Aflex Halogen Free Flexible Cables EPR/Polyurethane EPR/PUR ...

Aflex Halogen Free Flexible Cables EPR/Polyurethane EPR/PUR ...

Aflex Halogen Free Flexible Cables EPR/Polyurethane EPR/PUR ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

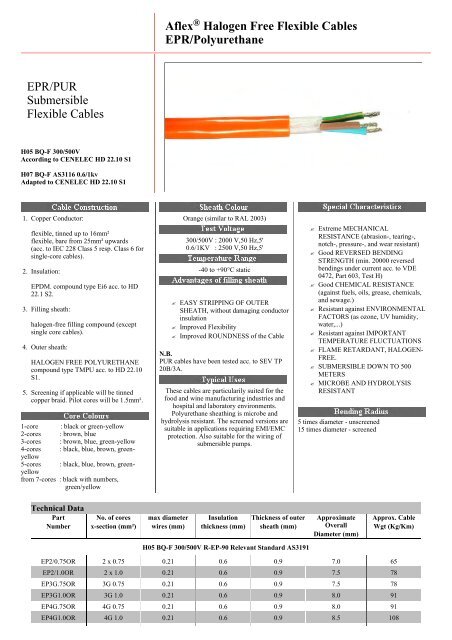

<strong>Aflex</strong> ® <strong>Halogen</strong> <strong>Free</strong> <strong>Flexible</strong> <strong>Cables</strong><br />

<strong>EPR</strong>/<strong>Polyurethane</strong><br />

<strong>EPR</strong>/<strong>PUR</strong><br />

Submersible<br />

<strong>Flexible</strong> <strong>Cables</strong><br />

H05 BQ-F 300/500V<br />

According to CENELEC HD 22.10 S1<br />

H07 BQ-F AS3116 0.6/1kv<br />

Adapted to CENELEC HD 22.10 S1<br />

1. Copper Conductor:<br />

flexible, tinned up to 16mm²<br />

flexible, bare from 25mm² upwards<br />

(acc. to IEC 228 Class 5 resp. Class 6 for<br />

single-core cables).<br />

2. Insulation:<br />

EPDM. compound type Ei6 acc. to HD<br />

22.1 S2.<br />

3. Filling sheath:<br />

halogen-free filling compound (except<br />

single core cables).<br />

4. Outer sheath:<br />

HALOGEN FREE POLYURETHANE<br />

compound type TMPU acc. to HD 22.10<br />

S1.<br />

5. Screening if applicable will be tinned<br />

copper braid. Pilot cores will be 1.5mm².<br />

1-core : black or green-yellow<br />

2-cores : brown, blue<br />

3-cores : brown, blue, green-yellow<br />

4-cores : black, blue, brown, greenyellow<br />

5-cores : black, blue, brown, greenyellow<br />

from 7-cores : black with numbers,<br />

green/yellow<br />

Orange (similar to RAL 2003)<br />

300/500V : 2000 V,50 Hz,5'<br />

0.6/1KV : 2500 V,50 Hz,5'<br />

-40 to +90°C static<br />

? EASY STRIPPING OF OUTER<br />

SHEATH, without damaging conductor<br />

insulation<br />

? Improved Flexibility<br />

? Improved ROUNDNESS of the Cable<br />

N.B.<br />

<strong>PUR</strong> cables have been tested acc. to SEV TP<br />

20B/3A.<br />

These cables are particularily suited for the<br />

food and wine manufacturing industries and<br />

hospital and laboratory environments.<br />

<strong>Polyurethane</strong> sheathing is microbe and<br />

hydrolysis resistant. The screened versions are<br />

suitable in applications requiring EMI/EMC<br />

protection. Also suitable for the wiring of<br />

submersible pumps.<br />

? Extreme MECHANICAL<br />

RESISTANCE (abrasion-, tearing-,<br />

notch-, pressure-, and wear resistant)<br />

? Good REVERSED BENDING<br />

STRENGTH (min. 20000 reversed<br />

bendings under current acc. to VDE<br />

0472, Part 603, Test H)<br />

? Good CHEMICAL RESISTANCE<br />

(against fuels, oils, grease, chemicals,<br />

and sewage.)<br />

? Resistant against ENVIRONMENTAL<br />

FACTORS (as ozone, UV humidity,<br />

water,...)<br />

? Resistant against IMPORTANT<br />

TEMPERATURE FLUCTUATIONS<br />

? FLAME RETARDANT, HALOGEN-<br />

FREE.<br />

? SUBMERSIBLE DOWN TO 500<br />

METERS<br />

? MICROBE AND HYDROLYSIS<br />

RESISTANT<br />

5 times diameter - unscreened<br />

15 times diameter - screened<br />

Technical Data<br />

Part<br />

Number<br />

No. of cores<br />

x-section (mm²)<br />

max diameter<br />

wires (mm)<br />

Insulation<br />

thickness (mm)<br />

Thickness of outer<br />

sheath (mm)<br />

Approximate<br />

Overall<br />

Diameter (mm)<br />

Approx. Cable<br />

Wgt (Kg/Km)<br />

H05 BQ-F 300/500V R-EP-90 Relevant Standard AS3191<br />

EP2/0.75OR 2 x 0.75 0.21 0.6 0.9 7.0 65<br />

EP2/1.0OR 2 x 1.0 0.21 0.6 0.9 7.5 78<br />

EP3G.75OR 3G 0.75 0.21 0.6 0.9 7.5 78<br />

EP3G1.0OR 3G 1.0 0.21 0.6 0.9 8.0 91<br />

EP4G.75OR 4G 0.75 0.21 0.6 0.9 8.0 91<br />

EP4G1.0OR 4G 1.0 0.21 0.6 0.9 8.5 108

EP5G.75OR 5G 0.75 0.21 0.6 1.0 9.0 113<br />

EP5G1.0OR 5G 1.0 0.21 0.6 1.0 9.5 137<br />

H07 BQ-F R-EP-90 Relevant Standard AS3191, AS3116 0.6/1Kv<br />

EP2/1.5OR 2 X 1.5 0.26 0.8 1.0 9.0 111<br />

EP3G1.5OR 3G 1.5 0.26 0.8 1.0 9.5 130<br />

EP3G2.5OR 3G 2.5 0.26 0.9 1.1 11.0 191<br />

EP3G4.0OR 3G 4.0 0.31 1.0 1.2 13.0 266<br />

EP4G1.5OR 4G 1.5 0.26 0.8 1.1 10.5 162<br />

EP4G2.5OR 4G 2.5 0.26 0.9 1.2 12.5 238<br />

EP4G4.0OR 4G 4.0 0.31 1.0 1.3 14.0 331<br />

EP4G6.0OR 4G 6.0 0.31 1.0 1.5 14.0 453<br />

EP5G1.5OR 5G 1.5 0.26 0.8 1.1 11.5 195<br />

EP5G2.5OR 5G 2.5 0.26 0.9 1.3 13.5 291<br />

EP5G4.0OR 5G 4.0 0.31 1.0 1.4 16.0 411<br />

EP5G6.0OR 5G 6.0 0.31 1.0 1.6 18.0 559<br />

EP5G1.0OR 5G 1.0 0.41 1.2 2.3 23.1 951<br />

EP5G16OR 5G 16 0.41 1.2 2.5 26.5 1351<br />

EP5G25OR 5G 25 0.41 1.4 2.7 33.5 2169<br />

EP5G35OR 5G 35 0.41 1.4 2.9 38.0 2923<br />

EP5G50OR 5G 50 0.41 1.6 3.2 43.5 3945<br />

EP7G1.5OR 7G 1.5 0.26 0.8 1.2 14.0 291<br />

EP7G2.5OR 7G 2.5 0.26 0.9 1.5 16.5 431<br />

Screened<br />

EP5G2.5/2.5 5G 2.5/2.5 0.26 0.9 1.5 16.2 454<br />

Screened with Pilots<br />

EP5G6/6P 5G 6/6+2 0.31 1.0 1.5 23.8 800<br />

EP5G10/10P 5G 10/10+2 0.41 1.2 2.0 25.9 2110