Aeronautics - Magazooms

Aeronautics - Magazooms

Aeronautics - Magazooms

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

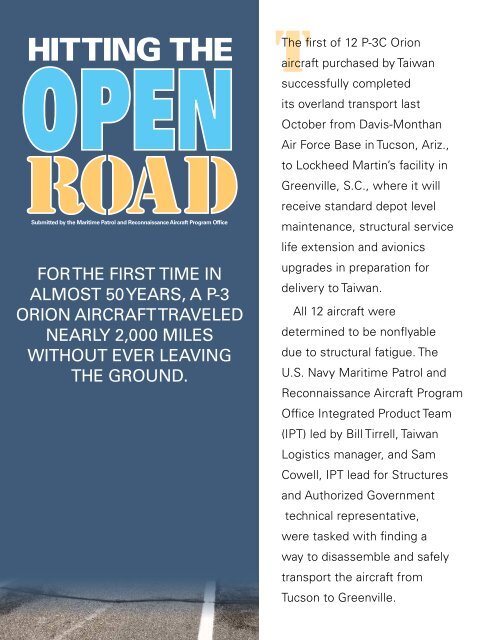

HITTING THE<br />

Submitted by the Maritime Patrol and Reconnaissance Aircraft Program Office<br />

FOR THE FIRST TIME IN<br />

ALMOST 50 YEARS, A P-3<br />

ORION AIRCRAFT TRAVELED<br />

NEARLY 2,000 MILES<br />

WITHOUT EVER LEAVING<br />

THE GROUND.<br />

TThe first of 12 P-3C Orion<br />

aircraft purchased by Taiwan<br />

successfully completed<br />

its overland transport last<br />

October from Davis-Monthan<br />

Air Force Base in Tucson, Ariz.,<br />

to Lockheed Martin’s facility in<br />

Greenville, S.C., where it will<br />

receive standard depot level<br />

maintenance, structural service<br />

life extension and avionics<br />

upgrades in preparation for<br />

delivery to Taiwan.<br />

All 12 aircraft were<br />

determined to be nonflyable<br />

due to structural fatigue. The<br />

U.S. Navy Maritime Patrol and<br />

Reconnaissance Aircraft Program<br />

Office Integrated Product Team<br />

(IPT) led by Bill Tirrell, Taiwan<br />

Logistics manager, and Sam<br />

Cowell, IPT lead for Structures<br />

and Authorized Government<br />

technical representative,<br />

were tasked with finding a<br />

way to disassemble and safely<br />

transport the aircraft from<br />

Tucson to Greenville.<br />

T“The fuselage was the challenge,” said<br />

Tirrell. “We looked into transport by<br />

rail; however, the fuselage requires<br />

special handling. Transport by rail would<br />

require the fuselage to be transferred on<br />

and off truck beds four times.”<br />

To reduce the risk of damage<br />

during loading, the team opted for<br />

transportation across country by<br />

flatbed truck — a process which<br />

would only require moving the fuselage<br />

twice. A suitable truck was located,<br />

and a transport cradle was designed<br />

specifically for holding the fuselage.<br />

According to Tirrell, the design of<br />

the cradle was crucial in preventing<br />

structural damage while ensuring the<br />

aircraft could sustain the 2,000-mile<br />

overland trip and remain operationally<br />

capable for Taiwan after reassembly.<br />

The team determined that a<br />

refurbished version of the BL-65 tool<br />

was the best option for securing the<br />

fuselage to the transport cradle. The<br />

BL-65 tool was used in the original P-3<br />

"Transport by rail would<br />

require the fuselage to<br />

be transferred on<br />

and off truck beds<br />

four times.”<br />

- BIll Tirrell<br />

production line more than 50 years ago<br />

as a substitute landing gear to move<br />

the aircraft around the production<br />

facility safely.<br />

“We pulled out the old blueprints<br />

and made a few modifications to<br />

withstand the heavy lifting that would<br />

be necessary to move the aircraft,”<br />

Cowell said.<br />

The redesigned BL-65 tool bolted to<br />

the aircraft at the wing joints and gave<br />

the team a sturdy framework that could<br />

be securely fastened to the transport<br />

cradle. Finally the entire assembly —<br />

fuselage, BL-65 tool apparatus and<br />

transport cradle — was chained to<br />

the flatbed truck.<br />

Once the team designed and built all<br />

the specialized components, the aircraft<br />

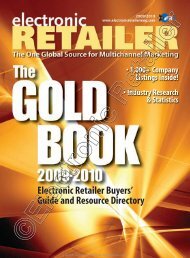

Official U.S. Navy Photo<br />

The first of 12 P-3C Orion aircraft purchased by Taiwan is secured on an oversize flatbed<br />

tractor trailer in preparation for delivery from Davis-Monthan Air Force Base in Tucson,<br />

Ariz., to the Lockheed Martin facility in Greenville, S.C., where it will undergo repairs and<br />

upgrades before final delivery to Taiwan.<br />

was disassembled and loaded onto nine<br />

trucks. Four oversize flatbed trucks<br />

carried the fuselage, wings, empennage<br />

and horizontal tail section. The<br />

remaining five tractor trailers housed a<br />

large number of crated components. The<br />

engines, propellers and landing gear will<br />

be shipped separately to various depots<br />

for repair and overhaul prior to final<br />

delivery to Greenville.<br />

The careful disassembly and<br />

preparation of the aircraft for<br />

transport was completed by Aerospace<br />

Maintenance and Regeneration Group<br />

(AMARG) at Davis-Monthan AFB<br />

under budget and in less than the<br />

anticipated six months.<br />

“When the aircraft arrived at<br />

Greenville, we performed extensive<br />

symmetry and alignment tests on<br />

the fuselage and found that all of the<br />

transport components performed as<br />

expected,” Cowell said. “The aircraft<br />

experienced no bending and no twisting<br />

during transport. It stayed true to shape.”<br />

The second aircraft is already<br />

undergoing disassembly by AMARG,<br />

and the remaining aircraft will be<br />

transported over the next three years.<br />

The final aircraft is scheduled to leave<br />

Davis-Monthan AFB in June 2013.<br />

“We consider the first complete<br />

nondestructive disassembly and<br />

overland transport highly successful,”<br />

Tirrell said. “All of the special support<br />

equipment performed as designed,<br />

and our procedures for loading and<br />

transporting the P-3C fuselage have<br />

proven successful.”<br />

The successful transport of the first<br />

P-3C aircraft has caught the interest of<br />

other government organizations. The<br />

method has been requested by the U.S.<br />

Forest Service and Homeland Security,<br />

as well as other Foreign Military Sales<br />

P-3 operators. ★<br />

“. . . we performed<br />

extensive symmetry<br />

and alignment tests on<br />

the fuselage and found<br />

that all of the transport<br />

components performed<br />

as expected.”<br />

- Sam Cowell<br />

22 23