Good Manufacturing Practice for the Manufacture of Paper - CEPI ...

Good Manufacturing Practice for the Manufacture of Paper - CEPI ...

Good Manufacturing Practice for the Manufacture of Paper - CEPI ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Recovered paper<br />

Risk<br />

Risk analysis<br />

Stock preparation<br />

<strong>Paper</strong> or board, o<strong>the</strong>r than internal broke or scrap, which is recovered<br />

from an operation within <strong>the</strong> paper supply chain and returned to a<br />

paper mill <strong>for</strong> conversion back into new paper.<br />

A function <strong>of</strong> <strong>the</strong> probability <strong>of</strong> an adverse health effect and <strong>the</strong><br />

severity <strong>of</strong> that effect, consequential to a hazard(s) in a food contact<br />

material.<br />

The process <strong>of</strong> defining <strong>the</strong> various threats to product safety,<br />

determining <strong>the</strong> extent <strong>of</strong> vulnerabilities and devising appropriate<br />

countermeasures.<br />

The addition <strong>of</strong> water to wood pulp and recovered paper and<br />

subsequent homogenisation and cleaning operations prior to<br />

processing on <strong>the</strong> paper machine wire.<br />

4. QUALITY ASSURANCE<br />

4.1 General<br />

A documented quality management system, such as ISO 9001 or equivalent, <strong>for</strong>ms <strong>the</strong> underlying<br />

basis <strong>for</strong> <strong>the</strong> procedures and instructions related to <strong>the</strong> GMP Regulation and <strong>the</strong> specific<br />

requirements <strong>for</strong> food packaging materials. The mill management system should be revised and<br />

amended to ensure that quality aspects related to food packaging applications are included in an<br />

appropriate way.<br />

The requirements on paper and board <strong>for</strong> food contact packaging are governed by <strong>the</strong> demands<br />

on <strong>the</strong> final packaging and aim to ensure suitable quality <strong>for</strong> <strong>the</strong> intended use. This implies<br />

that <strong>the</strong> paper and board must be manufactured to an agreed quality standard, including <strong>the</strong><br />

requirements in <strong>the</strong> Framework Regulation and o<strong>the</strong>r quasi-legislation <strong>for</strong> food contact.<br />

The existing procedures in <strong>the</strong> quality management system should be used <strong>for</strong> <strong>the</strong> areas which<br />

are not covered by this document.<br />

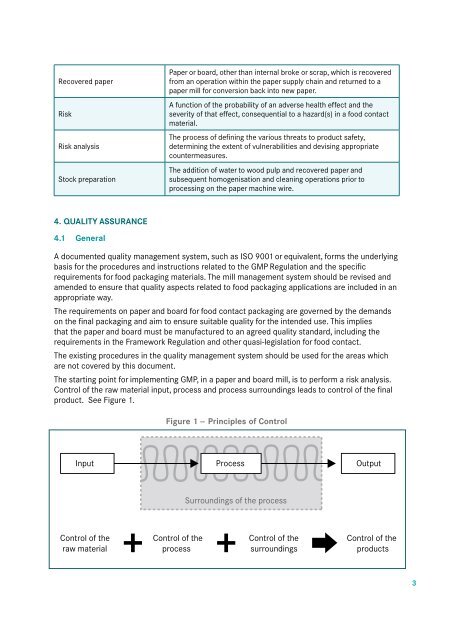

The starting point <strong>for</strong> implementing GMP, in a paper and board mill, is to per<strong>for</strong>m a risk analysis.<br />

Control <strong>of</strong> <strong>the</strong> raw material input, process and process surroundings leads to control <strong>of</strong> <strong>the</strong> final<br />

product. See Figure 1.<br />

Figure 1 -- Principles <strong>of</strong> Control<br />

Input Process Output<br />

Surroundings <strong>of</strong> <strong>the</strong> process<br />

Control <strong>of</strong> <strong>the</strong><br />

raw material<br />

Control <strong>of</strong> <strong>the</strong><br />

process<br />

Control <strong>of</strong> <strong>the</strong><br />

surroundings<br />

Control <strong>of</strong> <strong>the</strong><br />

products<br />

3