Magnetically controlled fluid level indicator, type ITA

Magnetically controlled fluid level indicator, type ITA

Magnetically controlled fluid level indicator, type ITA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

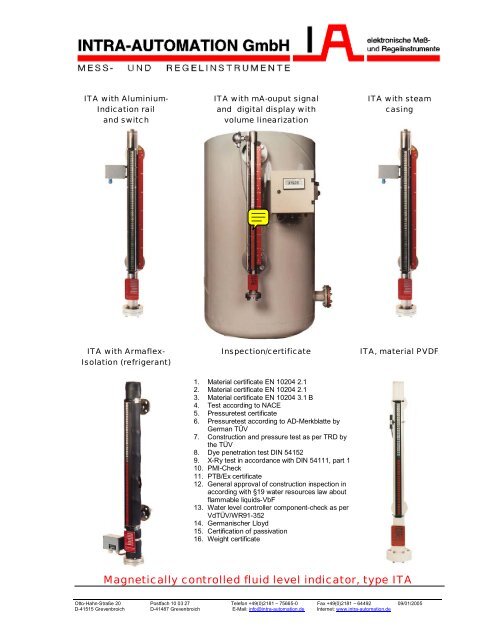

<strong>ITA</strong> with Aluminium-<br />

Indication rail<br />

and switch<br />

<strong>ITA</strong> with mA-ouput signal<br />

and digital display with<br />

volume linearization<br />

<strong>ITA</strong> with steam<br />

casing<br />

<strong>ITA</strong> with Armaflex-<br />

Isolation (refrigerant)<br />

Inspection/certificate<br />

<strong>ITA</strong>, material PVDF<br />

1. Material certificate EN 10204 2.1<br />

2. Material certificate EN 10204 2.1<br />

3. Material certificate EN 10204 3.1 B<br />

4. Test according to NACE<br />

5. Pressuretest certificate<br />

6. Pressuretest according to AD-Merkblatte by<br />

German TÜV<br />

7. Construction and pressure test as per TRD by<br />

the TÜV<br />

8. Dye penetration test DIN 54152<br />

9. X-Ry test in accordance with DIN 54111, part 1<br />

10. PMI-Check<br />

11. PTB/Ex certificate<br />

12. General approval of construction inspection in<br />

according with §19 water resources law about<br />

flammable liquids-VbF<br />

13. Water <strong>level</strong> controller component-check as per<br />

VdTÜV/WR91-352<br />

14. Germanischer Lloyd<br />

15. Certification of passivation<br />

16. Weight certificate<br />

<strong>Magnetically</strong> <strong>controlled</strong> <strong>fluid</strong> <strong>level</strong> <strong>indicator</strong>, <strong>type</strong> <strong>ITA</strong><br />

Otto-Hahn-Straße 20 Postfach 10 03 27 Telefon +49(0)2181 – 75665-0 Fax +49(0)2181 – 64492 09/01/2005<br />

D-41515 Grevenbroich D-41487 Grevenbroich E-Mail: info@intra-automation.de Internet: www.intra-automation.de

elektronische Meßund<br />

Regelinstrumente<br />

M E S S - U N D R E G E L I N S T R U M E N T E<br />

Table of contents<br />

ISO 9001 Certificate page 2<br />

Functioning and general information<br />

Magnetic Levelgauge <strong>type</strong> <strong>ITA</strong> page 3<br />

Level measurement tasks page 3<br />

Advantages page 4<br />

Floats page 4<br />

Switches and alarm contacts page 4<br />

Indication rail page 5<br />

Materials page 5<br />

Special versions page 5<br />

Additional equipment page 5<br />

Acceptance tests and certificates page 5<br />

Levelgauges<br />

<strong>ITA</strong>-3, <strong>ITA</strong>-3.0 page 6<br />

<strong>ITA</strong>-3 Cryo, <strong>ITA</strong>-3.0 Cryo page 7<br />

<strong>ITA</strong>-34, <strong>ITA</strong>-64 page 8<br />

<strong>ITA</strong>-3.5, <strong>ITA</strong>-3.5.0 page 9<br />

<strong>ITA</strong>-3.8 page 10<br />

<strong>ITA</strong>-4, <strong>ITA</strong>-4.0 page 11<br />

<strong>ITA</strong>-4.1, <strong>ITA</strong>-4.1.0 page 12<br />

<strong>ITA</strong>-5, <strong>ITA</strong>-5.0 page 13<br />

<strong>ITA</strong>-5.1, <strong>ITA</strong>-5.1.0 page 14<br />

<strong>ITA</strong>-5.5 page 15<br />

<strong>ITA</strong>-6, <strong>ITA</strong>-6.0 page 16<br />

<strong>ITA</strong>-6 Cryo, <strong>ITA</strong>-6.0 Cryo page 17<br />

<strong>ITA</strong>-6.8 page 18<br />

<strong>ITA</strong>-7, <strong>ITA</strong>-7.0 page 19<br />

<strong>ITA</strong>-8.1, <strong>ITA</strong>-8.2, <strong>ITA</strong>-8.3 page 20<br />

<strong>ITA</strong>-9.1, <strong>ITA</strong>-9.2, <strong>ITA</strong>-9.3 page 21<br />

<strong>ITA</strong>-10, <strong>ITA</strong>-10.0 page 22<br />

<strong>ITA</strong>-11, <strong>ITA</strong>-11.0 page 23<br />

<strong>ITA</strong>-12, <strong>ITA</strong>-12.0 page 24<br />

<strong>ITA</strong>-12.D, <strong>ITA</strong>-12.0.D page 25<br />

<strong>ITA</strong>-13, <strong>ITA</strong>-13.0 page 26<br />

Equipment<br />

<strong>ITA</strong>-3 Cryo, <strong>ITA</strong>-3.0 Cryo page 27<br />

Armaflex isolation page 28<br />

Technical data switches page 29-32<br />

Contact NJ-Ex page 33<br />

Indication rails page 34<br />

Digital indication with volume linnearization page 35<br />

Level-source page 36<br />

Reed-contact page 37<br />

Magnetostrictive Level Transmitter M-300, M-400 page 37.1/2<br />

Transmitter page 38<br />

<strong>ITA</strong>-T1S page 39-65<br />

<strong>ITA</strong>-T1R page 66<br />

Date : 08.10.2003<br />

- 1 -

Functioning and general information<br />

<strong>Magnetically</strong> <strong>controlled</strong> <strong>level</strong><br />

<strong>indicator</strong>, <strong>type</strong> <strong>ITA</strong><br />

The product line <strong>ITA</strong> is used wherever <strong>fluid</strong> <strong>level</strong> has to be monitored,<br />

indicated, and <strong>controlled</strong> in a reliable way, especially with corrosive,<br />

toxic, and inflammable <strong>fluid</strong>s.<br />

The <strong>ITA</strong> <strong>level</strong> <strong>indicator</strong>s offer a reliable, accident-free, and<br />

maintainance-free usage, through a simple and break-resistant<br />

construction at a maximum process pressure of 320 bar and a<br />

temperature range from -50 through 400 °C. The <strong>fluid</strong> <strong>level</strong> is<br />

indicated directly with a separation of the measurement and indication<br />

area. The magnetic transfer of the <strong>fluid</strong> <strong>level</strong> from the tank to the<br />

<strong>indicator</strong> is continuous and vibration-resistant, even in the case of fast<br />

changing <strong>level</strong>s.<br />

It is possible to mount the indication rail in any position on the pipediameter.<br />

There is no corrosion of the indication system. The <strong>ITA</strong><br />

instruments may be used in open or closed vessels. A definite <strong>level</strong><br />

measurement without any power supply is guaranteed because of a<br />

continuous rotation of the wafers, even if a power loss in the plant<br />

occurs.<br />

Level measurement tasks<br />

Functioning:<br />

A float chamber (2) is connected (1A and 1B) to the tank (1), and<br />

following the law of communicating tubes, the <strong>level</strong> in the float<br />

chamber is equal to the <strong>level</strong> in the tank. The float (3) follows the <strong>fluid</strong><br />

<strong>level</strong> and transmitts its movements contact-free to the indication rail<br />

(4) mounted on the outside. The float has a special magnet, which<br />

rotates the wafers by 180° as it passes them. This gives a clearly<br />

defined <strong>level</strong> indication, with the <strong>level</strong> shown in a continuous red stripe<br />

strongly contrasted to the white above. At increasing <strong>level</strong>s the color of<br />

the wafer changes from white to red and vice versa.<br />

The indication rail and the wafers are made of macrolon so that there<br />

will never be a problem of corrosion in humid and aggressive<br />

atmosphere. Each wafer has a permanent magnet, that is why the<br />

<strong>indicator</strong> is shock proof. Moreover, as there is no turbidness because of<br />

product contamination of the UV-radiation, the readability remains<br />

unobjectable even after some years.<br />

All models are available with electronic alarms, that can be mounted at<br />

any position during the operation of the system, which renders possible<br />

an optimal definition of the min. and max. data points. The <strong>indicator</strong><br />

can be equipped with a scale for volume or height (depending on the<br />

customer specifications).<br />

Level measurement task<br />

1) Indicating the <strong>fluid</strong> <strong>level</strong><br />

2) Monitoring the <strong>level</strong> with alarm contacts<br />

3) Transferring the <strong>level</strong> using measurement value sensors (analog<br />

signal 4 - 20 mA) to electrical display units<br />

4) Interface <strong>level</strong> measurement<br />

- 3 -

Functioning and general information<br />

Advantages<br />

Switches / alarm contacts<br />

No risk of glass breakage as a result of the separation of the<br />

measurement and <strong>indicator</strong> areas. The float principle means that<br />

changes of the density in the medium have very little influence on the<br />

indication accuracy.<br />

Magnetic <strong>level</strong> <strong>indicator</strong>s can be equipped with an arbitrary number of<br />

switch contacts. In contrast to electric float switches, switch contacts<br />

may be installed at any position of the stand pipe. Wherever additional<br />

float chambers are for float switches, magnetically <strong>controlled</strong> <strong>level</strong><br />

<strong>indicator</strong>s offer a considerable price benefit.<br />

Electrical <strong>level</strong> measurement transducers which use the displacement<br />

principle must be recalibrated each time the <strong>fluid</strong> density has changed.<br />

The price of a magnetically <strong>controlled</strong> <strong>level</strong> <strong>indicator</strong> with integral<br />

electrical measurement transducer is considerably lower than <strong>level</strong><br />

measurement transducers. The reed chain with an R/I measurement<br />

transducer can be changed without interrupting the operation. The<br />

measurement chamber is hermetically sealed - there is no contact<br />

between the <strong>fluid</strong> chamber and the reedchain.<br />

Floats<br />

The construction of the float requires a great amount of technical<br />

know-leage. The float with its special magnet can rotate freely in the<br />

float chamber. The Intra construction avoids a guide wire and other<br />

devices. The float materials are stainless steel, 1.4571, 1.4435 (316L)<br />

or titanium (PVC, PP, PVDF in case of the plastics <strong>level</strong> gages). Floats<br />

without gas-prestressing are used from a minimum density of 0,35<br />

kg/dm^3. The maximum process pressure for sealed floats is 250 bar;<br />

at higher pressures the floats must be relieved from pressure (not to be<br />

used for condensing media).<br />

The switches / alarm contacts are secured with pipe clips, and can be<br />

adjusted to any desired height. The connection is using a 3-core cable<br />

or casing terminals. The changeover contact can be used as opener or<br />

closer. The switches are also available as explosion-proof version.<br />

- 4 -

Functioning and general information<br />

Indication rail<br />

Materials<br />

The <strong>ITA</strong> <strong>level</strong> gauges can be delivered with indication rails made from<br />

2 different materials. Macrolon indication rails are resistable to<br />

breakage. The max. per-missible media-temperature is 120°C, with<br />

20°C ambient temperature and natural convection as test conditions.<br />

The rails are resistable to UV-radiation and aggressive atmosphere and<br />

are sealed against dust by two seal-caps. Aluminium indication rails<br />

can be delivered as a one part rail up to a length of 6m. The sight cover<br />

material depends on the temperature, up to 150°C the material is<br />

macrolon and up to 400°C it is glass. The surface of the indication rail<br />

can be coated with Säkaphen if required, the standardized surface is<br />

brown-anodized.<br />

The gauge chamber and the floats are made of stainless steel (1,4571),<br />

254SMO (1.4529), 1.4435 (316L), titanium, hasteloy, PVC, PP, PVDF,<br />

and PTFE. Other material on request.<br />

Special versions<br />

Additional equipment<br />

Inspection/certificate<br />

1. Transmitter, output signal 0-20 mA or 4-20 mA<br />

2. Steam jacket, e.g. for viscous media<br />

3. Float chamber with armaflex insulation, for temperatures below zero<br />

4. Scale made of gravoply (white plastics) or aluminium red-anodized<br />

5. Two-parts versions without interruption of the indication, for<br />

measuring lengths > 6m<br />

6. Works report DIN 50049<br />

7. Level <strong>indicator</strong> in GL-design (Germanischer Lloyd,Bureau<br />

Veriatas/Det Norsk Veritas, Lloyda Register)<br />

8. Usage as an overfilling guard for tanks for storing inflammable and<br />

non-flammable waterpolluting liquids<br />

9. <strong>ITA</strong> cryogenic version for refrigerants<br />

10. <strong>ITA</strong> with lining made of PTFE<br />

11. <strong>ITA</strong> with inside-coating made of E-CTFE (halar)<br />

1. Antifreezing heating belt for use in the open air<br />

2. Vent/drain valves, screw or flange connection<br />

3. Measurement scale, divisions to client' specification<br />

4. Armaflex insulation<br />

5. Protective hose, additional protection of the <strong>indicator</strong> against dust,<br />

dirt and moisture<br />

6. Plastics-<strong>indicator</strong> with armouring<br />

1. Material certificate EN 10204 2.1<br />

2. Material certificate EN 10204 2.2<br />

3. Material certificate EN 10204 3.1 A/B/C<br />

4. Test according to NACE<br />

5. Pressuretest certificate<br />

6. Pressuretest according to AD-Merkblatt by the German TÜV<br />

7. Construction and pressure test as per TRD by the TÜV<br />

8. Dye penetration test DIN 54 152<br />

9. X-ray test in accordance with DIN 54 111, part1<br />

10. PMI-check<br />

11. PTB/Ex certificate<br />

12. General approval of construction inspection in accordance with §19<br />

water resources law -WHG- and §12 law about flammable liquids -<br />

VbF<br />

13. Water <strong>level</strong> conroller component-check as per VdTÜV/WR91-352<br />

14. Germanischer Lloyd<br />

15. Certificate of passivation<br />

16. Weight certificate<br />

17. PED 97/23/EG<br />

- 5 -

-6-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-3 and <strong>ITA</strong>-3.0<br />

PN16<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-3 and <strong>ITA</strong>-3.0<br />

Principle : Communicating tubes with<br />

magnetic float<br />

Mounting position : vertical<br />

Measuring range :<br />

Pipe size :<br />

max. 5000 mm (one part)<br />

> 5000 mm 2- or multiparts<br />

60,3 x 2 mm welded,<br />

60,3 x 2 mm seamless,<br />

2“ sch10<br />

Buttweld construction with t-pieces<br />

Process connections :<br />

Vent/drain connections :<br />

Pipe material :<br />

Flange material :<br />

Float material :<br />

to specify:<br />

Flanged DN15-40 (½"-1½" 150#<br />

RF)<br />

Welding or threaded stud<br />

Flanged DN50 o. 2" 150# RF<br />

Plugged R½"<br />

(see. Code F)<br />

316 Ti<br />

Hasteloy C4 (2.4610),<br />

Inconel 625 (2.4856)<br />

Inconel 825 (2.4858)<br />

Titanium (3.7035)<br />

other materials also avaible<br />

as pipe material,<br />

(<strong>type</strong> <strong>ITA</strong>-3.0): Carbon steel<br />

316Ti<br />

Titanium, Titanium/E-CTFE coated<br />

Op. temperature : -50 bis +400 °C<br />

Op. pressure<br />

Density<br />

:<br />

:<br />

max. 16 bar<br />

0,7374 kg/dm³ *<br />

min.: 0,3371 kg/dm3 (depending on<br />

float <strong>type</strong>)<br />

Bolts, Nuts :<br />

Gaskets :<br />

Indicationrail :<br />

A193/A194 B7/2H<br />

A193/A194 B8/M8<br />

CS hot dipped galvanized<br />

SS<br />

PTFE up to 100 °C<br />

Klingersil up to 400°C<br />

Makrolon up to 120 °C<br />

Aluminium up to 400 °C<br />

316SS up to 400 °C<br />

Float <strong>type</strong>s<br />

Dimensions<br />

:<br />

:<br />

Cylindrical, sealed <strong>type</strong><br />

Length:<br />

270 mm<br />

130 mm<br />

150 mm<br />

210 mm<br />

330 mm<br />

430 mm<br />

530 mm<br />

630 mm<br />

A=240 *<br />

B=130<br />

C=40<br />

Base equipment printed bold!<br />

* For densitys < 0,7374 kg/dm³ enlarge the scale A<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, +49-(0)2181/75665-0, Fax: +49-(0)2181-64492<br />

Mail: info@intra-automation.de www.intra-automation.de

-7-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-3 Cryo and <strong>ITA</strong>-3.0 Cryo<br />

Cryogenic application<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Principle : Communicating tubes with magnetic<br />

float<br />

Mounting position : vertical<br />

Measuring range :<br />

Pipe size :<br />

Process connections :<br />

Vent/drain connections :<br />

Pipe material :<br />

max. 5000 mm (one part)<br />

> 5000 mm 2_ or multiparts<br />

60,3 x 2 mm welded (<strong>type</strong> Cryo and<br />

CR60)<br />

64 x 2 mm welded (<strong>type</strong> CR64)<br />

to specify:<br />

Flanged DN15-50 (½"-2"150# RF)<br />

Welding or threaded stud<br />

Plugged R½"<br />

(see Code F)<br />

316Ti<br />

Flange material :<br />

as pipe material,<br />

(<strong>type</strong> <strong>ITA</strong>-3.0 Cryo): Carbon steel<br />

Float material : Titanium<br />

Op. temperature<br />

Op. pressure<br />

:<br />

:<br />

-50 bis +100 °C<br />

max. 16 bar<br />

min. density : 0,389 kg/dm3 (depending on float)<br />

Bolts, Nuts<br />

:<br />

Gaskets :<br />

Indicationrail :<br />

Float <strong>type</strong>s :<br />

A193/A194 B7/2H<br />

A193/A194 B8/M8<br />

CS hot dipped galvanized<br />

SS<br />

PTFE<br />

Klingersil<br />

Aluminium<br />

316SS<br />

Cylindrical, sealed <strong>type</strong><br />

Cryo 50,8 x 270mm<br />

CR64 50,8 x 530mm<br />

CR60 45 x 530 mm<br />

Base equipment printed bold!<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20,D-41515 Grevenbroich, Tel.: +49-(0)2181-75665-0, Fax: +49-(0)2181/64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

-8-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-34 and <strong>ITA</strong>-64<br />

PN16-PN40<br />

Pricelist Unit 12.02.2003<br />

VK00-29<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-34 and <strong>ITA</strong>-64<br />

Principle : Communicating tubes with magnetic float<br />

Mounting position : vertical<br />

Measuring range :<br />

max. 5000 mm (one part)<br />

> 5000 mm 2- or multiparts<br />

Pipe size : 69 x 2,0 mm welded<br />

Process connections :<br />

Vent/drain connections :<br />

to specify:<br />

Flanged DN15-25 (½"-1")<br />

Flanged DN32-50 o.(1½"-2")<br />

Flanged DN15-25<br />

Flanged DN32-50<br />

see Code F<br />

Pipe material : 316Ti, wetted parts PTFE<br />

Flange material : as pipe material<br />

Float material : PVDF<br />

Op. temperature : -50 bis +120 °C<br />

Op. pressure : max. 16 bar<br />

not to use for vacuum service<br />

Density<br />

: 1,0 kg/dm3 *<br />

min.: 0,85 kg/dm³<br />

(depending on float)<br />

Bolts, Nuts :<br />

Indicationrail :<br />

Float <strong>type</strong>s :<br />

A193/A194 B7/2H<br />

A193/A194/B8/M8<br />

CS hot dipped galvanized<br />

SS<br />

Aluminium<br />

316SS<br />

Cylindrical, sealed <strong>type</strong><br />

Length: 270 mm<br />

(Special floats on request)<br />

Base equipment printed bold!<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel.: +49-(0)2181/75665-0, Fax: +49-(0)2181/64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

-9-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-3.5 and <strong>ITA</strong>-3.5.0<br />

PN16<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-3.5 and <strong>ITA</strong>-3.5.0<br />

Principle : Communicating tubes with magnetic float<br />

Mounting position : vertical<br />

Measuring range :<br />

Pipe size :<br />

Process connections :<br />

Vent/drain connections :<br />

max. 3100 mm (one part/<br />

length over all max. 3500 mm)<br />

> 3500 mm 2- or multiparts<br />

60,3 x 2 mm welded,<br />

60,3 x 2 mm seamless,<br />

2“ Sch10<br />

buttweld construction with t-pieces<br />

to specify:<br />

Flanged DN20-40 (¾"-1½" 150# RF)<br />

Flanged DN50 o. 2" 150# RF<br />

(see. Code F)<br />

Pipe material : 316Ti ,wetted parts E-CTFE<br />

Flange material :<br />

as pipe material<br />

Float material : Titanium/E-CTFE coated<br />

Op. temperature : -50 bis +160 °C<br />

Op. pressure : max. 16 bar<br />

Density<br />

Bolts, Nuts<br />

Gaskets<br />

Indicationrail<br />

:<br />

:<br />

:<br />

:<br />

1,0 kg/dm³ *<br />

min.: 0,55 kg/dm3<br />

(depending on float)<br />

A193/A194 B7/2H<br />

A193/A194 B8/M8<br />

CS hot dipped galvanized<br />

SS<br />

PTFE up to 100 °C<br />

Klingertop-chem-200 up to 260°C<br />

Makrolon up to 120 °C<br />

Aluminium up to 400 °C<br />

316SS up to 400°C<br />

Float <strong>type</strong>s :<br />

Dimensions :<br />

Cylindrical, sealed <strong>type</strong><br />

Length:<br />

270 mm<br />

150 mm<br />

330 mm<br />

430 mm<br />

530 mm<br />

A=240 *<br />

B=130<br />

Base equipment printed bold!<br />

* For densitys < 1,0 kg/dm³ enlarge the scale A<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel.: +49-(0)2181-75665-0, Fax: +49-(0)2181-64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

-10-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-3.8<br />

PN16<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-3.8<br />

Principle : Communicating tubes with magnetic float<br />

Mounting position : vertical<br />

Measuring range :<br />

Pipe size :<br />

max. 2800 mm (one part/<br />

length over all max. 2900 mm)<br />

> 2900 mm 2- or multiparts<br />

69 x 2 mm welded,<br />

69 x 2 mm seamless,<br />

Process connections :<br />

to specify:<br />

Flanged DN20-50 (¾"-2" 150# RF)<br />

Flanged DN50 o. 2" 150# RF<br />

Vent/drain connections : (see. Code F)<br />

Pipe material : 316Ti ,wetted parts E-CTFE<br />

Flange material :<br />

as pipe material<br />

Float material : Titanium/E-CTFE coated<br />

Op. temperature : -50 bis +160 °C<br />

Op. pressure : max. 16 bar / vacuum resistance<br />

Density :<br />

Bolts, Nuts :<br />

Gaskets :<br />

Indicationrail :<br />

Float <strong>type</strong>s :<br />

1,0 kg/dm³ *<br />

min.: 0,55 kg/dm3<br />

(depending on float)<br />

A193/A194 B7/2H<br />

A193/A194 B8/8M<br />

CS hot dipped galvanized<br />

SS<br />

PTFE up to 100 °C<br />

Klingertop-chem-200 up to 260°C<br />

Makrolon up to 120 °C<br />

Aluminium up to 400 °C<br />

316SS up to 400°C<br />

Cylindrical, sealed <strong>type</strong><br />

Length:<br />

270 mm<br />

150 mm<br />

330 mm<br />

430 mm<br />

530 mm<br />

Dimensions :<br />

A=240 *<br />

B=130<br />

C=40<br />

Base equipment printed bold!<br />

* For densitys < 1,0 kg/dm³ enlarge the scale A<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel.: +49-(0)2181-75665-0, Fax: +49-(0)2181-64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

-11-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-4 and <strong>ITA</strong>-4.0<br />

PN16<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-4 and <strong>ITA</strong>-4.0<br />

Principle : Communicating tubes with magnetic<br />

float<br />

Mounting position : top of tank<br />

Measuring range : max. 2750 mm<br />

Pipe size : 60,3 x 2 mm welded,<br />

Process connections :<br />

Vent connections :<br />

Pipe material :<br />

Flange material :<br />

Float material :<br />

to specify:<br />

Flanged DN50 PN16 or 2"150#<br />

(see Code F)<br />

Plugged R½"<br />

(see. Code F)<br />

316Ti<br />

Hasteloy C4 (2.4610),<br />

Inconel 625 (2.4856)<br />

Inconel 825 (2.4858)<br />

Titanium (3.7035)<br />

other materials also avaible<br />

as pipe material,<br />

(<strong>type</strong> <strong>ITA</strong>-4.0: Carbon steel)<br />

316Ti<br />

Titanium, Titanium/E-CTFE coated<br />

Op. temperature : -50 bis +400 °C<br />

Op. pressure : max. 16 bar<br />

min. density<br />

: 0,559 kg/dm3 (depending on meas.<br />

range)<br />

Bolts, Nuts : A193/A194 B7/2H<br />

A192/A194 B8/8M<br />

CS hot dipped glavanized<br />

SS<br />

Gaskets :<br />

Indicationrail :<br />

PTFE up to 100 °C<br />

Klingersil up to 400°C<br />

Makrolon up to 120 °C<br />

Aluminium up to 400 °C<br />

316SS up to 400°C<br />

Float <strong>type</strong>s : Cylindrical, sealed <strong>type</strong><br />

Base equipment printed bold!<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel.: +49-(0)2181-75665-0, Fax: +49-(0)2181/64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

-12-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-4.1 and <strong>ITA</strong>-4.1.0<br />

PN16<br />

Pricelist Unit 12.02.2003<br />

VK00-29<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-4.1 and <strong>ITA</strong>-4.1.0<br />

Principle : Communicating tubes with magnetic<br />

float<br />

Mounting position : top of tank<br />

Measuring range : max. 2750 mm<br />

Pipe size : 88,9 x 2 mm welded,<br />

Process connections :<br />

to specify:<br />

Flanged DN100 PN16 (4" 150# RF)<br />

Vent connections :<br />

Pipe material :<br />

Flange material :<br />

Plugged R½"<br />

316Ti<br />

Hasteloy C4 (2.4610),<br />

Inconel 625 (2.4856)<br />

Inconel 825 (2.4858)<br />

Titanium (3.7035)<br />

other materials also avaible<br />

as pipe material,<br />

(<strong>type</strong> <strong>ITA</strong>-4.1.0: Carbon steel)<br />

Float material : Titanium<br />

Op. temperature : -50 bis +400 °C<br />

Op. pressure : atmospheric<br />

min. density : 0,277 kg/dm3 (depending on meas.<br />

range))<br />

Bolts, Nuts<br />

Gaskets<br />

Indicationrail<br />

:<br />

:<br />

:<br />

A193/A194 B7/2H<br />

A193/A194 B8/8M<br />

CS hot dipped galvanized<br />

SS<br />

PTFE up to 100 °C<br />

Klingersil up to 400°C<br />

Makrolon up to 120 °C<br />

Aluminium up to 400 °C<br />

316SS up to 400°C<br />

Float <strong>type</strong>s : Cylindrical, sealed <strong>type</strong><br />

Base equipment printed bold!<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel.: +49-(0)2181/75665-0, Fax: +49-(0)2181-64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

-13-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-5 and <strong>ITA</strong>-5.0<br />

PN16-PN320<br />

Pricelist Unit 12.02.2003<br />

VK00-29<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-5 and <strong>ITA</strong>-5.0<br />

Principle : Communicating tubes with magnetic float<br />

Mounting position : vertical<br />

Measuring range :<br />

Pipe size :<br />

Process connection :<br />

Pipe material :<br />

Flange material :<br />

Float material :<br />

max. 5000 mm (one part)<br />

> 5000 mm 2- or multiparts<br />

60,3 x 2 mm welded<br />

2“ Sch10<br />

60,3 x 2- 8,7 mm seaml. (depending on<br />

pressure rating)<br />

to specify:<br />

R½" threaded (up to PN40)<br />

Welding or threaded stud<br />

Flanged DN15-DN50 (½"-2")<br />

316Ti<br />

Hasteloy C4 (2.4610),<br />

Inconel 625 (2.4856)<br />

Inconel 825 (2.4858)<br />

Titanium (3.7035)<br />

other materials also avaible<br />

as pipe material,<br />

(<strong>type</strong> <strong>ITA</strong>-5.0: Carbon steel)<br />

316Ti<br />

Titanium, Titanium/E-CTFE coated<br />

Op. temperature : -50 bis +400 °C<br />

Op. pressure : max. 16 bar up to 320 bar<br />

Density :<br />

Bolts, Nuts :<br />

Gaskets :<br />

Indicationrail :<br />

0,75 kg/dm³ *<br />

min.: 0,35 kg/dm3<br />

(depending on float)<br />

A193/A194 B7/2H<br />

A193/A194 B8/8M<br />

CS hot dipped galvanized<br />

SS<br />

PTFE up to 100 °C<br />

Klingersil up to 400°C<br />

Camprofile or spiral wound<br />

Makrolon up to 120 °C<br />

Aluminium up to 400 °C<br />

316SS up to 400°C<br />

Float <strong>type</strong>s : Cylindrical, sealed <strong>type</strong> or vented <strong>type</strong><br />

(depending on pressure rating)<br />

Dimensions :<br />

A=240 *<br />

B=130 (up to PN64)<br />

Base equipment printed bold!<br />

* For Densitys < 0,75 kg/dm³ enlarge the scale A<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel.: +49-(0)2181/75665-0,Fax: +49-(0)2181/64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

-14-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-5.1 and <strong>ITA</strong>-5.1.0<br />

PN16<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-5.1 and <strong>ITA</strong>-5.1.0<br />

Principle : Communicating tubes with<br />

magnetic float<br />

Mounting position : vertical<br />

Measuring range :<br />

Pipe size :<br />

Process connections :<br />

Pipe material :<br />

Flange material :<br />

Float material :<br />

max. 5000 mm (one part)<br />

> 5000 mm 2- or multiparts<br />

60,3 x 2 mm welded,<br />

60,3 x 2 mm seamless,<br />

2“ Sch 10<br />

to specify:<br />

R½" threaded<br />

Welding or threaded stud<br />

316Ti<br />

Hasteloy C4 (2.4610),<br />

Inconel 625 (2.4856)<br />

Inconel 825 (2.4858)<br />

Titanium (3.7035)<br />

other materials also avaible<br />

as pipe material,<br />

(<strong>type</strong> <strong>ITA</strong>-5.1.0: Carbon steel)<br />

316Ti<br />

Titanium, Titanium/E-CTFE<br />

coated<br />

Op. temperature : -50 bis +400 °C<br />

Op. pressure : max. 40 bar<br />

Density :<br />

Bolts, Nuts :<br />

0,639 kg/dm³ *<br />

min.: 0,3987 kg/dm3<br />

(depending on float)<br />

A193/A194 B7/2H<br />

A193/A194 B8/8M<br />

CS hot dipped galvanized<br />

SS<br />

Gaskets :<br />

Indicationrail :<br />

PTFE up to 100 °C<br />

Klingersil up to 400°C<br />

Makrolon up to 120 °C<br />

Aluminium up to 400 °C<br />

316SS up to 400°C<br />

Float <strong>type</strong>s : Cylindrical, sealed <strong>type</strong><br />

Dimensoins<br />

: A=240 *<br />

Base equipment printed bold!<br />

* For densitys < 0,75 kg/dm³ enlarge the scale A<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel.: +49-(0)2181/75665-0, Fax: +49-(0)2181-64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

-15-<br />

Mag. Levelgauge<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

<strong>ITA</strong>-5.5<br />

PN16<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-5.5<br />

Principle : Communicating tubes with magnetic<br />

float<br />

Mounting position : vertical<br />

Measuring range :<br />

max. 3100 mm (one part/<br />

hole length 3500 mm)<br />

> 3500 mm 2- or multiparts<br />

Pipe size : 60,3 x 2 mm welded<br />

Process connection : Flanged DN20-DN50 (¾"-2")<br />

Pipe material :<br />

316Ti<br />

wetted parts Halar (E-CTFE)<br />

Flange material :<br />

as pipe material,<br />

Float material : Titanium/Halar- coated<br />

Op. temperature : -50 bis +150 °C<br />

Op. pressure : max. 16 bar<br />

min. density : 0,55 kg/dm3 (depending on float)<br />

Bolts, Nuts<br />

Gaskets<br />

:<br />

:<br />

A193/A194 B7/2H<br />

A193/A194 B8/8M<br />

CS hot dipped galvanized<br />

SS<br />

PTFE up to 100 °C<br />

Klingertop-chem-200 up to 260°C<br />

Indicationrail :<br />

Float <strong>type</strong>s :<br />

Dimensions :<br />

Makrolon up to 100 °C<br />

Aluminium up to 400 °C<br />

316SS up to 400°C<br />

Cylindrical, sealed <strong>type</strong><br />

A=240<br />

B=130<br />

Base equipment printed bold!<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel.: +49-(0)2181-75665-0, Fax: +49-(0)2181-64492<br />

Mail: info@intra-automation.de Internet: www.intra-automation.de

-16-<br />

Mag. Levelgauge<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

<strong>ITA</strong>-6 and <strong>ITA</strong>-6.0<br />

PN40<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-6 and <strong>ITA</strong>-6.0<br />

Principle : Communicating tubes with magnetic<br />

float<br />

Mounting position : vertical<br />

Measuring range :<br />

max. 5000 mm (one part)<br />

Pipe size :<br />

> 5000 mm 2- or multiparts<br />

60,3 x 2 mm welded,<br />

Process connections :<br />

60,3 x 2 mm seamless,<br />

2“ Sch10<br />

buttweld construction with t-pieces<br />

to specify:<br />

Vent/drain connections :<br />

Flanged DN15-25 (½"-1" 300# RF)<br />

Welding or threaded stud<br />

Flanged DN50 o. 2" 300# RF<br />

Plugged R½"<br />

Pipe material :<br />

(see code F)<br />

316Ti<br />

Flange material :<br />

Hasteloy C4 (2.4610),<br />

Inconel 625 (2.4856)<br />

Inconel 825 (2.4858)<br />

Titanium (3.7035)<br />

other materials also avaible<br />

as pipe material,<br />

Float material :<br />

(<strong>type</strong> <strong>ITA</strong>-6.0: Carbon steel)<br />

316Ti<br />

Titanium, Titanium/E-CTFE coated<br />

Op. temperature : -50 bis +400 °C<br />

Op. pressure : max. 40 bar<br />

Density :<br />

0,639 kg/dm³ * up to 20 bar process<br />

Bolts, Nuts :<br />

pressure<br />

min.: 0,3987 kg/dm3 up to 40 bar<br />

process pressure<br />

(depending on float <strong>type</strong>)<br />

A193/A194 B7/2H<br />

Gaskets :<br />

A193/A194 B8/8M<br />

CS hot dipped galvanized<br />

SS<br />

PTFE up to 100 °C<br />

Indicationrail :<br />

Klingersil up to 400°C<br />

Makrolon up to 120 °C<br />

Float <strong>type</strong>s :<br />

Aluminium up to 400 °C<br />

316SS up to 400°C<br />

Cylindrical, sealed <strong>type</strong><br />

Length: 270 mm<br />

Dimensions :<br />

130 mm<br />

150 mm<br />

210 mm<br />

330 mm<br />

430 mm<br />

530 mm<br />

630 mm<br />

A=240 *<br />

B=130<br />

C=40<br />

Base equipment printed bold!<br />

* For densitys < 0,75 kg/dm³ enlarge the scale A<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel.: +49-(0)2181-75665-0, Fax: +49-(0)2181-64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

-17-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-6 Cryo and <strong>ITA</strong>-6.0 Cryo<br />

Cryogenic application<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-6 Cryo and <strong>ITA</strong>-6.0 Cyro<br />

Principle : Communicating tubes with magnetic float<br />

Mounting position : vertical<br />

Measuring range :<br />

Pipe size :<br />

Process connections :<br />

Vent/drain connections :<br />

Pipe material :<br />

max. 5000 mm (one part)<br />

> 5000 mm 2- or multiparts<br />

60,3 x 2 mm welded <strong>type</strong> Cryo and CR60<br />

64 x 2 mm welded <strong>type</strong> CR64<br />

to specify:<br />

Flanged DN15-50 (½"-2"300# RF)<br />

Welding or threaded stud<br />

Plugged R½"<br />

(see Code F)<br />

316Ti<br />

other material on request<br />

Flange material :<br />

as pipe material,<br />

(<strong>type</strong> <strong>ITA</strong>-6.0: Carbon steel)<br />

Float material : Titanium<br />

Op. temperature : -50 bis +100 °C<br />

Op. pressure : max. 40 bar<br />

min. density : 0,4566 kg/dm3 ((depending on float)<br />

Bolts, Nuts :<br />

Gaskets :<br />

Indicationrail :<br />

Float <strong>type</strong>s :<br />

Base equipment printed bold!<br />

A193/A194 B7/2H<br />

A193/A194 B8/8M<br />

CS hot dipped galvanized<br />

SS<br />

PTFE<br />

Klingersil<br />

Aluminium<br />

316SS<br />

Cylindrical, sealed <strong>type</strong><br />

Cryo 50,8 x 270 mm<br />

CR64 50,8 x 530 mm<br />

CR60 45 x 530 mm<br />

Mail: info@intra-automation.de<br />

internet: www.intra-automation.de

-18-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-6.8<br />

PN40<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-6.8<br />

Principle : Communicating tubes with magnetic float<br />

Mounting position : vertical<br />

Measuring range :<br />

Pipe size :<br />

max. 2800 mm (one part/<br />

length over all max. 2900 mm)<br />

> 2900 mm 2- or multiparts<br />

69 x 2 mm welded,<br />

69 x 2 mm seamless,<br />

Process connections :<br />

Vent/drain connections :<br />

to specify:<br />

Flanged DN20-50 (¾"-2" 300# RF)<br />

Flanged DN50 o. 2" 150# RF<br />

(see. Code F)<br />

Pipe material : 316Ti ,wetted parts E-CTFE<br />

Flange material :<br />

as pipe material<br />

Float material :<br />

Titanium/E-CTFE coated<br />

Op. temperature : -50 bis +160 °C<br />

Op. pressure : max. 40 bar / vacuum resistance<br />

Density :<br />

Bolts, Nuts :<br />

Gaskets :<br />

Indicationrail :<br />

Float <strong>type</strong>s :<br />

1,0 kg/dm³ *<br />

min.: 0,55 kg/dm3<br />

(depending on float)<br />

A193/A194 B7/2H<br />

A193/A194 B8/8M<br />

CS hot dipped galvanized<br />

SS<br />

PTFE up to 100 °C<br />

Klingertop-chem-200 up to 260°C<br />

Makrolon up to 120 °C<br />

Aluminium up to 400 °C<br />

316SS up to 400°C<br />

Cylindrical, sealed <strong>type</strong><br />

Length:<br />

270 mm<br />

150 mm<br />

330 mm<br />

430 mm<br />

530 mm<br />

Dimensions :<br />

A=240 *<br />

B=130<br />

C=40<br />

Base equipment printed bold!<br />

* For densitys < 1,0 kg/dm³ enlarge the scale A<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel.: +49-(0)2181-75665-0, Fax: +49-(0)2181-64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

-19-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-7 and <strong>ITA</strong>-7.0<br />

PN64<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-7 and <strong>ITA</strong>-7.0<br />

Principle : Communicating tubes with magnetic<br />

float<br />

Mounting position : vertical<br />

Measuring range :<br />

Pipe size :<br />

Process connections :<br />

Vent/drain<br />

:<br />

connections<br />

Pipe material :<br />

Flange material :<br />

max. 5000 mm (one part)<br />

> 5000 mm 2- or multiparts<br />

60,3 x 2,9 mm seamless,<br />

butt weld construction with t-pieces<br />

to specify:<br />

Flanged DN15-25 (½"-1" 300#)<br />

Welding or threaded stud<br />

Flanged DN32-50 (1¼ " or 2" 300#)<br />

plugged ½" NPT<br />

(see Code F)<br />

316Ti<br />

Hasteloy C4 (2.4610),<br />

Inconel 625 (2.4856)<br />

Inconel 825 (2.4858)<br />

Titanium (3.7035)<br />

other materials also avaible<br />

as pipe material,<br />

(<strong>type</strong> <strong>ITA</strong>-7.0: Carbon steel)<br />

Float material : Titanium, Titanium/E-CTFE coated<br />

Op. temperature : -50 bis +400 °C<br />

Op. pressure : max. 64 bar<br />

Density :<br />

Bolts, Nuts :<br />

Gaskets :<br />

Indicationrail :<br />

Float <strong>type</strong>s :<br />

Dimensions :<br />

0,682 kg/dm³ *<br />

min.: 0,4243 kg/dm3<br />

(depending on float)<br />

A193/A194 B7/2H<br />

A193/A194 B8/8M<br />

CS hot dipped galvanized<br />

SS<br />

Spiral wound, 316Ti<br />

Cam profile, 316Ti<br />

Makrolon up to 120 °C<br />

Aluminium up to 400 °C<br />

316SS up to 400°C<br />

Cylindrical, sealed <strong>type</strong><br />

Length:<br />

270 mm<br />

330 mm<br />

530 mm<br />

630 mm<br />

A=240 *<br />

B=130<br />

C=40<br />

Base equipment printed bold!<br />

* For densitys < 0,6 kg/dm³ enlarge the scale A<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel.: +49-(0)2181-75665-0, Fax: +49-(0)2181-64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

-20-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-8.1, <strong>ITA</strong>-8.2 and <strong>ITA</strong>-8.3<br />

PN6 (Plastics)<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-8.1, <strong>ITA</strong>-8.2 and <strong>ITA</strong>-8.3<br />

Principle : Communicating tubes with magnetic float<br />

Mounting position : vertical<br />

Measuring range :<br />

Pipe size :<br />

max. 5000 mm (one part)<br />

> 5000 mm 2- or multiparts<br />

<strong>ITA</strong>-8.1: 63 x 4,7 mm,<br />

<strong>ITA</strong>-8.2: 63 x 3,6 mm,<br />

<strong>ITA</strong>-8.3: 63 x 3 mm<br />

Process connections : Flanged DN15-50 (½"-2")<br />

Vent/drain connections :<br />

Pipe material :<br />

Plug R½"<br />

(see Code F)<br />

<strong>ITA</strong>-8.1: PVC,<br />

<strong>ITA</strong>-8.2: PP,<br />

<strong>ITA</strong>-8.3: PVDF<br />

Flange material :<br />

Float material :<br />

Op. temperature :<br />

as pipe material<br />

Op. pressure : max. 6 bar<br />

<strong>ITA</strong>-8.1: PVC,<br />

<strong>ITA</strong>-8.2: PP,<br />

<strong>ITA</strong>-8.3: PVDF<br />

PVC : -30 bis +60 °C<br />

PP : -10 bis +80 °C<br />

PVDF: -40 bis +120 °C<br />

min. density :<br />

<strong>ITA</strong>-8.1: 0,75 kg/dm³ *<br />

<strong>ITA</strong>-8.2: 0,65 kg/dm³ *<br />

<strong>ITA</strong>-8.3: 0,85 kg/dm³ *<br />

(depending on float)<br />

Bolts, Nuts : SS<br />

Gaskets : Viton<br />

Indicationrail : Aluminium<br />

316SS<br />

Float <strong>type</strong>s :<br />

Dimensions :<br />

Cylindrical, sealed <strong>type</strong><br />

Length: 255 mm<br />

135 mm<br />

A=240 *<br />

B=130<br />

D=110<br />

Base equipment printed bold!<br />

* For densitys < 0,75 kg/dm³ for <strong>ITA</strong>-8.1, < 0,65 kg/dm³ for <strong>ITA</strong>-8.2 and < 0,85 kg/dm³ for <strong>ITA</strong>-8.3 enlarge the scale A<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel.: +49-(0)2181-75665-0, Fax: +49-(0)2181-64492<br />

E-Mail: info@intra-automation.de Internet: www.intra-automation.de

-21-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-9.1, <strong>ITA</strong>-9.2 and <strong>ITA</strong>-9.3<br />

PN6 (Plastics)<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-9.1, <strong>ITA</strong>-9.2 and <strong>ITA</strong>-9.3<br />

Principle : Communicating tubes with magnetic float<br />

Mounting position : top of tank<br />

Measuring range : max. 2500 mm<br />

Pipe size :<br />

Process connections :<br />

Vent connections :<br />

Pipe material :<br />

Flange material :<br />

Float material :<br />

Op. temperature :<br />

<strong>ITA</strong>-9.1: 63 x 4,7 mm,<br />

<strong>ITA</strong>-9.2: 63 x 3,6 mm,<br />

<strong>ITA</strong>-9.3: 63 x 3 mm<br />

Flanged DN15-50 (½" - 2“)<br />

Flanged DN50-DN150 (2"-4")<br />

Flanged DN32 PN6<br />

(see Code F)<br />

<strong>ITA</strong>-9.1: PVC,<br />

<strong>ITA</strong>-9.2: PP,<br />

<strong>ITA</strong>-9.3: PVDF<br />

as pipe material<br />

<strong>ITA</strong>-9.1: PVC,<br />

<strong>ITA</strong>-9.2: PP,<br />

<strong>ITA</strong>-9.3: PVDF<br />

PVC : -30 bis +60 °C<br />

PP : -10 bis +80 °C<br />

PVDF: -40 bis +120 °C<br />

Op. pressure : atm.<br />

min. density : 0,7 kg/dm3 (depending on float and<br />

material)<br />

Bolts, Nuts : SS<br />

Gaskets : Viton<br />

Indicationrail :<br />

Aluminium<br />

316SS<br />

Float <strong>type</strong>s :<br />

Cylindrical, sealed <strong>type</strong><br />

Length: 250 mm<br />

(special sizes available)<br />

Base equipment printed bold!<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel.: +49-(0)2181-75665-0, Fax: +49-(0)2181-64492,<br />

E-Mail: info@intra-automation.de Internet: www.intra-automation.de

-22-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-10 and <strong>ITA</strong>-10.0<br />

PN100<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-10 and <strong>ITA</strong>-10.0<br />

Principle : Communicating tubes with magnetic<br />

float<br />

Mounting position : vertical<br />

Measuring range :<br />

Pipe size :<br />

Process connections :<br />

max. 5000 mm (one part)<br />

> 5000 mm 2- or multiparts<br />

60,3 x 3,2 mm seamless,<br />

butt weld construction with t-pieces<br />

to specify:<br />

Flanged DN15-25(½"-1" 600#)<br />

Welding or threaded stud<br />

Flanged DN32-50 (1¼" or 2" 600#)<br />

Vent/drain<br />

connections<br />

:<br />

Vent/Drain plug ½" NPT<br />

(see Code F)<br />

Pipe material :<br />

Flange material :<br />

316Ti<br />

Hasteloy C4 (2.4610),<br />

Inconel 625 (2.4856)<br />

Inconel 825 (2.4858)<br />

Titanium (3.7035)<br />

other materials also avaible<br />

as pipe material,<br />

(<strong>type</strong> <strong>ITA</strong>-10.0: Carbon steel)<br />

Float material : Titanium, Titanium/E-CTFE coated<br />

Op. temperature : -50 bis +400 °C<br />

Op. pressure : max. 100 bar<br />

Density :<br />

Bolts, Nuts :<br />

Gaskets :<br />

Indicationrail :<br />

0,8394 kg/dm³ *<br />

min.: 0,5698 kg/dm3<br />

(depending on float)<br />

A193/A194 B7/2H<br />

A193/A194 B8/8M<br />

CS hot dipped galvanized<br />

SS<br />

Spiral wound, 316Ti<br />

Cam profile, 316Ti<br />

Makrolon up to 120 °C<br />

Aluminium up to 400 °C<br />

316SS up to 400°C<br />

Float <strong>type</strong>s<br />

Dimensions<br />

:<br />

:<br />

Cylindrical, sealed <strong>type</strong><br />

Length:<br />

270 mm<br />

330 mm<br />

430 mm<br />

530 mm<br />

630 mm<br />

A=240 *<br />

B=170<br />

C=70<br />

Base equipment printed bold!<br />

* For densitys < 0,8394 kg/dm³ enlarge the scale A<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D- 41515 Grevenbroich, Tel.: +49-(0)2181-75665-0, Fax: +49-(0)2181-64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

-23-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-11 and <strong>ITA</strong>-11.0<br />

PN160<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-11 and <strong>ITA</strong>-11.0<br />

Principle : Communicating tubes with magnetic<br />

float<br />

Mounting position : vertical<br />

Measuring range :<br />

Pipe size :<br />

Process connections :<br />

max. 5000 mm (one part)<br />

> 5000 mm 2- or multiparts<br />

60,3 x 3,91 mm seamless<br />

60,3 x 3,6 mm seamless<br />

butt weld construction with t-pieces<br />

to specify:<br />

Flanged DN15-25 (½"-1" 1500#)<br />

Welding or threaded stud<br />

Flanged DN32-50 (1¼" o. 2" 1500#)<br />

Vent/drain<br />

connections<br />

:<br />

Plug ½" NPT<br />

(see Code F)<br />

Pipe material :<br />

Flange material :<br />

Float material :<br />

316Ti<br />

Hasteloy C4 (2.4610),<br />

Inconel 625 (2.4856)<br />

Inconel 825 (2.4858)<br />

Titanium (3.7035)<br />

other materials also avaible<br />

as pipe material,<br />

(<strong>type</strong> <strong>ITA</strong>-11.0: Carbon steel)<br />

Titanium<br />

316Ti<br />

Measuring length L<br />

Op. temperature : -50 bis +400 °C<br />

Op. pressure : max. 160 bar<br />

Density :<br />

0,7736 kg/dm³ vented <strong>type</strong><br />

0,8478 kg/dm3 sealed <strong>type</strong><br />

Bolts, Nuts :<br />

Gaskets :<br />

Indicationrail :<br />

Float <strong>type</strong>s :<br />

A193/A194 B7/2H<br />

A193/A194 B8/8M<br />

CS hot dipped galvanized<br />

SS<br />

Spiral wound, 316SS<br />

Cam profile, 3165SS<br />

Makrolon up to 120 °C<br />

Aluminium up to 400 °C<br />

316SS up to 400°C<br />

Titanium Length: 270 mm<br />

Length: 270 mm<br />

210 mm<br />

330 mm<br />

430 mm<br />

530 mm<br />

Dimensions :<br />

A=240 *<br />

B=170<br />

C=70<br />

Base equipment printed bold!<br />

* For densitys < 0,7 kg/dm³ enlarge the scale A<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel: +49-(0)2181-75665-0, Fax: +49-(0)2181-64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

-24-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-12 and <strong>ITA</strong>-12.0<br />

PN250<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-12 and <strong>ITA</strong>-12.0<br />

Principle : Communicating tubes with magnetic<br />

float<br />

Mounting position : vertical<br />

Measuring range :<br />

Pipe size :<br />

Process connections :<br />

Vent/drain connections :<br />

Pipe material :<br />

Flange material :<br />

Float material :<br />

max. 5000 mm (one part)<br />

> 5000 mm 2- or multiparts<br />

60,3 x 5,54 mm seamless,<br />

butt weld construction with t-pieces<br />

to specify:<br />

Flanged DN15-25 (½"-1" 1500#)<br />

Welding or threaded stud<br />

Flanged DN32-50 (1¼" o. 2" 1500#)<br />

Plug ½" NPT<br />

(see Code F)<br />

316Ti<br />

Hasteloy C4 (2.4610),<br />

Inconel 625 (2.4856)<br />

Inconel 825 (2.4858)<br />

Titanium (3.7035)<br />

other materials also avaible<br />

as pipe material,<br />

(<strong>type</strong> <strong>ITA</strong>-12.0: Carbon steel)<br />

Titanium<br />

Op. temperature :<br />

-50 bis +400 °C<br />

Op. pressure : max. 250 bar<br />

Density :<br />

0,57kg/dm3 vented float<br />

0,828 kg/dm³ sealed float<br />

Bolts, Nuts :<br />

Gaskets :<br />

Indicationrail :<br />

Float <strong>type</strong>s :<br />

Dimensions :<br />

A193/A194 B7/2H<br />

A193/A194 B8/8M<br />

CS hot dipped galvanized<br />

SS<br />

Spiral wound, 316Ti<br />

Cam profile, 316Ti<br />

Makrolon up to 120 °C<br />

Aluminium up to 400 °C<br />

316SS up to 400°C<br />

Length: 270 mm<br />

Cylindrical, sealed <strong>type</strong> (Titanium)<br />

Length: 270 mm<br />

430mm<br />

A=240 *<br />

B=170<br />

C=100<br />

Base equipment printed bold!<br />

* For densitys < 0,7 kg/dm³ enlarge the scale A<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D- 41515 Grevenbroich, Tel.: +49-(0)2181-75665-0, Fax: +49-(0)2181-64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

-25-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-12.D and <strong>ITA</strong>-12.0.D<br />

PN200<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-12.D and <strong>ITA</strong>-12.0.D<br />

Principle : Communicating tubes with magnetic<br />

float<br />

Mounting position : vertical<br />

Measuring range :<br />

Pipe size :<br />

max. 5000 mm (one part)<br />

> 5000 mm 2- or multiparts<br />

60,3 x 8,7 mm seamless,<br />

butt weld construction with t-pices<br />

Process<br />

connections<br />

Vent/drain<br />

connections<br />

:<br />

:<br />

to specify:<br />

Flanged DN15-25 (½"-1" 1500#)<br />

Welding or threaded stud<br />

Flanged DN32-50 (1¼" o. 2" 1500#)<br />

Plug ½" NPT<br />

(see Code F)<br />

Pipe material : 316Ti<br />

Flange material : as pipe material,<br />

(<strong>type</strong> <strong>ITA</strong>-12.0.D: Carbon steel)<br />

Float material : Titanium<br />

Float design : sealed<br />

Diameter<br />

Op. temperature :<br />

38mm<br />

+350 °C<br />

Op. pressure : max. 200 bar<br />

Density : 0,71 kg/dm3<br />

Bolts, Nuts<br />

Gaskets<br />

Indicationrail<br />

:<br />

:<br />

:<br />

A193/A194 B7/2H<br />

A193/A194 B8/8M<br />

CS hot dipped galvanized<br />

SS<br />

Spiral wound, 316SS<br />

Cam profile, 316SS<br />

Aluminium up to 400 °C<br />

316SS up to 400°C<br />

Float <strong>type</strong>s :<br />

Cylindrical, sealed <strong>type</strong>, (Titanium)<br />

Length: 430 mm<br />

Dimensions :<br />

A=400 *<br />

B=170<br />

C=100<br />

Base equipment printed bold!<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel.: +49-(0)2181/75665-0, Fax: +49-(0)2181/64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

-26-<br />

Mag. Levelgauge<br />

<strong>ITA</strong>-13 and <strong>ITA</strong>-13.0<br />

PN320<br />

Pricelist Unit 12.02.2003<br />

Type<br />

Rating<br />

Base equipment for mag. <strong>level</strong>gauge <strong>type</strong> <strong>ITA</strong>-13 and <strong>ITA</strong>-13.0<br />

Principle : Communicating tubes with magnetic float<br />

Mounting position : vertical<br />

Measuring range :<br />

Pipe size :<br />

Process connections :<br />

Vent/drain connections :<br />

Pipe material :<br />

Flange material :<br />

max. 5000 mm (one part)<br />

> 5000 mm 2- or multiparts<br />

60,3 x 8,7 mm seamless,<br />

butt weld construction with t-pieces<br />

to specify:<br />

Flanged DN15-25 (½"-1" 2500#)<br />

Welding or threaded stud<br />

Flanged DN32-50 (1¼" o. 2" 2500#)<br />

Vent/Drain plug ½" NPT<br />

(see Code F)<br />

316Ti<br />

Hasteloy C4 (2.4610),<br />

Inconel 625 (2.4856)<br />

Inconel 825 (2.4858)<br />

Titanium (3.7035)<br />

other materials also avaible<br />

as pipe material,<br />

(<strong>type</strong> <strong>ITA</strong>-13.0: Carbon steel)<br />

Float material : Titanium<br />

Op. temperature : -50 bis +400 °C<br />

Op. pressure : max. 320 bar<br />

min. density : 0,72 kg/dm3 * vented float<br />

Bolts, Nuts :<br />

Gaskets :<br />

Indicationrail :<br />

0,71 kg/dm3 sealed float (max.<br />

pressure 250bar)<br />

A193/A194 B7/2H<br />

A193/A194 B8/8M<br />

CS hot dipped galvanized<br />

SS<br />

Spiral wound, 316SS<br />

Cam profile, 316SS<br />

Makrolon up to 120 °C<br />

Aluminium up to 400 °C<br />

316SS up to 400°C<br />

Float <strong>type</strong>s :<br />

Dimensions :<br />

Cylindrical,vented <strong>type</strong>, (Titanium))<br />

Length: 270 mm<br />

330 mm<br />

430 mm<br />

A=240 *<br />

B=170<br />

C=100<br />

Base equipment printed bold!<br />

* For densitys < 0,72 kg/dm³ enlarge the scale A<br />

Intra-Automation GmbH, Otto-Hahn-Str. 20, D-41515 Grevenbroich, Tel.: +49-(0)2181/75665-0, Fax: +49-(0)2181/64492<br />

Mail: info@intra-automation.de internet: www.intra-automation.de

Information for use <strong>type</strong> <strong>ITA</strong>-3 and <strong>ITA</strong>-6 in Cryo-design<br />

If Armaflex is used for insulation (t=9mm) the material for the indication rail will be aluminium. As<br />

standard for the <strong>level</strong> gauge in cryo-design we use a float chamber 60,32mm with a float from<br />

titanium (50,8x240mm length) down to a liquid density of 0,6kg/dm 3 ).<br />

For temperatures below 40°C the Armaflex insulation is double ply, the upper layer only up to the<br />

indication rail.<br />

240<br />

(500)<br />

9<br />

D<br />

The customer should also insulate the processflanges.<br />

For vaporizing media (for example ammonia) we<br />

recom-mend you to use floats with 4 distance<br />

sleeves. (In this case the floats are smaller than<br />

standard floats). This construction prevents<br />

catapulting the float upwards<br />

(this would cause switch failures)<br />

if gas evolution appears.<br />

The distance sleeves (see<br />

drawing) hold the float in the<br />

center of the float chamber, so<br />

the gas can move away wihout<br />

shaking the float.<br />

For temperatures down to 20°C<br />

we are using a float chamber <br />

60,32mm and a titanium float<br />

45400mm, for temperatures<br />

below 20°C we are using a float<br />

chamber 642mm and a<br />

titanium float 50,8500mm.<br />

distance sleeve<br />

In every case we use flanges DN50 as drain<br />

connections (weld neck and blind flange with<br />

groove and tongue). When the diameter of the<br />

float chamber is 642mm it is necessary to<br />

modify the weld neck flange.<br />

On request by the customer we make use of a small<br />

hole (throttling part) to transmit the liquid <strong>level</strong> to<br />

the float chamber. It stabilize the float movement<br />

(damping).<br />

throttling part dependence on the temperature:<br />

ø4mm for T –20°C<br />

ø2mm for T < –20°C<br />

- 27 -

Armaflex isolation<br />

- 28 -

Heatisolation<br />

Ceramical fibre-textiles without asbestos parts.<br />

Limiting tempearutere: 1260°C<br />

Continious temperature: 600°C (with fiber glass reinforced)<br />

Bands tight selvedge with glass amplified, size 3mm.<br />

Technical datas:<br />

Composition of the ceramical fibre in % : ca. 45% Al2O3 + ca.54% SiO2 + ca. 1%<br />

Fe2O3, TiO2, MgO, Na2O + K2O, B2O3<br />

Portion organic substance : ca. 12% - 17%<br />

Saturant : without<br />

Combustible : no<br />

Density [g/ccm] : 9,6<br />

Limiting temperature : max. 1260°C - dependent upon application<br />

Continious temperature : 600°C, if fiberglass reinforced<br />

Degree of moisture : 1%<br />

Thermal conductivity : Crude fibre:ca.0,04 Kcal/mh at 400°C<br />

middle temperature<br />

ca. 0,08 Kcal/mh at 600°C<br />

middle temperature<br />

Annealing loss : no annealing loss, because there is no constitutional water<br />

Compressibility : on woven textile and bands: ca. 5% at 13kg/qm<br />

ca. 10% at 28 kg/qm<br />

Consolidation : through : 900°C 0%<br />

1000°C 1,25%<br />

1200°C 3,7%<br />

Resistance against : 1. Oil, steam, water and all chemical with exception of<br />

hydrofluoric acid, phosphorous acid and determined<br />

alkaline solution.<br />

2. Liquid metal. It don´t affected and wetted by fused<br />

Aluminium and Zinc.<br />

3. Inferior content upon compound of chlorine, there is little<br />

risk of fracture by chlorine corrosion.<br />

4. Good resistance against schocked occurrence heat and<br />

vibration.<br />

5. Good acoustical and electrical isolation.<br />

- 29 -

Technical data switches<br />

1. General table<br />

Switch 1690 16090 Ex LMS-A LMS-A-EExd MS09K MS10 EExd<br />

Case synthetic synthetic Al Si 12 Al Si 12 synthetic Aluminium<br />

Contact<br />

function<br />

bistable changeover<br />

contact<br />

bistable<br />

change-over<br />

contact<br />

bistable<br />

change-over<br />

contact<br />

bistable<br />

change-over<br />

contact **<br />

break- or<br />

make-contact,<br />

change-over<br />

contact<br />

break- or<br />

make-contact,<br />

change-over<br />

contact<br />

Dimension 20x15x80 20x15x80 65x65x40 Drm 138x80 110x75x50 120x120x110<br />

Breaking on 230VAC 230VAC 12 - 250 VAC 220VAC 250VAC 250VAC<br />

rupturing 0,8A 0,4A 1,5A 1,5A 10A 10A<br />

capacity 60VA 30VA 80VA 80VA --- ---<br />

Protective<br />

system<br />

IP65 IP65 IP65<br />

DIN40050<br />

IP65<br />

DIN40050<br />

IP65<br />

DIN40050<br />

IP65<br />

DIN40050<br />

Option IP67 IP67 --- --- --- ---<br />

DIN40050 DIN40050<br />

Switchhysteresis<br />

15mm 15mm 8 - 12mm 8 - 12mm --- ---<br />

Mediumtemperature<br />

max. 130°C max. 130°C max. 200°C * max. 200°C * max. 100°C max. 200°C<br />

EExprotection<br />

--- EEx d II CT6 --- EEx d II CT6 --- EEx dII CT6<br />

Connection --- --- PG7,5 4 connection PG11 ¾“ NPT<br />

(¾“ NPT)<br />

Electric connection with 3-channel plug and earth.<br />

For all Switchs valid the international standard EN 60529.<br />

* Typ LMS-AH with heat-protection-execution through a max. temperature of 400°C.<br />

** available with gold-contact.<br />

2. NI Ex NU-Switch<br />

Inherent safety EEx-switch, on inquiry with define error<br />

message.<br />

Contact- supply voltage: 8V DC<br />

transmiter max. temperature: 60°C<br />

cabel connection at<br />

PG11<br />

the case:<br />

Section supply voltage: 220V +15% (45 - 60Hz)<br />

switch power consumption: ca. 1,5V<br />

appliance open-cicuit voltage: 8V DC<br />

admit charge: 4A / 250V / 250VA<br />

admit temperature: -20°C bis +60°C<br />

3. Switchschema<br />

Type<br />

1680<br />

1690<br />

LMS-A<br />

Schema<br />

bistable changeover<br />

contact<br />

bistable changeover<br />

contact<br />

LMS-AH<br />

bistable changeover<br />

contact<br />

bistable changeover<br />

contact<br />

- 30 -

Technical data switches<br />

Switch LMS-A<br />

Scwitch LMS-AH<br />

Switch 1690 / 1690 Ex<br />

Switch MS 09 K<br />

Switch MS 10 EExd<br />

Switch LMS-A-Eexd<br />

- 31 -

Technical data switches<br />

Switch NI Ex NJ<br />

NI-Ex NI-Ex NI-Ex<br />

Switch NI-Ex-NJ<br />

- 32 -

Contact NJ-EX<br />

The Contact NJ-EX is an inductive contact NJ 1.5-6.5 N, kontex system,<br />

Protective system EEx ia IIC T6.<br />

Function<br />

Actuation is provided by the magnet installed in<br />

the float. The follow magnet system of the contact<br />

maker moves the switching disc, which serves for<br />

releasing the contact between two small<br />

inductances of the slotted initiator and thereby<br />

varies the attenduation of the resonant circuit.<br />

Technical Data<br />

electric connection : 8V DC<br />

temp./ambient temp. : 60°C<br />

cable connections : M20x1,5<br />

Switch Relay<br />

KFA6-SR2-Ex1.W : for 1 inductive contact EEx ia IIC<br />

KFA6-SR2-Ex2.W : for 2 inductive contacts EEx ia IIC<br />

- 33 -

Indication rails<br />

Armaflex-isolation and heating tape <strong>ITA</strong><br />

Indication rail with scale for <strong>ITA</strong><br />

Indication rail, material Makrolon Indication rail, material Aluminium Indication rail, material 316SS<br />

1. Sealing cap 1. U-profile 1. U-profile<br />

2. Indication lamina with magnet 2. Indication lamina with magnet 2. Indication lamina with magnet<br />

3. Rectangular profile 3. Transparent covering 3. Transparent covering<br />

4. U- profile<br />

- 34 -

<strong>ITA</strong> - magnetically <strong>controlled</strong> <strong>level</strong> <strong>indicator</strong> with analog signal (4-20mA) - and<br />

digital display<br />

Electrical <strong>level</strong> measurement transductors which use the diplacemant principle must be recalibrated each time the<br />

<strong>fluid</strong> density is changed.<br />

The price of a magnetically <strong>controlled</strong> <strong>level</strong> <strong>indicator</strong> with integral electrical measurement transducer is considerably<br />

lower than <strong>level</strong> measurement transducers.<br />

The reed chain with an R/I measurment transducer can be changed without interupting operation. The measurement<br />

chamber is hermetically sealed - there is no contact between the <strong>fluid</strong> chamber and the reed chain.<br />

With the microprocessor-<strong>controlled</strong> <strong>level</strong> <strong>indicator</strong> unit <strong>type</strong> 420, the <strong>level</strong> can be displayed direct in any arbitrary<br />

physical measurement unit. The <strong>indicator</strong> has a curve calculator with which nonlinear tank contents can be displayed<br />

direct in cubic meters.<br />

- 35 -

Niveau-source<br />

Measuring principle:<br />

The resistance chain with the reed contacts are build in a pipe made of material 316SS. This so called<br />

‘Reed Chain’ is mounted on the float chamber with jubilee clips. According to movement of the float,<br />

the float magnet closes one reed contact which produces a voltage (or resistance) proportional to the<br />

height of the liquid in the tank. You get an near-analogous output signal, with a resolution of about 10<br />

mm.<br />

The resistance chain receives its power supply from the transmitter. The 4-20mA transmitter output<br />

signal can be given to an <strong>indicator</strong> or can be used to drive alarm contacts. In the case of an error the<br />

output signal becomes higher than 22mA.<br />

Connection:<br />

As a standard the reed chain is supplied with a transmitter that is installed inside the housing-head, 2-<br />

wire connection to the transmitter, is only required.<br />

- 36 -

Standart reed chain<br />

Max. medium temperature: 150°C<br />

Protection pipe:<br />

14mm<br />

Material 316Ti<br />

Encosure:<br />

IP65<br />

Reed chain for higher temperature<br />

Max. medium temperature: 400°C<br />

Protection pipe:<br />

14mm<br />

Material 316Ti<br />

Enclusre:<br />

IP65<br />

Heat protection:<br />

50 x 4mm<br />

Clamp standart<br />

Clamp special<br />

Will be needed by armaflex isolation and secondary<br />

mounting off a reed chain.<br />

- 37 -

Data sheet M-300, M-400<br />

Description<br />

Magnetostrictive <strong>level</strong> transmitter for<br />

mounting to a <strong>level</strong> gauge <strong>type</strong> <strong>ITA</strong><br />

M-300/ M-400 series working on the magnetostrictive principle is<br />

High accurracy <strong>level</strong> transmitter for affordable price. The float inside<br />

of the <strong>level</strong> gauge <strong>type</strong> <strong>ITA</strong> containing a magnet moves along<br />

the magnetostrictive wire. A pulse generated by the electronics travels<br />

along the wire. When the pulse reaches the float’s maagnetic<br />

field, a twist develops in the wire. Reflected from the torsion point,<br />

the pulse creates an acoustic wave that travels back along the wire.<br />

The 4…20 mA output of the transmitter is proportional to the <strong>level</strong>.<br />

Technical Data<br />

Type rigid version flexible version plastic version<br />

principle/ execution<br />

magnetostrictive/ 2-wire-trqansmitter<br />

measured process values<br />

<strong>level</strong>, interface <strong>level</strong><br />

sensor length 0,5m … 3m 3m … 10m 0,5m … 3m<br />

material sensor Stainless steel (1.4571 –DIN) PVDF coated st.st.<br />

housing<br />

aluminium, powder paint coated or plastic (PBT)<br />

max. pressure<br />

depends on <strong>level</strong> gauge <strong>type</strong> <strong>ITA</strong><br />

temperatures medium max. 150 °C (+400 °C for high-temperature version)<br />

Ambient<br />

-25 °C …. +70 °C*<br />

linearity with dry calibration<br />

±1 mm<br />

resolution<br />

1mm or 5mm (depends on order)<br />

temperature coefficient<br />

0,04 mm/°C<br />

measuring range<br />

min. 200mm<br />

medium density<br />

depends on <strong>level</strong> gauge <strong>type</strong> <strong>ITA</strong><br />

outputs analogue 4 …. 20 mA or 20 …. 4 mA<br />

serial<br />

Hart<br />

display<br />

6 digits (7mm characters) icon; bargraph<br />

damping<br />

0 …. 60s programmable<br />

error indication<br />

3,8 mA or 22 mA<br />

output load<br />

Rt=(Us-12V)/0,02 A; Us = voltage of power supply<br />

power supply<br />

12 .... 36 VDC<br />

ATEX approval Ex II1G EEx ia IIB T6 (0,5m .... 5m)<br />

Ex II1G EEx ia IIA T6 (3m .... 10m)<br />

intrinsically safe data<br />

U max =30V ; I max =80mA ; P max =0,8W ; C i

*temperature-classification for Ex-application<br />

temperature class ambient temperature process temperature<br />

T6 -25 °C …. +70 °C<br />

T5 -25 °C …. +59 °C<br />

max. 400 °C, because no wetted parts<br />

T4 -25 °C …. +45 °C<br />

order specification<br />

M<br />

magnetostrictiv <strong>level</strong> transmitter<br />

function<br />

/ sensor execution (depends on tube-length)<br />

T with transmitter / rigid sensor (0,5-3m); flexible (> 3m)<br />

B with transmitter and display / rigid sensor (0,5-3m); flexible (> 3m)<br />

E with transmitter / PVDF-coated st.st.sensor<br />

G with transmitter and display / PVDF-coated st.st. sensor<br />

Connection to <strong>level</strong> gauge <strong>type</strong> <strong>ITA</strong><br />

U direct welded clamps; st.st.<br />

UX Hose band clip; st.st.<br />

-<br />

material electronic housing<br />

3 aluminium/ powder paint coated<br />

4 Plastic (PBT fibre-glass reinforced, flame retardant)<br />

measuring length<br />

ML measuring length in mm<br />

-<br />

output / resolution / approval<br />

2 4…20 mA / 1mm<br />

4 4…20 mA; Hart / 1mm<br />

6 4…20 mA / 1mm / Ex<br />

8 4…20 mA; Hart / 1mm / Ex<br />

A 4…20 mA / 5mm<br />

E 4…20 mA; Hart / 5mm / Ex<br />

M - -<br />

Intra-Automation GmbH Phone: 0 21 81 / 7 56 65 - 0 date: 28.08.2003<br />

Post Box 10 03 27 Fax: 0 21 81 / 6 44 92 file: TI_ M300_M400_en<br />

41487 Grevenbroich eMail: info@intra-automation.de<br />

Otto-Hahn-Strasse 20 Internet: www.intra-automation.de page: 37.2<br />

41515 Grevenbroich

Available housings<br />

Available transmitters<br />

Standard-transmitterhousing<br />

• material aluminium<br />

• Pg16 entry<br />

Type :INT 5333B<br />

● EExia IIC T5/T6<br />

● output:<br />

4 – 20 mA<br />

● power supply<br />

2 – 36 VDC<br />

● lineary:<br />

± 0,1 %<br />

Type: TMT 182<br />

Eexd transmitter<br />

housing<br />

● material aluminium<br />

epoxy coated<br />

● ½ » NPT cable entry<br />

● EExia IIC T4<br />

● output:<br />

4 – 20 mA<br />

(Hart-Protocol)<br />

● power supply<br />

13 – 30 VDC<br />

● lineary:<br />

400 Ω-area<br />

± 0,04 Ω<br />

4000 Ω-area<br />