Untitled - FHP Manufacturing

Untitled - FHP Manufacturing

Untitled - FHP Manufacturing

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2 EC Series<br />

Table of Contents<br />

MODEL NOMENCLATURE...............................................3<br />

<strong>FHP</strong> MANUFACTURING....................................................3<br />

ADVANTAGES OF <strong>FHP</strong>’s TECHNOLOGY.......................3<br />

EC SERIES MODEL 007 – 070.........................................3<br />

FEATURES........................................................................3<br />

Cabinet .......................................................................3<br />

Quiet Operation ..........................................................4<br />

Serviceability ..............................................................4<br />

Unit Configurations......................................................4<br />

Filter Racks.................................................................4<br />

Hanging Brackets........................................................4<br />

Blower & Motor............................................................5<br />

Water Connections......................................................6<br />

Refrigerant Circuit.......................................................6<br />

Unit Protection Module................................................7<br />

UPM Features.............................................................7<br />

UNIT OPTIONS .................................................................8<br />

Hot Gas Reheat..........................................................8<br />

Refrigerant Flow Path.................................................8<br />

Hot Gas Reheat Sequence of Operation -<br />

On/Off Control.............................................................9<br />

Hot Gas Reheat Control Options................................9<br />

Special Considerations...............................................9<br />

Low Temperature Well Water......................................9<br />

Indoor Pool Dehumidifying During Winter Months .....9<br />

Sequence of Operation - Modulating Hot Gas Reheat<br />

(MHGRH)..................................................................10<br />

Hot Gas Bypass........................................................10<br />

Psychometric Chart...................................................10<br />

Fluid Differential Pressure Switch.............................11<br />

DDC Controls:...........................................................11<br />

SYSTEMS........................................................................12<br />

Water Source Cooling Tower/Boiler Systems............12<br />

Geothermal Systems.................................................12<br />

Earth Coupling Options.............................................12<br />

Vertical Ground Loop System...................................13<br />

Horizontal Ground Loop System...............................13<br />

Surface Water, Lake or Pond System.......................13<br />

TYPICAL HEAT PUMP OPERATING MODES................14<br />

Cooling Mode............................................................14<br />

Heating Mode............................................................14<br />

TYPICAL UNIT INSTALLATION......................................15<br />

Unit Location.............................................................15<br />

Vertical Unit Installation.............................................15<br />

Horizontal Unit Installation .......................................15<br />

Ductwork and Sound Attenuation Considerations.....16<br />

Piping........................................................................17<br />

Condensate Drain Piping..........................................17<br />

UNIT CONTROLS............................................................17<br />

Thermostats..............................................................17<br />

HOSE KITS......................................................................17<br />

Operating Limits – Cooling & Heating.......................18<br />

CERTIFIED PERFORMANCE DATA...............................19<br />

EC007 (300 CFM).....................................................21<br />

EC009 (350 CFM).....................................................22<br />

EC012 (400 CFM).....................................................23<br />

EC015 (500 CFM).....................................................24<br />

EC018 (650 CFM).....................................................25<br />

EC024 (850 CFM).....................................................26<br />

EC030 (950 CFM).....................................................27<br />

EC036 (1200 CFM)...................................................28<br />

EC041 (1150 CFM)...................................................29<br />

EC042 (1500 CFM)...................................................30<br />

EC048 (1600 CFM)...................................................31<br />

EC060 (2000 CFM)...................................................32<br />

EC070 (2200 CFM)...................................................33<br />

ELECTRICAL DATA........................................................34<br />

BLOWER PERFORMANCE CFM....................................35<br />

PHYSICAL DATA.............................................................36<br />

VERTICAL UNIT DIMENSIONS......................................37<br />

Vertical Top Discharge Water Source Heat Pump.....37<br />

Vertical Counterflow Water Source Heat Pump........38<br />

HORIZONTAL UNIT DIMENSIONS.................................39<br />

Horizontal Water Source Heat Pump........................39<br />

TYPICAL WIRING DIAGRAMS.......................................40<br />

1/2 through 6 ton | Single stage unit | 208-230V/1ph<br />

with PSC direct drive motor .....................................40<br />

1 through 6 tons | Single stage unit | 208-230V/1ph<br />

with PSC direct drive motor – Hot Gas Reheat.........41<br />

1/2 through 6 tons | Single stage unit | 208/230V/1ph<br />

with PSC direct drive motor – Economizer................42<br />

3 through 6 tons | Single stage unit | 208/230V/1ph<br />

with PSC direct drive motor – Hot Gas Reheat &<br />

Economizer...............................................................43<br />

2 through 6 tons | Single stage unit | 208/230V/3ph<br />

with PSC direct drive motor.......................................44<br />

2 through 6 tons | Single stage unit | 208-230V/3ph<br />

with PSC direct drive motor – Hot Gas Reheat.........45<br />

2 through 6 tons | Single stage unit | 208/230V/3ph<br />

with PSC direct drive motor – Economizer................46<br />

2 through 6 tons | Single stage unit | 208/230V/3ph<br />

with PSC direct drive motor – Hot Gas Reheat &<br />

Economizer...............................................................47<br />

SPECIFICATION GUIDE.............................................48-51<br />

6720220353<br />

Subject to change without prior notice Revised 10-12

Model Nomenclature<br />

MODEL NOMENCLATURE<br />

EC Series 3<br />

EC 036- 1 VT C -F L T<br />

SERIES:<br />

EC<br />

NOMINAL CAPACITY:<br />

SUPPLY AIR LOCATION:<br />

T - TOP<br />

VOLTAGE DESIGNATION:<br />

F - FRONT<br />

0 - 115/1/60 R - REAR<br />

1 - 208/1/60 & 230/1/60 S - STRAIGHT THRU<br />

2 - 277/1/60 E - END BL0W<br />

3 - 208/3/60 & 230/3/60 B - BOTTOM<br />

4 - 460/3/60<br />

5 - 575/3/60 RETURN AIR LOCATION:<br />

L - LEFT<br />

CABINET CONFIGURATION:<br />

R - RIGHT<br />

VT - VERTICAL<br />

B - BACK<br />

HZ - HORIZONTAL<br />

F - FRONT<br />

CF - COUNTERFLOW<br />

WATER CONNECTIONS<br />

HEAT EXCHANGER MATERIAL:<br />

LOCATION:<br />

C - COPPER F - FRONT<br />

N - CUPRO-NICKEL<br />

<strong>FHP</strong> MANUFACTURING<br />

Specializing in efficient green technology for<br />

commercial heating and cooling products, <strong>FHP</strong> is<br />

one of the leading manufacturers of Geothermal<br />

and Water Source heat pumps, which assures that<br />

you are buying a unit you can trust. We are part of<br />

Bosch Thermotechnology Ltd., a Robert Bosch<br />

Group unit dedicated to providing highly efficient<br />

heating and cooling solutions to the private and<br />

public sector.<br />

<strong>FHP</strong> headquarters has a state of the art facility with<br />

the latest manufacturing technology available. Each<br />

unit is factory tested according to Bosch quality<br />

standards in order to ensure our customers the<br />

highest level of satisfaction and comfort. We<br />

carefully select our suppliers in order to equip our<br />

products with the best components available.<br />

ADVANTAGES OF <strong>FHP</strong>’s TECHNOLOGY<br />

• Low installation costs<br />

• Lower operating costs<br />

• Flexibility and comfort<br />

• Energy efficiency<br />

• Space savings<br />

• Superior quality<br />

• Quiet operation<br />

EC SERIES MODEL 007 – 070<br />

• 13 Models from ½ through 6 tons<br />

• Horizontal, Vertical and Counterflow Configurations<br />

FEATURES<br />

Cabinet<br />

<strong>FHP</strong> EC unit cabinetry is constructed using<br />

Galvalume + sheet metal with a clear acrylic<br />

coating. This steel provides superior corrosion<br />

protection for units located indoors.<br />

All interior surfaces are lined with ½" thick, 1.5 lb./cu.ft.<br />

density, Micromat insulation for thermal insulation and<br />

acoustical attenuation. This insulation is noncombustible,<br />

non-hydroscopic and does not support<br />

fungal growth. Insulation meets NFPA 90A and 90B for<br />

fire protection and is certified to meet the GREENGUARD<br />

Indoor Air Quality Standard for Low Emitting Products.<br />

Protection against corrosion is a feature in the EC series.<br />

A stainless steel drain pan will last the lifetime of the unit<br />

and resist corrosion and cracking that may occur with<br />

steel or plastic materials.<br />

Revised 10-12<br />

Subject to change without prior notice<br />

6720220353

4<br />

EC Series<br />

Quiet Operation<br />

Air side coils have aluminum side plates to prevent<br />

corrosion.<br />

Taking all into consideration the life expectancy of<br />

the EC series is anticipated to be well in excess of<br />

the industry standard of 19 years.<br />

Quiet Operation<br />

All panels are insulated with ½" thick, 1.5 lb./cu.ft.<br />

density fiberglass insulation for both thermal<br />

insulation and noise reduction.<br />

Noise reduction is a critical consideration of the unit<br />

design. Even under normal operating conditions,<br />

vibration may be transmitted to the building<br />

structure and introduced into the space as noise. All<br />

EC units have a unique floating base pan where the<br />

compressor is mounted on a heavy steel plate that<br />

rests on a high density rubber pad in the base of the<br />

unit. In addition, compressors are mounted on<br />

rubber grommets. This double isolation, unique to<br />

<strong>FHP</strong>, is standard in all EC series units preventing<br />

vibration and noise transmission from the<br />

compressor to the unit structure resulting in<br />

exceptionally quiet operation.<br />

Insulated bulkheads in all units, separate the<br />

compressor section from the blower section,<br />

allowing the unit to be serviced during operation.<br />

Large removable panels aid in servicing the unit,<br />

when necessary. Separate electrical knockouts in<br />

the unit corner post allow for easy and safe<br />

routing of high and low voltage lines to the inside<br />

of the cabinet.<br />

Unit Configurations<br />

All units are available in horizontal and vertical and<br />

counterflow configurations. Additionally, several<br />

options of return air and supply air are offered as<br />

standard, providing configuration flexibility.<br />

Filter Racks<br />

Units come standard with a 1" filter rack and<br />

construction filter. A 2" four-sided filter rack and<br />

pleated filter is optional and greatly reduces<br />

unfiltered air from entering the unit. Filter doors<br />

allow for easy routine maintenance and changing<br />

of the air filter. A 1" return duct collar is integral to<br />

the filter rack eliminating the need for field mounted<br />

duct collars. Units are shipped with a 1" filter;<br />

2" pleated filters are available as an option.<br />

For additional sound attenuation, a compressor<br />

blanket is available as an option on unit sizes 018<br />

and above.<br />

Serviceability<br />

Optional 2" Filter<br />

Hanging Brackets<br />

Optional 2" Filter Rack<br />

All horizontal units come standard with hanging<br />

bracket kits for suspending the unit from field<br />

supplied hanger rods. These kits include heavy duty<br />

steel brackets and rubber grommets for sound and<br />

vibration isolation from the building structure.<br />

All units are designed to be serviced from the front of<br />

the unit. Schrader valves for high and low pressure<br />

gauges and the electrical box components are easily<br />

accessible for diagnosing and servicing the unit.<br />

6720220353<br />

Subject to change without prior notice Revised 10-12

Unit Configurations<br />

EC Series 5<br />

Access<br />

Panel<br />

Condenser Water Out<br />

Access<br />

Panel<br />

Access<br />

Panel<br />

Condensate Drain<br />

Condenser Water In<br />

Electrical Knock-Outs<br />

Condenser Water Out<br />

Access<br />

Panel<br />

Condensate Drain<br />

Condenser Water In<br />

Left Hand Return Top Discharge FLT<br />

Electrical Knock-Outs<br />

Right Hand Return Top Discharge FRT<br />

Condenser<br />

Water Out<br />

Condenser<br />

Water In<br />

Electrical<br />

Knock-Outs<br />

Left Hand Return Bottom Discharge FLB<br />

Condensate Drain<br />

Right Hand Return Bottom Discharge FRB<br />

Front<br />

Return Air Left<br />

Return Air Right<br />

Front<br />

Straight Through FLS<br />

End Blow FLE<br />

End Blow FRE<br />

Straight Through FRS<br />

Typical Horizontal Unit Configurations<br />

Blower & Motor<br />

Large blower wheels allow the unit to operate at<br />

lower speeds for quieter operation.<br />

PSC blower motors are standard on all unit sizes .<br />

A 1" supply air duct-flange connection is standard,<br />

facilitating duct installation on the unit. Horizontal<br />

units are field convertible from straight through to<br />

an end discharge arrangement.<br />

1" Duct-Flange<br />

Revised 10-12<br />

Subject to change without prior notice<br />

6720220353

6<br />

EC Series<br />

Water Connections<br />

Water Connections<br />

All water connections are heavy duty bronze FPT<br />

fittings securely fastened to the unit corner post.<br />

This allows connecting to a flexible hose kit without<br />

the use of a backup wrench making for easier, faster<br />

installation.<br />

Refrigerant Circuit<br />

EC series units are designed using the optimum<br />

combination of compressor, water and air coils to<br />

provide peak performance.<br />

Heavy duty heat pump compressors are used in all<br />

units. Rotary, reciprocating and scroll compressors<br />

offer optimum performance for each unit size.<br />

In geothermal applications where fluid temperatures<br />

can drop below the dew point of the surrounding air,<br />

optional insulation is available to prevent water coils<br />

and refrigerant piping from sweating.<br />

Air coils are state of the art, employing lanced fin<br />

and rifled tubing for maximum heat transfer. Large<br />

face areas result in lower face velocity reducing<br />

sound while ensuring high latent heat removal for<br />

maximum dehumidification in the cooling mode.<br />

A pilot operated four-way reversing valve in the<br />

refrigeration circuit allows the unit to operate in<br />

either the heating or cooling mode. All <strong>FHP</strong> units<br />

have the reversing valve energized in cooling<br />

mode, which allows the unit to fail to heating<br />

mode for building protection. This will ensure you<br />

are not left without heat in the middle of winter.<br />

should the reversing valve coil fail.<br />

Refrigerant to water heat exchangers are coaxial<br />

tube-in-tube type providing a robust construction,<br />

ensuring years of trouble free operation. Coaxial<br />

coils are selected and designed for peak<br />

performance, offering the best combination of low<br />

water pressure drop and maximum heat transfer in<br />

both the cooling and heating modes. Standard<br />

coaxial coils have a copper interior water tube and<br />

a steel outer shell. Optional Cupro-Nickel coils are<br />

available for applications where the water is of<br />

lower quality.<br />

Refrigerant flow to the air coil is controlled by<br />

capillary tubes as standard in EC units through 5<br />

tons. Thermal Expansion Valves come standard on<br />

the optional Extended Range EC and are designed<br />

to vary the flow of refrigerant depending on the<br />

load. TXV’s provide unit optimization and a more<br />

stable control over a wider range of operating<br />

conditions.<br />

EC Series units are rated to withstand 600 PSIG<br />

working refrigerant pressure and 400 PSIG<br />

working water pressure.<br />

All EC units, two tons and above, are provided with<br />

filter driers to ensure that no residual water or<br />

other foreign material is present to contaminate<br />

the refrigerant system and lead to premature<br />

failure.<br />

6720220353<br />

Subject to change without prior notice Revised 10-12

Unit Protection Module<br />

High and low pressure switches are factory installed<br />

in the refrigerant circuit, protecting the unit against<br />

high pressure conditions or loss of refrigerant charge.<br />

Schrader service valves are standard on the high and<br />

low pressure lines of all units, allowing connection to<br />

gauges for service diagnostics and to either evacuate,<br />

reclaim or recharge refrigerant into the system.<br />

Unit Protection Module<br />

Each EC unit is factory provided with a Unit Protection<br />

Module (UPM) that controls the unit operation<br />

and monitors the safety controls that protect the<br />

unit. The UPM interfaces with the thermostat or<br />

direct digital controller. The main purpose of the<br />

UPM is to protect the compressors by monitoring<br />

the different states of switches and sensors. This<br />

module provides time delays and protects the unit<br />

against freezing of the water to refrigerant heat<br />

exchangers as well as condensate overflow when<br />

the appropriate sensors are installed.<br />

Safety controls include the following:<br />

• High pressure switch located in the refrigerant<br />

discharge line.<br />

• Low pressure switch located in the unit refrigerant<br />

suction line.<br />

• Optional low fluid temperature (freeze) protection<br />

sensor. The freeze protection sensor, located<br />

on the refrigerant liquid line entering the coaxial<br />

heat exchanger is designed to disable compressor<br />

operation when the unit is in the heating<br />

mode, should the refrigerant temperature fall<br />

below either 30°F or 15°F. (The default setting is<br />

30 degrees farenheit, however this can be<br />

changed to 15 degrees farenheit by cutting the<br />

R42 resistor located above the Dip Switch SW1).<br />

If the temperature drops below or remains at the<br />

freeze limit trip for 30 seconds, the controller will<br />

shut the compressor down and enter into a soft<br />

EC Series 7<br />

lockout condition. The status LED will display the<br />

fault code, but the alarm contact will be inactive.<br />

• Optional Condensate overflow protection sensor<br />

factory mounted in the drain pan of the unit. Standard<br />

on all horizontal units.<br />

UPM Features<br />

• ANTI-SHORT CYCLE TIMER—5 minute delay on<br />

break timer to prevent compressor short cycling.<br />

• RANDOM START—Each controller has a unique<br />

random start delay ranging from 270 to 300<br />

seconds after power is applied to the board. This<br />

will prevent the simultaneous start of multiple<br />

units after a power outage.<br />

• LOW PRESSURE BYPASS TIMER—The low<br />

pressure switch is bypassed for 120 seconds<br />

after it opens to prevent nuisance low pressure<br />

lockouts during cold start-up in the heating mode.<br />

• BROWNOUT/SURGE/POWER INTERRUPTION<br />

PROTECTION—Prevents compressor operation<br />

should the voltage drop below 10% of unit rated<br />

value. The unit will restart once the voltage is within<br />

tolerance and the random start has timed out.<br />

• MALFUNCTION (ALARM) OUTPUT—The controller<br />

has a set of contacts for remote fault indication.<br />

This can be either a steady output or can be<br />

set to pulse with the fault code. Two connections<br />

are available one to provide a 24 volt output, the<br />

other to provide a dry contact.<br />

• TEST SERVICE MODE—A dip switch setting is provided<br />

to reduce all time delay settings to 10<br />

seconds maximum during troubleshooting for<br />

verification of unit operation.<br />

• L.E.D. FAULT INDICATION—Two L.E.D. indicators<br />

are provided as follows:<br />

• GREEN: Power L.E.D. indicates 18 – 30 VAC<br />

present at the board.<br />

• RED: Fault indicator with blink codes<br />

identifying the particular fault.<br />

1 Blink - High Pressure<br />

2 Blinks - Low Pressure<br />

3 Blinks - Low Fluid Temperature (Freeze Protection)<br />

4 Blinks - Condensate Overflow<br />

5 Blinks - Brownout condition<br />

Revised 10-12<br />

Subject to change without prior notice<br />

6720220353

8<br />

EC Series<br />

Unit Options<br />

• INTELLIGENT RESET—If a fault condition is<br />

initiated, the 5 minute delay on break time period<br />

is initiated and the unit will restart after this delay<br />

expires. The UPM is configurable for either 2 or 4<br />

fault occurrences before going into a hard lockout.<br />

The selection is made through a dip switch<br />

setting on the board. If the fault condition still<br />

exists or reoccurs twice or four times within one<br />

hour, the unit will go into a hard lockout and<br />

requires a manual lockout reset. A condensate<br />

overflow fault will, however, put the unit into a<br />

hard lockout immediately.<br />

• LOCKOUT RESET—A hard lockout can be reset by<br />

turning the unit thermostat off and then back on<br />

or by shutting off unit power at the circuit breaker.<br />

The method of reset is selectable by the dip<br />

switch on the board.<br />

UNIT OPTIONS<br />

Hot Gas Reheat<br />

Hot gas reheat (HGR) allows the user to not only<br />

control space temperature, but also humidity levels<br />

within the conditioned space. Excessive moisture in<br />

the space can promote mold growth leading to<br />

damage in the structure or interior surfaces, as well<br />

as reducing the air quality and creating an unhealthy<br />

environment.<br />

Possible causes of excess humidity could be by the<br />

unit having to operate under a widely varying load,<br />

an oversized short cycling unit, a high percentage of<br />

unconditioned outside air being introduced into the<br />

space, a high latent load in the space or any location<br />

where humidity infiltration is a problem.<br />

Typical unit control is by a wall mounted thermostat<br />

that senses temperature in the occupied space. By<br />

utilizing a humidistat in addition to the thermostat,<br />

we are able to monitor the humidity levels in the<br />

space as well. The HGR option allows cooling and<br />

dehumidification to satisfy both the thermostat and<br />

humidistat while preventing over cooling of the<br />

space while in the dehumidification mode.<br />

Once the thermostat reaches set point temperature<br />

and the humidity is above set point, the unit controller<br />

will energize the reheat valve operating the<br />

unit in hot gas reheat mode, first cooling and<br />

dehumidify, then reheating the air using hot refrigerant<br />

gas before delivering it to the space, usually<br />

2° to 5°F below room temperature. The unit is<br />

operating as a dehumidifier. By reheating the air<br />

along a constant sensible heat line, the relative<br />

humidity of the leaving air is reduced. This option<br />

offers significant energy savings over the traditional<br />

means of reheating air with electric heating coils.<br />

The moisture removal capacity of a specific heat<br />

pump is determined by the unit latent capacity<br />

rating. A heat pump’s latent capacity can be determined<br />

by reviewing the heat pump specification<br />

data sheets. Depending upon the entering water<br />

and air conditions, a total and sensible capacity can<br />

be interpolated from the data sheets. Subtracting<br />

sensible capacity from total capacity yields latent<br />

capacity. Dividing the latent capacity by 1069 (BTU/<br />

LB of water vapor at 80° DB and 67° WB) yields the<br />

amount of moisture removal in pounds per hour.<br />

Refrigerant Flow Path<br />

Check Valve<br />

Sub-Assembly<br />

Figure 1<br />

Reheat Coil<br />

Air<br />

Flow<br />

Oil<br />

Return<br />

Bleed<br />

Line<br />

Evaporator<br />

Coil<br />

Bypass Regulator<br />

Hot Gas Line<br />

Distributor<br />

Air Flow<br />

Equalizer Line<br />

Expansion Valve<br />

Reversing<br />

Valve<br />

Hot Gas<br />

Reheat<br />

Equalizer Line<br />

Discharge Out<br />

Water<br />

Liquid<br />

Line<br />

Condenser<br />

Coil<br />

TXV<br />

Sensing<br />

Bulb<br />

Compressor Suction In<br />

A hot gas reheat valve and a reheat coil are included<br />

in the refrigerant circuit. The refrigerant circuit in<br />

the cooling and heating mode is identical to a<br />

standard heat pump.<br />

In the reheat mode, the compressor discharge gas<br />

is diverted through the reheat valve to the reheat<br />

coil which is located downstream of the cooling<br />

coil. The superheated refrigerant gas reheats the air<br />

leaving the cooling coil. The hot refrigerant gas then<br />

passes though the water to refrigerant coil where it<br />

6720220353<br />

Subject to change without prior notice Revised 10-12

Sequence of Operation<br />

EC Series 9<br />

is condensed to a liquid. From this point the rest of<br />

the cooling cycle is completed as in a regular heat<br />

pump. There are two check valves to prevent<br />

refrigerant flow into the reheat coil during standard<br />

cooling/heating cycles. A small copper bleeder line<br />

is connected to the outlet line of the reheat coil and<br />

between the expansion valve outlet and distributor<br />

to the air coil. This line is necessary to let any<br />

liquid/oil that may have migrated to the reheat coil<br />

during reheat to escape during standard cooling/<br />

heating modes. (See Figure 1)<br />

Hot Gas Reheat Sequence of Operation<br />

-On/Off Control<br />

The sequence of operation in the cooling and<br />

heating mode is the same as a regular heat pump.<br />

In the reheat mode, on a call from the humidistat,<br />

the reheat relay coil is energized through the “H”<br />

circuit. The cooling relay remains de-energized<br />

enabling the reheat solenoid. The blower relay,<br />

reversing valve and compressor contactor are<br />

energized through contacts on the reheat relay. See<br />

typical wiring diagram page 41. (Note: The reheat<br />

mode always operates in the cooling mode.) Should<br />

the temperature in the space increase above set<br />

point, the compressor terminal Y is energized,<br />

which will de-energize the reheat valve putting the<br />

unit into straight cooling mode. A call for cooling or<br />

heating will always take precedence over hot gas<br />

reheat.<br />

Hot Gas Reheat Control Options<br />

There are several ways to control heat pumps with<br />

hot gas reheat. You should choose the means that<br />

best suits your specific application. Please refer to<br />

the Hot Gas Reheat wiring diagrams for typical<br />

thermostat wiring. Most heat pump compatible<br />

thermostats in conjunction with a humidistat are<br />

acceptable for use, (Note: “O” output for reversing<br />

valve energized in cooling mode is required.)<br />

Combination thermostat/humidistat are also<br />

available.<br />

Special Considerations<br />

Some applications require special attention to<br />

maximize the performance of the hot gas reheat<br />

function:<br />

• Low Temperature Well Water<br />

• Indoor Pool Dehumidifying During Winter Months<br />

(Re: Heating Mode)<br />

Consult the factory for special application<br />

considerations.<br />

Low Temperature Well Water<br />

When low temperature well water is utilized as the<br />

water source (below 55°F), a means of establishing<br />

two flow rates, one for the cooling/reheat mode<br />

and one for heating mode is recommended. In the<br />

cooling mode at low entering water temperatures<br />

and standard flow rates, discharge pressures and<br />

corresponding discharge gas temperatures are<br />

relatively low. At these conditions, when the reheat<br />

mode is initiated, the low temperature discharge<br />

gas can reduce reheat capacity. A means to reduce<br />

the water flow rate and elevate the discharge<br />

pressure/ temperature in cooling/reheat mode<br />

should be provided. Conversely, at low entering<br />

water temperatures in the heating mode, system<br />

suction pressure is reduced causing a loss in<br />

heating capacity. A means of providing higher flow<br />

in the heating mode should be provided. The<br />

simplest way to accomplish the above is to install<br />

water regulating valves.<br />

Indoor Pool Dehumidifying During Winter<br />

Months<br />

It is important to remember that when in the<br />

reheat/dehumidification mode the heat pump is<br />

cooling and reheating. A secondary means of<br />

heating the space during the dehumidification<br />

mode should be provided. The indoor space temperature<br />

should be kept at least two (2) degrees F<br />

above the pool water temperature. If this is not<br />

done the warm pool water attempts to heat the<br />

space and the humidity levels increase exponentially.<br />

The heat pump is normally sized to handle the<br />

design latent load moisture removal. A second heat<br />

pump or resistance heat should be provided to<br />

handle the structures shell loss load.<br />

Protective coatings are highly recommended for<br />

all pool applications, due to the highly corrosive<br />

chemical environment.<br />

Revised 10-12<br />

Subject to change without prior notice<br />

6720220353

10<br />

EC Series<br />

Hot Gas Bypass<br />

Sequence of Operation - Modulating Hot<br />

Gas Reheat (MHGRH)<br />

Modulating Hot Gas Reheat differs from On/Off in<br />

that the reheat function is always active. The<br />

purpose of MHGRH is to deliver air at or close to<br />

neutral conditions.<br />

Air is cooled and dehumidified by the cooling coil to<br />

around 55°F DB/54°F WB. A sensor located in the<br />

supply air stream is set at the required leaving dry<br />

bulb temperature and will send a signal to the<br />

modulating hot gas reheat valve to direct the flow of<br />

hot gas to maintain that temperature. See psychometric<br />

chart diagram( Figure 2). A typical application<br />

for this would be in treating 100% outside air.<br />

This air would be ducted directly into the space<br />

relieving the unit handling the zone of any outside<br />

air load. This can result in a smaller zone unit, less<br />

air flow and a savings in both initial and operating<br />

cost.<br />

Control of the hot gas modulation is by the thermostat<br />

in the supply air duct or through a building<br />

management system. A separate controller is used<br />

to control the unit itself.<br />

Hot Gas Bypass<br />

The function of the hot gas bypass valve is to<br />

prevent icing of the air coil when the unit is operating<br />

at low load conditions. This situation could arise<br />

if the space experiences widely different loads, for<br />

example a conference center. Without a hot gas<br />

bypass circuit the evaporating temperature will fall<br />

and ice could form on the coil restricting air flow<br />

and aggravating the situation. Eventually the coil<br />

could be totally blocked resulting in possible<br />

refrigerant liquid entering the compressor and<br />

failure of the system.<br />

The hot gas bypass valve located in the compressor<br />

discharge line diverts hot gas to the inlet of the air<br />

coil. The valve is factory set to open when the<br />

evaporating pressure falls to 75 PSI and will modulate<br />

to prevent the pressure falling any lower. This<br />

setting is field adjustable and this set point may be<br />

adjusted as required.<br />

Psychometric Chart<br />

Figure 2<br />

85<br />

85<br />

85 WET BULB TEMPERATURE - °F<br />

80<br />

80<br />

75<br />

80<br />

75<br />

65<br />

70<br />

70<br />

75<br />

Entering<br />

70<br />

65<br />

DEW POINT TEMPERATURE - °F<br />

60<br />

90%<br />

65<br />

60<br />

50<br />

55<br />

Lvg. Coil<br />

80%<br />

70%<br />

55<br />

60%<br />

60<br />

Reheat<br />

25%<br />

55<br />

50<br />

40<br />

35<br />

45<br />

40<br />

45<br />

50<br />

50%<br />

40%<br />

30%<br />

20%<br />

10% RELATIVE HUMIDITY<br />

15%<br />

8% RELATIVE HUMIDITY<br />

6%<br />

4%<br />

2%<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

10<br />

0<br />

35 40 45 50 55 60 65 70 75 80 85 90 95 100<br />

Chart by: HANDS DOWN SOFTWARE, www.handsdownsoftware.com<br />

DRY BULB TEMPERATURE - °F<br />

6720220353<br />

Subject to change without prior notice Revised 10-12

DDC Controls<br />

EC Series 11<br />

Fluid Differential Pressure Switch<br />

The function of the differential pressure switch is to<br />

prevent or stop compressor operation should the<br />

water supply fail. This will prevent the unit from<br />

locking out on a safety requiring a manual reset to<br />

restart.<br />

The switch is piped between the water entering and<br />

leaving connections. Should the pressure drop fall<br />

below set value, the switch will open de-energizing<br />

the DPS relay, thereby stopping the compressor.<br />

The blower operation will not be affected by this<br />

option.<br />

DDC Controls:<br />

The <strong>FHP</strong> factory mounted DDC Controller is preprogrammed<br />

and installed in the unit with the Unit<br />

Protection Module (UPM) to be job site ready. The<br />

unit will operate in a 100% stand-alone control<br />

mode or connect to a Building Automation System<br />

(BAS) using open protocols BACnet, Modbus, N2 or<br />

LonWorks. Stand-alone DDC modules must use<br />

remote intelligent sensors and are to be programmed<br />

by the <strong>FHP</strong> bacview controller only.<br />

Zone temperatures, leaving air temperatures and<br />

water temperatures can be monitored from the<br />

central control computer and unit fault indication<br />

displayed.<br />

Available inputs/outputs include:<br />

• Discharge air temperature<br />

• Leaving water temperature<br />

• Fan run time<br />

• Override time remaining<br />

• Night setback status<br />

• Percent of units cooling<br />

• Percent of units heating<br />

• Cooling set points<br />

• Heating set points<br />

• Status of all the alarms<br />

• Space temperature<br />

• Occupied heating and cooling set points<br />

• Continuous or cycle fan during occupied mode<br />

• Command for occupied or unoccupied mode<br />

• Command for override of the unoccupied mode<br />

(unit resorts to occupied set points)<br />

• Set point adjustment<br />

To complement the controller, <strong>FHP</strong> offers a line of<br />

intelligent space sensors, which provide precision<br />

measurement and communication capabilities in an<br />

attractive low profile enclosure. A hidden communications<br />

jack provides access to the HVAC control<br />

system for commissioning and maintenance.<br />

Models available include:<br />

• The RS Standard which has no local temperature<br />

set point adjustment.<br />

• The RS Plus offers a local set point adjustment<br />

and override to an occupied mode and LED<br />

indication of current status.<br />

• The RS Pro has a large LCD display and easy-touse<br />

occupant controls for set point adjustment.<br />

A backview hand held diagnostic tool is available to<br />

allow local access to display and modify user<br />

defined properties without any computer software.<br />

RS Standard RS Plus RS Pro<br />

Revised 10-12<br />

Subject to change without prior notice<br />

6720220353

12<br />

EC Series<br />

Systems<br />

SYSTEMS<br />

EC series may be used in a variety of different<br />

applications depending on the system design. An<br />

overview of Tower/Boiler and Geothermal systems<br />

is given below. There could be several variations<br />

and combinations of these systems.<br />

Water Source Cooling Tower/Boiler Systems<br />

Water source cooling tower/boiler systems have<br />

been used for many years and are recognized as<br />

having a low installation cost and providing more<br />

energy efficient operation that most other systems<br />

on the market.<br />

In a typical building each office or space would<br />

receive its own heat pump. This ensures that the<br />

unit will independently satisfy the heating or<br />

cooling requirements for that space irrespective of<br />

the requirements of any other space. Unlike some<br />

other systems, this offers individual control and<br />

enhanced comfort in that area.<br />

All the units are connected to a common water loop<br />

containing, in addition to the heat pumps, a cooling<br />

tower, boiler, a primary and standby pump and a<br />

loop water temperature controller. In the summer<br />

cooling mode, the units are cooling and rejecting<br />

heat to the water loop. This heat is then rejected to<br />

the atmosphere through a cooling tower. In winter,<br />

heat is taken from the loop and, together with the<br />

compressor’s heat of compression, used to heat<br />

the space. The heat removed from the loop is then<br />

replenished by the boiler. The loop water temperature<br />

controller will keep the fluid within certain<br />

temperature limits typically 70°F in winter and 85°F<br />

in summer by cycling either the cooling tower or<br />

boiler operation.<br />

In today’s modern buildings the interior core<br />

usually has a net cooling requirement year round<br />

irrespective of the outside temperature. This is due<br />

to the internal heat gains from people, office<br />

equipment and lighting. The heat from these units<br />

in cooling is rejected to the common water loop and<br />

is absorbed by those units on the buildings perimeter<br />

that are in the heating mode. In effect we are<br />

transferring energy around the building from where<br />

it is in excess to those areas where it is needed. In<br />

many instances we find a balanced system where<br />

the heat generated in the interior space is sufficient<br />

to heat the perimeter resulting in neither the<br />

cooling tower nor boiler operating. This concept,<br />

unique to a water source system, provides the most<br />

energy efficient system on the market.<br />

Geothermal Systems<br />

The earth has a tremendous capacity of storing<br />

thermal energy, which can be utilized to heat or<br />

cool a building.<br />

A Geothermal system offers all the benefits of a<br />

cooling tower and boiler system with the additional<br />

advantage of having overall greater energy efficiency.<br />

As the cost of energy increases geothermal<br />

installations are becoming the system of choice by<br />

developers and design engineers.<br />

There are several alternative methods of utilizing<br />

the energy contained in a geothermal system, giving<br />

the design engineer several options for selecting<br />

the one that is right for a particular application.<br />

Earth Coupling Options<br />

Ground Loop Systems (Closed Loop)<br />

Lengths of high density polyethylene piping are<br />

buried in the earth either in vertical bore holes or<br />

horizontal trenches depending on the space available.<br />

Fluid from the loop inside the building circulates<br />

through these pipes either rejecting heat to the<br />

ground when there is a net cooling requirement or<br />

absorbing heat from the ground when heating is the<br />

dominant requirement.<br />

The temperature of the earth below 6 feet is relatively<br />

constant and is not affected by the ambient<br />

temperature. For this reason, the ground temperature<br />

is cooler than the summer ambient and warm-<br />

6720220353<br />

Subject to change without prior notice Revised 10-12

Vertical Ground Loop System<br />

EC Series 13<br />

er than the winter ambient in most regions. Geothermal<br />

systems are able to operate effectively in<br />

extreme ambient conditions exceeding 100°F in<br />

summer and -30°F in winter. This is one of the<br />

reasons why geothermal systems have such an<br />

advantage over other systems. An additional advantage<br />

is that no fossil fuels are used reducing the<br />

carbon emission of the building.<br />

Even in areas which are cooling or heating dominate<br />

a hybrid system can be used with a downsized<br />

cooling tower or boiler. This system will reduce the<br />

installed cost significantly with only a modest<br />

impact on overall operating efficiency.<br />

Geothermal systems may cost more to install but<br />

the savings in energy and low maintenance costs<br />

more than off set this with payback times typically<br />

five years or even less.<br />

Vertical Ground Loop System<br />

Horizontal Ground Loop System<br />

This type is cost effective on smaller projects or<br />

where there is sufficient space for the loop field.<br />

Trenches, three to six feet deep are dug in which a<br />

series of high density polyethylene pipes are laid.<br />

These loops are manifolded and connected to the<br />

loop inside the building which feeds the heat<br />

pumps. The fluid is then circulated, absorbing or<br />

rejecting heat to the earth depending on the requirement<br />

for heating or cooling.<br />

Surface Water, Lake or Pond System<br />

This method is used mainly in commercial buildings<br />

or where space for a loop field is limited. Vertical<br />

holes 100 to 400 feet deep are drilled in the ground,<br />

and a single loop of high density polyethylene pipe<br />

with a U-tube at the bottom is installed. The bore<br />

hole is then sealed with grout to ensure good<br />

contact for heat transfer with the soil. The size of<br />

the project will determine how many bore holes are<br />

required. The vertical ground loops are then connected<br />

to a horizontal header pipe that carries fluid<br />

to the building and circulated to each heat pump.<br />

The Earth’s temperature is stable below the surface<br />

which is an advantage for this system and provides<br />

for the greater efficiency. Vertical ground loop fields<br />

may be located under buildings or parking lots. The<br />

life expectancy is in excess of 50 years.<br />

This type of design is economical when a project is<br />

located near a body of water. Fluid circulates<br />

through polyethylene piping in a closed system, just<br />

as it does through ground loops but in this case<br />

underwater. The pipes may be coiled in a slinky to<br />

fit more surfaces into a given amount of space. The<br />

lake needs to be a minimum size and depth depending<br />

on the building load. Lake loops have no adverse<br />

impact on the aquatic system. Specialized<br />

lake heat exchangers are also available for this<br />

application. New technology is emerging for stainless<br />

steel and titanium heat exchangers.<br />

Revised 10-12<br />

Subject to change without prior notice<br />

6720220353

14<br />

EC Series<br />

Well Water System<br />

Well Water System<br />

This type of installation is only possible if there is<br />

sufficient ground water available in a well. The<br />

water must be of good quality. Local codes may<br />

limit the use of this system in certain areas. The<br />

arrangement is referred to as an open system<br />

which means that water is pumped directly from<br />

the source into the geothermal unit and then<br />

discharged either into a return well or a body of<br />

water. The water quality is unaffected other than a<br />

change in the temperature.<br />

TYPICAL HEAT PUMP OPERATING<br />

MODES<br />

Cooling Mode<br />

In the cooling mode, the refrigerant, a hot gas, is<br />

pumped from the compressor to the water to<br />

refrigerant heat exchanger via the reversing valve.<br />

Water, generally with an anti freeze, flowing<br />

through the water-to-refrigerant heat exchanger<br />

transfers heat from the refrigerant to the fluid<br />

raising its temperature while condensing the hot<br />

gas into a liquid. This liquid refrigerant then flows<br />

through a metering device to the air-to-refrigerant<br />

heat exchanger coil.<br />

In evaporating into a gas, the liquid absorbs heat<br />

and cools and dehumidifies the air that passes over<br />

the coil surface. The cooling cycle is completed<br />

when the refrigerant flows as a low pressure gas<br />

through the reversing valve and back to the suction<br />

side of the compressor.<br />

Cool dehumidified air is circulated to the space<br />

maintaining comfort conditions.<br />

Heating Mode<br />

During the heating mode, the refrigerant, a hot gas,<br />

is pumped from the compressor to the air-to-refrigerant<br />

heat exchanger coil via the reversing valve.<br />

In the air-to-refrigerant heat exchanger coil, the<br />

heat is removed by the air that passes over the coil<br />

surface, and the hot gas condenses into a liquid.<br />

The heated air is ducted to the space and provides<br />

heating for the building.<br />

The refrigerant liquid then flows through a metering<br />

system to the water-to-refrigerant heat exchanger.<br />

Basic Refrigeration Cycle<br />

Water to Air Heat Pump Cycle—<br />

Cooling Mode<br />

Loop Fluid<br />

Loop Fluid<br />

Loop<br />

Loop<br />

Fluid<br />

Fluid<br />

Loop Fluid<br />

Loop Fluid<br />

Loop<br />

Loop<br />

Fluid<br />

Fluid<br />

Loop Fluid<br />

Cool Refrigerant Gas<br />

Cool Refrigerant Gas<br />

Air to<br />

Air to<br />

Refrigerant<br />

Refrigerant<br />

Heat<br />

Heat<br />

Cool<br />

Exchanger<br />

Refrigerant Cool<br />

Exchanger<br />

Refrigerant Gas<br />

Thermal<br />

Gas<br />

Expansion Thermal<br />

Expansion Valve<br />

Valve<br />

Warm Liquid Refrigerant<br />

Warm Liquid Refrigerant<br />

Water Water to to<br />

Refrigerant<br />

Heat<br />

Exchanger<br />

Hot Refrigerant Gas Gas<br />

Cold Liquid Refrigerant<br />

Water to<br />

Refrigerant<br />

Heat<br />

Exchanger<br />

Cold Liquid Refrigerant<br />

Cold Liquid Refrigerant<br />

Water to Air Heat Pump Cycle—<br />

Heating Mode<br />

Cool<br />

Cool<br />

Refrigerant<br />

Refrigerant<br />

Gas<br />

Gas<br />

ReversingValve<br />

ReversingValve<br />

Hot<br />

Hot<br />

Refrigerant<br />

Refrigerant<br />

Gas Gas<br />

Compressor<br />

Compressor<br />

Hot Hot Refrigerant Gas Gas<br />

Hot Refrigerant Gas<br />

Air to<br />

Refrigerant<br />

Heat<br />

Hot<br />

Exchanger<br />

Refrigerant<br />

Gas<br />

Thermal<br />

Expansion<br />

Valve<br />

Cool Refrigerant Gas<br />

Warm Liquid Refrigerant<br />

Cool<br />

Refrigerant Gas<br />

ReversingValve<br />

Hot<br />

Refrigerant<br />

Gas<br />

Hot Refrigerant Gas<br />

Compressor<br />

6720220353<br />

Subject to change without prior notice Revised 10-12

Typical Unit Installation<br />

Water, generally with an anti freeze, circulates<br />

through this heat exchanger and is cooled by the<br />

evaporating refrigerant which evaporates into a gas.<br />

The heating cycle is completed when the refrigerant<br />

flows as a low pressure gas through the reversing<br />

valve and back to the suction side of the compressor.<br />

TYPICAL UNIT INSTALLATION<br />

Unit Location<br />

Any mechanical device will, at some point in time<br />

require servicing and repair.<br />

With this in mind sufficient space must be provided<br />

around the unit for service personnel to perform<br />

maintenance or repair.<br />

Units are not designed for outdoor installation. Avoid<br />

locations where the unit may be exposed to freezing<br />

conditions or where the humidity levels could cause<br />

condensation on the unit panels for example when<br />

exposed to outdoor ambient conditions.<br />

Vertical Unit Installation<br />

EC Series 15<br />

Sufficient space must be provided for filter replacement<br />

and access to the compressor and blower for<br />

service.<br />

Units should be set on a piece of rubber, neoprene<br />

or other vibration absorbing material at least 1/3"<br />

to ½" thick. The pad should extend 3/4" over the<br />

entire base of the unit.<br />

Avoid direct line of sight to the unit. Install a sound<br />

baffle over any door that has a return air grille.<br />

See figure 3 for typical installation.<br />

Horizontal Unit Installation<br />

Figure 3<br />

Vertical units are normally installed in a closet or<br />

mechanical plant room.<br />

If installed in a closet or other confined space,<br />

ensure adequate space for return air to the unit.<br />

Horizontal units are typically suspended above the<br />

ceiling by four (field supplied) 3/8" threaded rods<br />

fastened to the unit by the factory supplied hanger<br />

bracket kits. The kits include rubber isolators to<br />

help prevent transmission of vibration and noise to<br />

the building structure. Units should be located<br />

directly below a structural member so that it is<br />

securely anchored.<br />

A horizontal unit should be positioned to allow for<br />

removal of the filters and access panels. Allow at<br />

least 18" clearance on each side of the unit for<br />

service and 36" in front of the unit for maintenance<br />

access. The filter needs to be slid out and sufficient<br />

space must be provided to allow this.<br />

Do not install the unit above any piping or electrical<br />

raceways. The unit should be able to be removed to<br />

the floor without major rearrangement of other<br />

mechanical or ceiling components.<br />

Consideration needs to be made as to the location<br />

of the units. Avoid installing units directly above<br />

occupied spaces (e.g. above office desks or classrooms).<br />

This will minimize possible disruption to<br />

the occupants if maintenance or service is required<br />

Revised 10-12<br />

Subject to change without prior notice<br />

6720220353

16<br />

EC Series<br />

Typical Unit Installation<br />

as well as keeping a potential source of noise out of<br />

the area. If possible, units should be installed above<br />

the hallway drop ceiling in schools, and the supply<br />

and return air is routed directly into classrooms.<br />

Local code may require fire dampers to be used in<br />

this application.<br />

Ductwork and Sound Attenuation<br />

Considerations<br />

Take-offs should be at<br />

least five feet away<br />

from the plenum<br />

Lining the first<br />

five feet of supply duct<br />

reduces noise<br />

Supply Air Ducting<br />

Turns attenuate<br />

blower hose<br />

Sound is becoming an increasingly important factor in<br />

Lining the first<br />

all HVAC installations. five feet of supply The duct EC series has been designed<br />

Turns attenuate<br />

to minimize reduces sound, noise but sound acoustical blower hose design plays<br />

an important part of the sound level in the space.<br />

Most of the problems associated Flex with HVAC<br />

duct<br />

generated sound can be avoided by paying Flex close<br />

Take-offs should be at<br />

duct<br />

attention to duct design and equipment placement.<br />

least five feet away<br />

from the plenum<br />

A discharge flange is provided on all horizontal unit<br />

models for fastening of ductwork. We recommend<br />

Return air<br />

using a flexible filter and collar grillebetween the discharge flange<br />

and the duct transformation to reduce vibration<br />

transmission from the cabinet and to simplify<br />

disconnection of the unit from the ceiling ductwork.<br />

Return air<br />

filter and grille<br />

Flex<br />

duct<br />

Return Air Ducting<br />

Flex<br />

duct<br />

Return air to the unit could be either free return or<br />

ducted. The filter rack is provided with a 1" flange<br />

should a ducted return be used. We recommend<br />

using a flexible collar between the return flange<br />

and the duct transformation to reduce vibration<br />

transmission from the cabinet and to simplify<br />

disconnection of the unit from the ductwork.<br />

Sound is transmitted down ductwork and it is<br />

important to avoid direct line of sight between the<br />

unit and the space, both on the return or supply<br />

side. To accomplish this, design the duct runs with<br />

two 90° turns.<br />

As a general recommendation, duct interiors<br />

should have an acoustic / thermal lining of least 1 / 2 "<br />

thick over the entire duct run or a minimum of the<br />

first 5 feet of the supply trunk.<br />

Line the last five diameters of duct before each<br />

outlet with one-inch thick sound blanket. Line<br />

elbows and transition pieces, as well as a short<br />

distance upstream and downstream of the fittings.<br />

Elbows, tees and dampers can create turbulence or<br />

distortion in the airflow. Using aerodynamic fittings<br />

will help in reducing this effect. Place a straight<br />

length of duct, 5 to 10 times the duct width, before<br />

the next fitting to smooth out airflow.<br />

Diffusers that are located in the bottom of a trunk<br />

duct can also produce noise.<br />

Balancing dampers should be located several duct<br />

widths upstream from an air outlet.<br />

Ductwork should be mounted and supported using<br />

isolation devices that absorb vibration.<br />

Applications such as Hotel, Motel, Dormitory or<br />

Nursing Home that use a single duct discharge are<br />

susceptible to noise. These applications typically<br />

have low static pressures and short duct lengths. In<br />

these applications the discharge duct must be fully<br />

lined and have a square elbow without turning<br />

vanes. A velocity not exceeding 500 to 600 fpm is<br />

recommended. Return air for these applications<br />

should enter through a sidewall grille and route up<br />

the stud space to a ceiling plenum.<br />

For horizontal heat pumps mounted in the ceiling<br />

plenum, an insulated return plenum is sometimes<br />

placed at the return air opening to further attenuate<br />

line-of-sight sound transmission through return<br />

openings.<br />

6720220353<br />

Subject to change without prior notice Revised 10-12

Unit Controls<br />

EC Series 17<br />

Piping<br />

The water loop system is typically designed using a<br />

“reverse return” piping system which includes a<br />

flow control device so that flow requirements are<br />

met for each zone.<br />

A high pressure stainless steel flexible hose kit is<br />

recommended to connect the unit to the building’s<br />

hard piping and acts as a sound attenuator for both<br />

the unit operating noise and hydraulic pumping<br />

noise. One end of the hose has a swivel fitting to<br />

facilitate removal of the unit for replacement or<br />

service.<br />

Hose kits come in several configurations, but in all<br />

cases should include supply and return shutoff ball<br />

valves to allow removal of a unit without the need to<br />

shut down the entire heat pump system. The hose<br />

kit may contain either a manual or automatic flow<br />

control that may be preset to ensure correct water<br />

flow to the unit.<br />

Other components of the hose kit may be a Y-strainer<br />

to prevent dirt from fouling the water coil. A blow<br />

down valve is recommended with the Y-strainer.<br />

Many installations today use variable frequency<br />

drives on the water loop pump as an energy saving<br />

measure. This requires the flow to the unit be shut<br />

off when it is not operating. This can be accomplished<br />

by including a 2-way solenoid valve in the<br />

hose kit, which is field wired to open when the<br />

compressor is energized.<br />

Pressure / Temperature ports should be included in<br />

these fittings to allow the service technician to<br />

measure water flow and temperatures when checking<br />

unit operation.<br />

Condensate Drain Piping<br />

Condensate piping can be made of steel, copper or<br />

PVC pipe. In most cases, PVC pipe eliminates the<br />

need to wrap insulation around the pipe to prevent<br />

sweating.<br />

A ¾" FPT condensate drain connection is installed<br />

in the unit. The condensate piping must be trapped<br />

at the unit and pitched away from the unit not less<br />

than 1/4" per foot. A vent is required after the trap<br />

so that the condensate will drain away from the<br />

unit. The vent can also act as a cleanout if the trap<br />

becomes clogged. The condensate drain should not<br />

be directly piped to a drain/waste/vent stack. See<br />

local codes for the correct application of condensate<br />

piping to drains.<br />

UNIT CONTROLS<br />

Thermostats<br />

The unit control may be as simple as a single stage<br />

thermostat or the unit may have a DDC controller<br />

integrated into the building management system.<br />

Multiple Stage Thermostats<br />

All external low voltage control wiring is made to<br />

the thermostat terminal located in the unit electrical<br />

box.<br />

Thermostats may be manual changeover, auto<br />

change over, programmable or non programmable<br />

depending on the requirements of the project. A<br />

full line of thermostats are available from <strong>FHP</strong> as<br />

an accessory.<br />

HOSE KITS<br />

Hose kits are recommended between the unit and<br />

system loop piping. This will help eliminate the<br />

transmission of vibration and noise from the unit<br />

to the space.<br />

Hoses are fire rated fiber reinforced EPDM Stainless<br />

Steel braid hoses with swivel connections.<br />

Maximum working pressure 400 PSI for sizes ½" –<br />

1" and 300 PSI for sizes 1 ¼" – 2".<br />

A variety of hose kits are available depending on<br />

the job requirement.<br />

Kit 1 Hose only either 24" or 36" long.<br />

Revised 10-12<br />

Subject to change without prior notice<br />

6720220353

18<br />

EC Series<br />

Performance Data<br />

Kit 2 Hose kit 1 with ball valves on the supply and<br />

return hoses. Valves have P/T (pressure/temperature)<br />

ports to facilitate pressure and temperature<br />

readings.<br />

Kit 3 Hose kit 2 with an automatic flow control<br />

valve. The design flow rate is preset at the factory<br />

per the design conditions and will automatically<br />

limit the flow to this value. This will greatly<br />

facilitate balancing of the fluid loop and ensuring<br />

each unit gets the required flow.<br />

Kit 4 Hose kit 3 with a Y-strainer and blow down<br />

valve on the supply side. The filter screen is 20<br />

mesh, 304 stainless steel to help prevent dirt and<br />

debris from entering the water coil.<br />

Kit 5 Hose kit 3 with a 24 v 2 position solenoid<br />

valve. This could be used to shut off flow to the unit<br />

when there is not call for heating or cooling. A<br />

typical application would be with VFD pumping.<br />

Kit 6 Hose kit 4 with a 24 v 2 position solenoid<br />

valve. Hose kit options are available in the accessories<br />

section of the BST selection software.<br />

Operating Limits<br />

<strong>FHP</strong> EC series are capable of operating over a wide<br />

range of conditions. For operation in a geothermal<br />

application or any other installation where the loop<br />

fluid temperature may drop below the ambient dew<br />

point, the extended range option is recommended.<br />

This consists of additional insulation on the piping<br />

to prevent condensation.<br />

• Maximum and minimum fluid conditions are at<br />

unit rated flow rate.<br />

• Maximum and minimum operating limits may not<br />

be combined. If one value is at either maximum<br />

or minimum the other two should be at normal<br />

operating range.<br />

• Entering fluid temperatures below 45°F in the<br />

heating mode require antifreeze.<br />

Operating Limits – Cooling & Heating<br />

Standard Unit<br />

Extended Range<br />

Option<br />

COOLING<br />

Minimum ambient air temperature °F 50 50<br />

Maximum ambient air temperature °F 100 100<br />

Minimum evaporator entering air db/wb °F 68/57 68/57<br />

Rated air coil entering air db/wb °F 80/67 80/67<br />

Maximum evaporator entering air db/wb °F 95/85 95/85<br />

Minimum water coil entering fluid temperature °F 50 50<br />

Water loop typical coil entering fluid range temperature °F 70/90 70/90<br />

Maximum water coil entering fluid temperature °F 110 110<br />

HEATING<br />

Minimum ambient air temperature °F 50 40<br />

Maximum ambient air temperature °F 100 85<br />

Minimum evaporator entering air db °F 50 50<br />

Rated air coil entering air °F 68 68<br />

Maximum evaporator entering air db °F 80 80<br />

Normal water coil entering fluid range °F 50-80 25-80<br />

Minimum water coil entering Fluid °F 50 20*<br />

* = antifreeze solution is required at these fluid temperatures.<br />

6720220353<br />

Subject to change without prior notice Revised 10-12

Certified Performance Data<br />

EC Series 19<br />

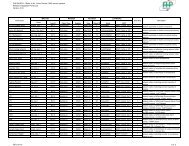

CERTIFIED PERFORMANCE DATA<br />

ARI/ISO 13256-1 PERFORMANCE DATA<br />

ENTERING WATER TEMPERATURES<br />

MODEL<br />

Fluid<br />

Flow<br />

Rate<br />

86˚F 68˚F 59°F 50°F 77˚F 32˚F<br />

WATER LOOP GROUND WATER GROUND LOOP<br />

CAPACITY AND EFFICIENCY DATA<br />

Cooling<br />

Capacity<br />

(WLHP)<br />

EER<br />

(WLHP)<br />

Heating<br />

Capacity<br />

(WLHP)<br />

COP<br />

(WLHP)<br />

Cooling<br />

Capacity<br />

(GWHP)<br />

EER<br />

(GWHP)<br />

Heating<br />

Capacity<br />

(GWHP)<br />

COP<br />

(GWHP)<br />

Cooling<br />

Capacity<br />

(GLHP)<br />

EER<br />

(GLHP)<br />

Heating<br />

Capacity<br />

(GLHP)<br />

COP<br />

(GLHP)<br />

EC007 2.0 6,200 12.50 8,000 5.10 7,200 20.0 6,000 4.0 6,500 15.00 4,500 3.20<br />

EC009 2.5 7,800 13.70 11,400 4.70 9,000 20.0 8,600 3.8 8,100 14.80 6,400 3.20<br />

EC012 3.0 11,000 13.00 14,500 4.50 12,400 19.0 11,500 3.6 11,500 14.50 8,700 3.10<br />

EC015 4.0 14,000 13.00 18,000 4.60 15,800 19.0 13,500 3.8 14,500 15.00 10,100 3.30<br />

EC018 5.0 18,500 13.00 24,000 4.40 21,400 19.0 18,000 3.8 19,800 14.10 13,400 3.30<br />

EC024 6.0 25,000 13.80 30,000 4.50 28,200 20.6 23,800 3.8 26,500 15.20 17,900 3.30<br />

EC030 7.0 29,000 13.00 35,000 4.30 33,000 18.6 28,400 3.8 31,000 14.40 21,000 3.30<br />

EC036 9.0 36,000 13.80 46,000 4.50 40,200 19.5 36,200 4.0 37,800 15.50 27,400 3.30<br />

EC041 9.0 38,000 12.50 49,000 4.20 40,400 16.1 39,000 3.7 39,200 14.10 28,500 3.1<br />

EC042 10.0 42,000 13.00 53,000 4.20 44,500 18.5 42,000 3.8 43,800 14.20 32,200 3.30<br />

EC048 12.0 48,000 14.00 58,000 4.80 58,000 20.6 46,600 4.2 52,000 15.40 36,800 3.50<br />

EC060 15.0 62,000 13.20 79,000 4.40 67,000 18.3 61,500 3.9 63,600 14.70 50,000 3.30<br />

EC070 16.0 68,000 13.50 80,000 4.50 76,000 19.8 68,000 4.0 70,000 15.20 53,000 3.30<br />

Tabulated performance data is at noted water temperatures and entering air conditions of 80.6°F DB/66.2°F WB at<br />

ARI/ISO 13256-1 rated CFM.<br />

Revised 10-12<br />

Subject to change without prior notice<br />

6720220353

20<br />

EC Series<br />

Unit Selection<br />

UNIT SELECTION<br />

To ensure that you get the optimal performance<br />

from your <strong>FHP</strong> heat pump it is important that they<br />

be selected accurately to match your design<br />

conditions.<br />

Prior to making equipment selections the zone<br />

conditions need to be determined. <strong>FHP</strong> <strong>Manufacturing</strong><br />

recommends using a building load program to<br />

determine the heating and cooling loads.<br />

The catalog provides a wide range of entering air<br />

and water conditions that will meet most applications.<br />

The unit performance can be determined by<br />

referring to the data tables from page 21 to 35.<br />

Our Bosch Select Tools Selection Software (BST) is<br />

designed to provide you with a fast and accurate<br />

selection based on your specific conditions. This<br />

software is available through the commercial<br />

website. You may click on the BST link and request<br />

an account.<br />

The following is a typical example for a unit selection.<br />

Design conditions are given as follows:<br />

Total Cooling Load<br />

Sensible Cooling Load<br />

Total Heating Load<br />

Air Flow Required<br />

= 35.57 MBTUH<br />

= 29.00 MBTUH<br />

= 38.92 MBTUH<br />

= 1400 CFM<br />

Entering Air Temp Cooling (db/wb) = 75°F / 63°F<br />

Entering Air Temp Heating = 60°F<br />

Entering Water Temp Cooling = 80°F<br />

Entering Water Temp Heating = 70°F<br />

<strong>FHP</strong> model EC036 would not be sufficient given<br />

these conditions as it provides a total cooling<br />

capacity of 36.9 MBTUH and a sensible capacity of<br />

28.1 MBTUH.<br />

The next size unit, the EC041 has a total cooling<br />

capacity of 40.7 MBTUH and a sensible capacity of<br />

29.3 MBTUH. This meets the design conditions as<br />

closely as possible.<br />

Please be aware that interpolation between ratings<br />

within a table is allowed, but extrapolation is a<br />

method of estimating new data by expanding<br />

outside a known range of data points and should<br />

not be considered accurate.<br />

6720220353<br />

Subject to change without prior notice Revised 10-12

Capacity Data<br />

EC Series 21<br />

EC007 (300 CFM)<br />

Entering<br />

Fluid Temp<br />

(F)<br />

50<br />

60<br />

70<br />

80<br />

85<br />

90<br />

100<br />

110<br />

Water<br />

Flow<br />

(GPM)<br />

Pressure<br />

Drop<br />

(FOH)<br />

1 1.8<br />

2 6.3<br />

3 13.1<br />

1 1.7<br />

2 6.1<br />

3 12.6<br />

1 1.7<br />

2 5.9<br />

3 12.2<br />

1 1.6<br />

2 5.7<br />

3 11.8<br />

1 1.6<br />

2 5.6<br />

3 11.6<br />

1 1.6<br />

2 5.5<br />

3 11.4<br />

1 1.5<br />

2 5.4<br />

3 11.1<br />

1 1.5<br />

2 5.2<br />

3 10.8<br />

COOLING<br />

Total<br />

Entering Air<br />

Capacity<br />

Temp (db/wb) F<br />

(MBTUH)<br />

Sensible<br />

Capacity<br />

(MBTUH)<br />

Heat of<br />

Rejection<br />

(MBTUH)<br />

Power<br />

Input (kW)<br />

EER<br />

Entering<br />

Fluid Temp<br />

(F)<br />

Entering<br />

Air Temp<br />

(F)<br />

HEATING<br />

Total<br />

Capacity<br />

(MBTUH)<br />

Heat of<br />

Absorption<br />

(MBTUH)<br />

75/63 7.7 6.2 9.0 0.40 19.2<br />

60 5.2 3.5 0.50 3.0<br />

80/67 8.2 6.5 9.5 0.40 20.7 70 5.1 3.3 0.53 2.8<br />

85/71 8.7 6.7 10.1 0.39 22.2 80 5.0 3.0 0.56 2.6<br />

75/63 7.9 6.4 9.2 0.38 21.0 60 5.5 3.8 0.51 3.2<br />

80/67 8.5 6.6 9.8 0.37 23.3 30 70 5.4 3.5 0.54 2.9<br />

85/71 9.1 6.8 10.5 0.36 25.5 80 5.2 3.2 0.57 2.7<br />

75/63 8.0 6.4 9.3 0.36 22.1 60 5.6 3.9 0.51 3.2<br />

80/67 8.6 6.6 9.9 0.36 24.3 70 5.4 3.6 0.54 2.9<br />

85/71 9.2 6.8 10.5 0.35 26.6 80 5.3 3.3 0.57 2.7<br />

75/63 7.3 6.1 8.6 0.45 16.4<br />

60 5.6 4.3 0.52 3.2<br />

80/67 7.8 6.3 9.1 0.44 17.7 70 5.6 4.0 0.55 3.0<br />

85/71 8.3 6.5 9.7 0.44 19.0 80 5.6 3.7 0.59 2.8<br />

75/63 7.5 6.2 8.8 0.42 17.9 60 6.5 4.7 0.51 3.7<br />

80/67 8.0 6.4 9.4 0.42 19.3 40 70 5.5 4.3 0.56 2.9<br />

85/71 8.6 6.6 10.0 0.41 21.1 80 5.5 4.0 0.60 2.7<br />

75/63 7.6 6.2 8.9 0.41 18.7 60 6.6 4.9 0.52 3.7<br />

80/67 8.1 6.5 9.5 0.40 20.2 70 6.1 4.5 0.56 3.2<br />

85/71 8.7 6.7 10.1 0.40 22.1 80 5.5 4.1 0.60 2.7<br />

75/63 6.8 5.9 8.2 0.49 13.9<br />

60 6.9 5.2 0.52 3.9<br />

80/67 7.3 6.1 8.7 0.49 15.0 70 6.8 4.9 0.56 3.6<br />

85/71 7.8 6.3 9.3 0.49 16.1 80 6.6 4.5 0.60 3.2<br />

75/63 7.1 6.0 8.4 0.47 15.3 60 7.5 5.7 0.52 4.2<br />

80/67 7.6 6.2 9.0 0.46 16.5 50 70 7.2 5.3 0.56 3.7<br />

85/71 8.1 6.5 9.5 0.46 17.7 80 7.0 4.9 0.61 3.4<br />

75/63 7.2 6.0 8.5 0.45 15.9 60 7.6 5.9 0.52 4.3<br />

80/67 7.7 6.3 9.1 0.45 17.2 70 7.4 5.5 0.56 3.8<br />

85/71 8.2 6.5 9.6 0.45 18.5 80 7.1 5.0 0.61 3.4<br />

75/63 6.4 5.7 7.8 0.54 11.9<br />

60 7.9 6.2 0.52 4.4<br />

80/67 6.9 6.0 8.3 0.54 12.9 70 7.7 5.8 0.56 4.0<br />

85/71 7.4 6.2 8.9 0.54 13.9 80 7.5 5.4 0.61 3.6<br />

75/63 6.7 5.8 8.0 0.51 13.1 60 8.5 6.8 0.52 4.7<br />

80/67 7.1 6.1 8.5 0.51 14.0 60 70 8.2 6.3 0.57 4.2<br />

85/71 7.6 6.3 9.1 0.51 15.0 80 7.9 5.9 0.61 3.8<br />

75/63 6.8 5.8 8.1 0.50 13.6 60 8.7 7.0 0.52 4.8<br />

80/67 7.2 6.1 8.6 0.50 14.5 70 8.4 6.5 0.57 4.3<br />

85/71 7.8 6.3 9.2 0.50 15.8 80 8.1 6.1 0.62 3.8<br />

75/63 6.2 5.6 7.6 0.56 11.1<br />

60 8.8 7.2 0.52 4.9<br />

80/67 6.7 5.9 8.1 0.56 12.0 70 8.6 6.7 0.57 4.4<br />

85/71 7.1 6.1 8.6 0.56 12.7 80 8.4 6.3 0.62 4.0<br />

75/63 6.4 5.7 7.8 0.54 12.0 60 9.5 7.9 0.53 5.3<br />

80/67 6.9 6.0 8.3 0.54 13.0 70 70 9.3 7.4 0.58 4.7<br />

85/71 7.4 6.2 8.9 0.53 13.9 80 9.0 6.9 0.62 4.2<br />

75/63 6.5 5.7 7.9 0.53 12.4 60 9.8 8.2 0.53 5.4<br />

80/67 7.0 6.0 8.4 0.52 13.4 70 9.5 7.6 0.58 4.8<br />

85/71 7.5 6.3 9.0 0.52 14.5 80 9.2 7.1 0.63 4.3<br />