golf series - Rudy Project

golf series - Rudy Project

golf series - Rudy Project

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

RUDY PROJECT REVEALS CUTTING EDGE LENS TECHNOLOGY THE MOST ADVANCED TECHNOLOGICAL SOLUTION IN THE FIELD OF VISION<br />

PROTECTION GUARANTEED UNBREAKABLE FOR LIFE.<br />

WHAT IS<br />

Since the development of CR-39 and Polycarbonate over 40 years ago, there have been few advances and innovations in high impactresistant<br />

optical polymer development. NXT® is a family of patented polyurethane optical polymers, transparent and unbreakable,<br />

originally developed for the military to provide superior protection and performance: NXT® was born in the USA in the early 1990’s when<br />

the U.S. Government contracted Simula Technologies to develop a new bullet-proof, transparent, and light-weight material capable of<br />

providing superior protection, reliability and longer lasting performance than polycarbonate. This material is also used in the windows in<br />

post Sept. 11 cockpit doors being installed on airplanes and Apache helicopter windshields panels; it is today available for <strong>Rudy</strong> <strong>Project</strong><br />

Technically Cool Eyewear under a unique and unparalleled lens program: ImpactX.<br />

ImpactXrepresents today the most advanced technological solution in the field of vision protection. Thanks to their transparency and<br />

superior optical quality, lenses made in NXT® ensure sharp vision and unbeatable comfort: they are made by casting, a process which<br />

ensures lower internal stress, higher optical homogeneity and mechanical stability compared to traditional Polycarbonate lenses.<br />

ImpactXPolarized Photochromic<br />

TRUE GREY<br />

Luminous Transmittance 12 / 30%<br />

Filter category 2/3<br />

ImpactXPhotochromic<br />

RED<br />

Luminous Transmittance 21 / 50%<br />

Filter category 1/2<br />

ImpactXPhotochromic Clear<br />

TRANSPARENT / GREY<br />

Luminous Transmittance 18 / 78%<br />

Filter category 1/3<br />

ImpactXPhotochromic<br />

GOLF<br />

Luminous Transmittance 14 / 38%<br />

Filter category 2/3<br />

ImpactXlens technology offers breakthrough NXT®semi-rigid molecular properties formulated exclusively for <strong>Rudy</strong> <strong>Project</strong>. After years<br />

of laboratory research and field tests with professional athletes, ImpactX has been perfected with cutting edge light management<br />

technology by combining photochromic particles and advanced polarized technology in the mass, incorporating thus superior impact<br />

resistance with enhanced visual acuity, for virtually any climatic condition.<br />

WHY<br />

1. GUARANTEED UNBREAKABLE FOR LIFE<br />

IMPACTX is stronger than any other lens material, guaranteed not to break or crack, even in complex rimless frame.<br />

2. SUPERIOR OPTICS<br />

IMPACTX has lower refractive index, internal stress and chromatic dispersion than polycarbonate, resulting in sharper images, higher<br />

definition, reduces “rainbowing”, and more visual comfort<br />

3. SUPERIOR ANTI-SCRATCH PROPERTIES<br />

IMPACTX lenses feature a superior Quartzscratch-resistant antistatic coatings, which doesn’t attract dust.<br />

4. LIGHTWEIGHT<br />

IMPACTX is 16% lighter than CR-39 and 10% lighter than Polycarbonate.<br />

5. EXCLUSIVE SEMI-RIGID PLATFORM<br />

Tailor-made IMPACTX formula for superior safety and unparalleled protection.<br />

6. CUTTING-EDGE PHOTOCHROMIC AND POLARIZED TECHNOLOGY<br />

Enhanced visual acuity for any climatic conditions.<br />

FACTS<br />

Lightweight. IMPACTX is about 16% lighter than CR-39®and 10% than polycarbonate.<br />

Impact resistance. IMPACTX impact resistance is higher than polycarbonate and passes all impact resistance standards.<br />

No stress Cracking or Crazing. Unlike polycarbonate and other materials IMPACTX is not sensitive to stress cracking, so it does not craze<br />

or break when subjected to mechanical strains.<br />

Excellent workability. Unlike CR-39®, polycarbonate and polyamide, IMPACTX can be easily drilled without brittleness or stress cracking<br />

problems.<br />

Processed by casting. Lenses in IMPACTX are made by casting, which ensures low internal stress, high optical homogeneity, thermal<br />

and mechanical stability. Such properties make IMPACTX the material ideally suited for high quality unbreakable polarized lenses.<br />

Excellent optical properties. IMPACTX has lower refraction index, internal stress, and chromatic dispersion (Abbe number) than polycarbonate,<br />

resulting in lower surface reflection and “rainbow effect”, higher definition and sharper images.<br />

High Chemical Resistance. Unlike polycarbonate and polyamide , IMPACTX is not attacked by common chemicals or solvents (i.e.<br />

acetone and methyl alcohol)<br />

High thermal stability. IMPACTX polymer has high thermal stability and is not subject to optical or mechanical distorsions, even when<br />

exposed to temperatures in excess of 80°.<br />

ImpactXPolarized Photochromic<br />

BROWN<br />

Luminous Transmittance 10 / 25%<br />

Filter category 2/3<br />

For more information on complete product line,<br />

ask for the 2012 RX Collection Catalogue,<br />

or visit www.rudyproject.com.<br />

2012 RX COLLECTION<br />

29,7 x 21 cm<br />

AC 04 01 10 English<br />

AC 04 01 10 IT Italiano<br />

ImpactXPhotochromic<br />

GREY<br />

Luminous Transmittance 16 / 40%<br />

Filter category 2/3<br />

ImpactXPhotochromic<br />

Laser Clear<br />

TRANSPARENT / GREY<br />

Luminous Transmittance 16 / 62%<br />

Filter category 1/3<br />

REVOLUTION IN RX SPORTS<br />

<strong>Rudy</strong> <strong>Project</strong> is pleased to announce the application of ImpactX technology in a revolutionary prescription program:<br />

ImpactRX<br />

Through our strategic partnership with Shamir Optical Laboratories and using the most sophisticated edging equipment<br />

available in the world, <strong>Rudy</strong> <strong>Project</strong> is now able to offer Rx lenses directly in the frame in a vast array of its<br />

semi-rimless sport models, with the most advanced technological solution in the field of vision protection guaranteed<br />

unbreakable for life : this gives your patients even more options than ever before. Now for patients that want to<br />

stay away from optical inserts, you can offer them the option of Rx-ing their favourite <strong>Rudy</strong> models directly in the frame.<br />

And best of all they can have two or three Rx lenses in different tints to manage field requirements ot light condition.<br />

The ImpactRX Interchangeable lenses are custom ground to your patients’ prescription and attach to the<br />

<strong>Rudy</strong> frame similar to the plano counterparts. Lenses interchange in a snap, yet stay snugly in place during sports.<br />

With ImpactRX, <strong>Rudy</strong> <strong>Project</strong> is commited to excellence and redefines the concept of RX solutions for sports.<br />

ImpactXPhotochromic Laser<br />

RACING RED<br />

Luminous Transmittance 15 / 49%<br />

Filter category 1/3<br />

- Leggendary cutting-edge Racing Red formula<br />

- New photochromic pigment generation,<br />

more stable to temperatures<br />

- Patented UV & Light Activation technology<br />

- Patented Full Activation Multilaser coating<br />

IMPACTRX KICKOFF KIT 3.0<br />

AC 03 00 24<br />

Including:<br />

- ImpactRX Photochromic Clear lens<br />

- ImpactX Photochromic Red lens<br />

- ImpactX Photochromic Golf/Tennis lens<br />

- ImpactX Pure Grey lens<br />

- ImpactX Polarized Photochromic Grey<br />

- ImpactX Polarized Photochromic Brown<br />

Rydon cut (OD)<br />

Rydon cut (OD) (PLANO)<br />

Rydon cut (OS) (PLANO)<br />

Rydon cut (OS) (PLANO)<br />

Rydon cut (OS) (PLANO)<br />

Rydon cut (OS) (PLANO)<br />

93<br />

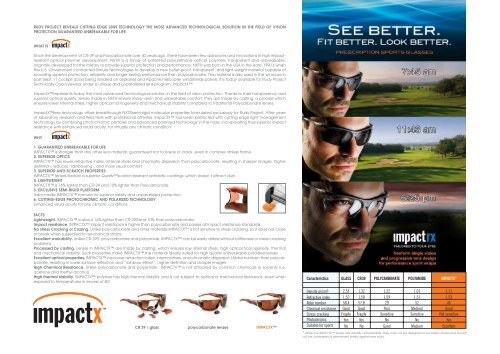

CR 39 / glass<br />

polycarbonate lenses<br />

IMPACTX<br />

* While the IMPACTX lenses are virtually unbreakable, they may not be designed to be safety lenses and should<br />

not be considered a permanent shield against eye injury.