Virginia Tech Foundry Institute for Research and Education

Virginia Tech Foundry Institute for Research and Education

Virginia Tech Foundry Institute for Research and Education

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

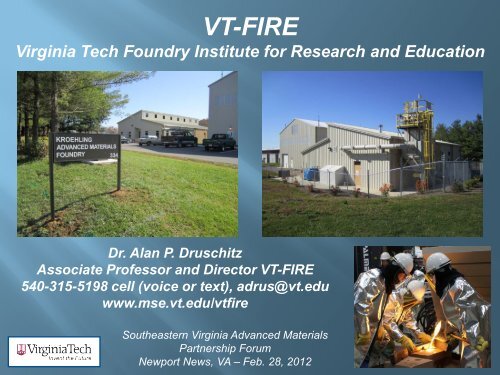

VT-FIRE<br />

<strong>Virginia</strong> <strong>Tech</strong> <strong>Foundry</strong> <strong>Institute</strong> <strong>for</strong> <strong>Research</strong> <strong>and</strong> <strong>Education</strong><br />

Dr. Alan P. Druschitz<br />

Associate Professor <strong>and</strong> Director VT-FIRE<br />

540-315-5198 cell (voice or text), adrus@vt.edu<br />

www.mse.vt.edu/vtfire<br />

Southeastern <strong>Virginia</strong> Advanced Materials<br />

Partnership Forum<br />

Newport News, VA – Feb. 28, 2012

• History<br />

− What is VT-FIRE<br />

− Supporters<br />

− <strong>Education</strong><br />

− Capabilities<br />

− <strong>Research</strong><br />

Outline<br />

• Interactions<br />

− Professional Societies, National Labs, VT<br />

− Industry<br />

− Other Activities/Outreach<br />

• What VT-FIRE can do <strong>for</strong> Southeast<br />

<strong>Virginia</strong> Industry

̶<br />

̶<br />

̶<br />

̶<br />

̶<br />

̶<br />

̶<br />

Kroehling Advanced Materials <strong>Foundry</strong><br />

(Home of VT-FIRE)<br />

• >50% of funding from individuals & industry<br />

• <strong>Education</strong> <strong>and</strong> <strong>Research</strong> Emphasis<br />

• Interdisciplinary Team Teaching & Collaboration<br />

College of Engineering<br />

Materials Science <strong>and</strong> Engineering<br />

Mechanical Engineering<br />

Industrial Systems Engineering<br />

College of Architecture <strong>and</strong> Urban Studies<br />

School of Visual Arts<br />

Industrial Design Program<br />

• Facility mostly completed & first class started in Jan 2011

Steel Industry<br />

• Steel Dynamics Inc.<br />

<strong>Foundry</strong> Industry<br />

• Carolina Industrial <strong>Foundry</strong><br />

• Cast Metals <strong>Institute</strong><br />

• Conbraco<br />

• Dominion Metallurgical<br />

• Electro-Mechanical Corp.<br />

• Fairmont Minerals<br />

• Foseco<br />

• Graham-White<br />

• Heraeus Electro-Nite<br />

• Inductotherm<br />

• Investment Casting <strong>Institute</strong><br />

• Minco<br />

• Palmer Manufacturing<br />

• Piedmont <strong>Foundry</strong> Supply<br />

• United Erie<br />

• <strong>Virginia</strong> Castings LLC<br />

• W Abrasives<br />

• Walker <strong>Foundry</strong><br />

• Wheelabrator<br />

Supporters<br />

Manufacturing Industry<br />

• Ameripumps<br />

• CMC Howell<br />

• General Dynamics<br />

• Newport News Shipbuilding<br />

• Precision Castparts Corp.<br />

Others<br />

• AFS Piedmont Chapter<br />

• AIST Southeast Chapter<br />

• Black Lab Corp.<br />

• BWF America<br />

• CA Tooling<br />

• Commercial Steel Erectors<br />

• Digital Lumens<br />

• Mory Metal Fabricators<br />

• Peter E. Macler Associates<br />

• Rex Heat Treat – Alabama, Inc.<br />

• Royal United/Specialty <strong>Foundry</strong><br />

Products<br />

• SE&M<br />

• Southwest Specialty Heat Treat

<strong>Education</strong><br />

• New metal casting & metallurgy oriented classes<br />

– <strong>Foundry</strong> Safety<br />

– Government Regulations<br />

– Elementary & Advanced Metal Casting Labs<br />

– Physical Metallurgy of Metal Casting<br />

– Modeling of Metal Casting (ProCast)<br />

– Test Methods <strong>for</strong> <strong>Foundry</strong> Laboratories<br />

– Metals & Alloys<br />

– Rapid Prototyping (ME Dept.)<br />

– Manufacturing Processes (ISE Dept.)<br />

– Topics in Sculpture: Metal Casting (Art Dept.)<br />

– New option in metallurgy (target 2014)<br />

– New minor in metal casting (target 2014)

Molding<br />

bonded s<strong>and</strong><br />

investment casting<br />

printed molds<br />

Capabilities<br />

Melting<br />

iron, steel, brass & bronze (up to 300 lbs)<br />

capability <strong>for</strong> air melt nickel & cobalt alloys<br />

electric resistance melting <strong>for</strong> aluminum<br />

Analytical<br />

mold filling <strong>and</strong> solidification modeling<br />

on-site chemical analysis <strong>for</strong> aluminum, iron & steel <strong>and</strong> brass &<br />

bronze alloys<br />

Rapid Prototyping<br />

3-D printer <strong>for</strong> patterns, molds or “additive manufacturing”

Capabilities<br />

Casting Process<br />

Idea<br />

Pattern<br />

Mold<br />

Melt & Cast<br />

Finish<br />

Final Product<br />

Molding<br />

• versatile<br />

• high volume<br />

• highest precision available<br />

• fast, unique (eliminate pattern)<br />

Melting<br />

• all common engineering materials<br />

Analytical<br />

• no guess work<br />

Rapid Prototyping<br />

• fast to market<br />

• advancing the state-of-the-art; potentially<br />

re-inventing the cast metals industry

Bonded S<strong>and</strong> Molding

3-D Printing: Patterns or Molds<br />

“impossible” to mold network structure (ME Dept.)<br />

prototype transducer housing

Investment Casting

Investment Casting

Melting<br />

induction tilt (300 lb capacity)<br />

induction crucible (#60 crucible)<br />

electric resistance (#30 crucible)

VT Metal Casting Undergraduate Students

Molten Metal Treatment & Analysis<br />

Rotary inert degas &<br />

reduced pressure test

Advanced CCD Based Optical Emission<br />

Spectrometer<br />

Chemical Analysis<br />

Spectrometer Elements<br />

Iron & Steel Alloys: C, Si, Mn, P, S, Cr, Mo, Ni,<br />

Cu, Al, As, B, Bi, Ca, Ce, Co, Nb, Pb, Sb, Sn,<br />

Ta, La, Ti, V, W, Zr, Zn, Se, Mg<br />

Aluminum Alloys: Si, Fe, Cu, Mn, Mg, Cr, Ni,<br />

Zn, Ti, Ag, B, Ba, Be, Bi, Ca, Cd, Co, Ga, In, Li,<br />

Mo, Na, P, Pb, Sn, Sr, V, Zr, Sb, Hg<br />

Copper Alloys: Zn, Pb, Sn, P, Mn, Fe, Ni, Si,<br />

Mg, Cr, Al, S, As, Be, Ag, Co, Bi, Cd, Sb, Zr, Ti,<br />

Au, C, Nb, Se, Te<br />

Thermal Analysis <strong>for</strong> Iron

Cast Metals <strong>Research</strong> Projects - Current<br />

• Undergraduate Independent Study<br />

− Shot Blasting (MSE)<br />

− 3D Printed Molding (ISE & ME)<br />

− Investment Casting (ISE)<br />

− Heat Treatment of Ferrous <strong>and</strong> Non-Ferrous Alloys (MSE)<br />

− Intercritical Austempering of AISI 9310 Steel (CHEM)<br />

• Senior Design<br />

− Optimized Rotor Design <strong>for</strong> Small Rotary Inert Degasser<br />

• Undergraduate Paid Positions<br />

− “Fall Prevention” at Steel Dynamics Inc. Roanoke Bar Division

Cast Metals <strong>Research</strong> Project Proposals<br />

• Sacrificial Anodes <strong>for</strong> Naval Applications<br />

−<br />

−<br />

melting <strong>and</strong> casting<br />

electrochemical (corrosion) testing<br />

• Additive Manufacturing <strong>Tech</strong>niques <strong>for</strong> Advanced<br />

Structures<br />

−<br />

−<br />

−<br />

−<br />

structural design<br />

printing molds or wax assembly & investment molding<br />

melting <strong>and</strong> casting<br />

mechanical testing<br />

• Intercritically Austempered Irons & Steels (high strength,<br />

high toughness)<br />

−<br />

−<br />

−<br />

−<br />

alloy design<br />

melting <strong>and</strong> casting<br />

heat treatment<br />

mechanical testing

Senior Design Project

Interactions<br />

• Professional Societies, National labs, VT<br />

– FEF (<strong>Foundry</strong> <strong>Education</strong> Foundation)<br />

– AFS (American <strong>Foundry</strong> Society) Piedmont Chapter<br />

– AIST (Association <strong>for</strong> Iron & Steel <strong>Tech</strong>nology) Southeast Section<br />

– Oak Ridge National Laboratory research at High Flux Isotope Reactor<br />

& Spallation Neutron Source on trans<strong>for</strong>mation characteristics of austenite<br />

– Organizing “Advances in Metal Casting <strong>Tech</strong>nologies” symposium at MS&T<br />

<strong>for</strong> 2012<br />

– Working with VT Human Powered Submarine, SAE Formula Team, Center<br />

<strong>for</strong> Intelligent Materials Systems <strong>and</strong> Structures, Turbomachinery Group

Interactions: Industry<br />

• Steel Dynamics, Inc., Roanoke Bar Division<br />

• Naval <strong>Research</strong> Laboratory & Naval Surface Weapons<br />

Center – Carderock Division (discussions on mutual interests)<br />

• Newport News Shipbuilding<br />

• Discussions/Visits<br />

− Ameripumps<br />

− CMC Howell<br />

− Electro-Mechanical Corp.<br />

− Graham-White<br />

− Precision Castparts Corp.<br />

− Southwest Specialty Heat Treat<br />

− <strong>Virginia</strong> Castings, LLC

Other Activities/Outreach<br />

• Cast Metals <strong>Institute</strong> (May 3-5, 2011) – through VT Continuing Ed<br />

− “Gray <strong>and</strong> Ductile Iron Metallurgy” Class – 20 students from industry<br />

• Cast Metals <strong>Institute</strong> (March 13-15, 2012) – through VT Continuing Ed<br />

− “Induction Melted Cast Iron Processing” Class – 12 registered<br />

• Air Force <strong>Research</strong> Laboratories (Innovation Based Manufacturing)<br />

− 1 day in the foundry – 12 participants<br />

• CEED (Center <strong>for</strong> Enhancement of Engineering Diversity)<br />

− 50 high school students<br />

• MSE In<strong>for</strong>mal Seminar <strong>for</strong> Freshman<br />

− 31 students<br />

• Engineering <strong>Research</strong> Seminar <strong>for</strong> College of Engineering<br />

− 175-200 engineering freshman<br />

• Roanoke Governors School<br />

− 80 high school juniors & seniors plus staff & faculty

What VT-FIRE can do <strong>for</strong><br />

Southeast <strong>Virginia</strong> Industry<br />

• Work<strong>for</strong>ce Development<br />

− our students<br />

− continuing education programs <strong>for</strong> existing work<strong>for</strong>ce<br />

− alliances, such as Newport News Apprentice School<br />

• Industry Support<br />

− problem solving<br />

− failure analysis<br />

− fast replacement parts<br />

• Industry/Small Business R&D<br />

− metal casting materials & processes<br />

− steel & steel making

VT Office of Economic Development<br />

• John Provo<br />

• Whitney Bonham<br />

• Amy Jahnke (Graduate Assistant)<br />

• Deborah Hamilton (Assoc Dir., Corp. & Fdn. Relations, COE)<br />

• Per<strong>for</strong>med economic impact study of “foundries” in VA<br />

• Developed list of potential companies to visit<br />

• Setting-up Road Trips<br />

− get the word out<br />

− gather data on specific needs<br />

• Thinking about job training programs<br />

• Thinking about how to promote VT <strong>for</strong> industry/small<br />

business R&D

The First Class of <strong>Virginia</strong> <strong>Tech</strong> Metal Casters<br />

with Joan <strong>and</strong> John Kroehling