Polyolefins Brochure.pdf - Qenos

Polyolefins Brochure.pdf - Qenos

Polyolefins Brochure.pdf - Qenos

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

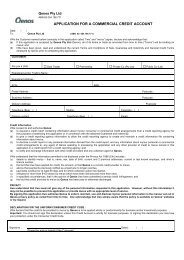

<strong>Polyolefins</strong> at a Glance<br />

Third Edition

Alkatuff ® LLDPE Film Grades<br />

Additives<br />

Applications<br />

Grades<br />

Melt Index (g/10 min)<br />

based on D1238<br />

@190°C, 2.16kg<br />

Density (g/cm3) based<br />

on ASTM D1505<br />

Antiblock<br />

Slip<br />

Lamination<br />

Frozen Food<br />

General Purpose<br />

Ice Bags<br />

Garbage Bags<br />

Stretch Wrap<br />

Personal Care<br />

Overwrap<br />

Clarity<br />

Blending<br />

LL438 0.80 0.922 • •<br />

LL488 0.80 0.922 * H • •<br />

LL0130AB 1 0.90 0.925 * • • •<br />

LL0132HS 1 0.90 0.925 * VH • • • •<br />

LL501 1.0 0.925 • •<br />

LL601 1.0 0.925 * H • •<br />

LL401 1.0 0.925 * VH •<br />

LL425 2.5 0.918 •<br />

LL525 2.5 0.935 •<br />

LL535 3.5 0.939 • •<br />

1 = Alkatuff Optimix grades<br />

Alkathene ® LDPE Film Grades<br />

Additives<br />

Applications<br />

Grades<br />

Melt Index (g/10 min)<br />

based on D1238<br />

@190°C, 2.16kg<br />

Density<br />

(g/cm3)<br />

based on ASTM D1505<br />

Antiblock<br />

Slip<br />

Heavy Duty<br />

Shrink<br />

Lamination<br />

Frozen Food<br />

Produce<br />

Carry Bags<br />

General Purpose<br />

Clarity<br />

Bread<br />

Cling Wrap<br />

XDS34 0.30 0.922 • •<br />

LDF433 0.45 0.925 * • •<br />

LDD201 0.45 0.922 • • •<br />

LDD203 0.45 0.922 * • •<br />

LDD204 0.45 0.922 * M • •<br />

LDD205 0.45 0.922 * H • • •<br />

LDH210 1.0 0.922 •<br />

LD0128MS 1.0 0.922 * M • •<br />

LDH215 1.0 0.922 * H • •<br />

XJF143 2.5 0.921 • •<br />

LDJ226 2.5 0.922 * M 1 • •<br />

LD0220MS 2.5 0.922 * M • •<br />

LDJ225 2.5 0.922 * VH • •<br />

XLF197 5.5 0.920 • •<br />

LDO520HS 5.5 0.920 * VH •<br />

1 Based on antistat additive<br />

Quality<br />

Endorsed<br />

Company

Alkathene ® LDPE Extrusion Coating Grades<br />

Grades Melt Index (g/10 min) Density (g/cm 3 ) Applications<br />

based on D1238 based on D1505<br />

@190°C, 2.16kg<br />

XLC177 4.5 0.922 Extrusion coating with low moisture transmission<br />

WNC199 8.0 0.918 Extrusion coating<br />

LDN248 8.5 0.922 High line speed extrusion coating with low extractables,<br />

low odour<br />

LD1217 12 0.918 High line speed, low neck-in extrusion coating with low<br />

odour<br />

PE Pipe Extrusion Grades<br />

Grades Melt Index (g/10 min) Density (g/cm 3 ) Applications<br />

based on D1238<br />

@190°C, 2.16kg<br />

GM5049B* 0.045 0.956 2 High density PE100 Type resin according to AS/NZS4131<br />

for use in pressure pipes<br />

GM5010T2* 0.10 0.958 2 General Purpose high density PE80 Type C resin<br />

according to AS/NZS4131 for use in pressure and nonpressure<br />

pipes<br />

MD0592 0.12 0.942 1 Designed for extrusion into a full range of pipe<br />

products where medium density resins are required<br />

MD0898* 0.12 0.952 1 Medium density PE80 Type B resin according to<br />

AS/NZS4131 designed for extrusion into full range of<br />

pipe and fitting sizes<br />

LL0228 1.90 0.920 3 Linear low density resin for use in pipe extrusion<br />

applications<br />

*ISO Certified to AS/NZS4131 1 = ASTM D1505/D2839 2 = ASTM D792 3 = ASTM 1505<br />

HDPE/MDPE Wire and Cable Grades<br />

Grades Melt Index (g/10 min) Density (g/cm 3 ) Applications<br />

based on D1238<br />

@190°C, 2.16kg<br />

GM5010T2* 0.10 0.958 2 Designed for use as a general purpose jacketing<br />

compound for buried wires and cables where abrasion<br />

resistance and cut-through resistance in rocky terrain<br />

is required<br />

MD0592 0.12 0.942 1 Designed for extrusion into a full range of wire and cable<br />

products where medium density resins are required<br />

MD0898* 0.12 0.952 1 Designed for use as a general purpose jacketing<br />

compound for buried wires and cables where abrasion<br />

resistance and cut-through resistance in rocky terrain<br />

is required<br />

*ISO Certified to AS/NZS4131 1 = ASTM D1505/D2839 2 = ASTM D792<br />

HDPE Tape and Monofilament Grades<br />

Grades Melt Index (g/10 min) Density (g/cm 3 ) Applications<br />

based on D1238 based on D792<br />

@190°C, 2.16kg<br />

GF7740F2 0.40 0.944 Extrusion applications including stretched tape, monofilament,<br />

tarpaulins, and over-pouches for medical solutions<br />

Quality<br />

Endorsed<br />

Company

HDPE Blow Moulding Grades<br />

Grades Melt Index (g/10 min)<br />

based on D1238<br />

Density (g/cm 3 ) Applications<br />

@190°C, 2.16kg<br />

HD0840 0.03 0.953 1 Large part mouldings, especially blow moulded<br />

self-supported drums and tanks (25 - 220 litres)<br />

HD1155 0.04 0.953 1 Large part blow mouldings, including 25 litre to 220 litre<br />

tanks and drums<br />

GM7655 0.20 0.949 2 Blow moulded containers including household and<br />

industrial chemical (HIC). Suitable for larger part mouldings<br />

GF7660 0.30 0.973 2 Blow moulding and extrusion applications, injection<br />

Black19<br />

moulding of parts with very thick wall sections and<br />

simple flow paths. Yields extremely good weatherability<br />

GF7660 0.40 0.953 2 HIC containers, including detergent and<br />

pharmaceutical bottles<br />

GF7660LS10 0.40 0.954 2 Blow moulding and extrusion applications requiring<br />

good UV stability<br />

GE4760 0.60 0.958 2 Blow moulded water, dairy and fruit juice bottles<br />

HD6095 0.85 0.960 1 Thin walled bottles where ESCR is not a requirement,<br />

such as dairy containers, fruit juice and cordial bottles,<br />

and packaging for powders<br />

HD5148 0.85 0.960 1 High speed dairy packaging applications and other thin<br />

walled bottles, where ESCR is not a requirement<br />

such as milk, cream, fruit juice and cordial<br />

1 = ASTM D1505/D2839 2 = ASTM D792<br />

HDPE Injection Moulding Grades<br />

Grades Melt Index (g/10 min) Density (g/cm 3 ) Applications<br />

based on D1238 based on D1505<br />

@190°C, 2.16kg<br />

HD0390 4.0 0.955 Stackable crates for transport, storage and bottles, and<br />

industrial mouldings<br />

HD0397UV 4.0 0.955 Mouldings demanding combination of food contact<br />

suitability and long-term weatherability, including<br />

MGB's, crates and industrial mouldings.<br />

HD0490 4.5 0.955 Stackable transport, storage and bottles crates,<br />

and industrial mouldings<br />

HD0499UV 4.5 0.955 Mouldings requiring the combination of food contact<br />

suitability and long-term weatherability, including<br />

MGB's, crates, and industrial mouldings.<br />

HD0790 7.0 0.956 Industrial pails, sealant cartridges, crates and closures<br />

HD1090 10 0.956 Industrial pails, sealant cartridges, crates and closures<br />

HD1099UV 10 0.956 Crates and tote boxes requiring good UV resistance<br />

HD2090 20 0.956 Housewares, thin-walled containers and closures<br />

HD3690 36 0.956 Housewares, thin-walled mouldings and closures.<br />

Quality<br />

Endorsed<br />

Company

Alkathene ® Injection LDPE Moulding Grades<br />

Grades Melt Index (g/10 min) Density (g/cm 3 ) Applications<br />

based on D1238 Based on D1505<br />

@190°C, 2.16kg<br />

XDS34 0.30 0.922 Injection moulded caps and closures<br />

WJG117 1.7 0.918 Injection moulded caps and closures, industrial<br />

containers, and thick sections<br />

XJF143 2.5 0.921 Injection moulded caps and closures, and thick-walled<br />

sections<br />

LDN248 8.5 0.922 Injection moulded closures and caps<br />

WRM124 22 0.920 Injection moulded housewares, lids and toys<br />

WSM168 63 0.919 Injection moulded thin sections<br />

LLDPE Injection Moulding Grades<br />

Grades Melt Index (g/10 min) Density (g/cm 3 ) Applications<br />

based on D1238<br />

@190°C, 2.16kg<br />

Alkatuff ®<br />

LL820 20 0.925 1 Injection moulding and compounding applications<br />

such as housewares and lids<br />

ExxonMobil*<br />

LL6101XR 20 0.924 2 Injection moulding and compound applications requiring<br />

medium flow<br />

LL6101RQ 20 0.924 2 Powder for compounding and injection applications<br />

requiring medium flow<br />

LL6201XR 50 0.926 2 High flow and toughness injection moulding<br />

applications<br />

LL6201RQ 50 0.926 2 Powder for compounding and injection moulding<br />

applications requiring high flow and toughness<br />

*ExxonMobil Chemical products distributed by <strong>Qenos</strong> in Australia 1 = ASTM D1505 2 = ASTM D1928/4883<br />

Alkatuff ® LLDPE Rotational Moulding Grades<br />

Grades Melt Index (g/10 min) Density (g/cm 3 ) Applications<br />

based on D1238 based on D1505<br />

@190°C, 2.16kg<br />

LL711UV 3.5 0.939 Applications requiring balance of toughness and stiffness<br />

where excellent ESCR and high level UV protection<br />

required such as water and chemical tanks, septic systems<br />

and kayaks<br />

LL722 3.5 0.939 Mouldings requiring balance of toughness and stiffness<br />

with excellent ESCR such as water and chemical tanks,<br />

septic systems and kayaks<br />

LL705UV 5.0 0.935 Applications requiring high ESCR, toughness, stiffness<br />

and high level UV stabliser such as leisure craft,<br />

playground equipment and agricultural tanks.<br />

LL755 5.0 0.935 Applications requiring high ESCR, toughness and stiffness<br />

LL710UV 10 0.930 Good ESCR, high chemical resistance, toughness and UV<br />

protection suitable for intricate items and low cycle times<br />

Quality<br />

Endorsed<br />

Company

PP Homopolymer Injection Moulding Grades<br />

Grades Melt Index (g/10 min) Density (g/cm 3 ) Applications<br />

based on D1238 based on D792<br />

@230°C, 2.16kg<br />

PPR1070 4.0 0.903 Injection moulded closures and housewares<br />

PPT1070 5.5 0.903 Injection moulded garden furniture, housewares,<br />

caps and closures<br />

PPU1080 15 0.902 Injection moulded closures, housewares and flower<br />

pots<br />

PPV1780 22 0.901 Thin-walled injection mouldings and food containers<br />

PPW1780 48 0.903 Thin-walled injection moulded containers and drinking<br />

cups<br />

A range of PP Powders are also available<br />

PP Copolymer Injection Moulding Grades<br />

Grades Melt Index (g/10 min) Density (g/cm 3 ) Applications<br />

based on D1238 based on D792<br />

@230°C, 2.16kg<br />

PPK2032 0.80 0.899 Injection moulded crates and automotive parts.<br />

Blow moulded bottles. Thermoformed sheets<br />

PPK4132 0.80 0.899 Injection moulded automotive parts and domestic<br />

white goods for high heat applications<br />

PPN2033 1.8 0.899 Injection moulded crates. Blow moulded containers.<br />

Thermoformed sheet<br />

PPR2042 4.0 0.902 Injection moulded crates, tote boxes, domestic appliances,<br />

automotive parts, and industrial mouldings<br />

PPT1052 7.0 0.903 Injection moulded sink traps<br />

White24<br />

PPT2052 7.0 0.903 Injection moulded housewares and automotive parts<br />

PPU1062 16 0.903 Injection moulded housewares<br />

PPV2753 22 0.898 Injection moulded thin-walled food containers,<br />

thin section automotive parts<br />

PPW1762 43 0.902 Thin-walled injection moulded food containers and<br />

packaging, and flower pots<br />

PP Homopolymer Extrusion Grades<br />

Grades Melt Index (g/10 min) Density (g/cm 3 ) Applications<br />

based on D1238 based on D792<br />

@230°C, 2.16kg<br />

PPK1060 1.0 0.905 Extruded pipe, film, tape and strapping<br />

PPN1060F 1.5 0.903 Extruded lashings and tape. Blow moulded bottles,<br />

Thermoformed food containers.<br />

PPN1780 1.5 0.906 Extruded strappings and tape. Thermoformed food<br />

containers.<br />

PPR1060F 4.0 0.902 Extruded stretched weaving tapes, bailer twine and<br />

lashings<br />

A range of PP Powders are also available<br />

Quality<br />

Endorsed<br />

Company

Exceed Metallocene LLDPE Film Grades<br />

Additives<br />

Applications<br />

Grades<br />

Melt Index (g/10 min)<br />

based on D1238<br />

@190°C, 2.16kg<br />

Density<br />

(g/cm3)<br />

based on EM Method<br />

Antiblock<br />

Slip<br />

Heavy Duty Bags<br />

Stretch<br />

Shopping Bags<br />

General Purpose<br />

Lamination<br />

Freezer Film<br />

Clarity<br />

FFS<br />

Agricultural Film<br />

Exceed 1018CA 1.0 0.918 • • • • • • • • •<br />

Exceed 1018FA 1.0 0.918 * H • • • • • • •<br />

Exceed 1327CA 1.3 0.927 • • • • • • • • •<br />

Note: Exceed is an ExxonMobil Chemical product distributed by <strong>Qenos</strong> in Australia.<br />

HDPE Film Grades<br />

Grades Melt Index (g/10 min) Density (g/cm 3 ) Applications<br />

based on D1238<br />

@190°C, 2.16kg<br />

HD0811 0.06 0.952 1 Supermarket check-out bags, garbage bags, kitchen<br />

tidy bags, singlet and other merchant bags, bags-on-roll<br />

and slap sheets<br />

GM4755F 0.10 0.949 2 Carry bags and liners<br />

HDF895 0.80 0.960 1 High Density resin for merchant bags, freezer wrap and<br />

bags, laminating and general liners<br />

1 = ASTM D1505/D2839 2 = ASTM D792<br />

<strong>Qenos</strong> also supplies a broad range of specialty polymers. For further enquiries and contact details, see overleaf.<br />

This information is offered solely for your consideration, verification and should not be construed as a warranty or representation for which <strong>Qenos</strong> Pty Ltd<br />

assumes legal liability , except to the extent that such liability is imposed by legislation and cannot be excluded. Values quoted are the result of tests on representative<br />

samples, and the product supplied may not conform in all respects. <strong>Qenos</strong> Pty Ltd reserves the right to make any improvements or amendments<br />

to the composition of any grade or product without alteration to the code number. In using <strong>Qenos</strong> Pty Ltd's products, you must establish for yourself the<br />

most suitable formulation, production method and control tests, to ensure the uniformity and quality of your product is in compliance with all laws.<br />

<strong>Qenos</strong>, Alkathene and Alkatuff are registered trademarks of <strong>Qenos</strong> Pty Ltd. Alkatuff Optimix is a trademark of <strong>Qenos</strong> Pty. Ltd.<br />

<strong>Qenos</strong> is the Australian distributor for ExxonMobil Chemical polymers.<br />

Exceed is a trademark of Exxon Mobil Corporation.<br />

Quality<br />

Endorsed<br />

Company

<strong>Qenos</strong> Alkathene ®<br />

and Alkatuff ®<br />

production<br />

ISO 9001<br />

Lic No. QEC0272<br />

<strong>Qenos</strong> Plastics & Resins<br />

HDPE, MDPE and PP<br />

production<br />

ISO 9001<br />

Lic No. QEC0372<br />

<strong>Qenos</strong> Customer Service<br />

<strong>Polyolefins</strong> Phone: 1800 805 538 Specialties, Mobil Films & Elastomers Phone: 1800 672 215<br />

(PE and PP) Phone: 1800 682 379 International Trade Phone: 1800 331 230<br />

Phone: 1800 063 573<br />

Customer Service Fax: 1800 638 981<br />

Email: customer.service@qenos.com<br />

<strong>Qenos</strong> Cnr Kororoit Creek Road & Maidstone Street, Altona Victoria 3018<br />

Phone: 61 3 9258 7333 Fax 61 3 9258 7451 www.qenos.com<br />

Published by <strong>Qenos</strong> Corporate Affairs Department 2004 <strong>Qenos</strong> Pty Ltd ABN 62 054 196 771