108 Series Hydraulic Power Units Oildyne

108 Series Hydraulic Power Units Oildyne

108 Series Hydraulic Power Units Oildyne

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

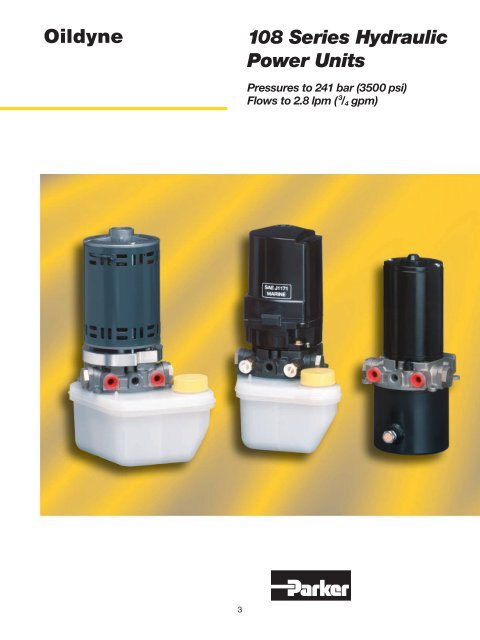

<strong>Oildyne</strong><br />

<strong>108</strong> <strong>Series</strong> <strong>Hydraulic</strong><br />

<strong>Power</strong> <strong>Units</strong><br />

Pressures to 241 bar (3500 psi)<br />

Flows to 2.8 lpm ( 3 / 4 gpm)<br />

3

Catalog HY22-1121/US<br />

Features<br />

<strong>Hydraulic</strong> <strong>Power</strong> <strong>Units</strong><br />

<strong>108</strong> <strong>Series</strong><br />

Typical applications<br />

Positioning<br />

• <strong>Hydraulic</strong> door operators<br />

• Conveyor belt tensioners<br />

• Medical chairs, beds, and equipment<br />

Recreational Vehicles<br />

• Leveling<br />

• Slideouts<br />

• Tent Trailers<br />

Clamping<br />

• Tool fixtures and jigs<br />

• <strong>Hydraulic</strong> brakes<br />

• Crimping tools<br />

• Arbor presses<br />

• Truck restraints<br />

Cycling<br />

• Garbage compactors<br />

• Valve operators<br />

• Press controls<br />

• Packing equipment<br />

• Indexing tables<br />

Lifting<br />

• Handicap lifts<br />

• Scissor lift tables<br />

• Pallet movers<br />

<strong>108</strong> <strong>Series</strong> Self-contained<br />

<strong>Hydraulic</strong> <strong>Power</strong> <strong>Units</strong><br />

Our compact <strong>108</strong> <strong>Series</strong> power units let you put the<br />

power where you need it. They’re completely self-contained<br />

with an AC or DC motor, gear pump, reservoir,<br />

internal valving, load hold checks and relief valves.<br />

The <strong>108</strong> <strong>Series</strong> models are designed for intermittent<br />

service and come in four standard pump sizes which<br />

produce flows of .0098, .0187, .0246, and .0321 cubic<br />

inches per revolution. Locking check valves are available<br />

in all models. Performance will vary with the type<br />

of fluid used. Several hydraulic circuits are available.<br />

<strong>108</strong> <strong>Series</strong> units are available with single- or bi-directional<br />

rotation. Single units are commonly used to<br />

charge accumulators, power one-direction hydraulic<br />

motors and cylinders, provide pilot flow to servo<br />

valves, pressurize lube systems and supply multifunction<br />

circuits with external valving.<br />

Bi-directional, reversible units operate double-acting<br />

cylinders and two-way motors.<br />

We’d like to work with you on your special hydraulic<br />

applications. Our people know small hydraulics. We<br />

know how to design them, how to make them and<br />

how to apply them. Therefore, we can offer you a<br />

practical, economical solution to your fluid power<br />

problems.<br />

<strong>Oildyne</strong> has pioneered top quality, compact hydraulic<br />

components since 1955. We can provide standard<br />

products or custom design high pressure, space saving<br />

solutions to your specific needs.<br />

4<br />

Parker Hannifin Corporation<br />

<strong>Oildyne</strong> Division<br />

Minneapolis, MN 55428 USA

Catalog HY22-1121/US<br />

Technical Information<br />

<strong>Hydraulic</strong> <strong>Power</strong> <strong>Units</strong><br />

<strong>108</strong> <strong>Series</strong><br />

Standard Product Ordering Code<br />

<strong>108</strong><br />

<strong>108</strong> SERIES POWER UNIT<br />

STANDARD ORDERING CODE<br />

<strong>108</strong> POWER UNIT<br />

- includes relief<br />

valve(s)<br />

AE<br />

AM<br />

BE<br />

BI<br />

HA<br />

HD<br />

IA<br />

MOTOR CODE<br />

12 vdc Permanent Magnet<br />

12 vdc <strong>Series</strong> Wound<br />

24 vdc Permanent Magnet<br />

24 vdc <strong>Series</strong> Wound<br />

115 vac, 1 phase, Open<br />

230 vac, 1 phase, Open<br />

36 vdc Permanent Magnet<br />

PUMP TYPE<br />

S Standard<br />

C Cold Temp<br />

DN RV SETTING<br />

(Right Hand Port)<br />

Use 00 for Single Dir.<br />

In multiples of 100 psi<br />

Examples<br />

04 = 400 psi<br />

12 = 1200 psi<br />

29 = 2900 psi<br />

UP RV SETTING<br />

(Left Hand Port)<br />

In multiples of 100 psi<br />

Examples<br />

04 = 400 psi<br />

12 = 1200 psi<br />

29 = 2900 psi<br />

A<br />

B<br />

C<br />

D<br />

F<br />

G<br />

H<br />

I<br />

J<br />

P<br />

Q<br />

R<br />

S<br />

PUMP SIZE<br />

10 .0098 CIPR<br />

19 .0187 CIPR<br />

25 .0249 CIPR<br />

32 .0321 CIPR<br />

RESERVOIR<br />

26 cu. in. (13 cu. in. usable)<br />

46 cu. in. (23 cu. in. usable)<br />

46 cu. in. (26 cu. in. usable)<br />

Alternate orientation version of C<br />

122 cu. in. (82 cu. in. usable)<br />

69 cu. in. (46 cu. in. usable)<br />

1/2 gallon usable<br />

1 gallon usable<br />

1-1/2 gallon usable<br />

1/4 gal. usable (plastic)<br />

1/2 gal. usable (plastic)<br />

1 gal. usable (plastic)<br />

3/4 gal. usable (plastic)<br />

NOTES: C and D reservoirs<br />

are available as Vertical<br />

Mount ONLY. A reservoir with<br />

pump 32 is available ONLY as<br />

vertical mount.<br />

V<br />

H<br />

PORTS<br />

1 7/16-20 (SAE -4)<br />

2 7/16-24 (Inv. Flare)<br />

3 1/8" Pipe (NPSF)<br />

4 1/8" Pipe (BSPP)<br />

MOUNTING<br />

Vertical (motor up)<br />

Horizontal<br />

CIRCUIT TYPE<br />

NN Single direction<br />

WW Single direction with check<br />

RR Reversible<br />

LL Reversible locking<br />

RB Reversible with Back Pressure<br />

LB Reversible locking with Back Pressure<br />

Each Solenoid Valve option below<br />

includes the WW circuit:<br />

S1 12 vdc, Normally Closed<br />

S2 24 vdc, Normally Closed<br />

S3 120 vac, Normally Closed<br />

S4 240 vac, Normally Closed<br />

S5 12 vdc, Normally Open<br />

S6 24 vdc, Normally Open<br />

S7 120 vac, Normally Open<br />

S8 240 vac, Normally Open<br />

ORDERING CODE INSTRUCTIONS<br />

Select the model code needed based on catalog information. All boxes above must be filled in before <strong>Oildyne</strong> can process the<br />

order. If the power unit is a single direction unit use '00' for the DN (Right Hand) relief valve box.<br />

<strong>Hydraulic</strong> Fluid<br />

ATF, OD18, or other clean hydraulic oil with a viscosity<br />

of 150 to 300 SUS at 38°C (100°F) is acceptable.<br />

If another type of fluid is needed, please consult the<br />

factory.<br />

Temperature Range<br />

Normal operating range is +20°F to +140°F. Please<br />

review your application with the factory for uses below<br />

-7°C and over +60°C (+20°F and over +140°F).<br />

ALL DATA SUBJECT TO CHANGE WITHOUT NOTICE<br />

FOR POWER UNIT CONFIGURATIONS OTHER THAN THOSE SHOWN PLEASE CONSULT OILDYNE.<br />

5<br />

Parker Hannifin Corporation<br />

<strong>Oildyne</strong> Division<br />

Minneapolis, MN 55428 USA

Catalog HY22-1121/US<br />

Technical Information<br />

<strong>Hydraulic</strong> <strong>Power</strong> <strong>Units</strong><br />

<strong>108</strong> <strong>Series</strong><br />

12/24 V DC Permanent Magnet Motor • Code AE • BE<br />

Motor Type: AE and BE<br />

For intermittent duty cycles.<br />

-12 VDC SUPPLY (AE)<br />

-24 VDC SUPPLY (BE)<br />

12/24 V DC <strong>Series</strong> Wound Motor • Code AM • BI<br />

Motor Type: AM and BI<br />

For intermittent duty cycles.<br />

115/230 V AC Capacitor Start Motor • Code HA • HD<br />

Motor Type: HA and HD<br />

Dual voltage 1/3 HP, 60/50 hz,<br />

3450/2850 rpm, intermittent<br />

duty, single phase, open frame.<br />

Capacitor and relay included.<br />

Wiring Diagram: AE • BE<br />

DPDT CENTER<br />

OFF TOGGLE SWITCH<br />

Output Flow - lpm (cipm)<br />

Output Flow - lpm (cipm)<br />

Output Flow - lpm (cipm)<br />

.82<br />

(50)<br />

.100 Pump (.0098 cipr)<br />

with AE / BE Motor<br />

+12 VDC SUPPLY (AE)<br />

.66<br />

20<br />

+24 VDC SUPPLY (BE)<br />

(40)<br />

Flow<br />

LEFT HAND<br />

RIGHT HAND<br />

PORT<br />

PORT<br />

.49<br />

Current 15<br />

(30)<br />

@ 12 VDC<br />

GREEN OR<br />

BLUE OR<br />

ORANGE<br />

BLACK<br />

.33<br />

MOTOR LEAD<br />

MOTOR LEAD<br />

(20)<br />

10<br />

.16<br />

(10)<br />

5<br />

Current<br />

MOTOR<br />

@ 24 VDC<br />

0<br />

0<br />

0 34 69 103 138 172 207<br />

DPDT CENTER OFF TOGGLE<br />

(500) (1000) (1500) (2000) (2500) (3000)<br />

SWITCH USABLE UP TO 20 AMPS<br />

@ 12 VDC<br />

Pressure - bar (psi)<br />

Wiring Diagram: AM • BI<br />

.100 Pump (.0098 cipr)<br />

1.6 with AM / BI Motor<br />

+12 VDC SUPPLY (AM)<br />

-12 VDC SUPPLY (AM)<br />

60<br />

(100)<br />

+24 VDC SUPPLY (BI)<br />

-24 VDC SUPPLY (BI)<br />

SPDT<br />

CENTER OFF<br />

1.3 Flow<br />

TOGGLE SWITCH<br />

(80)<br />

48<br />

Current<br />

LEFT HAND RIGHT HAND<br />

@ 12 VDC<br />

PORT<br />

PORT<br />

.98<br />

36<br />

(60)<br />

SOL<br />

SOL<br />

SWITCH<br />

1 2<br />

SWITCH<br />

.66<br />

(40)<br />

24<br />

SOL 1 SWITCH<br />

SOL 2 SWITCH<br />

CONTACTS<br />

CONTACTS<br />

.33<br />

(20)<br />

12<br />

Current<br />

@ 24 VDC<br />

BLUE<br />

GREEN<br />

MOTOR LEAD<br />

MOTOR LEAD<br />

0<br />

0<br />

BLACK<br />

0 34 69 103 138 172 207 241<br />

MOTOR LEAD<br />

(500) (1000) (1500) (2000) (2500) (3000) (3500)<br />

NOTES: AM MOTOR HAS 100 AMP<br />

Pressure - bar (psi)<br />

THERMAL BREAKER; MOTOR<br />

BI MOTOR HAS 50 AMP<br />

THERMAL BREAKER.<br />

.100 Pump (.0098 cipr)<br />

.82 with HA / HD Motor<br />

5<br />

Wiring Diagram: HA<br />

(50)<br />

B<br />

R<br />

2 3<br />

RELAY<br />

Current<br />

O<br />

.66<br />

@ 115 VAC<br />

BLUE<br />

4<br />

W<br />

(40)<br />

4<br />

WHITE<br />

N<br />

L-2<br />

BLACK<br />

115 VOLTAGE<br />

Flow<br />

CONNECTION MOTOR<br />

GREEN/YELLOW 161-193 MFD/125V<br />

RED<br />

.49<br />

3<br />

YELLOW<br />

(30)<br />

ORANGE<br />

L-1<br />

7 AMP<br />

TO REVERSE, INTERCHANGE<br />

.33<br />

RED AND BLACK LEADS<br />

(20) Current<br />

2<br />

@ 230 VAC<br />

Wiring Diagram: HD B<br />

.16<br />

R 2 (10)<br />

1<br />

3<br />

O RELAY<br />

WHITE<br />

W 4<br />

BLACK<br />

N<br />

L-2<br />

0<br />

GREEN/YELLOW<br />

0<br />

230 VOLTAGE<br />

BLUE<br />

0 34 69 103 138 172 207<br />

CONNECTION MOTOR<br />

161-193 MFD/230V<br />

ORANGE<br />

(500) (1000) (1500) (2000) (2500) (3000)<br />

RED<br />

Pressure - bar (psi)<br />

YELLOW<br />

L-1<br />

3 AMP<br />

Note: 50 hz performance is 83% of curves shown.<br />

25<br />

Current - Amps<br />

Current - Amps<br />

Current - Amps<br />

6<br />

Parker Hannifin Corporation<br />

<strong>Oildyne</strong> Division<br />

Minneapolis, MN 55428 USA

Catalog HY22-1121/US<br />

Technical Information<br />

<strong>Hydraulic</strong> <strong>Power</strong> <strong>Units</strong><br />

<strong>108</strong> <strong>Series</strong><br />

Output Flow - lpm (cipm)<br />

1.2<br />

(75)<br />

.98<br />

(60)<br />

.74<br />

(45)<br />

.49<br />

(30)<br />

.25<br />

(15)<br />

.190 Pump (.0187 cipr)<br />

with AE / BE Motor<br />

Flow<br />

Current<br />

@ 24 VDC<br />

Current<br />

@ 12 VDC<br />

0<br />

0<br />

0 34 69 103 138 172 207<br />

(500) (1000) (1500) (2000) (2500) (3000)<br />

Pressure - bar (psi)<br />

50<br />

40<br />

30<br />

20<br />

10<br />

Current - Amps<br />

Performance data based on ATF @ 21°C ( 70°F)<br />

Output Flow - lpm (cipm)<br />

.250 Pump (.0246 cipr)<br />

with AE / BE Motor<br />

1.6<br />

(100)<br />

1.3<br />

(80)<br />

.98<br />

(60)<br />

.66<br />

(40)<br />

.33<br />

(20)<br />

Flow<br />

Current<br />

@ 24 VDC<br />

Current<br />

@ 12 VDC<br />

30<br />

20<br />

10<br />

0<br />

0<br />

0 34 69 103 138 172 207<br />

(500) (1000) (1500) (2000) (2500) (3000)<br />

Pressure - bar (psi)<br />

50<br />

40<br />

Current - Amps<br />

Output Flow - lpm (cipm)<br />

2.5<br />

(150)<br />

2.0<br />

(120)<br />

1.5<br />

(90)<br />

.98<br />

(60)<br />

.49<br />

(30)<br />

.327 Pump (.0321 cipr)<br />

with AE / BE Motor<br />

0<br />

0 34<br />

(500)<br />

Flow<br />

Current<br />

@ 24 VDC<br />

69<br />

(1000)<br />

Current<br />

@ 12 VDC<br />

103<br />

(1500)<br />

Pressure - bar (psi)<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

138<br />

(2000)<br />

Current - Amps<br />

Output Flow - lpm (cipm)<br />

.190 Pump (.0187 cipr)<br />

with AM / BI Motor<br />

2.5<br />

(150)<br />

2.0<br />

(120)<br />

1.5<br />

(90)<br />

.98<br />

(60)<br />

.49<br />

(30)<br />

0<br />

Flow<br />

Current<br />

@ 24 VDC<br />

Current<br />

@ 12 VDC<br />

Pressure - bar (psi)<br />

75<br />

60<br />

45<br />

30<br />

15<br />

0<br />

0 34 69 103 138 172 207 241<br />

(500) (1000) (1500) (2000) (2500) (3000) (3500)<br />

Current - Amps<br />

Output Flow - lpm (cipm)<br />

.250 Pump (.0246 cipr)<br />

with AM / BI Motor<br />

3.3<br />

(200)<br />

2.6<br />

(160)<br />

2.0<br />

(120)<br />

1.3<br />

(80)<br />

.66<br />

(40)<br />

0<br />

Flow<br />

Current<br />

@ 24 VDC<br />

Current<br />

@ 12 VDC<br />

Pressure - bar (psi)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

0 34 69 103 138 172 207<br />

(500) (1000) (1500) (2000) (2500) (3000)<br />

Current - Amps<br />

Output Flow - lpm (cipm)<br />

.327 Pump (.0321 cipr)<br />

with AM / BI Motor<br />

4.1<br />

(250)<br />

3.3<br />

(200)<br />

2.5<br />

(150)<br />

1.6<br />

(100)<br />

.82<br />

(50)<br />

0<br />

Flow<br />

0 34<br />

(500)<br />

Current<br />

@ 24 VDC<br />

69<br />

(1000)<br />

103<br />

(1500)<br />

Current<br />

@ 12 VDC<br />

138<br />

(2000)<br />

Pressure - bar (psi)<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

172<br />

(2500)<br />

Current - Amps<br />

Output Flow - lpm (cipm)<br />

.190 Pump (.0187 cipr)<br />

with HA / HD Motor<br />

1.6<br />

(100)<br />

1.3<br />

(80)<br />

.98<br />

(60)<br />

.66<br />

(40)<br />

.33<br />

(20)<br />

Flow<br />

Current<br />

@ 115 VAC<br />

Current<br />

@ 230 VAC<br />

0<br />

0<br />

0 34 69 103 138 172 207<br />

(500) (1000) (1500) (2000) (2500) (3000)<br />

Pressure - bar (psi)<br />

10<br />

8<br />

6<br />

4<br />

2<br />

Current - Amps<br />

Output Flow - lpm (cipm)<br />

.250 Pump (.0246 cipr)<br />

with HA / HD Motor<br />

1.6<br />

(100)<br />

1.3<br />

(80)<br />

.98<br />

(60)<br />

.66<br />

(40)<br />

Flow<br />

Current<br />

@ 115 VAC<br />

.33<br />

(20)<br />

2<br />

Current<br />

@ 230 VAC<br />

0<br />

0<br />

0 34 69 103 138 172 207<br />

(500) (1000) (1500) (2000) (2500) (3000)<br />

Pressure - bar (psi)<br />

10<br />

8<br />

6<br />

4<br />

Current - Amps<br />

Note: Performance data is for reference only.<br />

Output Flow - lpm (cipm)<br />

.327 Pump (.0321 cipr)<br />

with HA / HD Motor<br />

2.0<br />

(125)<br />

1.6<br />

(100)<br />

1.3<br />

(75)<br />

.82<br />

(50)<br />

.41<br />

(25)<br />

0<br />

0<br />

Flow<br />

Current<br />

@ 115 VAC<br />

Current<br />

@ 230 VAC<br />

1<br />

21 41 62 83 103 124<br />

(300) (600) (900) (1200) (1500) (1800)<br />

Pressure - bar (psi)<br />

6<br />

5<br />

4<br />

3<br />

2<br />

Current - Amps<br />

7<br />

Parker Hannifin Corporation<br />

<strong>Oildyne</strong> Division<br />

Minneapolis, MN 55428 USA

Catalog HY22-1121/US<br />

Circuits<br />

<strong>Hydraulic</strong> <strong>Power</strong> <strong>Units</strong><br />

<strong>108</strong> <strong>Series</strong><br />

TRV<br />

UP<br />

DN<br />

UP<br />

DN<br />

RV<br />

RV<br />

“WW” CIRCUIT<br />

“NN” CIRCUIT<br />

TRV<br />

RV<br />

UP<br />

Thermal Relief Valves—<br />

Why?<br />

The thermal relief valve’s (TRV) purpose is to allow a<br />

bleed off of built up pressure due to thermal expansion<br />

of the fluid or to act as a (limited) shock load protection,<br />

should a cylinder in the system get bumped.<br />

The thermal relief valve is included in circuits using<br />

a pilot operated check valve. The single direction<br />

units get one; the reversing units get two. It is located<br />

between the check valve and the <strong>108</strong> <strong>Series</strong> pump<br />

outlet port. It is a fixed relief valve with a pressure<br />

setting approximately 100-140 bar (1500-2000 psi)<br />

above the system relief valve pressure.<br />

“S*” CIRCUIT<br />

8<br />

Parker Hannifin Corporation<br />

<strong>Oildyne</strong> Division<br />

Minneapolis, MN 55428 USA

Catalog HY22-1121/US<br />

Circuits<br />

<strong>Hydraulic</strong> <strong>Power</strong> <strong>Units</strong><br />

<strong>108</strong> <strong>Series</strong><br />

UP<br />

DN<br />

UP<br />

DN<br />

BACK PRESSURE CIRCUIT<br />

HPRV<br />

LPRV<br />

HPRV<br />

LPRV<br />

“RR” CIRCUIT<br />

“RB” CIRCUIT<br />

UP<br />

DN<br />

UP<br />

DN<br />

TRV<br />

TRV<br />

TRV<br />

TRV<br />

BACK PRESSURE CIRCUIT<br />

HPRV<br />

LPRV<br />

HPRV<br />

LPRV<br />

“LL” CIRCUIT<br />

Back Pressure Circuits—<br />

Why?<br />

The basic reversible circuit is essentially a closed loop.<br />

The oil returning from the system is fed back into the<br />

pump inlet. When a cylinder is being retracted more<br />

oil is being returned to the power unit than is leaving<br />

it due to the rod volume. This results in the DN side<br />

relief valve cracking open allowing the rod volume of oil<br />

to go back to the tank. The larger the rod volume the<br />

more open the relief valve will be. In many applications<br />

this is not a problem. However, if work is being done<br />

on the retract stroke, or if a pressure switch is used to<br />

signal the cylinder is fully retracted, the back pressure<br />

circuit is required. This circuit allows the rod volume of<br />

“LB” CIRCUIT<br />

oil to return to the reservoir through a special shuttle<br />

spool, before it reaches the pump. Full relief valve<br />

pressure is then available to retract the cylinder, also<br />

preventing a pressure switch from tripping before the<br />

full retract position is achieved.<br />

Recommended uses:<br />

• In systems where work is being done on the<br />

retract stroke<br />

• Where a pressure switch is used to signal the full<br />

retract position<br />

• In systems requiring a faster retract than extend<br />

speed<br />

9<br />

Parker Hannifin Corporation<br />

<strong>Oildyne</strong> Division<br />

Minneapolis, MN 55428 USA

2<br />

Catalog HY22-1121/US<br />

Dimensions<br />

Overall Dimensions<br />

FRONT VIEW<br />

STANDARD RESERVOIR<br />

ORIENTATION IS SHOWN<br />

ALTERNATE ORIENTATION<br />

WOULD HAVE FILLER CAP ON<br />

LEFT SIDE (IN FRONT VIEW)<br />

<strong>Hydraulic</strong> <strong>Power</strong> <strong>Units</strong><br />

<strong>108</strong> <strong>Series</strong><br />

SIDE VIEW<br />

A<br />

B<br />

BACK VIEW<br />

112.8<br />

(4.44)<br />

PORT SIZE SEE CODING<br />

RESERVOIR<br />

FILLER CAP<br />

30.7<br />

(1.21)<br />

C<br />

THIRD ANGLE<br />

PROJECTION<br />

With<br />

Solenoid<br />

29.2<br />

(1.15)<br />

MAX<br />

MIN<br />

149.4<br />

29.2 (5.88)<br />

(1.15)<br />

12 VDC MOTOR<br />

MAX<br />

MIN<br />

85.3<br />

(3.36)<br />

46 CU IN<br />

RESERVOIR<br />

75.4±0.8<br />

(Ø2.97±.03)<br />

97.3<br />

(3.83)<br />

29.4<br />

(1.16)<br />

29.4<br />

(1.16)<br />

64.9<br />

(2.55)<br />

2 MOUNTING HOLES<br />

3/8-16 UNC-2B X 7/16 DP.<br />

7/16-20 PRESSURE PORT<br />

UNUSED PRESSURE PORT PLUG<br />

RESERVOIR FILLER CAP<br />

SOLENOID VALVE<br />

126.2<br />

(4.97)<br />

30.7<br />

(1.21)<br />

83.8±1.5<br />

(3.30±.06)<br />

Motor Dimensions ±.1.3 (±.050)<br />

A B C<br />

AE/BE 75.4 126.2 241.3<br />

(2.97) (4.97) (9.50)<br />

AM/BI 95.8 151.4 266.4<br />

(3.77) (5.96) (10.49)<br />

IA 75.4 128.8 244.1<br />

(2.97) (5.07) (9.61)<br />

HA/HD 100.1 161.0 276.4<br />

(3.94) (6.34) (10.88)<br />

29.2 29.2<br />

(1.15) (1.15)<br />

141.7±1.5<br />

(5.58±.06)<br />

Reservoir Dimensions<br />

162.1<br />

(6.38)<br />

1.27±0.8<br />

(.05±.03)<br />

Note: All dimensions in mm (inches).<br />

Note: refer to page 17 for information on the P, Q, R and S reservoirs.<br />

149.4<br />

(5.88)<br />

8<br />

HDPE<br />

123.8<br />

(4.88)<br />

91.2<br />

(Ø3.59)<br />

93.9<br />

(Ø3.70)<br />

80.3<br />

(3.16)<br />

93.9<br />

(Ø3.70)<br />

“A” RESERVOIR<br />

28 CU. IN. (13 CU. IN. USABLE) ALUMINUM<br />

(459 CC: 213 CC USABLE)<br />

161.0<br />

(6.34)<br />

85.3<br />

(3.36)<br />

“B” RESERVOIR<br />

46 CU. IN. (23 CU. IN. USABLE) ALUMINUM<br />

(754 CC: 377 CC USABLE)<br />

101.6<br />

(Ø4.00)<br />

"G" RESERVOIR<br />

#3-69 CU. IN. (46 CU. IN. USABLE) EXTRUDED ALUMINUM<br />

(1130 CC: 754 USABLE)<br />

“C” RESERVOIR<br />

46 CU. IN. (26 CU. IN. USABLE)<br />

HIGH DENSITY POLYETHYLENE WITH UV ADDITIVE STD.<br />

(754 CC: 426 CC USABLE)<br />

266.7<br />

(10.50)<br />

175.3<br />

(6-7/8)<br />

H<br />

1/2 GAL<br />

(2 Liter)<br />

I<br />

1.0 GAL<br />

(4 Liter)<br />

J<br />

1.5 GAL<br />

(5.6 Liter)<br />

142.3<br />

(5.60)<br />

101.6<br />

(Ø4.00)<br />

"F" RESERVOIR<br />

122 CU. IN. (82 CU. IN. USABLE) STEEL<br />

(2000 CC: 1344 CC USABLE)<br />

"H,<br />

H,<br />

I ,<br />

I,<br />

J"<br />

J<br />

RESERVOIR<br />

RESERVOIR<br />

-<br />

STEEL<br />

STEEL<br />

184.6<br />

(7.27)<br />

311.7<br />

(12.27)<br />

413.3<br />

(16.27)<br />

10<br />

Parker Hannifin Corporation<br />

<strong>Oildyne</strong> Division<br />

Minneapolis, MN 55428 USA