SMART DIFFERENTIAL PRESSURE TRANSMITTER PYRD-2000ALW

SMART DIFFERENTIAL PRESSURE TRANSMITTER PYRD-2000ALW

SMART DIFFERENTIAL PRESSURE TRANSMITTER PYRD-2000ALW

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PD vers<br />

<strong>SMART</strong> <strong>DIFFERENTIAL</strong><br />

<strong>PRESSURE</strong> <strong>TRANSMITTER</strong><br />

<strong>PYRD</strong>-<strong>2000ALW</strong><br />

The <strong>PYRD</strong>-<strong>2000ALW</strong> transmitter is suitable for the measuring of differential pressures of gases, vapours and liquids.<br />

• 4 - 20 mA output<br />

• signal + HART protocol<br />

• ATEX Intrinsically Safe<br />

• ATEX Flameproof<br />

• PED Conformity (97/23/EC)<br />

• Programmable zero range, shift, unit selection •<br />

• and damping ratio with local panel keys<br />

• Accuracy 0.075%<br />

• Hastelloy diaphragm<br />

• SIL 2 certificate option<br />

• Gold plated diaphragm option<br />

• Static pressure limit up to 420 Bar<br />

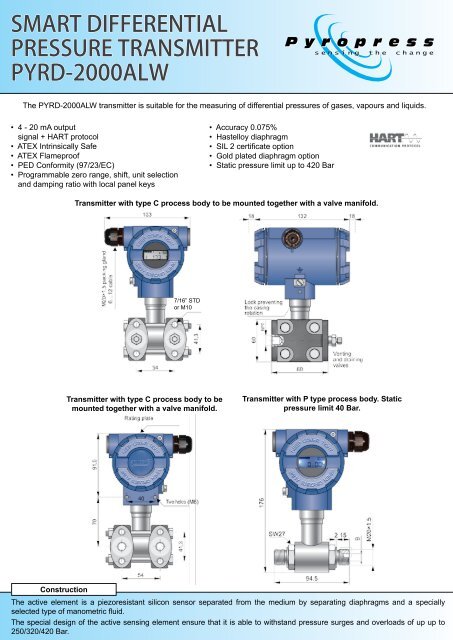

Transmitter with type C process body to be mounted together with a valve manifold.<br />

SMAR<br />

The APCE-2000 pressure trans<br />

of gases, vapours and liquids.<br />

a diaphragm and by specially se<br />

7/16” STD<br />

or M10<br />

APCE-20<br />

Transmitter with type C process body to be<br />

mounted together with a valve manifold.<br />

Transmitter with P type process body. Static<br />

pressure limit 40 Bar.<br />

Construction<br />

Economical version<br />

- housing 304ss<br />

- protection IP65<br />

- electrical connecti<br />

- the electronics enc<br />

a protective silicon g<br />

-ATEX Intrinsic safe<br />

II 1/2G<br />

Ga/Gb Exia IIC T4/T5<br />

I M1 Ex ia I<br />

II 1D Ex iaD 20 T110°<br />

The active element is a piezoresistant silicon sensor separated from the medium by separating diaphragms and a specially<br />

selected type of manometric fluid.<br />

The special design of the active sensing element ensure that it is able to withstand pressure surges and overloads of up up to<br />

250/320/420 Bar.

<strong>PYRD</strong>-<strong>2000ALW</strong> <strong>SMART</strong> <strong>PRESSURE</strong> <strong>TRANSMITTER</strong><br />

Communication, configuration and installation<br />

EX<br />

EX<br />

ATEX Intrinsic safety II 1/2<br />

ATEX Explosion – proof<br />

II 1/2G Exia/d IIC T6/ T5<br />

II 1/2D ExiaD 20/tD A21 T85<br />

The casing is of epoxy painted cast aluminium alloy or 316 stainless steel, degree of protection Version IP66/IP67. APR-2000ALE The design<br />

of the casing enables the use of a local display, rotation of the display by 90°, rotation 0…20 of the mA, casing 0…5 by mA, 0–355° 4…20 mA<br />

relative to the sensor, and a choice of cable direction.<br />

protocol<br />

Possibilities of the of the adjus<br />

of the measuring range accord<br />

the display panel keys<br />

Configurable display (LCD) 3½<br />

• 4 - 20 mA output signal + HART protocol or digital temperature Profibus range PA signal –40…+85°C<br />

No EEx or Profibus PA<br />

• Local push buttons for adjusting both zero and span, measuring range,<br />

• units etc with the display panel keys<br />

Communication and<br />

• Configurable display 5 digits with illumination The (working communication temperature standard for<br />

• range –40 to +85°C)<br />

the transmitter is the Hart protoco<br />

• ATEX Intrinsic safety EX II 1/2G Exia IIC T4/T5 Communication with the transmitt<br />

– aKAP-03 communicator,<br />

– some other Hart type communi<br />

• ATEX Flameproof EX II 1/2G Exia/d IIC T6/T5<br />

– a PC using an RS-Hart co<br />

II 1/2D Exia/d 20/tD A21<br />

configuration<br />

T85/T100<br />

software.<br />

Installation<br />

(*) .eddl files available on<br />

www.ap<br />

The transmitter with type P process body can be installed<br />

directly on the installation. A universal mounting bracket is<br />

available for mounting the transmitter on a 2” pipe (AL or ALS<br />

mounting bracket). When the pressure of steam or other hot<br />

media is measured, a siphon or impulse line should be used.<br />

The C type body connections can be fitted directly to a 3 or 5<br />

way manifold valve (or be supplied with one fitted - see type<br />

VM manifolds on seperate literature).<br />

If not fitted with an integral manifold the transmitter can be<br />

mounted on a wall or similar flat surface, or a 2” pipe using a<br />

C-2” mounting bracket.<br />

For applications where the medium is aggressive to the<br />

standard wetted parts the transmitter can be supplied with<br />

suitable diaphragm seals either direct connected or via st.<br />

steel capillary.<br />

For hygienic (e.g. food industry) applications it can be<br />

supplied fitted with suitable hygiene seals.<br />

For these options see separate literature or contact Pyropress<br />

sales office.<br />

Communication and configuration<br />

The communication standard for data interchange with<br />

the transmitter is Hart protocol. Communication with the<br />

transmitter via one of the following:<br />

– a KAP-03 communicator<br />

– industry standard Hart type communicators<br />

– a PC using an RS-Hart converter and Raport-02<br />

configuration software<br />

Electrical diagrams for <strong>PYRD</strong>-<br />

<strong>2000ALW</strong> with HART protocol<br />

Milliammeter<br />

Version: APR-<strong>2000ALW</strong><br />

mA<br />

TEST<br />

4÷20<br />

mA<br />

Power supply<br />

SIGNAL<br />

Transmitter 20 <br />

Electrical diagram<br />

RS-HART converter<br />

or communicator<br />

TEST<br />

Jumper<br />

Millia<br />

m

– conversion characteristic (inversion, Error due touser’s supplynon-<br />

linear characteristic);<br />

Electrical parameters<br />

voltagechanges 0.002% (FSO)<br />

G Ex ia IIC T4/T5<br />

read the currently measuredPower pressure supply value of<br />

Electrical<br />

the<br />

parameters<br />

12...55 VDC (Ex ia13,5...28<br />

<strong>PYRD</strong>-<strong>2000ALW</strong> <strong>SMART</strong> output current <strong>PRESSURE</strong> and the percentage<br />

Power <strong>TRANSMITTER</strong><br />

output<br />

supply<br />

control level;<br />

12...55 VDC (Ex ia13,5...28<br />

(Exd 13,5…4<br />

(Exd 13,5…4<br />

force anoutput current with aset<br />

Technical Data<br />

Additional value;<br />

/T100<br />

voltage drop<br />

calibrate the transmitter in relation Additional<br />

when display to amodel voltage<br />

illumination pressure.<br />

when display illumination switched on 3V<br />

drop<br />

switched on 3V<br />

Measuring ranges Output signal<br />

4...20mA, two wire transmiss<br />

Installation Output signal<br />

4...20mA, two wire transmiss<br />

Overpressure limit/ static<br />

No. Nominal measuringThe range(FSO) transmitter withMinimum P typesetprocess range connection Rangeability is not<br />

pressure limit<br />

, output signal + HART<br />

19 1 0 to 0...16 Bar bar (0...1,6Mpa)<br />

heavy, to 1.6 MPa)<br />

so it can1.6 befitted<br />

1,6 Bar bar<br />

directly<br />

(160kPa) onto<br />

kPa)<br />

impulse lines.<br />

10:1<br />

For<br />

<br />

R[<br />

Usup[V]<br />

12V<br />

2 0...2,5 bar (0...250kPa) 0,25 bar (25kPa)<br />

Loadresistance<br />

10:1<br />

250 bar /(320, 420 bar<br />

14 0 to 0.25 Bar fitting to inany desired 0.25 Bar position werecommend an universal Bar<br />

Bar<br />

R[ ]<br />

<br />

option) 0.85<br />

ting both start 113 and 0 end to 0...1 1 Bar bar (0...100kPa) Aplisens to kPa) mounting 70 mBar 70mbar bracket for (7kPa) 2" pipe (AL mounting<br />

14:1<br />

(400,02A<br />

Bar bar for Ptype<br />

ing to set pressure 08 4 0 with to 0...0,25 0.25 Bar bar (0...25 bracket, to 100 kPa) kPa) see page 1065).<br />

mBar 10mbar (1kPa) 25:1<br />

-15Vwhendisplay Process connection)<br />

illuminationswitched on<br />

455 -100…100mbar to mBar (-10…10kPa) to 4 mBar 4mbar (0,4kPa) (0.4 kPa)<br />

50:1<br />

(250 Bar bar for PED version)<br />

42 6 -5-5...70mbar to mBar (-0,5...7kPa) The (-0.5 to version 7 kPa) with4 mBar C4mbar type process (0,4kPa) (0.4 kPa) connections<br />

Resistance 18:1 can<br />

required be<br />

forcommunication 250...1100<br />

digits (working<br />

477 -0.5 -0,5...0,5 to 0.5 Bar bar (-50...50kPa) fitted to directly kPa) to a3-or5-valve 0.10,1 Bar bar ( 10kPa) manifold. (10 kPa) Werecommend<br />

10:1<br />

)<br />

8 factory-mounted transmitters with VMtype valve manifold<br />

44 -20-20...20 to mBar mbar (-2...2kPa) to 2 kPa) 2 mBar 2mbar (0,2kPa) (0.2 kPa) 20:1 20 bar Bar<br />

(page 62). Atransmitter without avalve manifold can be<br />

fitted in any positionTechnical on a2" pipe data or on awall using the C-<br />

Accuracy depending<br />

configuration Operating parameters<br />

Metrological2" parameters mounting bracket (page 65).<br />

Accuracy on Materials the depending set range<br />

on the set range<br />

Accuracy<br />

±0.075% of calibrated range<br />

Accuracy ≤ ±0.075% of the calibrated range<br />

Wetted parts: type Pprocess connection 316Lss<br />

data interchange with<br />

When the special process connections are required for<br />

±0.1% of calibrated range<br />

(≤ ±0.1% for ranges 42 and 44)<br />

type Cprocess Accuracy connection 316ss<br />

l.<br />

the measurement of specific media levels inclosed tanks<br />

Long term stability<br />

accuracy for 3years<br />

Long-term (for thestability<br />

nominal measuring ≤ accuracy range) (e.g. Diaphragms:<br />

Hastelloy C276, Au<br />

for inthe 3 years sugar and chemical industries) the transmitter<br />

(for the nominal measuring range)<br />

Thermal error<br />

±0.08% (FSO) /10°C<br />

Casing:<br />

1<br />

er is Aluminium<br />

Thermal<br />

carried out<br />

max. error<br />

with:<br />

is fitted with an Aplisens diaphragm seal. Sets of differential<br />

(FSO) compensation pressure / 10°Ctransmitters temperature with diaphragm seals Option: 316SS<br />

±0.3% (FSO) < in±0.08% the whole<br />

range<br />

max. ±0.3% (FSO) are described<br />

indetail inthe further part-NACE of theMR–01–75compatible<br />

catalogue.<br />

(in the whole compensation temp range) 0<br />

cators (*)<br />

Set range<br />

Thermal compensation range -25…80°C<br />

nverter Thermal andcompensation Raport-02 range -25 to 80°C<br />

Operating conditions<br />

Zero shift error for static pressure<br />

Operating temperature range 10(ambient 30 temp.) -25...85°C 100<br />

[%]<br />

Zero shift 0.01% error (FSO) for /10 static bar forpressure<br />

range 3, 4<br />

EEx version -25…80°C<br />

0.01% (FSO)<br />

0.03%<br />

/(FSO) 10 Bar<br />

/10<br />

for<br />

bar for<br />

ranges 5,<br />

116,<br />

and 8<br />

0 – error for nominal measuring<br />

0.03% (FSO)<br />

0.08%<br />

/(FSO) 10 Bar<br />

/10<br />

for<br />

bar for ranges45 1,2,7,8<br />

Medium temperature range<br />

-25...120°C<br />

and 42<br />

range (0...100% FSO)<br />

Zeroing the transmitter inconditions ofstatic pressure can eliminate<br />

(FSO) this error. / 10 Bar for ranges 19, 14, 47 and 44<br />

<br />

1<br />

– error for range 0...10% FSO<br />

or diaphragm seals<br />

over 120°C –measurement with the use of impulse line<br />

0.05%<br />

lisens.com<br />

(Zeroing Additional this transmitter electronic under damping regular static pressure 0…60 s can eliminate this error)<br />

up to 100C PED version<br />

<br />

1 = 2×<br />

<br />

0<br />

Error due to supply voltage changes 0.002% (FSO) /V<br />

Additional electronic damping<br />

0 to 60 s CAUTION: the medium must Numerical not be allowed error tofreeze values inthe are given impulse<br />

line orclose to the process the technical connection data of the under transmitter operating metrological<br />

Error due to supply Electrical voltage changes parameters 0.002% (FSO) / V<br />

parameters<br />

in<br />

Special versions, certificates<br />

s for transmitters with HART protocol<br />

Power supply 12...55 VDC (Ex ia 13,5...28 V)<br />

<br />

Special versions, certificates<br />

Diaphragms: Hastelloy C-276, Au<br />

Casing: Aluminium<br />

Option: 316 Stainless steel<br />

NACE MR - 01 - 75 compatible<br />

(Ex d13,5…45V)<br />

Electrical parameters<br />

Ex ia –Atex Intrinsic safety<br />

Additional voltage drop when<br />

<br />

6 Ex d –Atex explosion proof<br />

Exia Version: – display ATEX APR-2000ALE<br />

illumination Intrinsically switched safe on 3V<br />

Version: PED Power APR-2000ALE<br />

–European supply Pressure 12 to Equipment 55V DC Directive (Exia N 13.5 97/23/EC to 28V)<br />

Exd with<br />

Output<br />

– ATEX 4…20mA<br />

signal<br />

Flameproof output signal<br />

4...20 mA, two wire transmission<br />

with 0…5 or (Exd 13.5 to 45V)<br />

APC-2000ALE: 0…20 or0…5, 4…20 [mA]<br />

<br />

0…20mA<br />

320 bar -static<br />

output<br />

pressure<br />

signal<br />

limit: 320 bar (not for PED version)<br />

<br />

320 Bar – Static pressure limit: U 320 Bar (not PED version)<br />

Additional voltage drop when display illumination is<br />

sup[V]<br />

12V<br />

Loadresistance R[ ]<br />

<br />

RS-HART<br />

0.85<br />

converter<br />

420 bar -static pressure limit: 420 bar (not for PED version)<br />

0,02A or communicator<br />

Tlen<br />

switched<br />

–transmitter<br />

on<br />

designed<br />

3V<br />

for oxygen<br />

420 Bar – Static pressure limit: 420 Bar (not PED version)<br />

-15V Power when display supply illumination switched on<br />

Power Special Output supply range: signal -1,6…2bar RS-HART 4 to 20 converter mA, two wire transmission<br />

PED – Resistance European required Pressure for communication Equipment Directive 250...1100N° 97/23/EC<br />

or communicator<br />

-1,6…16bar U sup<br />

[V] - 12V*<br />

Load resistance R [Ω] ≤ .<br />

OXY – Transmitter designed for oxygen<br />

0.85<br />

4÷20<br />

Thermal compensation from -40°C 0.02A<br />

Special<br />

mA<br />

SIL2<br />

range – -1.6 to 2 Bar, -1.6 to 16 Bar<br />

*-15V – Functional when display Safety.According illumination toIEC 61508/61511 switched on<br />

mmeter<br />

Device with Declaration ofSIL2 for use insafety related applications<br />

Accuracy depending on the set range<br />

Thermal compensation down to -40°C<br />

Resistance up to SIL2 required for communication:<br />

0÷20<br />

MR 240 – Marine to 1100 Certificate Ω –DNV<br />

Accuracy<br />

SIL2 – Functional safety. According to IEC 61508/61511 0÷<br />

5<br />

SS – Housingmaterial –316ss<br />

Adevice with declaration of SIL2 for use in safety related mA<br />

1<br />

Au<br />

applications up to SIL2<br />

Operating – gold plated diaphragm, conditions<br />

only Ctype connection (range<br />

0<br />

no. 4)<br />

Set range<br />

ALW/SS – Housing material 316 Stainless steel<br />

Others Operating temperature<br />

10 30 100 [%]<br />

range (ambient temp.) -25 to 85°C<br />

CG – Gold plated diaphragm. (range no. 8 only and C type<br />

process body only) - Hydrogen<br />

0 – error for nominal measuring<br />

applications<br />

Ex version -25 to 80°C<br />

range (0...100% FSO)<br />

Process temperature range -25 to 120°C<br />

Materials 4 3 2 1<br />

1 – error for range 0...10% FSO 4 3 2 1<br />

1 = 2× 0<br />

Note: PED version -25 to 100°C<br />

Wetted parts: Type P<br />

Numerical<br />

process<br />

error<br />

body<br />

values<br />

316L<br />

are given<br />

Stainless steel<br />

the technical data under metrological<br />

Type C parameters process body 316 Stainless steel<br />

For processes over 120°C, impulse lines or diaphragm<br />

seals should be used.<br />

OUTPUT<br />

3 WIRE<br />

TEST<br />

2 WIRE<br />

TEST<br />

R0<br />

OUTPUT<br />

3 WIRE<br />

TEST<br />

2 WIRE<br />

TEST<br />

R0<br />

CAUTION: the medium must not be allowed to freeze in<br />

the impulse line or close to the process connection of the<br />

transmitter.

<strong>PYRD</strong>-<strong>2000ALW</strong> <strong>SMART</strong> <strong>PRESSURE</strong> <strong>TRANSMITTER</strong><br />

Ordering Procedure<br />

Model: <strong>PYRD</strong>-<strong>2000ALW</strong><br />

Description: Differential Pressure transmitter<br />

Certification<br />

Nominal<br />

Range Code<br />

-D .................................<br />

-IS ................................<br />

-SSIS ...........................<br />

-23............................<br />

-19 ...............................<br />

-14 ...............................<br />

-11 ...............................<br />

-08 ...............................<br />

-45 ...............................<br />

-42 ...............................<br />

-47 ...............................<br />

-44 ...............................<br />

Exd certification<br />

Exia certification<br />

Exia certification with stainless steel housing<br />

0 - 70 Bar<br />

0 - 16 Bar<br />

0 - 2.5 Bar<br />

0 - 1 Bar<br />

0 - 0.25 Bar<br />

-100 to +100 mBar<br />

-5 to +70 mBar<br />

-0.5 to +0.5 Bar<br />

-20 to +20 mBar (20 Bar max only)<br />

Range in relation to 4 -20mA<br />

Example: 0-10B = 0-10 Bar<br />

P = PSI K = KG/CM 2 MB = Mbar (other units available)<br />

Process<br />

Connection<br />

-P .................................<br />

-GB ..............................<br />

-N4 ...............................<br />

-GA ..............................<br />

-C .................................<br />

-CG ..............................<br />

-X .................................<br />

M20 X 1.5 Male with 12 dia hole - SS316 - 40 Bar max<br />

G1/2” Male with 4 dia hole - SS316 via adaptors - 40 Bar max<br />

1/4” NPT Female - SS316 via adaptors - 40 Bar max<br />

G1/4” Male - SS316 via adaptors - 40 Bar max<br />

Manifold flange, SS316 wetted parts with Hastelloy diaphragm<br />

with 2 x 1/4” NPT female process connections - 250 Bar max<br />

Manifold flange as above with gold plated diaphragm (range 08 only)<br />

Diaphragm seal<br />

Options<br />

List if more than one<br />

-OXY ............................<br />

-C32 .............................<br />

-C42 .............................<br />

-PED ............................<br />

-SIL ..............................<br />

-BCZ ............................<br />

-BCS ............................<br />

-AL ...............................<br />

-ALS ............................<br />

-BF ...............................<br />

-UL ...............................<br />

For oxygen service - Fluorolube filled (only available with “P”<br />

type process body)<br />

320 Bar option on “C” type process body<br />

420 Bar option on “C” type process body<br />

European Pressure Equipment Directive No 97/23/EC, Cat IV.<br />

Suitable for use within SIL2 systems<br />

2” pipe & wall mounting bracket for “C” type process body - zinc<br />

plated steel<br />

2” pipe & wall mounting bracket for “C” type process body -<br />

stainless steel<br />

2” pipe mounting universal bracket, zinc plated steel<br />

2” pipe mounting universal bracket, stainless steel<br />

25mm pipe mounting bracket for “P” type process body only<br />

1/2” NPT female entry<br />

Tel: +44 (0)1752 339866<br />

Email: sales@pyropress.com<br />

Web: www.pyropress.com<br />

Pyropress Engineering Company Ltd<br />

Bell Close, Plympton<br />

Plymouth, Devon, PL7 4JH<br />

United Kingdom