0499 - UKAS

0499 - UKAS

0499 - UKAS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

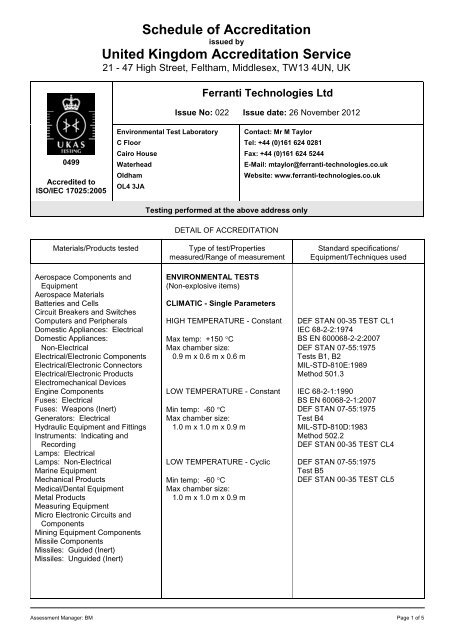

Schedule of Accreditation<br />

issued by<br />

United Kingdom Accreditation Service<br />

21 - 47 High Street, Feltham, Middlesex, TW13 4UN, UK<br />

Ferranti Technologies Ltd<br />

Issue No: 022 Issue date: 26 November 2012<br />

<strong>0499</strong><br />

Accredited to<br />

ISO/IEC 17025:2005<br />

Environmental Test Laboratory<br />

C Floor<br />

Cairo House<br />

Waterhead<br />

Oldham<br />

OL4 3JA<br />

Contact: Mr M Taylor<br />

Tel: +44 (0)161 624 0281<br />

Fax: +44 (0)161 624 5244<br />

E-Mail: mtaylor@ferranti-technologies.co.uk<br />

Website: www.ferranti-technologies.co.uk<br />

Testing performed at the above address only<br />

Materials/Products tested<br />

DETAIL OF ACCREDITATION<br />

Type of test/Properties<br />

measured/Range of measurement<br />

Standard specifications/<br />

Equipment/Techniques used<br />

Aerospace Components and ENVIRONMENTAL TESTS<br />

Equipment<br />

(Non-explosive items)<br />

Aerospace Materials<br />

Batteries and Cells<br />

CLIMATIC - Single Parameters<br />

Circuit Breakers and Switches<br />

Computers and Peripherals HIGH TEMPERATURE - Constant DEF STAN 00-35 TEST CL1<br />

Domestic Appliances: Electrical IEC 68-2-2:1974<br />

Domestic Appliances: Max temp: +150 C BS EN 600068-2-2:2007<br />

Non-Electrical Max chamber size: DEF STAN 07-55:1975<br />

Electrical/Electronic Components 0.9 m x 0.6 m x 0.6 m Tests B1, B2<br />

Electrical/Electronic Connectors<br />

MIL-STD-810E:1989<br />

Electrical/Electronic Products Method 501.3<br />

Electromechanical Devices<br />

Engine Components LOW TEMPERATURE - Constant IEC 68-2-1:1990<br />

Fuses: Electrical BS EN 60068-2-1:2007<br />

Fuses: Weapons (Inert) Min temp: -60 C DEF STAN 07-55:1975<br />

Generators: Electrical Max chamber size: Test B4<br />

Hydraulic Equipment and Fittings 1.0 m x 1.0 m x 0.9 m MIL-STD-810D:1983<br />

Instruments: Indicating and Method 502.2<br />

Recording<br />

DEF STAN 00-35 TEST CL4<br />

Lamps: Electrical<br />

Lamps: Non-Electrical LOW TEMPERATURE - Cyclic DEF STAN 07-55:1975<br />

Marine Equipment<br />

Test B5<br />

Mechanical Products Min temp: -60 C DEF STAN 00-35 TEST CL5<br />

Medical/Dental Equipment<br />

Max chamber size:<br />

Metal Products<br />

1.0 m x 1.0 m x 0.9 m<br />

Measuring Equipment<br />

Micro Electronic Circuits and<br />

Components<br />

Mining Equipment Components<br />

Missile Components<br />

Missiles: Guided (Inert)<br />

Missiles: Unguided (Inert)<br />

Assessment Manager: BM Page 1 of 5

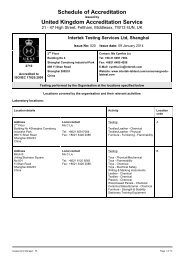

Schedule of Accreditation<br />

issued by<br />

United Kingdom Accreditation Service<br />

21 - 4 7 High Street, Felt ham, Mi ddl es e x, TW 13 4UN, UK<br />

<strong>0499</strong><br />

Accredited to<br />

ISO/IEC 17025:2005<br />

Ferranti Technologies Ltd<br />

Issue No: 022 Issue date: 26 November 2012<br />

Testing performed at main address only<br />

Materials/Products tested<br />

Continued from Page 1<br />

Type of test/Properties<br />

measured/Range of measurement<br />

ENVIRONMENTAL TESTS<br />

(Non-explosive items) (cont’d)<br />

Standard specifications/<br />

Equipment/Techniques used<br />

Motor Vehicle Accessories and THERMAL SHOCK -<br />

Components Two Chamber - manual transfer IEC 68-2-14:1984<br />

Office Equipment: Electrical<br />

BS 2011:Na:1985<br />

Office Equipment: Mechanical Max Temp: +150 C DEF STAN 07-55:1975<br />

Power Supplies: Electrical Min temp: -60 C Test B14 (Proc A)<br />

Radar Equipment Limited chamber size: MIL-STD-810D:1983<br />

Sonar Equipment 0.9 m x 0.6 m x 0.6 m Method 503.2<br />

Telecommunication Equipment IEC 68-2-14:1984<br />

Transformers Electrical<br />

BS 2011:Nb:1985<br />

Weapons and Sub-Assemblies<br />

BS EN 60068-2-14:2000Na<br />

BS EN 60068-2-14:2009Na<br />

DEF STAN 00-35 TESTCL14<br />

(PROC A)<br />

THERMAL SHOCK -<br />

Single chamber method<br />

Max temp: +150 C<br />

Min temp: -60 C<br />

Max change: 10 C per minute<br />

Chamber size:<br />

0.59 m x 0.70 m x 0.85 m<br />

BS EN 60068-2-14:2000 Na<br />

DEF STAN 00-35 TEST CL14<br />

(PROC B)<br />

BS EN 60068-2-14:2009Nb<br />

HIGH HUMIDITY - Constant IEC 68-2-3:1969<br />

BS 2011:Ca:1977<br />

Max temp: +75C DEF STAN 07-55:1975<br />

Max humidity: 100 % rh<br />

Test B7<br />

Max chamber size:<br />

DEF STAN 00-35 TEST CL7<br />

0.9 m x 0.6 m x 0.6 m BS EN 60068-2-78:2002<br />

HIGH HUMIDITY - Cyclic IEC 68-2-30:1980<br />

IEC 68-2-38:1974<br />

Max temp: +75C<br />

BS 2011:Db:1981<br />

Humidity range: 15% rh to 100% rh DEF STAN 07-55:1975<br />

Max chamber size:<br />

Test B6<br />

0.9 m x 0.6 m x 0.6 m MIL-STD-810B:1967<br />

Method 507.1<br />

MIL-STD-810D:1983<br />

Method 507.2<br />

MIL-STD-810E:1989<br />

Method 507.3<br />

BS 2011:Z/AD:1977<br />

BS EN 60068-2-30:1999 Db<br />

BS EN 60068-2-38:1999 Z/AD<br />

Assessment Manager: BM Page 2 of 5

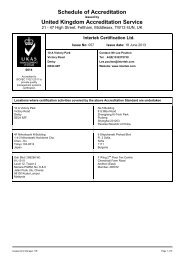

Schedule of Accreditation<br />

issued by<br />

United Kingdom Accreditation Service<br />

21 - 4 7 High Street, Felt ham, Mi ddl es e x, TW 13 4UN, UK<br />

<strong>0499</strong><br />

Accredited to<br />

ISO/IEC 17025:2005<br />

Ferranti Technologies Ltd<br />

Issue No: 022 Issue date: 26 November 2012<br />

Testing performed at main address only<br />

Materials/Products tested<br />

As listed on Pages 1 and 2<br />

Type of test/Properties<br />

measured/Range of measurement<br />

ENVIRONMENTAL TESTS<br />

(Non-explosive items) (cont’d)<br />

HIGH HUMIDITY - Cyclic (cont’d)<br />

Standard specifications/<br />

Equipment/Techniques used<br />

DEF STAN 00-35 TEST CL6<br />

(PROC B)<br />

LOW PRESSURE<br />

BS EN 60068-2-13:1999 M<br />

IEC 68-2-13:1983<br />

Maximum geopotential altitude (H): BS 2011:M:1984<br />

15,850 m (80 mm Hg) DEF STAN 07-55:1975<br />

Chamber size:<br />

Tests B11, B12, B13<br />

0.9 m x 0.6 m x 0.6 m DEF STAN 00-35:TEST CL11,<br />

CL12, CL13<br />

MIL-STD-810D:1983<br />

Method 500.2<br />

TEMPERATURE/PRESSURE IEC 68-2-40:1976<br />

HUMIDITY IEC 68-2-41:1976<br />

BS 2011:Z/AMD:1977<br />

Temp range: -60 C to +100 C BS 2011:Z/AM:1977<br />

Humidity range: 15% rh to 100% rh BS 2011:Z/BM:1977<br />

Max geopotential altitude (H): MIL-STD-810D:1983<br />

15,850 m(80 mm Hg) Method 520 (Proc 3)<br />

Max chamber size:<br />

BS EN 60068-2-39:1999:Z/AMD<br />

0.9 m x 0.6 m x 0.6 m BS EN 60068-2-40:2000:Z/AM<br />

BS EN 60068-2-41:2000:Z/BM<br />

CORROSION, SALT IEC 68-2-11:1981<br />

IEC 68-2-52:1996<br />

Temp range: amb to +60 C BS 2011:Ka:1982<br />

Chamber size:<br />

BS 2011:Kb:1987<br />

0.8 m x 1.8 m x 0.7 m BS EN 60068-2-52:1996:Kb<br />

DEF STAN 07-55:1975<br />

Test C6<br />

MIL-STD-810D:1983<br />

Method 509.2<br />

MIL-STD-810B:1967<br />

Method 509<br />

MIL-STD-202F:1980<br />

Method 101D<br />

BS EN 60068-2-11:1999:Ka<br />

DEF STAN 00-35:2000:Test CN2<br />

DYNAMIC<br />

Single Parameters<br />

DEF STAN 00-35:TEST M1<br />

BS EN 60068-2-51:2000:Z/BFC<br />

BS EN 60068-2-50:2000:Z/AFC<br />

Assessment Manager: BM Page 3 of 5

Schedule of Accreditation<br />

issued by<br />

United Kingdom Accreditation Service<br />

21 - 4 7 High Street, Felt ham, Mi ddl es e x, TW 13 4UN, UK<br />

<strong>0499</strong><br />

Accredited to<br />

ISO/IEC 17025:2005<br />

Ferranti Technologies Ltd<br />

Issue No: 022 Issue date: 26 November 2012<br />

Testing performed at main address only<br />

Materials/Products tested<br />

Type of test/Properties<br />

measured/Range of measurement<br />

Standard specifications/<br />

Equipment/Techniques used<br />

As listed on Pages 1 and 2<br />

ENVIRONMENTAL TESTS<br />

(Non-explosive items) (cont’d)<br />

VIBRATION - Sinusoidal<br />

(ambient and high/low temp)<br />

Freq range: 2-2000 Hz<br />

Peak thrust: 20 kN<br />

Max load (static): 400 kg<br />

Peak thrust: 7.5 kN<br />

Max load (static): 200 kg<br />

Max temp: +90 C<br />

Min temp: -50 C<br />

Max chamber size:<br />

1.0 m x 1.0 m x 0.9 m<br />

VIBRATION - Random<br />

(ambient and high/low temp)<br />

Freq range: 5-2000 Hz<br />

Peak thrust: 13.3 kN<br />

Max load (static); 400 kg<br />

RMS thrust: 3.3 kN<br />

Max load (static): 200 kg<br />

Max temp: +90 C<br />

Min temp: -50 C<br />

Max chamber size:<br />

1.0 m x 1.0 m x 0.9 m<br />

SHOCK<br />

BUMP (Ambient and High/Low<br />

Temp)<br />

(½ Sine, Saw Tooth)<br />

Max gn: 80<br />

Max thrust: 7.5 kN<br />

Max load: 77 kg<br />

Max displacement: 12.5 mm<br />

Max temp: +90 C<br />

Min temp: -50 C<br />

Max chamber size:<br />

1.0 m x 1.0 m x 0.9 m<br />

IEC 68-2-6:2008<br />

IEC 68-2-50:1983<br />

IEC 68-2-51:1983<br />

BS EN 60068-2-6:1996<br />

BS 3G100:Part 2<br />

Subsection 3.1:1969<br />

DEF STAN 07-55:1975<br />

Test A1<br />

MIL-STD-810E:1989<br />

Method 514.4<br />

BS 2011:Z/AFc:1984<br />

BS 2011:Z/BFc:1984<br />

IEC 68-2-34/36:1973<br />

BS 2011:Fd/Fdb:1973<br />

BS 3G100:Part 2<br />

Subsection 3.1:1969<br />

DEF STAN 07-55:1975<br />

Test A2<br />

MIL-STD-202f:1980<br />

Method 214<br />

MIL-STD-810E:1989<br />

Method 514.4<br />

BRB/LU Ltd/RIA<br />

Specification No 20:1988 (Ed 1)<br />

DEF STAN 00-35:TEST M1<br />

BS EN 60068-2-64:2008<br />

BS EN 61373:2010, Cat 1<br />

BS EN 60068-2-27 :2009<br />

BS EN 60068-2-29:1993<br />

IEC 60068-2-29:1987<br />

DEF STAN 00-35:Test M12<br />

MIL-STD-810E<br />

Excluding trapezoidal<br />

Assessment Manager: BM Page 4 of 5

Schedule of Accreditation<br />

issued by<br />

United Kingdom Accreditation Service<br />

21 - 4 7 High Street, Felt ham, Mi ddl es e x, TW 13 4UN, UK<br />

<strong>0499</strong><br />

Accredited to<br />

ISO/IEC 17025:2005<br />

Ferranti Technologies Ltd<br />

Issue No: 022 Issue date: 26 November 2012<br />

Testing performed at main address only<br />

Materials/Products tested<br />

Type of test/Properties<br />

measured/Range of measurement<br />

Standard specifications/<br />

Equipment/Techniques used<br />

As listed on Pages 1 and 2<br />

ENVIRONMENTAL TESTS<br />

(Non-explosive items) (cont’d)<br />

SHOCK<br />

(½ sine, saw tooth)<br />

Max drop height: 2.0 m<br />

Max item mass: 90.7 kg<br />

Max item size:<br />

0.4 m x 0.6 m x 0.6 m (high)<br />

Max shock: 100 g<br />

Max item mass: 35.3 kg<br />

Max item size:<br />

0.23 m x 0.23 m x var. height<br />

Max shock: 200 g<br />

FREE FALL<br />

Max item mass: 250 kg<br />

Max drop height: 2.0 m<br />

ACCELERATION - steady state<br />

Max mass (total): 5.4 kg<br />

Radius: 0.25 m<br />

Max speed: 500 rpm<br />

Severity: 70 g<br />

Max mass (total): 30 kg<br />

Radius: 0.76 m<br />

Max speed: 250 rpm<br />

Severity: 50 g<br />

Slip rings (electrical)<br />

facility available on both<br />

BS EN 60068-2-27 :2009<br />

IEC 68-2-27:1987<br />

BS EN 60068-2-27:1993<br />

DEF STAN 07-55:1975<br />

Test A3<br />

MIL-STD-202F:1980<br />

Method 213B<br />

MIL-STD-810D:1983<br />

Method 516.3<br />

BRB/LU Ltd/RIA<br />

Specification No 20:1988 (Ed 1)<br />

Specification No 20:1995 (Ed 2)<br />

DEF STAN 00-35:TEST M3<br />

BS EN 61373:1999, Cat 1<br />

IEC 678-2-32:1975<br />

BS EN 60068-2-32:1993<br />

(superseded)<br />

BS EN 60068-2-31 :2008, Free Fall<br />

proc 1 only<br />

DEF STAN 07-55:1975<br />

Test A9<br />

DEF STAN 00-35:TEST M5<br />

(Vertical)<br />

IEC 68-2-7:1983<br />

BS EN 60068-2-7:1993<br />

BS3G100:Part 2<br />

Subsection 3.6:1972(1983)<br />

DEF STAN 07-55:1975<br />

Test A6<br />

MIL-STD-202F:1980<br />

Method 212A<br />

MIL-STD-810D:1983<br />

Method 513.3<br />

DEF STAN 00-35:TEST M13<br />

END<br />

Assessment Manager: BM Page 5 of 5