NEXANS SPIDER terrain dredger system

NEXANS SPIDER terrain dredger system

NEXANS SPIDER terrain dredger system

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

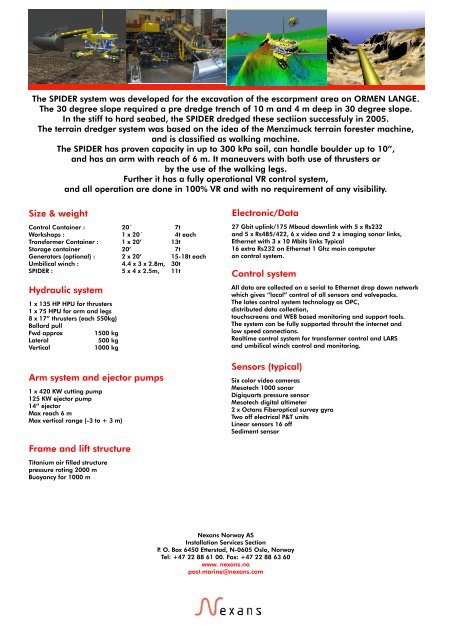

The <strong>SPIDER</strong> <strong>system</strong> was developed for the excavation of the escarpment area on ORMEN LANGE.<br />

The 30 degree slope required a pre dredge trench of 10 m and 4 m deep in 30 degree slope.<br />

In the stiff to hard seabed, the <strong>SPIDER</strong> dredged these sectiion successfuly in 2005.<br />

The <strong>terrain</strong> <strong>dredger</strong> <strong>system</strong> was based on the idea of the Menzimuck <strong>terrain</strong> forester machine,<br />

and is classified as walking machine.<br />

The <strong>SPIDER</strong> has proven capacity in up to 300 kPa soil, can handle boulder up to 10”,<br />

and has an arm with reach of 6 m. It maneuvers with both use of thrusters or<br />

by the use of the walking legs.<br />

Further it has a fully operational VR control <strong>system</strong>,<br />

and all operation are done in 100% VR and with no requirement of any visibility.<br />

Size & weight<br />

Control Container :<br />

Workshops :<br />

Transformer Container :<br />

Storage container<br />

Generators (optional) :<br />

Umbilical winch :<br />

<strong>SPIDER</strong> :<br />

Hydraulic <strong>system</strong><br />

1 x 135 HP HPU for thrusters<br />

1 x 75 HPU for arm and legs<br />

8 x 17” thrusters (each 550kg)<br />

Bollard pull<br />

Fwd approx<br />

Lateral<br />

Vertical<br />

1500 kg<br />

500 kg<br />

1000 kg<br />

Arm <strong>system</strong> and ejector pumps<br />

1 x 420 KW cutting pump<br />

125 KW ejector pump<br />

14” ejector<br />

Max reach 6 m<br />

Max vertical range (-3 to + 3 m)<br />

Frame and lift structure<br />

Titanium air filled structure<br />

pressure rating 2000 m<br />

Buoyancy for 1000 m<br />

20´<br />

1 x 20´<br />

1 x 20’<br />

20’<br />

2 x 20’<br />

4.4 x 3 x 2.8m,<br />

5 x 4 x 2.5m,<br />

7t<br />

4t each<br />

13t<br />

7t<br />

15-18t each<br />

30t<br />

11t<br />

Electronic/Data<br />

27 Gbit uplink/175 Mbaud downlink with 5 x Rs232<br />

and 5 x Rs485/422, 6 x video and 2 x imaging sonar links,<br />

Ethernet with 3 x 10 Mbits links Typical<br />

16 extra Rs232 on Ethernet 1 Ghz main computer<br />

on control <strong>system</strong>.<br />

Control <strong>system</strong><br />

All data are collected on a serial to Ethernet drop down network<br />

which gives “local” control of all sensors and valvepacks.<br />

The lates control <strong>system</strong> technology as OPC,<br />

distributed data collection,<br />

touchscreens and WEB based monitoring and support tools.<br />

The <strong>system</strong> can be fully supported throuht the internet and<br />

low speed connections.<br />

Realtime control <strong>system</strong> for transformer control and LARS<br />

and umbilical winch control and monitoring.<br />

Sensors (typical)<br />

Six color video cameras<br />

Mesotech 1000 sonar<br />

Digiquarts pressure sensor<br />

Mesotech digital altimeter<br />

2 x Octans Fiberoptical survey gyro<br />

Two off electrical P&T units<br />

Linear sensors 16 off<br />

Sediment sensor<br />

Nexans Norway AS<br />

Installation Services Section<br />

P. O. Box 6450 Etterstad, N-0605 Oslo, Norway<br />

Tel: +47 22 88 61 00. Fax: +47 22 88 63 60<br />

www. nexans.no<br />

post.marine@nexans.com