicone Oil GF GF E- G- EG<br />

Silver Acetate GN GN — — EE<br />

Silver Nitrate EG EG E- E- EG<br />

Skydrol LD4 NN NN NN NN GF<br />

Sodium Acetate, Sat. GN GN NN NN EE<br />

Sodium Hydroxide, 1% EG EG E- E- EE<br />

Sodium Hydroxide, 50%-Sat. GN GN G- G- GG<br />

Sodium Hypochlorite, 15% EG EG EG NN EE<br />

Stearic Acid, Crystals EG EG EF EF EE<br />

Sulfuric Acid, 1-6% EG EG GN EF EE<br />

Sulfuric Acid, 20% EF EF FN EF EE<br />

Sulfuric Acid, 60% FN FN NN NN EG<br />

Sulfuric Acid, 98% NN NN NN NN GG<br />

Sulfur Dioxide, Liq., 46 psig NN NN — — NN<br />

Sulfur Dioxide, Wet or Dry GN GN — — EE<br />

Sulfur Salts GN GN — — FN<br />

Tartaric Acid EG FG G- G- EE<br />

Tetrahydrofuran NN NN NN NN FN<br />

Thionyl Chloride NN NN — — NN<br />

Toluene NN NN FN NN FN<br />

Tributyl Citrate NN NN NN NN GF<br />

Trichloroacetic Acid FN FN NN NN FN<br />

1,2,4-Trichlorobenzene NN NN NN NN NN<br />

Trichloroethane NN NN NN NN NN<br />

Trichloroethylene NN NN NN NN NN<br />

Triethylene Glycol FN FN GF FN EG<br />

2,2,4-Trimethylpentane NN FN GF FN FN<br />

Tripropylene Glycol FN FN GF FN EE<br />

Tris Buffer Solution FN FN — — EG<br />

Turpentine FN FN GF GF FN<br />

Undecyl Alcohol GF GF EG GF EF<br />

Urea GN GN F- F- EE<br />

Vinylidene Chloride NN NN NN NN NN<br />

Xylene NN NN FN NN GN<br />

Zinc Stearate GF GF E- G- EE<br />

*Mercury will permeate through all resins listed but only chemically attack those resins not listed as EE.<br />

<strong>Chemical</strong> <strong>Resistance</strong> Classifications<br />

E 30 days of constant exposure cause no damage. Plastic may even tolerate for years.<br />

G Little or no damage after 30 days of constant exposure to the reagent.<br />

F Some effect after 7 days of constant exposure. Depending on the plastic, the effect may be crazing, cracking, loss of strength or discoloration.<br />

Solvents may cause softening, swelling and/or permeation losses.<br />

N Not recommended for continuous use. Immediate damage may occur. Depending on the plastic, the effect will be a more severe crazing,<br />

cracking, loss of strength, discoloration, deformation, dissolution or permeation loss.<br />

— Not tested. Finger Lakes Extrusion recommends that you test under your own conditions.<br />

NOTE: The chemical resistance information in this chart is a general guide only. Because many factors can affect chemical resistance,<br />

you should test under your own conditions. If any doubt exists about specific applications, contact Finger Lakes Extrusion.

<strong>Chemical</strong> Usage Guide<br />

Ether-PUR Ester-PUR<br />

ClearFLEX 60 ClearFLEX 70 FuelFLEX 65 BraidFLEX 70N FLEX GP70 FLEX 84 FLEX 85 PolyFLEX 50<br />

Material PVC PVC PVC Fuel PVC Reinf. PVC PUR Ether PUR Ester LDPE<br />

Acids – Weak E E E E E F F E<br />

Acids – Strong F F F F F N N E<br />

Alcohols – Aliphatic G G E G G F F E<br />

Aldehydes N N N N N F F G<br />

Bases – Weak E E E E E G G E<br />

Bases – Strong G G G G G F F G<br />

Esters N N N N N N N G<br />

Hydrocarbons - Aliphatic F F G F F E E F<br />

Hydrocarbons – Aromatic N N N N N N N F<br />

Hydrocarbons – Halogenated N N N N N N N N<br />

Ketones N N N N N N N G<br />

Oxidizing Agents – Strong F F F F F N N F<br />

NOTE: The chemical resistance information in this chart is a general guide only. Because many factors can affect chemical resistance,<br />

you should test under your own conditions. If any doubt exists about specific applications, contact Finger Lakes Extrusion.<br />

Tolerances<br />

Ether-PUR Ester-PUR<br />

ClearFLEX 60 ClearFLEX 70 FuelFLEX 65 BraidFLEX 70N FLEX GP70 FLEX 84 FLEX 85 PolyFLEX 50<br />

Inside Dia., +/- inches PVC PVC PVC Fuel PVC Reinf. PVC PUR Ether PUR Ester LDPE<br />

1/16 and under 1/8 .003 .003 .005 — .007 .005 .005 .007<br />

1/8 and under 5/16 .005 .005 .008 .010 .010 .009 .009 .007<br />

5/16 and under 1/2 .008 .008 .010 .012 .015 .012 .012 .007<br />

1/2 and under 3/4 .010 .010 .015 .015 .020 .018 .018 .010<br />

3/4 and under 1-1/8 .015 .015 .020 .015 .030 .025 .025 .015<br />

1-1/8 and under 1-3/4 .020 .020 — .020 .040 .035 .035 —<br />

1-3/4 and under 2-1/2 .031 .031 — .031 .055 — — —<br />

2-1/2 and under 3 — — — — .065 — — —<br />

3 and under 4 — — — — .080 — — —<br />

Wall Thickness, +/- inches<br />

0 to under 1/16 .003 .003 .004 — .005 .005 .005 .006<br />

1/16 to under 1/8 .003 .003 .005 — .006 .006 .006 .008<br />

1/8 to under 1/4 .005 .005 .010 — .020 .009 .009 —<br />

1/4 to under 3/8 .010 .010 .015 — .030 — — —<br />

3/8 to 1/2 .015 .015 .025 — .040 — — —<br />

04/01 00 15M