Thermocouple Catalog (North America) - English - Pyrotek

Thermocouple Catalog (North America) - English - Pyrotek

Thermocouple Catalog (North America) - English - Pyrotek

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

GENERAL TECHNICAL REFERENCES AND TABLES<br />

LETTER OF CALIBRATION<br />

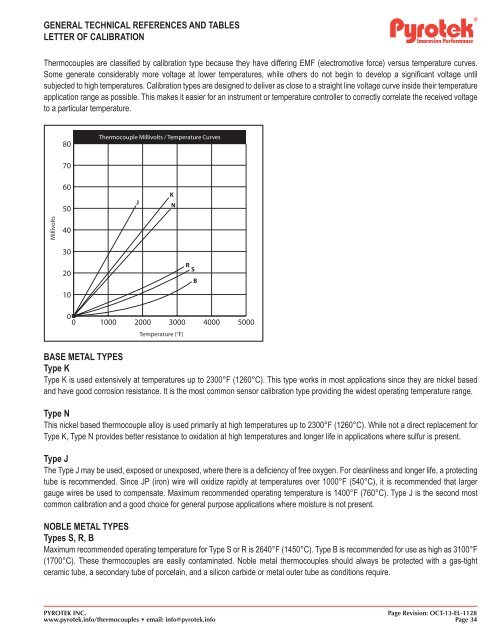

<strong>Thermocouple</strong>s are classified by calibration type because they have differing EMF (electromotive force) versus temperature curves.<br />

Some generate considerably more voltage at lower temperatures, while others do not begin to develop a significant voltage until<br />

subjected to high temperatures. Calibration types are designed to deliver as close to a straight line voltage curve inside their temperature<br />

application range as possible. This makes it easier for an instrument or temperature controller to correctly correlate the received voltage<br />

to a particular temperature.<br />

80<br />

<strong>Thermocouple</strong> Millivolts / Temperature Curves<br />

70<br />

60<br />

50<br />

J<br />

K<br />

N<br />

Millivolts<br />

40<br />

30<br />

20<br />

R<br />

S<br />

B<br />

10<br />

0<br />

0 1000 2000 3000 4000 5000<br />

Temperature (°F)<br />

BASE METAL TYPES<br />

Type K<br />

Type K is used extensively at temperatures up to 2300°F (1260°C). This type works in most applications since they are nickel based<br />

and have good corrosion resistance. It is the most common sensor calibration type providing the widest operating temperature range.<br />

Type N<br />

This nickel based thermocouple alloy is used primarily at high temperatures up to 2300°F (1260°C). While not a direct replacement for<br />

Type K, Type N provides better resistance to oxidation at high temperatures and longer life in applications where sulfur is present.<br />

Type J<br />

The Type J may be used, exposed or unexposed, where there is a deficiency of free oxygen. For cleanliness and longer life, a protecting<br />

tube is recommended. Since JP (iron) wire will oxidize rapidly at temperatures over 1000°F (540°C), it is recommended that larger<br />

gauge wires be used to compensate. Maximum recommended operating temperature is 1400°F (760°C). Type J is the second most<br />

common calibration and a good choice for general purpose applications where moisture is not present.<br />

NOBLE METAL TYPES<br />

Types S, R, B<br />

Maximum recommended operating temperature for Type S or R is 2640°F (1450°C). Type B is recommended for use as high as 3100°F<br />

(1700°C). These thermocouples are easily contaminated. Noble metal thermocouples should always be protected with a gas-tight<br />

ceramic tube, a secondary tube of porcelain, and a silicon carbide or metal outer tube as conditions require.<br />

PYROTEK INC.<br />

Page Revision: OCT-13-EL-1128<br />

www.pyrotek.info/thermocouples • email: info@pyrotek.info Page 34