INDUSTRIAL LUMINESCENT ACRYLIC ENAMEL - Rust-Oleum

INDUSTRIAL LUMINESCENT ACRYLIC ENAMEL - Rust-Oleum

INDUSTRIAL LUMINESCENT ACRYLIC ENAMEL - Rust-Oleum

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

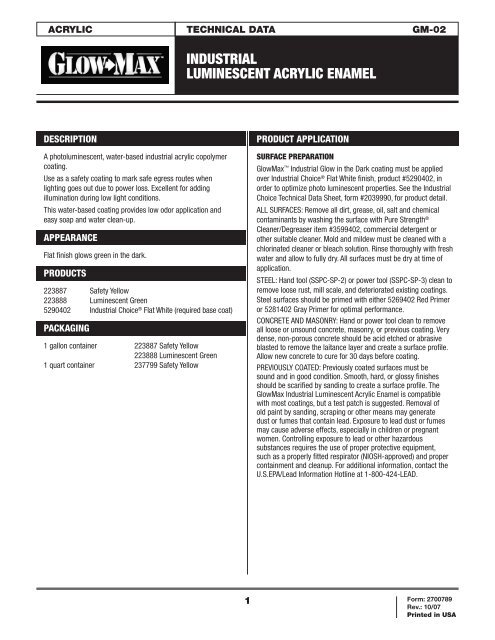

<strong>ACRYLIC</strong><br />

TECHNICAL DATA<br />

GM-02<br />

<strong>INDUSTRIAL</strong><br />

<strong>LUMINESCENT</strong> <strong>ACRYLIC</strong> <strong>ENAMEL</strong><br />

DESCRIPTION<br />

PRODUCT APPLICATION<br />

A photoluminescent, water-based industrial acrylic copolymer<br />

coating.<br />

Use as a safety coating to mark safe egress routes when<br />

lighting goes out due to power loss. Excellent for adding<br />

illumination during low light conditions.<br />

This water-based coating provides low odor application and<br />

easy soap and water clean-up.<br />

APPEARANCE<br />

Flat finish glows green in the dark.<br />

PRODUCTS<br />

223887 Safety Yellow<br />

223888 Luminescent Green<br />

5290402 Industrial Choice ® Flat White (required base coat)<br />

PACKAGING<br />

1 gallon container 223887 Safety Yellow<br />

223888 Luminescent Green<br />

1 quart container 237799 Safety Yellow<br />

SURFACE PREPARATION<br />

GlowMax Industrial Glow in the Dark coating must be applied<br />

over Industrial Choice ® Flat White finish, product #5290402, in<br />

order to optimize photo luminescent properties. See the Industrial<br />

Choice Technical Data Sheet, form #2039990, for product detail.<br />

ALL SURFACES: Remove all dirt, grease, oil, salt and chemical<br />

contaminants by washing the surface with Pure Strength ®<br />

Cleaner/Degreaser item #3599402, commercial detergent or<br />

other suitable cleaner. Mold and mildew must be cleaned with a<br />

chlorinated cleaner or bleach solution. Rinse thoroughly with fresh<br />

water and allow to fully dry. All surfaces must be dry at time of<br />

application.<br />

STEEL: Hand tool (SSPC-SP-2) or power tool (SSPC-SP-3) clean to<br />

remove loose rust, mill scale, and deteriorated existing coatings.<br />

Steel surfaces should be primed with either 5269402 Red Primer<br />

or 5281402 Gray Primer for optimal performance.<br />

CONCRETE AND MASONRY: Hand or power tool clean to remove<br />

all loose or unsound concrete, masonry, or previous coating. Very<br />

dense, non-porous concrete should be acid etched or abrasive<br />

blasted to remove the laitance layer and create a surface profile.<br />

Allow new concrete to cure for 30 days before coating.<br />

PREVIOUSLY COATED: Previously coated surfaces must be<br />

sound and in good condition. Smooth, hard, or glossy finishes<br />

should be scarified by sanding to create a surface profile. The<br />

GlowMax Industrial Luminescent Acrylic Enamel is compatible<br />

with most coatings, but a test patch is suggested. Removal of<br />

old paint by sanding, scraping or other means may generate<br />

dust or fumes that contain lead. Exposure to lead dust or fumes<br />

may cause adverse effects, especially in children or pregnant<br />

women. Controlling exposure to lead or other hazardous<br />

substances requires the use of proper protective equipment,<br />

such as a properly fitted respirator (NIOSH-approved) and proper<br />

containment and cleanup. For additional information, contact the<br />

U.S.EPA/Lead Information Hotline at 1-800-424-LEAD.<br />

Form: 2700789<br />

Rev.: 10/07<br />

Printed in USA

TECHNICAL DATA<br />

<strong>INDUSTRIAL</strong> <strong>LUMINESCENT</strong> <strong>ACRYLIC</strong> <strong>ENAMEL</strong><br />

PRODUCT APPLICATION (cont.)<br />

MIXING<br />

Thoroughly stir material prior to use to ensure all of the<br />

photoluminescent pigment is completely dispersed. Stir<br />

material periodically during application.<br />

APPLICATION<br />

Apply only when the air and surface temperatures are between<br />

50-100°F (10-38°C) and the surface temperature is at least<br />

5°F (3°C) above the dew point. The relative humidity should not<br />

be greater than 85%. Extremely high or low relative humidity<br />

can effect dry times and the final gloss of the coating.<br />

Apply 5290 Flat White base coat. Apply 2 coats of GlowMax <br />

Industrial Glow in the Dark coating. Do not exceed the<br />

recommended film thickness per coat.<br />

EQUIPMENT RECOMMENDATIONS<br />

BRUSH/ROLLER: Use a good quality synthetic brush or 3/8" nap<br />

roller cover.<br />

AIR-ATOMIZED SPRAY:<br />

Method Fluid Tip Fluid Delivery Atom. Pressure<br />

Pressure 0.055-.070 10-16 oz./min. 25-50 psi<br />

Siphon 0.055-.070 — 35-60 psi<br />

HVLP (var.) 0.043-.070 — 10 psi (at tip)<br />

AIRLESS SPRAY:<br />

Pump Ratio Fluid Press. Fluid Tip Filter Mesh<br />

30:1 2,500-3,000 psi 0.013-0.017 60<br />

THINNING<br />

No thinning is needed.<br />

AIR ATOMIZED SPRAY: Water: Up to 12% (1 pint per gallon)<br />

AIRLESS SPRAY: Water: Up to 6% (½ pint per gallon)<br />

CLEANUP<br />

Soap and water<br />

<br />

Form: 2700789<br />

Rev.: 10/07<br />

Printed in USA

TECHNICAL DATA<br />

<strong>INDUSTRIAL</strong> <strong>LUMINESCENT</strong> <strong>ACRYLIC</strong> <strong>ENAMEL</strong><br />

PHYSICAL PROPERTIES<br />

GLOW IN THE DARK COATING<br />

Resin Type<br />

Pigment Type<br />

Solvents<br />

Weight<br />

Per Gallon<br />

Per Liter<br />

Acrylic Copolymer Dispersion<br />

Doped Silico Aluminate<br />

Water and methyl carbitol<br />

10.2-10.7 lbs.<br />

1.2-1.3 kg.<br />

Solids<br />

By Weight 51-56%<br />

By Volume 40-44%<br />

Volatile Organic Compounds<br />

Recommended Dry Film<br />

Thickness (DFT) Per Coat<br />

200°F (93°C) Setaflash<br />

No lead has been deliberately added<br />

PROTECT FROM FREEZING. WARNING. HARMFUL IF INHALED. MAY AFFECT THE BRAIN OR NERVOUS<br />

SYSTEM CAUSING DIZZINESS, HEADACHE OR NAUSEA. MAY BE HARMFUL IF ABSORBED THROUGH<br />

THE SKIN. FOR <strong>INDUSTRIAL</strong> OR COMMERCIAL USE ONLY. SEE THE PRODUCT MATERIAL SAFETY DATA<br />

SHEET (MSDS) AND LABEL WARNINGS FOR ADDITIONAL SAFETY INFORMATION<br />

Form: 2700789<br />

Rev.: 10/07<br />

Printed in USA

The technical data and suggestions for use contained herein are correct to the best of our knowledge, and offered in good faith. The statements of this literature do not constitute<br />

a warranty, express, or implied, as to the performance of these products. As conditions and use of our materials are beyond our control, we can guarantee these products only to<br />

conform to our standards of quality, and our liability, if any, will be limited to replacement of defective materials. All technical information is subject to change without notice.<br />

<strong>Rust</strong>-<strong>Oleum</strong> Corporation<br />

11 Hawthorn Parkway<br />

Vernon Hills, Illinois 60061<br />

An RPM Company<br />

Phone: 877•385•8155<br />

www.rustoleum.com/industrial<br />

Form: 2700789<br />

Rev.: 10/07<br />

Printed in USA