shower

shower

shower

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>shower</strong> booster pumps<br />

<strong>shower</strong>s<br />

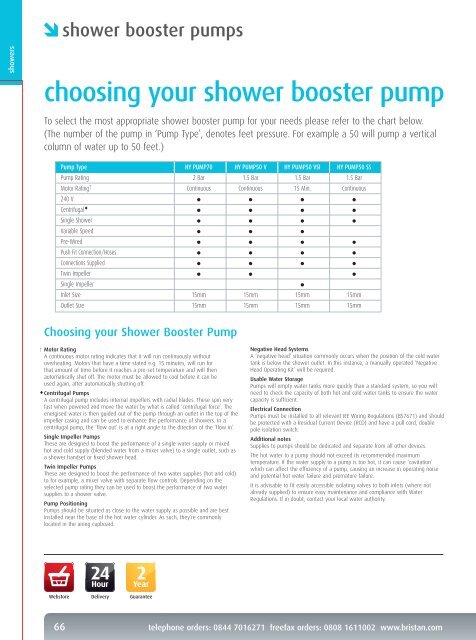

choosing your <strong>shower</strong> booster pump<br />

To select the most appropriate <strong>shower</strong> booster pump for your needs please refer to the chart below.<br />

(The number of the pump in ‘Pump Type’, denotes feet pressure. For example a 50 will pump a vertical<br />

column of water up to 50 feet.)<br />

Pump Type HY PUMP70 HY PUMP50 V HY PUMP50 VSI HY PUMP50 SS<br />

Pump Rating 2 Bar 1.5 Bar 1.5 Bar 1.5 Bar<br />

Motor Rating † Continuous Continuous 15 Min. Continuous<br />

240 V ● ● ● ●<br />

Centrifugal ◆ ● ● ● ●<br />

Single Shower ● ● ● ●<br />

Variable Speed ● ● ●<br />

Pre-Wired ● ● ● ●<br />

Push Fit Connection/Hoses ● ● ● ●<br />

Connections Supplied ● ● ● ●<br />

Twin Impeller ● ● ●<br />

Single Impeller<br />

Inlet Size 15mm 15mm 15mm 15mm<br />

Outlet Size 15mm 15mm 15mm 15mm<br />

●<br />

Choosing your Shower Booster Pump<br />

† Motor Rating<br />

A continuous motor rating indicates that it will run continuously without<br />

overheating. Motors that have a time stated e.g. 15 minutes, will run for<br />

that amount of time before it reaches a pre-set temperature and will then<br />

automatically shut off. The motor must be allowed to cool before it can be<br />

used again, after automatically shutting off.<br />

◆ Centrifugal Pumps<br />

A centrifugal pump includes internal impellers with radial blades. These spin very<br />

fast when powered and move the water by what is called ‘centrifugal force’. The<br />

energised water is then guided out of the pump through an outlet in the top of the<br />

impeller casing and can be used to enhance the performance of <strong>shower</strong>s. In a<br />

centrifugal pump, the ‘flow out’ is at a right angle to the direction of the ‘flow in’.<br />

Single Impeller Pumps<br />

These are designed to boost the performance of a single water supply or mixed<br />

hot and cold supply (blended water from a mixer valve) to a single outlet, such as<br />

a <strong>shower</strong> handset or fixed <strong>shower</strong> head.<br />

Twin Impeller Pumps<br />

These are designed to boost the performance of two water supplies (hot and cold)<br />

to for example, a mixer valve with separate flow controls. Depending on the<br />

selected pump rating they can be used to boost the performance of two water<br />

supplies to a <strong>shower</strong> valve.<br />

Pump Positioning<br />

Pumps should be situated as close to the water supply as possible and are best<br />

installed near the base of the hot water cylinder. As such, they’re commonly<br />

located in the airing cupboard.<br />

Negative Head Systems<br />

A ‘negative head’ situation commonly occurs when the position of the cold water<br />

tank is below the <strong>shower</strong> outlet. In this instance, a manually operated ‘Negative<br />

Head Operating Kit’ will be required.<br />

Usable Water Storage<br />

Pumps will empty water tanks more quickly than a standard system, so you will<br />

need to check the capacity of both hot and cold water tanks to ensure the water<br />

capacity is sufficient.<br />

Electrical Connection<br />

Pumps must be installed to all relevant IEE Wiring Regulations (BS7671) and should<br />

be protected with a Residual Current Device (RCD) and have a pull cord, double<br />

pole isolation switch.<br />

Additional notes<br />

Supplies to pumps should be dedicated and separate from all other devices.<br />

The hot water to a pump should not exceed its recommended maximum<br />

temperature. If the water supply to a pump is too hot, it can cause ‘cavitation’<br />

which can affect the efficiency of a pump, causing an increase in operating noise<br />

and potential hot water failure and premature failure.<br />

It is advisable to fit easily accessible isolating valves to both inlets (where not<br />

already supplied) to ensure easy maintenance and compliance with Water<br />

Regulations. If in doubt, contact your local water authority.<br />

Webstore<br />

Delivery<br />

Year<br />

Guarantee<br />

66 telephone orders: 0844 7016271 freefax orders: 0808 1611002 www.bristan.com