NEXANS SPIDER terrain dredger system

NEXANS SPIDER terrain dredger system

NEXANS SPIDER terrain dredger system

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

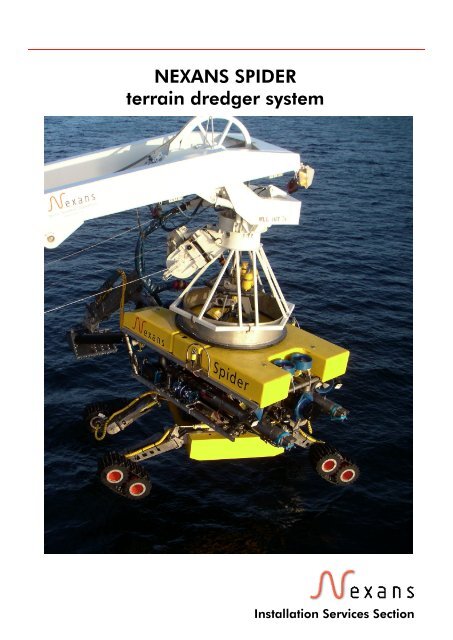

<strong>NEXANS</strong> <strong>SPIDER</strong><br />

<strong>terrain</strong> <strong>dredger</strong> <strong>system</strong><br />

Installation Services Section

The <strong>SPIDER</strong> <strong>system</strong> was developed for the excavation of the escarpment area on ORMEN LANGE.<br />

The 30 degree slope required a pre dredge trench of 10 m and 4 m deep in 30 degree slope.<br />

In the stiff to hard seabed, the <strong>SPIDER</strong> dredged these sectiion successfuly in 2005.<br />

The <strong>terrain</strong> <strong>dredger</strong> <strong>system</strong> was based on the idea of the Menzimuck <strong>terrain</strong> forester machine,<br />

and is classified as walking machine.<br />

The <strong>SPIDER</strong> has proven capacity in up to 300 kPa soil, can handle boulder up to 10”,<br />

and has an arm with reach of 6 m. It maneuvers with both use of thrusters or<br />

by the use of the walking legs.<br />

Further it has a fully operational VR control <strong>system</strong>,<br />

and all operation are done in 100% VR and with no requirement of any visibility.<br />

Size & weight<br />

Control Container :<br />

Workshops :<br />

Transformer Container :<br />

Storage container<br />

Generators (optional) :<br />

Umbilical winch :<br />

<strong>SPIDER</strong> :<br />

Hydraulic <strong>system</strong><br />

1 x 135 HP HPU for thrusters<br />

1 x 75 HPU for arm and legs<br />

8 x 17” thrusters (each 550kg)<br />

Bollard pull<br />

Fwd approx<br />

Lateral<br />

Vertical<br />

1500 kg<br />

500 kg<br />

1000 kg<br />

Arm <strong>system</strong> and ejector pumps<br />

1 x 420 KW cutting pump<br />

125 KW ejector pump<br />

14” ejector<br />

Max reach 6 m<br />

Max vertical range (-3 to + 3 m)<br />

Frame and lift structure<br />

Titanium air filled structure<br />

pressure rating 2000 m<br />

Buoyancy for 1000 m<br />

20´<br />

1 x 20´<br />

1 x 20’<br />

20’<br />

2 x 20’<br />

4.4 x 3 x 2.8m,<br />

5 x 4 x 2.5m,<br />

7t<br />

4t each<br />

13t<br />

7t<br />

15-18t each<br />

30t<br />

11t<br />

Electronic/Data<br />

27 Gbit uplink/175 Mbaud downlink with 5 x Rs232<br />

and 5 x Rs485/422, 6 x video and 2 x imaging sonar links,<br />

Ethernet with 3 x 10 Mbits links Typical<br />

16 extra Rs232 on Ethernet 1 Ghz main computer<br />

on control <strong>system</strong>.<br />

Control <strong>system</strong><br />

All data are collected on a serial to Ethernet drop down network<br />

which gives “local” control of all sensors and valvepacks.<br />

The lates control <strong>system</strong> technology as OPC,<br />

distributed data collection,<br />

touchscreens and WEB based monitoring and support tools.<br />

The <strong>system</strong> can be fully supported throuht the internet and<br />

low speed connections.<br />

Realtime control <strong>system</strong> for transformer control and LARS<br />

and umbilical winch control and monitoring.<br />

Sensors (typical)<br />

Six color video cameras<br />

Mesotech 1000 sonar<br />

Digiquarts pressure sensor<br />

Mesotech digital altimeter<br />

2 x Octans Fiberoptical survey gyro<br />

Two off electrical P&T units<br />

Linear sensors 16 off<br />

Sediment sensor<br />

Nexans Norway AS<br />

Installation Services Section<br />

P. O. Box 6450 Etterstad, N-0605 Oslo, Norway<br />

Tel: +47 22 88 61 00. Fax: +47 22 88 63 60<br />

www. nexans.no<br />

post.marine@nexans.com