PG Distribution - Magaya

PG Distribution - Magaya

PG Distribution - Magaya

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CASE STUDY:<br />

<strong>PG</strong> <strong>Distribution</strong><br />

<strong>Distribution</strong><br />

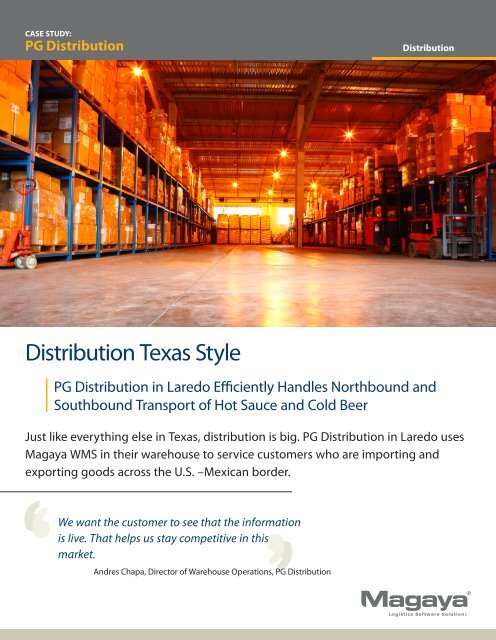

<strong>Distribution</strong> Texas Style<br />

<strong>PG</strong> <strong>Distribution</strong> in Laredo Efficiently Handles Northbound and<br />

Southbound Transport of Hot Sauce and Cold Beer<br />

Just like everything else in Texas, distribution is big. <strong>PG</strong> <strong>Distribution</strong> in Laredo uses<br />

<strong>Magaya</strong> WMS in their warehouse to service customers who are importing and<br />

exporting goods across the U.S. –Mexican border.<br />

,<br />

We want the customer to see that the information<br />

is live. That helps us stay competitive in this<br />

market.<br />

,<br />

Andres Chapa, Director of Warehouse Operations, <strong>PG</strong> <strong>Distribution</strong>

<strong>PG</strong> <strong>Distribution</strong><br />

At a Glance<br />

<strong>PG</strong> <strong>Distribution</strong><br />

http://www.palos-garza.com<br />

Industry<br />

<strong>Distribution</strong><br />

Solution<br />

<strong>Magaya</strong> WMS and <strong>Magaya</strong> WMS Mobile<br />

<strong>PG</strong> <strong>Distribution</strong> of Laredo, Texas is part of the Palos Garza Company, which offers<br />

warehousing, logistics, forwarding, and fleet services. They have three warehouses<br />

totaling 200,000 square feet and 86 docks.<br />

A Growth Region<br />

The streets of Laredo, Texas, are full of semi-trailer trucks carrying<br />

goods across the border between Mexico and the United States.<br />

Over 9,000 trucks cross at the Port of Laredo daily. In contrast, about<br />

3,500 trucks cross the California–Mexico border daily. According to<br />

the Laredo Chamber of Commerce, the Port of Laredo handles 39%<br />

of U.S.–Mexico trade on the U.S. Southern Border. Trade in the district<br />

increased by 17% in 2011, and the population has doubled since 1990.<br />

It is the largest port of entry on the U.S.–Mexico border, and the third<br />

largest inland border port of entry behind Detroit, MI and Buffalo, NY.<br />

Laredo has four bridges that cross the border. The largest is the World<br />

Trade International Bridge with 14 lanes. The other bridges have 4 or<br />

8 lanes. It’s not just the roads that are busy; the Laredo International<br />

Airport experienced an increase of 58% in pounds of cargo from 2009<br />

to 2010.<br />

All kinds of freight cross the bridges, including automotive parts,<br />

cellular phone components, chemicals, food ingredients and more.<br />

The distribution business is very competitive in Laredo, so <strong>PG</strong><br />

<strong>Distribution</strong> combines technology and customer service to handle<br />

many of these commodities efficiently for their customers.<br />

The company has three warehouses in Laredo, totaling approximately<br />

200,000 square feet. In 2010, <strong>PG</strong> <strong>Distribution</strong> installed the <strong>Magaya</strong><br />

WMS and <strong>Magaya</strong> WMS Mobile applications in one of the divisions of<br />

the company which is run by Operations Manager Andres Chapa to<br />

manage their distribution of commodities such as beer and hot sauce.<br />

<strong>PG</strong> <strong>Distribution</strong> was started by Mario Palos Garza in 1988. He began<br />

his career as a customs broker in Mexico. Over the years, he expanded<br />

his business by adding a trucking division and a freight forwarding<br />

service. Seeing the growth in the distribution industry in the area, he<br />

opened the distribution business in Laredo, Texas, in 2009 to meet the<br />

warehousing and distribution needs of customers.<br />

Software Selection and Setup<br />

When <strong>PG</strong> <strong>Distribution</strong> opened their warehouse, they tried a different<br />

software program, but it did not provide enough features for all their<br />

needs. Operations Manager Andres Chapa read an ad for <strong>Magaya</strong><br />

software in the industry magazine Inbound Logistics. He downloaded<br />

a trial of the software, tested it, and decided to sign up for it when he<br />

saw the features he needed such as In & Out reports, notifications,<br />

inventory tracking, integrated accounting, online visibility, and more.<br />

“The fact that <strong>Magaya</strong> software has accounting features integrated<br />

with it was one of the major factors that lead us to select it. Before<br />

that, we used two software programs, one for accounting and one for<br />

WMS,” Mr. Chapa said. When making the software purchasing decision,<br />

he looked at his present and future needs. “There are also a lot of<br />

add-ons available that we can use in the future. We needed a software<br />

company that has the vision for a whole package.”<br />

When they evaluated their warehouse to install the wireless handheld<br />

setup, <strong>PG</strong> <strong>Distribution</strong> hired an IT company to help them plan where to<br />

place the hotspots to ensure all the wireless units have a strong signal

<strong>PG</strong> <strong>Distribution</strong><br />

inside the 100,000 square-foot building. They also placed hotspots<br />

near loading docks so that scanning cargo in and out of the trucks<br />

goes smoothly.<br />

As part of the system setup, <strong>PG</strong> created Inventory Item Definitions<br />

in the <strong>Magaya</strong> system. The purpose of defining items is to assign a<br />

part number to the data so that each time the same items arrive, the<br />

information is already in the system. All that needs to be done is scan<br />

the barcode on the label, and the system immediately identifies the<br />

part number and populates the Warehouse Receipt document with<br />

the item details.<br />

Scanning Barcodes and Connecting<br />

Data<br />

The warehouse employees use the WMS Mobile handheld units<br />

to receive the cargo. The barcodes of items are scanned and the<br />

information is saved directly into the <strong>Magaya</strong> WMS. The system<br />

also enables them to send a tracking link to their customers via the<br />

Transaction Tracking feature.<br />

“We can store items by serial numbers easily using the handheld<br />

scanners. It gives us more control for pick and packing so we can<br />

provide specialized attention to customers,” Mr. Chapa said.<br />

Mr. Chapa uses the Warehouse Inspector screen in the software to view<br />

the warehouse locations and see what is on hand. Mr. Chapa creates<br />

a report per location in the warehouse and gives it to the warehouse<br />

staff to perform an inventory count for that location. The warehouse<br />

coordinator gives out the Load Tasks to the warehouse employees.<br />

“We have visibility into the status of the tasks as they are being<br />

performed in the warehouse.”<br />

The <strong>PG</strong> <strong>Distribution</strong> warehouse is organized by customer. Shipments<br />

arrive from different carriers, mostly delivering Full Truckload (FTL).<br />

They also receive consolidated shipments from carriers such as FedEx<br />

Freight which contain items from different customers. Each pallet or<br />

case is scanned and placed in the correct location in the warehouse<br />

that is dedicated to each customer. The locations and item details are<br />

saved in the database.<br />

The software includes a built-in customization feature so custom fields<br />

can be added to input data specific to any business. <strong>PG</strong> <strong>Distribution</strong><br />

added a custom field for trailer numbers to help them track which<br />

trucks are carrying which goods. This number and other data can be<br />

used throughout the system.<br />

“We also run reports per customer from the Commodity List every day<br />

and send it to the customer. Everyone here can run these reports,” he<br />

said. “We can customize it based on what the customer wants to see.”<br />

All the item data that is scanned and saved is also available to their<br />

accounting department and customs broker.<br />

The system also enables them to save and attach scanned paper<br />

documents as a PDF. “We attach pictures and documents such as the<br />

Bill of Lading, Packing List, or a Certificate of Analysis, which is required<br />

for food grade products,” Mr. Chapa said.<br />

Mr. Chapa explained that some customers provide <strong>PG</strong> <strong>Distribution</strong><br />

with load numbers. “We enter the load number into their webpage<br />

to get information about the cargo such as the consignee,” Mr. Chapa<br />

said. “When we invoice our customers from the <strong>Magaya</strong> system, we<br />

include the load number on the invoice. We also include the other<br />

relevant charges such as drayage, distribution, cross-docking, and final<br />

transport.”<br />

“We enter charges such as storage charges, packing or handling, pick<br />

and pack, and shrink wrap charges. We also enter costs per transaction<br />

so we know if a trailer was Full Truckload or LTL and how much it costs<br />

the customer.” The office staff at <strong>PG</strong> <strong>Distribution</strong> itemizes the costs on<br />

the customer’s invoices.

<strong>PG</strong> <strong>Distribution</strong><br />

Online Benefits<br />

“We like the software features that let the customers create their own<br />

custom reports from the website. It’s one of the advantages that helps<br />

set us apart from competitors.” <strong>PG</strong> <strong>Distribution</strong> is using the interactive<br />

online tool called <strong>Magaya</strong> LiveTrack which gives their customers 24/7<br />

real-time tracking details. “When we show our customers the tracking<br />

page, they are amazed at how user-friendly it is. They also have the<br />

option to chat online with one of our account representatives or the<br />

accounting department. They are able to get information about their<br />

shipments and invoices and everything all on one web page. The<br />

information is live, up to the minute.”<br />

“When items arrive at the warehouse, the information about the items<br />

is visible online right away. Some customers need more information<br />

than others such as purchase order numbers, so we enter it and it’s<br />

available online for them to see. We want the customer to see that the<br />

information is live. They can see what is actually being loaded right now.<br />

That helps us stay competitive in this market.”<br />

In Conclusion<br />

One of the main benefits that <strong>PG</strong> <strong>Distribution</strong> has gained from using the<br />

software is getting a clear view of everything. “It was new for us to see<br />

the real-time status of items and know what is pending or loaded.”<br />

“We save time with the <strong>Magaya</strong> system,” Mr. Chapa said. “The old<br />

system was not detailed enough. We have much more detail now, and<br />

everyone here can search the whole database to find anything and give<br />

a quick response to the customer’s questions.”<br />

All rights reserved. <strong>Magaya</strong>, the <strong>Magaya</strong> logo and all products<br />

are all trademarked unless specifically specified as of a third party.<br />

© Copyright 2011, <strong>Magaya</strong> Corporation. 786. 845. 9150 info@magaya.com magaya.com