Darrtt Controls Full Linnee Catalog - Dart Controls

Darrtt Controls Full Linnee Catalog - Dart Controls

Darrtt Controls Full Linnee Catalog - Dart Controls

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

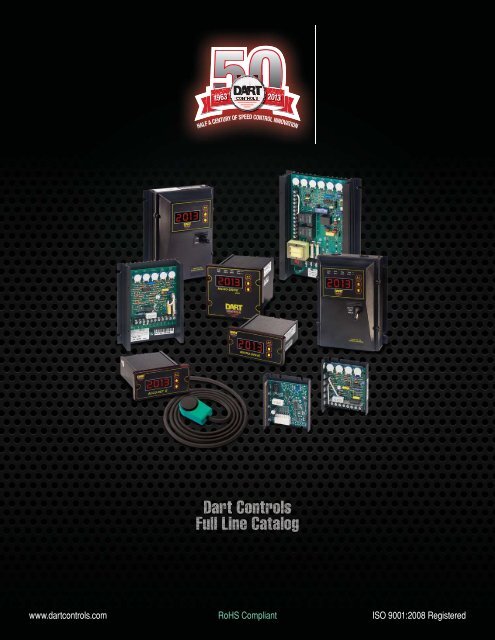

1963<br />

2013<br />

HALF A CENTURY OF SPEED CONTROL INNOVATION<br />

<strong>Dart</strong> <strong>Controls</strong><br />

<strong>Full</strong> Line <strong>Catalog</strong><br />

www.dartcontrols.com RoHS Compliant ISO 9001:2008 Registered

<strong>Dart</strong> Delivers What You Want…<br />

When You Need It!<br />

Since 1963, <strong>Dart</strong> <strong>Controls</strong> has<br />

been designing and manufacturing<br />

variable speed drives, controls,<br />

and accessories for electric<br />

motors in our Zionsville,<br />

Indiana facility.<br />

Our Mission is to lead<br />

the market in development<br />

of technologically advanced<br />

variable speed motor controls<br />

and accessory products while<br />

maintaining our commitment to customers,<br />

employees and owners.<br />

Our Passion is to develop or<br />

make available for sale the broadest<br />

range of products possible to<br />

meet customer’s<br />

variable speed<br />

drive and motor<br />

requirements. We<br />

listen to customers<br />

and when<br />

needed, we will<br />

modify existing or add a new design<br />

to our product offering. We also<br />

leverage our industry relationships to<br />

make available for sale<br />

related products (AC<br />

drives, motors and gear<br />

reducers for example)<br />

from manufacturers who<br />

share our passion for excellence<br />

and value.<br />

This Total Solutions<br />

Provider approach allows us to deliver<br />

Total Value to our customers.<br />

DART DELIVERS!<br />

PUT US TO THE TEST<br />

All information contained in this<br />

catalog is intended to be correct,<br />

however information and data in<br />

this catalog are subject to change<br />

without notice. <strong>Dart</strong> <strong>Controls</strong>, Inc.<br />

(DCI) makes no warranty of any kind<br />

with regard to this information or<br />

data. Further, DCI is not responsible<br />

for any omissions or errors or<br />

consequential damage caused by<br />

the user of the product. DCI reserves<br />

the right to make manufacturing<br />

changes which may not be included<br />

in this catalog.<br />

1963<br />

2013<br />

HALF A CENTURY OF SPEED CONTROL INNOVATION<br />

P.O. Box 10, 5000 W. 106th Street, Zionsville, Indiana 46077<br />

Phone: (317) 873-5211 FAX: (317) 873-1105<br />

www.dartcontrols.com<br />

ISO 9001:2008 REGISTERED RoHS Compliant<br />

2

TABLE OF CONTENTS<br />

PAGE<br />

SCR DC SPEED CONTROLS (1/50–3 Horsepower) 4–13<br />

500 Series<br />

250 Series<br />

130 Series<br />

125 Series<br />

15 Series<br />

Voltage Signal Isolator<br />

DIGITAL DC SPEED CONTROLS (1/50–2 Horsepower) 14–19<br />

MD Series<br />

MD plus Series<br />

MD II Series<br />

SMART SPEED POT CONTROL ACCESSORIES 20–25<br />

Accu-Set Series<br />

Accu-Set plus Series<br />

Accu-Set II Series<br />

DC BRUSHLESS MOTOR SPEED CONTROLS 26–31<br />

700/Commutrol Series<br />

BATTERY OPERATED MOTOR SPEED CONTROLS 32–33<br />

65 Series<br />

FIELD PROGRAMMABLE DIGITAL TACHOMETERS 34–36<br />

DM8000 Series<br />

DP4 Series<br />

SPEED SENSORS 37–40<br />

PU-E Pick-up Series<br />

Optical Pick-up Series<br />

CF Pick-up Series<br />

MPU-A Pick-up Series<br />

VARIABLE AC VOLTAGE SUPPLIES 41<br />

55AC Series and AC03 Series<br />

MASTER SPEED CONTROL 42<br />

STANDARD STOCK DC MOTORS (1/4–2.0 Horsepower) 43<br />

Stock DC Motors<br />

APPLICATION HIGHLIGHTS 44–46<br />

DEFINITION OF TERMS 47<br />

www.dartcontrols.com<br />

3

500 Series<br />

Variable Speed Control<br />

NEMA 4/12<br />

“RC” Chassis<br />

Washdown Duty<br />

cULus Recognized<br />

<strong>Dart</strong>’s most fully featured<br />

analog DC speed control is<br />

reliable, versatile, and economical.<br />

Rated to 3 horsepower, it provides<br />

many standard features typically<br />

offered as options.<br />

The <strong>Dart</strong> 500 Series control<br />

combines advanced engineering<br />

design, quality component selection<br />

and rigorous quality control to deliver<br />

an excellent off-the-shelf SCR control.<br />

Dependable, time-proven circuitry<br />

offers performance characteristics<br />

previously available only in more<br />

costly controls.<br />

MADE IN THE<br />

<br />

While providing a wide range<br />

of standard features, many options<br />

quickly and easily extend the 500<br />

Series’ capabilities to meet specific<br />

application requirements.<br />

An integral part of a distinguished<br />

line of quality products, the 500 Series<br />

is representative of <strong>Dart</strong>’s continuing<br />

effort to provide reliable, versatile<br />

controls to the OEM, distributor, and<br />

the industrial markets.<br />

Speed Potentiometer<br />

Kit Included<br />

4 www.dartcontrols.com

500 SERIES STANDARD FEATURES<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

knob included<br />

<br />

<br />

remote switching of AC power with low current momentary<br />

contacts. Prevents automatic restart after interruption of<br />

AC power.<br />

<br />

<br />

<br />

<br />

<br />

<br />

1000 RPM)<br />

<br />

<br />

<br />

<br />

<br />

<br />

500 SERIES SELECTION GUIDE<br />

H.P. CHASSIS ENCLOSED CHASSIS WITH<br />

RANGE “C” “RE” RELAY “RC”<br />

115 VAC Single Phase Input, 0-90 VDC Output 1<br />

<br />

1.5 533BC Available in chassis only, limited options available.<br />

230 VAC Single Phase Input, 0-180 VDC Output<br />

<br />

3.0 533BC Available in chassis only, limited options available.<br />

Horsepower settings are adjustable, see installation manual. Control is tested<br />

<br />

<br />

horsepower rating.<br />

DIMENSIONAL SPECIFICATIONS<br />

MODEL WIDTH LENGTH DEPTH WEIGHT<br />

English (inches)<br />

<br />

<br />

Metric (centimeters)<br />

Chassis 17.02 22.86 5.08 1134 gm.<br />

Enclosed 17.02 25.40 12.07 1422 gm.<br />

OPERATING CONDITIONS<br />

Temperature .......................................................... <br />

AC Input Voltage ................................... <br />

Input Frequency .............................................................<br />

ELECTRICAL SPECIFICATIONS AC INPUT 50/60 HZ<br />

115 VAC Single Phase Input, 0-90 VDC Output<br />

MAX. AC<br />

MAX. ARM*<br />

H.P. AMPS KVA AMPS DC<br />

1/8 1.8 0.22 1.4<br />

1/6 2.6 0.31 2.1<br />

1/4 3.5 0.42 2.7<br />

1/3 4.4 0.53 3.4<br />

1/2 6.5 0.78 5.0<br />

3/4 9.3 1.12 7.2<br />

1.0 13.2 1.58 10.2<br />

1.5 21.5 2.57 14.7<br />

230 VAC Single Phase Input, 0-180 VDC Output<br />

MAX. AC<br />

MAX. ARM*<br />

H.P. AMPS KVA AMPS DC<br />

1/4 1.8 0.42 1.4<br />

1/3 2.2 0.53 1.7<br />

1/2 3.3 0.78 2.5<br />

3/4 4.8 1.15 3.7<br />

1.0 6.5 1.56 5.0<br />

1.5 9.7 2.33 7.5<br />

2.0 12.9 3.10 9.9<br />

3.0 22.0 5.30 15.0<br />

<br />

POPULAR OPTIONS<br />

-5 option<br />

OPTION DESCRIPTION<br />

-36M option<br />

OPTION<br />

SUFFIX<br />

Jog (enclosed only) ...................................................................<br />

........................<br />

........................................<br />

Ten turn speed pot and dial plate (chassis only) ....................<br />

..................... <br />

NEMA 4/12 Enclosure .....................................................Standard<br />

<br />

Direction controlled with SPDT switch, relay contact (dry contact<br />

switching), or NPN open collector. Once direction change is initiated,<br />

cannot be aborted until motor stops; prevents relay contact welding<br />

(available through 2 H.P.)<br />

120 VAC ....................................................................... 1<br />

240 VAC ....................................................................... 1<br />

Other options are available, please consult factory for your requirement.<br />

* Field installable on chassis version only.<br />

<br />

www.dartcontrols.com<br />

5

250 Series<br />

Variable Speed Control<br />

Chassis<br />

NEMA 4/12<br />

Washdown Duty<br />

Speed Potentiometer<br />

Kit Included<br />

cULus Listed<br />

MADE IN THE<br />

<br />

The 250 Series offers superb<br />

flexibility, reliability, and value. A<br />

general purpose, economical control<br />

rated to 2 horsepower, it provides<br />

the ultimate in standard features and<br />

versatility including: dual voltage<br />

(120/240 VAC), adjustable H.P.<br />

settings, packaged power bridge,<br />

barrier terminal strip, fully ratedno<br />

auxiliary heatsink required,<br />

and chassis or NEMA 4/12 enclosure.<br />

Many options further extend<br />

the 250’s capabilities.<br />

A logical, easily accessible layout<br />

simplifies installation and adjustment.<br />

Clean design, quality components<br />

and careful assembly are trademarks<br />

of <strong>Dart</strong> <strong>Controls</strong>.<br />

History Note–1963<br />

The Easy<br />

Bake® oven<br />

was the #1<br />

toy seller<br />

<strong>Dart</strong><br />

<strong>Controls</strong><br />

was<br />

incorporated<br />

6 www.dartcontrols.com

250 SERIES STANDARD FEATURES<br />

<br />

<br />

<br />

<br />

<br />

±<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

ungrounded analog input signal (0–12 VDC)<br />

<br />

<br />

<br />

<br />

200V for 240 VAC input)<br />

<br />

<br />

250 SERIES SELECTION GUIDE<br />

H.P. RANGE CHASSIS “C” ENCLOSED “E”<br />

120 VAC Single Phase Input, 0-90 VDC Output<br />

<br />

<br />

240 VAC Single Phase Input, 0-180 VDC Output<br />

<br />

<br />

<br />

<br />

its category.<br />

DIMENSIONAL SPECIFICATIONS<br />

MODEL WIDTH LENGTH DEPTH WEIGHT<br />

English (inches)<br />

<br />

<br />

Metric (centimeters)<br />

Chassis 14.1 17.78 4.14 404 gm.<br />

Enclosed 14.1 18.42 6.98 486 gm.<br />

OPERATING CONDITIONS<br />

Temperature .......................................................... <br />

AC Input Voltage ................................... <br />

Input Frequency .............................................................<br />

ELECTRICAL SPECIFICATIONS AC INPUT 50/60 HZ<br />

120 VAC Single Phase Input, 0-90 VDC Output<br />

MAX. AC<br />

MAX. ARM*<br />

H.P. AMPS KVA AMPS DC<br />

1/50 0.5 0.06 0.4<br />

1/20 1.0 0.12 0.8<br />

1/8 2.0 0.24 1.6<br />

1/4 3.5 0.42 2.7<br />

1/3 4.4 0.53 3.4<br />

1/2 6.5 0.78 5.0<br />

3/4 9.3 1.12 7.2<br />

1 13.2 1.58 10.2<br />

240 VAC Single Phase Input, 0-180 VDC Output<br />

MAX. AC<br />

MAX. ARM*<br />

H.P. AMPS KVA AMPS DC<br />

1/4 1.8 0.42 1.4<br />

1/3 2.2 0.53 1.7<br />

1/2 3.3 0.78 2.5<br />

3/4 4.8 1.15 3.7<br />

1 6.5 1.56 5.0<br />

1 1/2 9.7 2.33 7.5<br />

2 12.9 3.10 9.9<br />

For dual voltage 250 series, use table for the input voltage you are using.<br />

<br />

POPULAR OPTIONS<br />

-5 option board<br />

OPTION DESCRIPTION<br />

-55G2 option<br />

boards<br />

OPTION<br />

SUFFIX<br />

NEMA 4X Enclosure .................................................................<br />

........................<br />

......................................... 1<br />

Decel equals Accel time .........................................................<br />

<br />

(center blocked, no Dynamic Brake–enclosed only) ...................<br />

<br />

..............................................................<br />

Torque control (enclosed only) ..............................................<br />

Isolated voltage follower (120/240 VAC input) – controls speed from<br />

any external grounded or ungrounded signal: 0-5 VDC thru 0-250 VDC<br />

adjustable (chassis only) ....................................................... <br />

........................... 1<br />

Other options are available, please consult factory for your requirement.<br />

* Field installable<br />

<br />

www.dartcontrols.com<br />

7

130 Series Reversing Control<br />

for PM and Shunt Wound DC Motors<br />

through 2 HP<br />

cULus Listed<br />

MADE IN THE<br />

<br />

Speed Potentiometer<br />

Kit Included<br />

Instant reversing, quick stopping,<br />

rapid cycling… The 130<br />

Series reversing control outperforms<br />

other dynamic braking and<br />

reversing controls by utilizing<br />

<strong>Dart</strong>’s unique zero-speed detect<br />

and dynamic braking circuits.<br />

These circuits eliminate the<br />

contact arcing and failed braking<br />

problems associated with other<br />

reversing and dynamic braking<br />

controls. <strong>Dart</strong>’s zero speed detect<br />

circuit also eliminates motor plug<br />

reversing problems.<br />

In the event of a power loss<br />

or emergency stop condition, the<br />

130 Series control will drop into a<br />

dynamic brake condition to safely<br />

and quickly bring the motor to a<br />

stop and remain there until power<br />

is reapplied and a run condition<br />

is recognized.<br />

History Note–1968<br />

UCLA wins<br />

men's NCAA®<br />

basketball<br />

title (again)<br />

Silicon<br />

Controlled<br />

Rectifier<br />

(SCR)<br />

patented<br />

8 www.dartcontrols.com

130 SERIES STANDARD FEATURES<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

VAC input or 200V for 240 VAC input)<br />

<br />

<br />

<br />

130 SERIES OPERATING CONDITIONS<br />

Temperature ........................................................... <br />

AC Input Voltage ................................... <br />

Input Frequency ..............................................................<br />

TYPICAL APPLICATIONS<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

130 SERIES MODEL NUMBERS AND RATINGS<br />

INPUT OUTPUT CYCLE<br />

MODEL VOLTAGE HP RANGE AMPS DC RATE<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

* Up to 10 amps continuous output current at 1 Hp 90VDC with suitable external heat sink.<br />

** Up to 10 amps continuous output current at 2 Hp 180VDC with suitable external heat sink.<br />

130 SERIES MECHANICAL SPECIFICATIONS, ADJUSTMENTS AND HOOK-UPS<br />

130 Series Hook-up<br />

4.063<br />

130 Series HC Models<br />

130 Series LC Models<br />

All dimensions in inches<br />

www.dartcontrols.com<br />

9

125 Series<br />

Variable Speed DC Control<br />

125DV-C<br />

Speed Potentiometer<br />

Kit Included<br />

cULus Recognized<br />

MADE IN THE<br />

<br />

The 125 Series is a compact,<br />

cost efficient, reliable control for<br />

PM, shunt wound, and universal<br />

motors that incorporates up-to-date<br />

design and engineering into a<br />

compact package.<br />

Installation and field adjustments<br />

are facilitated using a barrier type<br />

terminal strip and large, easily<br />

adjusted trimpots. Adjustable horsepower<br />

range.<br />

The 123D-C model operates on a<br />

low input voltage of 24/36 VAC with<br />

an output of 150mA–5.5 ADC<br />

Standard features include an<br />

inhibit circuit for start-stop operation<br />

and 1% speed regulation over<br />

a 50:1 speed range. Dual voltage<br />

120/240VAC or 24/36VAC models<br />

are available.<br />

Long life and quality are assured<br />

by 100% full load testing.<br />

The 125 Series is ideal for applications<br />

such as: office machinery, conveyors,<br />

office packaging equipment,<br />

printers, process equipment, centrifuges,<br />

and exercise equipment.<br />

History Note–1973<br />

Streaking is<br />

all the rage,<br />

for some<br />

reason<br />

<strong>Dart</strong><br />

introduces<br />

first SCR<br />

control for<br />

industrial<br />

use<br />

10 www.dartcontrols.com

125 SERIES STANDARD FEATURES<br />

<br />

<br />

<br />

<br />

<br />

±<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

supplying ungrounded analog input signal (0–12 VDC)<br />

<br />

<br />

<br />

<br />

125 SERIES SELECTION GUIDE<br />

H.P. RANGE MODEL INPUT OUTPUT<br />

<br />

}<br />

<br />

<br />

<br />

<br />

}<br />

<br />

<br />

<br />

from 5.5 amps DC to 10.0 amps DC.<br />

<br />

<br />

OPERATING CONDITIONS<br />

Temperature .......................................................... <br />

AC Input Voltage ................................... <br />

Input Frequency .............................................................<br />

ELECTRICAL SPECIFICATIONS AC INPUT 50/60 HZ<br />

120 VAC Single Phase Input, 0-90 VDC Output<br />

MAX. AC<br />

MAX. ARM*<br />

H.P. AMPS KVA AMPS DC<br />

1/50 0.5 0.06 0.4<br />

1/20 1.0 0.12 0.8<br />

1/8 2.0 0.24 1.6<br />

1/4 3.5 0.42 2.7<br />

1/3 4.4 0.53 3.4<br />

1/2 6.5 0.78 5.0<br />

240 VAC Single Phase Input, 0-180 VDC Output<br />

MAX. AC<br />

MAX. ARM*<br />

H.P. AMPS KVA AMPS DC<br />

1/4 1.8 0.42 1.4<br />

1/3 2.2 0.53 1.7<br />

1/2 3.3 0.78 2.5<br />

3/4 4.8 1.15 3.7<br />

1 6.5 1.56 5.0<br />

<br />

DIMENSIONAL SPECIFICATIONS<br />

MODEL WIDTH HEIGHT DEPTH WEIGHT<br />

English (inches)<br />

<br />

Metric (centimeters)<br />

Chassis 9.20 10.80 3.30 227 gm.<br />

ADJUSTMENTS AND HOOK-UP<br />

MIN<br />

MAX<br />

IR COMP<br />

CUR LIM<br />

POPULAR OPTIONS<br />

-55G option<br />

-5 option<br />

OPTION DESCRIPTION<br />

INHIBIT<br />

SPEEDPOT LO<br />

SPEEDPOT WIPER<br />

SPEEDPOT HI<br />

+FIELD<br />

-ARM/-FIELD<br />

+ARM<br />

AC INPUT<br />

AC INPUT<br />

-2A option<br />

OPTION<br />

SUFFIX<br />

Electronic speed control interlock – when AC power to control is<br />

applied, prevents motor from starting until speedpot is first<br />

rotated to the zero position, then CW. Also, should AC power<br />

be interrupted then restored, prevents automatic restart .....................<br />

Independently adjustable linear accel and decel<br />

............................................................... <br />

...............................................<br />

..........................................<br />

.................................. <br />

...................................... <br />

<br />

(center blocked, no Dynamic Brake) ................................... <br />

Isolated voltage follower (120/240 VAC input)– controls speed<br />

from any external grounded or ungrounded signal: 0-5 VDC thru 0-250<br />

VDC adjustable ...................................................................... <br />

.............................. <br />

<br />

........................... <br />

Other options are available, please consult factory for your requirement.<br />

* Field installable<br />

-8<br />

-7<br />

-6<br />

-5<br />

-4<br />

-3<br />

-2<br />

-1<br />

P1<br />

www.dartcontrols.com<br />

11

15DV1A<br />

MADE IN THE<br />

<br />

cULus Recognized<br />

15DV-E<br />

15 Series<br />

Adjustable Speed DC Control<br />

15DV2A<br />

The 15 Series is a general purpose, economical variable speed<br />

control for small DC and universal motor applications featuring:<br />

dual input voltages of 12/24 VAC or 120/240 VAC with a DC output<br />

current rating of 2 Amps, adjustable trimpot settings, and quick<br />

connect terminal pins. The 15 Series is available in two compact<br />

panel mount styles and a NEMA 4/12 enclosed model.<br />

15 SERIES STANDARD FEATURES<br />

Dual voltage models of 12/24 VAC or 120/240 VAC input<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

} Enclosed Model<br />

15 SERIES SELECTION GUIDE<br />

Suffix -1 and -2 refer to mounting configuration, see diagram below.<br />

MODEL DC OUTPUT INPUT OUTPUT<br />

CURRENT<br />

<br />

<br />

<br />

<br />

<br />

<br />

* Rating for D.C. Output Current can be increased from 2.0 to 4.0 amps w/suitable external heatsink<br />

(equiv. to 4” x 4” x .125” aluminum plate).<br />

DIMENSIONAL SPECIFICATIONS<br />

MODEL WIDTH HEIGHT DEPTH WEIGHT<br />

English (inches)<br />

<br />

<br />

<br />

Metric (centimeters)<br />

13DV1A/15DV1A 7.20 3.30 8.40 75 gm.<br />

13DV2A/15DV2A 7.20 3.90 8.40 83 gm.<br />

<br />

OPERATING CONDITIONS<br />

Temperature .......................................................... <br />

AC Input Voltage ................................... <br />

Input Frequency .............................................................<br />

ELECTRICAL SPECIFICATIONS AC INPUT 50/60 HZ<br />

MAXIMUM MAX.<br />

CONTINUOUS CONTINUOUS MAX<br />

MODEL AC AMPS ARM AMPS* HP<br />

12 VAC Single Phase Input, 0-11 VDC Output<br />

13DVA 2.6 2.0 1/40<br />

<br />

24 VAC Single Phase Input, 0-22 VDC Output<br />

13DVA 2.6 2.0 1/20<br />

<br />

120 VAC Single Phase Input, 0-90 VDC Output<br />

15DVA 2.6 2.0 1/6<br />

<br />

240 VAC Single Phase Input, 0-180 VDC Output<br />

15DVA 2.6 2.0 1/3<br />

<br />

* Minimum Armature Amps: 150mA D.C.<br />

HOOK-UP DIAGRAM<br />

HEATSINK DIMENSIONS AND STYLES<br />

.592<br />

.140<br />

.216<br />

.240<br />

2.500 +/-.050<br />

2.055<br />

.318 .178<br />

.203<br />

1.261<br />

.377 DIA.<br />

(1 HOLE)<br />

C L<br />

2.126<br />

2.326<br />

OPTION DESCRIPTION<br />

MAX<br />

IR COMP<br />

MIN<br />

.140 DIA.<br />

(2 PLACES)<br />

.750<br />

.230<br />

+ FIELD<br />

AC INPUT<br />

AC INPUT<br />

- FIELD<br />

- ARMATURE<br />

+ ARMATURE<br />

1 HOUSING<br />

(SIDE PROFILE)<br />

2 HOUSING<br />

OPTION<br />

SUFFIX<br />

Single pole AC switch integral with speedpot for<br />

120 VAC application only .................................................<br />

.............<br />

12 www.dartcontrols.com

VSI Series<br />

Voltage Signal Isolator*<br />

MADE IN THE<br />

<br />

The <strong>Dart</strong> VSI (voltage signal isolator) permits the user to control<br />

the output of a variable speed motor drive from any external<br />

grounded or ungrounded DC input signal. A single model accepts<br />

a wide range of input voltages (0-5 through 0-25VDC or 0-25<br />

through 0-250VDC). The GAIN trimpot is used to adjust the output<br />

of the VSI to full on when a full speed signal is applied to its<br />

input terminals. The VSI incorporates <strong>Dart</strong>’s unique feedback circuit,<br />

which virtually eliminates output changes due to the thermal<br />

drift of logic components. The VSI is packaged in an aluminum<br />

chassis mount housing and contains an on-board power supply<br />

for its logic circuit. An electrical isolation rating of 2500Vrms is<br />

achieved by the use of an optically isolated IC package.<br />

The <strong>Dart</strong> VSI can be used with virtually any motor speed control<br />

that has a speed reference circuit of +5 to +15VDC and an<br />

input impedance greater than 47K ohms. The output of the VSI<br />

is a filtered, pulse width modulated signal that is directly proportional<br />

to the input speed signal. The wide input range allows the<br />

VSI to follow signals as low as +0-5V logic levels and up to the<br />

180 VDC levels present at the armature leads of a 180 VDC motor.<br />

By simply connecting the input terminals across the armature<br />

leads of a “master motor”, you can use the VSI for master/follower<br />

operation. The addition of a scaling pot will provide for proportional<br />

follower operation.<br />

* By adding a resistor across signal input, VSI can function as<br />

a Current Signal Isolator.<br />

VSI SERIES SELECTION GUIDE<br />

MODEL<br />

<br />

SUPPLY VOLTAGE<br />

<br />

DIMENSIONAL SPECIFICATIONS<br />

WIDTH LENGTH DEPTH WEIGHT<br />

English<br />

<br />

Metric<br />

9.220 cm 10.795 cm 4.191 cm 277.3 gm<br />

VSI HOOK-UP CONFIGURATIONS<br />

AC INPUT<br />

DUAL VOLTAGE INPUT<br />

CONNECT TO<br />

SPEEDPOT INPUT<br />

OF MOTOR CONTROL{<br />

SIGNAL COMMON<br />

N.C.<br />

SIGNAL POSITIVE<br />

P3<br />

AC<br />

AC<br />

HI<br />

W<br />

LO<br />

COMMON<br />

+5V<br />

SIGNAL IN<br />

GAIN<br />

TRIMPOT<br />

STANDARD<br />

HOOK-UP<br />

P4<br />

-3<br />

-2<br />

-1<br />

JUMPER<br />

CLIP **<br />

CONNECT TO<br />

SPEEDPOT INPUT<br />

OF MOTOR CONTROL<br />

- ARM<br />

+ ARM<br />

www.dartcontrols.com<br />

MASTER<br />

MOTOR<br />

AC INPUT<br />

DUAL VOLTAGE INPUT<br />

250VDC<br />

MAX.<br />

{<br />

N.C.<br />

250K<br />

RATIO POT *<br />

(0-100% of Master)<br />

P3<br />

AC<br />

AC<br />

HI<br />

W<br />

LO<br />

COMMON<br />

+5V<br />

SIGNAL IN<br />

P4<br />

-3<br />

-2<br />

-1<br />

JUMPER<br />

CLIP **<br />

GAIN<br />

TRIMPOT<br />

FOLLOWER MODE<br />

HOOK-UP<br />

NOTES:<br />

*<br />

**<br />

If ratio of Master is NOT needed,<br />

delete the 250K pot and connect<br />

+Armature directly to Signal<br />

Input.<br />

Jumper clip is used to select<br />

input voltage range. When<br />

installed from P4-1 to P4-2, the<br />

range is 0-25VDC thru 0-250VDC;<br />

when installed from P4-2 to P4-3,<br />

range is 0-5VDC thru 0-25VDC.<br />

13

MD3E<br />

MD3P<br />

MD Series<br />

Digital Closed Loop DC Speed Control<br />

The MD Series is a compact, programmable DC speed control<br />

with digital closed loop feedback and LED display for DC<br />

motors rated to 2 horsepower. An on-board microprocessor with<br />

non-volatile memory, coupled with sophisticated internal software,<br />

makes <strong>Dart</strong>’s Micro-Drive the ultimate value in accuracy<br />

and control.<br />

Friendly front-panel field programming permits customizing<br />

the MD for specific applications. The MD can be set to<br />

display the target speed directly in RPM, FPM, GPM, process<br />

time, or any other engineering unit. Programmable parameters<br />

include maximum and minimum set speed, decimal points, and<br />

operating mode (master or follower).<br />

The Micro-Drive is simple to operate: set the desired RPM,<br />

rate, or time in the large 1/2" LED display by depressing the “Up”<br />

and “Down” pushbuttons on the front panel. Settings can be one<br />

digit at a time or fast sweep. The Micro-Drive settings are exact<br />

and repeatable. It will precisely control speed to ±1/2 RPM of set<br />

speed, long term. No calibrations of the control are necessary.<br />

The MD10P and MD3P have 1/8 DIN and 1/4 DIN<br />

industry standard cutout dimensions respectively, providing easy<br />

panel installations.<br />

TYPICAL APPLICATIONS<br />

<br />

<br />

<br />

processes, and heat shrink packaging<br />

<br />

<br />

<br />

<br />

<br />

MD10P<br />

MD SERIES STANDARD FEATURES<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

future use<br />

<br />

<br />

<br />

new settings<br />

<br />

lockout capability<br />

<br />

<br />

<br />

<br />

and intensity<br />

<br />

<br />

<br />

<br />

85–265 VAC<br />

<br />

<br />

<br />

form C relay<br />

<br />

OPTION DESCRIPTION<br />

MADE IN THE<br />

<br />

OPTION<br />

SUFFIX<br />

Provision for remote pushbutton switches ...............................<br />

...............................................................................<br />

Pluggable terminal strip ........................................................... <br />

...................................................<br />

14 www.dartcontrols.com

Tach<br />

MD SERIES SELECTION GUIDE<br />

MODEL MAX. ARM MAX<br />

NUMBER DC AMPS H.P. INPUT OUTPUT<br />

<br />

<br />

MOUNTING SPECIFICATIONS<br />

CONTROLS Page<br />

Ite<br />

Valu<br />

m<br />

4.000"<br />

Tach<br />

ENTER<br />

4.000"<br />

3.622"<br />

MD10P<br />

HOUSING DEPTH<br />

4.625"<br />

0.885"<br />

1.770"<br />

<br />

<br />

1/8 DIN<br />

MICRO-DRIVE<br />

.140" x 2<br />

PANEL CUT-OUT<br />

MD3E <br />

<br />

<br />

<br />

<br />

-Sensor must have minimum output current of 10 mA.<br />

-Drive includes supply for external sensor of 5VDC @50 mA max.<br />

-Shipped set for 0-2400 RPM with one pulse per revolution.<br />

MICRO-DRIVE<br />

CONTROLS<br />

ENTER<br />

.140" x 4<br />

3.622<br />

MD3P<br />

HOUSING DEPTH<br />

4.625"<br />

PANEL CUT-OUT<br />

0.811"<br />

3.622"<br />

2.000"<br />

OPERATING SPECIFICATIONS<br />

Temperature ........................................................... <br />

AC input voltage ........................................................ 85–265 VAC<br />

Input frequency ...............................................................<br />

Overload capacity ............................................ <br />

Transducer signal input ....................................... <br />

...........................................5 VDC, 50mA<br />

DIMENSIONAL SPECIFICATIONS<br />

MODEL WIDTH HEIGHT DEPTH<br />

MD10P inches (millimeters)<br />

Housing 3.620 (91.95) 1.656 (42.06) 4.625 (117.47)<br />

Lens 4.539 (115.29) 2.289 (58.13) 0.375 (9.52)<br />

MD3P inches (millimeters)<br />

Housing 3.620 (91.95) 3.497 (88.82) 4.625 (117.47)<br />

Lens 4.539 (115.29) 4.179 (106.15) 0.375 (9.52)<br />

1/4 DIN<br />

WIRING DIAGRAMS<br />

MD3E<br />

P1-1<br />

P1-2<br />

P1-3<br />

P1-4<br />

P1-5<br />

P1-6<br />

P1-7<br />

P1-8<br />

P1-9<br />

P1-10<br />

P1-11<br />

P1-12<br />

N<br />

L<br />

-A<br />

+A<br />

COM<br />

+5V<br />

S1<br />

S2<br />

NO<br />

C<br />

NC<br />

IN1<br />

-ARM<br />

+ARM<br />

COMMON<br />

+5VDC<br />

SIGNAL<br />

*Jog Input<br />

Ground Lug<br />

AC INPUT<br />

AC INPUT} 85-265VAC<br />

black<br />

red<br />

white<br />

Alarm Output - Normally Open<br />

Alarm Output - Common<br />

Alarm Output - Normally Closed<br />

*INHIBIT<br />

User Input 1<br />

MOTOR<br />

COM (P1-5)<br />

}<br />

Form<br />

* P1-8 & P1-12 user input may be programmed<br />

for a number of functions. Including (jog, inhibit, etc.)<br />

C<br />

Relay Output<br />

(Programmable)<br />

PICK-UP MOUNTED<br />

TO MOTOR SHAFT<br />

(Mounts on rotating<br />

end shaft with 10-32<br />

tapped hole, 1/2" deep)<br />

MOUNTING SPECIFICATIONS MD3E<br />

5.530<br />

Page Item Valu Tach<br />

ENTER<br />

7/32" TYP.<br />

(4 SLOTS)<br />

.350 DEEP<br />

MDP<br />

MASTER<br />

P1-1<br />

P1-2<br />

P1-3<br />

P1-4<br />

P1-5<br />

P1-6<br />

P1-7<br />

P1-8<br />

P1-9<br />

P1-10<br />

P1-11<br />

P1-12<br />

AC INPUT<br />

FUSE<br />

N<br />

MD10P = 7.5 Amp* }85-265VAC<br />

MD3P = 15 Amp*<br />

L<br />

AC INPUT<br />

-A<br />

-ARM<br />

+A<br />

+ARM<br />

MOTOR<br />

COM<br />

COMMON black<br />

+5V<br />

+5VDC red<br />

S1<br />

SIGNAL white<br />

S2<br />

**Jog Input<br />

NO Alarm Output - Normally Open<br />

C Alarm Output - Common<br />

Form C<br />

Relay Output<br />

NC Alarm Output - Normally Closed}<br />

(Programmable)<br />

IN1<br />

User Input 1<br />

**INHIBIT<br />

PICK-UP MOUNTED<br />

TO MOTOR SHAFT<br />

(Mounts on rotating<br />

end shaft with 10-32<br />

tapped hole, 1/2" deep)<br />

COM (P1-5)<br />

black<br />

CONTROLS<br />

* For AC inputs utilizing two hot lines, both inputs should be<br />

protected with appropriately sized fuses or circuit breakers.<br />

** P1-8 & P1-12 user input may be programmed<br />

for a number of functions. Including (jog, inhibit, etc.)<br />

white<br />

7.400<br />

ON<br />

OFF<br />

5.500<br />

.750<br />

MDP<br />

FOLLOWER<br />

P1-1<br />

P1-2<br />

P1-3<br />

P1-4<br />

P1-5<br />

P1-6<br />

P1-7<br />

P1-8<br />

P1-9<br />

P1-10<br />

P1-11<br />

P1-12<br />

N<br />

L<br />

FUSE<br />

MD10P = 7.5 Amp*<br />

MD3P = 15 Amp*<br />

-A<br />

-ARM<br />

+A<br />

+ARM<br />

COM<br />

COMMON<br />

+5V<br />

+5VDC<br />

S1<br />

SIGNAL 1<br />

S2<br />

NO Alarm Output - Normally Open<br />

C Alarm Output - Common<br />

NC Alarm Output - Normally Closed<br />

IN1<br />

User Input 1<br />

**INHIBIT<br />

SIGNAL 2<br />

COM (P1-5)<br />

AC INPUT<br />

}85-265VAC<br />

AC INPUT<br />

}<br />

MOTOR<br />

black<br />

red<br />

white<br />

Form C<br />

Relay Output<br />

(Programmable)<br />

FOLLOWER PICK-UP<br />

MOUNTED TO<br />

MOTOR SHAFT<br />

(Mounts on rotating<br />

end shaft with 10-32<br />

tapped hole, 1/2" deep)<br />

5.125 TYP.<br />

* For AC inputs utilizing two hot lines, both inputs should be<br />

protected with appropriately sized fuses or circuit breakers.<br />

** P1-8 & P1-12 user input may be programmed<br />

for a number of functions. Including (jog, inhibit, etc.)<br />

www.dartcontrols.com<br />

15

MD50E<br />

MD50P<br />

MD40P<br />

MADE IN THE<br />

<br />

MD Plus Series<br />

Digital Closed Loop DC Drive<br />

IDEAL FOR METERING PUMP AND OTHER APPLICATIONS<br />

REQUIRING AN ISOLATED 4-20MA INPUT/OUTPUT SIGNAL<br />

The MD plus is a field-programmable closed loop DC<br />

drive system employing an advanced velocity-form PID algorithm<br />

for accurate and responsive control. The MD plus system<br />

also features an optional isolated 4-20mA input and output<br />

for easy integration with existing Process Control systems.<br />

The MD plus system is ideally suited for metering pump<br />

applications by efficiently combining all of the application<br />

requirements into a single compact package. The MD plus<br />

system, when used with the OPT420 option, not only<br />

accepts a 4-20mA signal to control the pump speed,<br />

but it also provides a 4-20mA output signal back to the<br />

Process Control that is proportional to the actual running<br />

speed. Both the input and output signals are isolated from each<br />

other and from the control itself. The MD plus system also<br />

has two field-programmable Form C relay contacts that<br />

can be set to indicate a wide variety of conditions such as<br />

the pump is running, a “fault” condition exists, and many<br />

other events.<br />

The MD plus system is available in both enclosed and<br />

panel-mount versions. The MD50E version comes in a NEMA<br />

4X enclosure complete with an auto/off/manual switch on the<br />

cover. The 1/8 DIN MD40P and 1/4 DIN MD50P panel-mount<br />

versions come complete with a NEMA 4X rated faceplate, gasket<br />

kit, stainless steel mounting hardware, and connections for<br />

an external auto/manual switch.<br />

STANDARD FEATURES<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

AVAILABLE OPTIONS<br />

<br />

<br />

<br />

OPERATING SPECIFICATIONS<br />

Ambient Temp .........................................................<br />

Line Input Frequency ......................................................<br />

Overload Capacity ........................................... <br />

Transducer Input ................................................. <br />

<br />

Power Supply ...........................................................5 VDC, 50mA<br />

.............................................. ± <br />

16 www.dartcontrols.com

MD plus SERIES SELECTION GUIDE<br />

MODEL MAX. ARM MAX<br />

NUMBER DC AMPS H.P. INPUT OUTPUT<br />

<br />

<br />

<br />

<br />

<br />

<br />

DIMENSIONS (INCHES)<br />

MODEL WIDTH HEIGHT DEPTH<br />

MD40P (1/8 DIN)<br />

Housing 3.620 1.656 4.625<br />

Lens 4.539 2.289 0.375<br />

MD50P (1/4 DIN)<br />

Housing 3.620 3.497 4.625<br />

Lens 4.539 4.179 0.375<br />

MD50E (NEMA 4 enclosed)<br />

Housing 3.620 3.497 4.625<br />

Lens 4.539 4.179 0.375<br />

APPLICATIONS<br />

The MD plus system is ideal in many process applications<br />

requiring a closed-loop DC variable speed drive with an optional<br />

isolated 4-20mA input and output.<br />

Typical applications include:<br />

• Waste water treatment<br />

• Chemical metering processes<br />

• Laboratory mixing equipment<br />

• Industrial auger/mixing equipment<br />

• Polymer injection processes<br />

OPT420 OPTION<br />

The OPT420 Option may be factory or field installed to any<br />

drive in the MD Plus Series. The 4-20mA output is Loop Powered,<br />

relying on another device in the loop for its power. Both the<br />

4-20mA input and output are individually isolated. A second relay<br />

output is available when this option is used to indicate alarm and<br />

status information.<br />

OPT420 OPTION WIRING DIAGRAM<br />

+<br />

-<br />

+<br />

-<br />

P6<br />

P3<br />

3<br />

2<br />

1<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

MD50E DRIVE TYPICAL WIRING DIAGRAM<br />

OPT420<br />

SEE<br />

4-20mA HOOK-UP<br />

5A 250V<br />

Form C<br />

}<br />

OPT420 RELAY Output - Common<br />

OPT420 RELAY Output - Normally Open Relay Output<br />

(Programmable)<br />

OPT420 RELAY Output - Normally Closed<br />

Auto / Manual Switch<br />

(Open = Manual)<br />

- 4-20mA In (Black)<br />

WIRING DIAGRAM – MASTER/FOLLOWER<br />

MD plus<br />

MASTER<br />

MD plus<br />

FOLLOWER<br />

P1-1<br />

P1-2<br />

P1-3<br />

P1-4<br />

P1-5<br />

P1-6<br />

P1-7<br />

P1-8<br />

P1-9<br />

P1-10<br />

P1-11<br />

P1-12<br />

MD<br />

MASTER<br />

P1-1<br />

P1-2<br />

P1-3<br />

P1-4<br />

P1-5<br />

P1-6<br />

P1-7<br />

P1-8<br />

P1-9<br />

P1-10<br />

P1-11<br />

P1-12<br />

P1-1<br />

P1-2<br />

P1-3<br />

P1-4<br />

P1-5<br />

P1-6<br />

P1-7<br />

P1-8<br />

P1-9<br />

P1-10<br />

P1-11<br />

P1-12<br />

N<br />

L<br />

-A<br />

+A<br />

COM<br />

+5V<br />

S1<br />

S2<br />

NO<br />

C<br />

NC<br />

IN1<br />

- 4-20mA Out (Black)<br />

-ARM<br />

+ARM<br />

COMMON<br />

+5VDC<br />

SIGNAL<br />

*Jog Input<br />

Ground Lug<br />

-<br />

4-20mA OUT<br />

(White)<br />

4-20mA IN (White)<br />

AC INPUT<br />

AC INPUT} 85-265VAC<br />

MOTOR<br />

black<br />

red<br />

white<br />

Alarm Output - Normally Open<br />

Alarm Output - Common<br />

Alarm Output - Normally Closed<br />

User Input 1<br />

**INHIBIT<br />

COM (P1-5)<br />

* For AC inputs utilizing two hot lines, both inputs should be<br />

protected with appropriately sized fuses or circuit breakers.<br />

** P1-8(S2) & P1-12(IN1) user input may be programmed<br />

for a number of functions, including (jog, inhibit, etc.)<br />

+<br />

+<br />

-<br />

Form C<br />

Relay Output<br />

}(Programmable)<br />

AC INPUT<br />

FUSE<br />

N MD40P = 7.5 Amp* }85-265VAC<br />

MD50P = 15 Amp*<br />

L<br />

AC INPUT<br />

-A<br />

-ARM<br />

+A<br />

+ARM<br />

MOTOR<br />

COM<br />

COMMON black<br />

+5V<br />

+5VDC red<br />

S1<br />

SIGNAL white<br />

S2<br />

**Jog Input<br />

NO Alarm Output - Normally Open<br />

C Alarm Output - Common<br />

Form C<br />

Relay Output<br />

}<br />

NC Alarm Output - Normally Closed (Programmable)<br />

IN1<br />

User Input 1<br />

**INHIBIT<br />

COM (P1-5)<br />

black<br />

white<br />

AC INPUT<br />

FUSE<br />

N MD40P = 7.5 Amp* }85-265VAC<br />

MD50P = 15 Amp*<br />

L<br />

AC INPUT<br />

-A<br />

-ARM<br />

+A<br />

+ARM<br />

MOTOR<br />

COM<br />

COMMON<br />

black<br />

+5V<br />

red<br />

+5VDC<br />

S1<br />

SIGNAL 1<br />

white<br />

S2<br />

SIGNAL 2<br />

NO Alarm Output - Normally Open<br />

C Alarm Output - Common<br />

Form C<br />

Relay Output<br />

NC<br />

}<br />

Alarm Output - Normally Closed (Programmable)<br />

IN1<br />

User Input 1<br />

**INHIBIT<br />

COM (P1-5)<br />

+ -<br />

9-36VDC<br />

EXCITATION<br />

SUPPLY<br />

PICK-UP MOUNTED<br />

TO MOTOR SHAFT<br />

(Mounts on rotating<br />

end shaft with 10-32<br />

tapped hole, 1/2" deep)<br />

CUSTOMER<br />

SUPPLIED<br />

IF NEEDED<br />

PICK-UP MOUNTED<br />

TO MOTOR SHAFT<br />

(Mounts on rotating<br />

end shaft with 10-32<br />

tapped hole, 1/2" deep)<br />

FOLLOWER PICK-UP<br />

MOUNTED TO<br />

MOTOR SHAFT<br />

(Mounts on rotating<br />

end shaft with 10-32<br />

tapped hole, 1/2" deep)<br />

www.dartcontrols.com<br />

17

MD30P<br />

MD20P<br />

MADE IN THE<br />

<br />

The MDII Series digital motor speed controls, employing<br />

an advanced 16-bit microprocessor, are designed for digital closed<br />

loop operation of up to 2 horsepower DC permanent magnet<br />

motors. This control features a true P-I-D algorithm, for extremely<br />

responsive and precise control over a wide variety<br />

of desired speeds and applications. The MDII Series is<br />

designed as a companion or direct replacement control to the MD<br />

Series, while offering expanded performance features.<br />

Set or actual speed is displayed directly in RPM, FPM,<br />

PROCESS TIME, or other engineering units. Field programming<br />

permits customizing specific operating parameters.<br />

The integrated RS485/RS422/RS232 serial interface port is<br />

perfect for monitoring or control using almost any computer or<br />

process controller. Units can even be attached in a Local Area<br />

Network, and can then be controlled and programmed either individually<br />

or all at once. Multiple programs allow the user to choose<br />

between a “menu” of up to six programmed configurations.<br />

The MDII series is the ultimate answer for precise, responsive,<br />

cost-effective and flexible closed loop motor speed control.<br />

COMMUNICATION FEATURES<br />

MD30E<br />

MDII Series<br />

Programmable Digital Closed Loop<br />

DC Speed Control with P-I-D and<br />

RS Communication<br />

<br />

<br />

<br />

<br />

<br />

<br />

via one cable. <strong>Controls</strong> can be individually programmed<br />

or integrated.<br />

<br />

<br />

be followed together over single RS485 twisted pair<br />

<br />

STANDARD FEATURES<br />

<br />

<br />

<br />

<br />

<br />

time, or other engineering units<br />

<br />

<br />

±1/2 RPM of set speed<br />

<br />

<br />

<br />

<br />

programmable parameters<br />

<br />

<br />

control target speed, current program or frequency generator<br />

output<br />

<br />

<br />

control units<br />

<br />

front panel lockout prevents accidental setting changes<br />

<br />

<br />

<br />

<br />

<br />

<br />

leader frequency.<br />

<br />

membrane seals faceplate from environment<br />

<br />

<br />

selected from the front panel via the up/down pushbutton<br />

switches<br />

PROGRAMMING FEATURES<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

rate or time<br />

<br />

<br />

<br />

<br />

<br />

<br />

follower, Network Follower)<br />

<br />

<br />

<br />

<br />

18 www.dartcontrols.com

MDII SERIES SELECTION GUIDE<br />

MODEL MAX. ARM MAX<br />

NUMBER DC AMPS H.P. INPUT OUTPUT<br />

<br />

<br />

<br />

<br />

OPERATING SPECIFICATIONS<br />

Temperature ..........................................................<br />

AC Input Voltage ...................................................... 85–265 VAC<br />

Input Frequency ............................................................<br />

Overload Capacity .......................................... <br />

Transducer Signal Input .................<br />

WIRING DIAGRAM–MASTER/FOLLOWER<br />

<br />

<br />

<br />

<br />

<br />

-Sensor must have minimum output current of 10 mA.<br />

-Drive includes supply for external sensor of 5VDC @25 mA max.<br />

-Shipped set for 0-2400 RPM with one pulse per revolution.<br />

MDII<br />

MASTER<br />

P1-1<br />

P1-2<br />

P1-3<br />

P1-4<br />

P1-5<br />

P1-6<br />

P1-7<br />

P1-8<br />

P1-9<br />

P1-10<br />

P1-11<br />

P1-12<br />

FUSE*<br />

-ARM<br />

+ARM<br />

COMMON<br />

+5VDC<br />

SIGNAL 1<br />

UNUSED<br />

UNUSED<br />

UNUSED<br />

UNUSED<br />

black<br />

red<br />

white<br />

OPTIONAL<br />

INHIBIT<br />

SWITCH<br />

* MD20P = 7.5 Amp<br />

MD30P = 15 Amp<br />

AC AC INPUT} 85-265VAC<br />

MOTOR<br />

black<br />

white<br />

PICK-UP MOUNTED<br />

TO MOTOR SHAFT<br />

(Mounts on rotating<br />

end shaft with 10-32<br />

tapped hole, 1/2" deep)<br />

OPTION DESCRIPTION<br />

OPTION<br />

SUFFIX<br />

<br />

signal input (MD30E only) .......................................................<br />

....................................................<br />

...................................................<br />

Pluggable terminal strip ............................................................ <br />

WIRING DIAGRAM - MASTER<br />

MDII<br />

FOLLOWER<br />

P1-1<br />

P1-2<br />

P1-3<br />

P1-4<br />

P1-5<br />

P1-6<br />

P1-7<br />

P1-8<br />

P1-9<br />

P1-10<br />

P1-11<br />

P1-12<br />

FUSE*<br />

-ARM<br />

+ARM<br />

COMMON<br />

UNUSED<br />

UNUSED<br />

UNUSED<br />

+5VDC<br />

SIGNAL 1<br />

UNUSED<br />

OPTIONAL<br />

INHIBIT<br />

SWITCH<br />

AC AC INPUT} 85-265VAC<br />

black<br />

red<br />

white<br />

MOTOR<br />

FOLLOWER PICK-UP<br />

MOUNTED TO<br />

MOTOR SHAFT<br />

(Mounts on rotating<br />

end shaft with 10-32<br />

tapped hole, 1/2" deep)<br />

P1-1<br />

P1-2<br />

P1-3<br />

P1-4<br />

P1-5<br />

P1-6<br />

P1-7<br />

P1-8<br />

P1-9<br />

P1-10<br />

P1-11<br />

P1-12<br />

Page<br />

FUSE*<br />

-ARM<br />

+ARM<br />

COMMON<br />

+5VDC<br />

SIGNAL 1<br />

UNUSED<br />

UNUSED<br />

UNUSED<br />

UNUSED<br />

OPTIONAL<br />

INHIBIT<br />

SWITCH<br />

Item<br />

CONTROLS<br />

5.530<br />

Valu<br />

black<br />

red<br />

white<br />

COM (P1-5)<br />

Tach<br />

AC AC INPUT} 85-265VAC<br />

ENTER<br />

MOTOR<br />

MOUNTING SPECIFICATIONS - MD30E<br />

PICK-UP MOUNTED<br />

TO MOTOR SHAFT<br />

(Mounts on rotating<br />

end shaft with 10-32<br />

tapped hole, 1/2" deep)<br />

7/32" TYP<br />

(4 SLOTS)<br />

.350 DEEP<br />

<br />

fusing or switch needed.<br />

DIMENSIONAL SPECIFICATIONS<br />

MODEL WIDTH HEIGHT DEPTH<br />

MD20P inches (millimeters)<br />

Housing 3.620 (91.95) 1.656 (42.06) 4.625 (117.47)<br />

Lens 4.539 (115.29) 2.289 (58.13) 0.375 (9.52)<br />

MD30P inches (millimeters)<br />

Housing 3.620 (91.95) 3.497 (88.82) 4.625 (117.47)<br />

Lens 4.539 (115.29) 4.179 (106.15) 0.375 (9.52)<br />

MOUNTING SPECIFICATIONS - MD20P / MD30P<br />

CONTROLS<br />

Page<br />

Item<br />

4.000"<br />

Valu<br />

Tach<br />

MICRO-DRIVE II<br />

4.000"<br />

ENTER<br />

* MD20P = 7.5 Amp<br />

MD30P = 15 Amp<br />

Dia .140" x 2<br />

4.000"<br />

3.622"<br />

MD20P<br />

HOUSING DEPTH<br />

4.625"<br />

PANEL CUT-OUT<br />

4.000"<br />

3.622"<br />

.885"<br />

1.770"<br />

7.400<br />

5.500<br />

Page<br />

Item<br />

Valu<br />

Tach<br />

ENTER<br />

MD30P<br />

.811"<br />

ON<br />

OFF<br />

MICRO-DRIVE II<br />

HOUSING DEPTH<br />

4.625"<br />

3.622"<br />

2.000"<br />

CONTROLS<br />

PANEL CUT-OUT<br />

Dia .140" x 4<br />

.750<br />

5.125 TYP.<br />

www.dartcontrols.com<br />

19

Accu-Set Series<br />

Smart Speed Potentiometer<br />

for Improved AC or DC Drive<br />

System Performance<br />

MADE IN THE<br />

<br />

The Accu-Set is a compact, economical control that can<br />

be used with conventional AC, DC, or Brushless DC adjustable<br />

speed drive systems to provide an LED display of set<br />

speeds and precise, digital closed loop motor speed control.<br />

An on-board microprocessor with non-volatile memory coupled<br />

with sophisticated internal software makes <strong>Dart</strong>’s Accu-Set the<br />

ultimate in accuracy and control.<br />

Target speeds are displayed directly in RPM, FPM, GPM,<br />

process time, or any other engineering unit of measure.<br />

Friendly front-panel field programming permits customizing the<br />

Accu-Set to the exact specifications for each application; maximum<br />

and minimum set speed, decimal points or colon, operating<br />

mode (master or follower), and the constant which takes into account<br />

motor gear ratios.<br />

The Accu-Set is simple to operate… just set the desired RPM,<br />

rate, or time in the large 1/2" LED display by depressing the<br />

“up-down” pushbuttons, one digit at a time or fast sweep. The<br />

Accu-Set settings are exact and repeatable. It will precisely control<br />

speed to a remarkable ±1/2 RPM of set speed, long term.<br />

The panel mount unit is easy to install in the industry standard<br />

cutout dimensions of 1/8 DIN. All wiring connects directly to a<br />

European style terminal strip through the easy access rear panel.<br />

TYPICAL APPLICATIONS<br />

<strong>Dart</strong>’s Accu-Set design is ideal for providing the same precise<br />

closed loop control and digital readout as the MD Series Micro-<br />

Drive in new or retro-fit applications that use an AC, DC, or Brushless<br />

DC motor drive system.<br />

OPERATING SPECIFICATIONS<br />

Temperature .......................................................... -10° to +45° C<br />

AC input voltage .......................................................85–265 VAC<br />

Input frequency ...............................................................50/60 Hz<br />

Transducer signal input ......................................0-5 to 0-24 VDC<br />

On-board power supply ..........................................5 VDC, 50mA<br />

(for external sensors)<br />

History Note–1978<br />

The<br />

Unabomber<br />

sends<br />

his first<br />

"package"<br />

<strong>Dart</strong><br />

expands<br />

into<br />

worldwide<br />

markets<br />

20 www.dartcontrols.com

Tach<br />

ACCU-SET SERIES STANDARD FEATURES<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

with parameter lockout capability<br />

<br />

(linear or accelerating)<br />

<br />

<br />

and intensity<br />

<br />

<br />

<br />

<br />

input from 85–265 VAC<br />

<br />

<br />

<br />

<br />

<br />

stored for future use<br />

<br />

<br />

<br />

ASP SELECTION GUIDE<br />

MODEL INPUT DISPLAY UNITS STD. SPEED RANGE<br />

ASP10 120/240 VAC Rate or Time Field Programmable*<br />

Requires <strong>Dart</strong> PU-E or other pick-up.<br />

* Shipped set for 0–2400 RPM with one pulse per revolution<br />

ASP<br />

ASTER<br />

ACCU-SET HOOK-UP- MASTER AND FOLLOWER<br />

M<br />

A<br />

S<br />

T<br />

E<br />

R<br />

P1-1<br />

P1-2<br />

P1-3<br />

P1-4<br />

P1-5<br />

P1-6<br />

P1-7<br />

P1-8<br />

P1-9<br />

P1-10<br />

P1-11<br />

P1-12<br />

ASP CONFIGURATIONS<br />

2 AMP AC AC INPUT} 85-265VAC<br />

HIGH OUTPUT<br />

Connect to the speedpot<br />

of the control being driven.<br />

WIPER OUTPUT } High must be positive<br />

voltage with respect to low.<br />

LOW OUTPUT<br />

COMMON<br />

+5VDC<br />

SIGNAL 1<br />

black<br />

red<br />

white<br />

SIGNAL 2<br />

Alarm Output - Normally Open<br />

Form C<br />

Relay output<br />

}<br />

Alarm Output - Common<br />

Alarm Output - Normally Closed (Programmable)<br />

* P1-9 signal input may be programmed for a number of functions. Incl (jog, inhibit, etc.)<br />

F<br />

O<br />

L<br />

ASP<br />

OLLOWER L<br />

O<br />

W<br />

E<br />

R<br />

P1-1<br />

P1-2<br />

P1-3<br />

P1-4<br />

P1-5<br />

P1-6<br />

P1-7<br />

P1-8<br />

P1-9<br />

P1-10<br />

P1-11<br />

P1-12<br />

COMMON<br />

+5VDC<br />

* Optional Inhibit Switch<br />

*<br />

black<br />

red<br />

SIGNAL 1<br />

white<br />

*<br />

SIGNAL 2<br />

Alarm Output - Normally Open<br />

Form C<br />

Relay output<br />

}<br />

Alarm Output - Common<br />

Alarm Output - Normally Closed (Programmable)<br />

black<br />

2 AMP AC AC INPUT} 85-265VAC<br />

HIGH OUTPUT Connect to the speedpot<br />

of the control being driven.<br />

WIPER OUTPUT } High must be positive<br />

voltage with respect to low.<br />

LOW OUTPUT<br />

white<br />

PICK-UP MOUNTED<br />

TO MOTOR SHAFT<br />

(Mounts on rotating<br />

end shaft with 10-32<br />

tapped hole, 1/2" deep)<br />

FOLLOWER PICK-UP<br />

MOUNTED TO<br />

MOTOR SHAFT<br />

(Mounts on rotating<br />

end shaft with 10-32<br />

tapped hole, 1/2" deep)<br />

OPTION DESCRIPTION<br />

OPTION<br />

SUFFIX<br />

Provisions for remote pushbutton switches ...............................<br />

Pluggable terminal strip ............................................................ <br />

....................................................<br />

DIMENSIONAL SPECIFICATIONS<br />

MODEL WIDTH HEIGHT DEPTH<br />

ASP 10 inches (millimeters)<br />

Housing 3.620 (91.95) 1.656 (42.06) 4.625 (117.47)<br />

Lens 4.539 (115.29) 2.289 (58.13) 0.375 (9.52)<br />

FEED<br />

REEL<br />

PU-2E<br />

ASP10<br />

motor<br />

PICK-UP<br />

Constant rate control<br />

speed<br />

control<br />

TAKE UP<br />

REEL<br />

SPEED<br />

CONTROL<br />

Ideal for maintaining precise SCR speed<br />

load regulation<br />

MOTOR<br />

ASP10<br />

MOUNTING SPECIFICATIONS<br />

4.000"<br />

4.000"<br />

3.622"<br />

speed<br />

control<br />

motor<br />

PU-2E<br />

ASP10<br />

speed<br />

control<br />

motor<br />

PU-2E<br />

CONTROLS<br />

Page<br />

Ite<br />

m<br />

Valu<br />

Tach<br />

ENTER<br />

ASP10<br />

HOUSING DEPTH<br />

4.625"<br />

0.885"<br />

1.770"<br />

Follower motor as % of master motor speed<br />

MICRO-DRIVE<br />

ACCU-SET<br />

.140" x 2<br />

PANEL CUT-OUT<br />

PU-2E<br />

motor<br />

speed<br />

control<br />

ASP10<br />

ASP10<br />

speed<br />

control<br />

motor<br />

PU-2E<br />

PU-2E<br />

motor<br />

speed ASP10<br />

control<br />

System for mixing and blending ratio control<br />

www.dartcontrols.com<br />

21

ASP Plus Series<br />

Smart Speed Pot for Any * Drive<br />

*must accept a 3-wire speed pot input<br />

Performance matched with<br />

<strong>Dart</strong>'s PU Series Encoder<br />

MADE IN THE<br />

<br />

The ASP PLUS Series is the<br />

latest development from <strong>Dart</strong> in the<br />

area of SMART speed pots.<br />

A SMART speed pot is:<br />

• Digital<br />

• Programmable<br />

• Closed-loop<br />

• Multi-function<br />

• Multi-mode<br />

The ASP PLUS is ideal for<br />

applications where a remote PLC/<br />

SCADA system sends the motor<br />

drive a set speed.<br />

History Note–1980<br />

Rubik's Cube,<br />

Pac-Man,<br />

J.R. Ewing<br />

(Dallas)<br />

<strong>Dart</strong><br />

introduces the<br />

Micro-Drive<br />

digital DC<br />

speed control<br />

The ASP PLUS works in con-<br />

junction with any drive by providing<br />

an isolated input for the PLC/SCADA<br />

command, using encoder feedback<br />

closes the motor loop to maintain tight<br />

speed regulation, and sends analog<br />

or serial communication data back<br />

to the supervisory system to verify<br />

actual motor speed. Along with motor<br />

not running indication, remote stop<br />

and Auto/Manual control modes the<br />

ASP PLUS packs all these features<br />

in one small package eliminating<br />

installation space and labor costs.<br />

The ASP PLUS is a real problem<br />

solver for plant maintenance,<br />

system integrator and OEM equipment<br />

designers.<br />

22 www.dartcontrols.com

ASP PLUS STANDARD FEATURES<br />

<br />

to suit your process control needs<br />

<br />

to accommodate a wide variety of I/O<br />

±1/2 RPM of<br />

set speed or equivalent<br />

<br />

impractical or undesired<br />

<br />

when power has been removed<br />

<br />

<br />

options, alarm options, and more<br />

<br />

<br />

<br />

<br />

automatically adjusts as needed.<br />

<br />

industrial environments<br />

<br />

<br />

<br />

at least 3mA<br />

<br />

<br />

<br />

<br />

Jog functionality<br />

<br />

(colon displayed in Time mode)<br />

<br />

Polycarbonate membrane and gasket (which are included) meet<br />

NEMA 4X standards when used with NEMA 4X enclosures<br />

<br />

block available<br />

<br />

<br />

<br />

<br />

<br />

<br />

Gallons per Second, etc.<br />

<br />

<br />

<br />

ASP PLUS SELECTION GUIDE<br />

MODEL INPUT ENCODER 4-20mA<br />

@ 50-60HZ REQUIRED? OUTPUT?<br />

<br />

<br />

DIMENSIONAL SPECIFICATIONS<br />

MODEL WIDTH HEIGHT DEPTH<br />

ASP40/ASP40-420 English (inches)<br />

Housing 3.620 1.656 4.625<br />

Lens 4.539 2.289 0.375<br />

ASP40/ASP40-420 Metric (millimeters)<br />

Housing 91.95 42.06 117.47<br />

Lens 115.29 58.14 9.52<br />

SPECIFICATIONS<br />

Signal Input Voltage Range .................................. 5VDC to 24VDC<br />

<br />

<br />

Speed Pickup<br />

Input Frequency (S1 and S2 Inputs) ..........................0 – 600,000<br />

<br />

<br />

Display Range .........................................................0.001 – 9,999<br />

"Engineering Units” .......................User Programmable, any Units<br />

Sensor / Pickup Power Supply ................................... <br />

ASP40 Isolated Alarm Relay Output Rating .............<br />

OPT420 Isolated Alarm Relay Output Rating .............<br />

Voltage Difference<br />

between PotLo and PotHi Inputs ....................... 2VDC to 24VDC<br />

<br />

voltage range ...................<br />

OPERATING CONDITIONS<br />

Temperature .......................................................... <br />

us<br />

ASP PLUS HOOK-UP– MASTER AND FOLLOWER<br />

M<br />

A<br />

S<br />

T<br />

E<br />

R<br />

P1-1<br />

P1-2<br />

P1-3<br />

P1-4<br />

P1-5<br />

P1-6<br />

P1-7<br />

P1-8<br />

P1-9<br />

P1-10<br />

P1-11<br />

P1-12<br />

2 AMP AC AC INPUT} 85-265VAC<br />

HIGH OUTPUT<br />

Connect to the speedpot<br />

of the control being driven.<br />

WIPER OUTPUT } High must be positive<br />

voltage with respect to low.<br />

LOW OUTPUT<br />

COMMON black<br />

red<br />

+5VDC<br />

SIGNAL 1 white<br />

*<br />

SIGNAL 2<br />

Alarm Output - Normally Open<br />

Alarm Output - Common<br />

Alarm Output - Normally Closed<br />

Form C<br />

Relay output<br />

} (Programmable)<br />

signal input may be programmed for a number of functions. Incl (jog, inhibit, etc.)<br />

P1-9 signal input may be programmed for a number of functions. Incl (jog, inhibit, etc.<br />

F<br />

O<br />

L<br />

L<br />

O<br />

W<br />

E<br />

R<br />

us<br />

R<br />

P1-1<br />

P1-2<br />

P1-3<br />

P1-4<br />

P1-5<br />

P1-6<br />

P1-7<br />

P1-8<br />

P1-9<br />

P1-10<br />

P1-11<br />

P1-12<br />

2 AMP AC AC INPUT} 85-265VAC<br />

HIGH OUTPUT Connect to the speedpot<br />

of the control being driven.<br />

WIPER OUTPUT } High must be positive<br />

voltage with respect to low.<br />

LOW OUTPUT<br />

COMMON<br />

+5VDC<br />

SIGNAL 1<br />

SIGNAL 2<br />

Alarm Output - Normally Open<br />

Alarm Output - Common<br />

Alarm Output - Normally Closed<br />

* Optional Inhibit Switch<br />

black<br />

red<br />

black<br />

white<br />

*<br />

Form C<br />

Relay output<br />

}<br />

(Programmable)<br />

white<br />

PICK-UP MOUNTED<br />

TO MOTOR SHAFT<br />

(Mounts on rotating<br />

end shaft with 10-32<br />

tapped hole, 1/2" deep)<br />

FOLLOWER PICK-UP<br />

MOUNTED TO<br />

MOTOR SHAFT<br />

(Mounts on rotating<br />

end shaft with 10-32<br />

tapped hole, 1/2" deep)<br />

www.dartcontrols.com<br />

23

MADE IN THE<br />

<br />

Accu-Set II Series<br />

Smart Speed Potentiometer<br />

for Use with Conventional<br />

AC Frequency or DC Drives<br />

The Accu-Set II Series digital control unit, with an advanced<br />

16-bit Microprocessor, is designed for use with conventional AC<br />

frequency or DC drives, any horsepower, to provide: LED display<br />

of set or actual speed, closed loop motor speed control, Master or<br />

Follower modes, and Serial communications.<br />

The Accu-Set II Series is a companion control to the<br />

Accu-Set Series, while offering significantly improved<br />

performance. This control features a true P-I-D algorithm, for<br />

extremely responsive and precise control over a wide variety of<br />

desired speeds and applications.<br />

Set or actual speed is displayed directly in RPM, FPM, Process<br />

Time, or other engineering units. Field programming permits<br />

customizing specific operating parameters.<br />

The integrated RS485/RS422/RS232 serial interface port is<br />

perfect for monitoring or control using almost any computer or<br />

process controller. Units can even be attached in a Local Area<br />

Network, and can then be controlled and programmed either individually<br />

or all at once. Multiple programs allow the user to choose<br />

between a “menu” of up to six programmed configurations.<br />

The Accu-Set II Series is ideally suited for commercial or<br />

industrial applications, including system up-grades.<br />

COMMUNICATION FEATURES<br />

<br />

<br />

<br />

<br />

<br />

<br />

via one cable. <strong>Controls</strong> can be individually programmed<br />

or integrated.<br />

<br />

9600 baud<br />

<br />

followed together over single RS485 twisted pair wire or over<br />

<br />

ACCU-SET II SERIES STANDARD FEATURES<br />

<br />

<br />

<br />

<br />

process time, or other engineering units<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

programmable parameters<br />

<br />

<br />

control target speed, current program or frequency generator<br />

output<br />

<br />

<br />

control units<br />

<br />

front panel lockout prevents accidental setting changes<br />

<br />

<br />

<br />

<br />

<br />

leader frequency.<br />

<br />

<br />

<br />

<br />

be selected from the front panel via the up/down pushbutton<br />

switches<br />

PROGRAMMING FEATURES<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

rate or time<br />

<br />

<br />

<br />

be programmed<br />

<br />

<br />

network follower)<br />

<br />

<br />

<br />

<br />

24 www.dartcontrols.com

ACCU-SET II SERIES ASP20 SELECTION GUIDE<br />

MODEL INPUT DISPLAY UNITS STD. SPEED RANGE<br />

ASP20 120/240 VAC Rate or Time Field Programmable*<br />

Requires <strong>Dart</strong> PU-E or other pick-up.<br />

* Shipped set for 0 - 3600 RPM with one pulse per revolution.<br />

OPERATING SPECIFICATIONS<br />

Temperature .......................................................... <br />

AC input voltage ........................................................ 85–265 VAC<br />

Input frequency ..............................................................<br />

Transducer signal input ....................................... <br />

...........................................5 VDC, 50mA<br />

<br />

MOUNTING SPECIFICATIONS - ASP20<br />

CONTROLS<br />

Page<br />

Item<br />

4.000"<br />

Valu<br />

Tach<br />

MICRO-DRIVE<br />

ACCU-SET II<br />

DIMENSIONAL SPECIFICATIONS<br />

Dia .140" x 2<br />

4.000"<br />

3.622"<br />

ASP20<br />

HOUSING DEPTH<br />

4.625"<br />

PANEL CUT-OUT<br />

.885"<br />

1.770"<br />

MODEL WIDTH HEIGHT DEPTH<br />

ASP20 inches (millimeters)<br />

Housing 3.620 (91.95) 1.656 (42.06) 4.625 (117.47)<br />

Lens 4.539 (115.29) 2.289 (58.13) 0.375 (9.52)<br />

OPTION DESCRIPTION<br />

OPTION<br />

SUFFIX<br />

....................................................<br />

................................................................................<br />

HOOK-UP DIAGRAMS - ASP20<br />

A<br />

S<br />

P<br />

20<br />

M<br />

A<br />

S<br />

T<br />

E<br />

R<br />

A<br />

S<br />

P<br />

20<br />

F<br />

O<br />

L<br />

L<br />

O<br />

W<br />

ER<br />

P1-1<br />

P1-2<br />

P1-3<br />

P1-4<br />

P1-5<br />

P1-6<br />

P1-7<br />

P1-8<br />

P1-9<br />

P1-10<br />

P1-11<br />

P1-12<br />

P1-1<br />

P1-2<br />

P1-3<br />

P1-4<br />

P1-5<br />

P1-6<br />

P1-7<br />

P1-8<br />

P1-9<br />

P1-10<br />

P1-11<br />

P1-12<br />

FUSE<br />

2 Amp<br />

COMMON<br />

+5VDC<br />

SIGNAL 1<br />

SIGNAL 2<br />

UNUSED<br />

UNUSED<br />

UNUSED<br />

HIGH OUT<br />

WIPER OUT<br />

LOW OUT<br />

FUSE<br />

2 Amp<br />

HIGH OUT<br />

WIPER OUT<br />

LOW OUT<br />

COMMON<br />

+5VDC<br />

SIGNAL 1<br />

UNUSED<br />

UNUSED<br />

UNUSED<br />

black<br />

red<br />

white<br />

AC INPUT} AC INPUT<br />

85-265VAC<br />

SIGNAL 2<br />

* OPTIONAL INHIBIT SWITCH<br />

(Open = Inhibit)<br />

(Closed = Run)<br />

AC AC INPUT} 85-265VAC<br />

*<br />

Output<br />

Connection<br />

}See<br />

Note Below<br />

* OPTIONAL INHIBIT<br />

SWITCH<br />

(Open = Run)<br />

(Closed = Inhibit)<br />

Output<br />

Connection<br />

}See<br />

Note Below<br />

*<br />

white<br />

black<br />

red<br />

white<br />

PICK-UP MOUNTED<br />

TO MOTOR SHAFT<br />

(Mounts on rotating<br />

end shaft with 10-32<br />

tapped hole, 1/2" deep)<br />

red<br />

black<br />

FOLLOWER PICK-UP<br />

MOUNTED TO<br />

MOTOR SHAFT<br />

(Mounts on rotating<br />

end shaft with 10-32<br />

tapped hole, 1/2" deep)<br />

MASTER PICK-UP<br />