lk Cmm - Optoteam.at

lk Cmm - Optoteam.at

lk Cmm - Optoteam.at

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CAMIO7 multi-sensor CMM metrology software<br />

The standard for DMIS co-ordin<strong>at</strong>e measuring machine programming<br />

CAMIO7 is the world’s leading multi-sensor CMM programming software supporting traditional touch-trigger probes,<br />

continuous contact scanning probes and the full range of Nikon laser scanning probes.<br />

Regardless of whether inspecting stamped, moulded, fabric<strong>at</strong>ed or machined parts CAMIO7 drives accur<strong>at</strong>e and efficient<br />

inspection programs for geometric fe<strong>at</strong>ures or full surface analysis with CAD compare.<br />

Fe<strong>at</strong>ures<br />

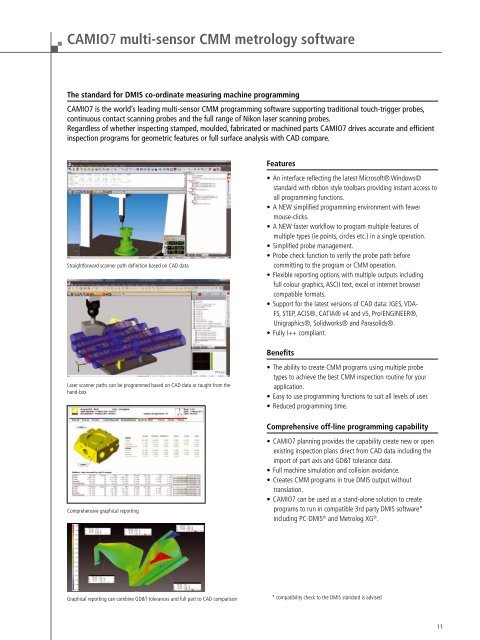

Straightforward scanner p<strong>at</strong>h definition based on CAD d<strong>at</strong>a<br />

• An interface reflecting the l<strong>at</strong>est Microsoft® Windows©<br />

standard with ribbon style toolbars providing instant access to<br />

all programming functions.<br />

• A NEW simplified programming environment with fewer<br />

mouse-clicks.<br />

• A NEW faster workflow to program multiple fe<strong>at</strong>ures of<br />

multiple types (ie points, circles etc.) in a single oper<strong>at</strong>ion.<br />

• Simplified probe management.<br />

• Probe check function to verify the probe p<strong>at</strong>h before<br />

committing to the program or CMM oper<strong>at</strong>ion.<br />

• Flexible reporting options with multiple outputs including<br />

full colour graphics, ASCII text, excel or internet browser<br />

comp<strong>at</strong>ible form<strong>at</strong>s.<br />

• Support for the l<strong>at</strong>est versions of CAD d<strong>at</strong>a: IGES, VDA-<br />

FS, STEP, ACIS®, CATIA® v4 and v5, Pro/ENGINEER®,<br />

Unigraphics®, Solidworks® and Parasolids®.<br />

• Fully I++ compliant.<br />

Benefits<br />

Laser scanner p<strong>at</strong>hs can be programmed based on CAD d<strong>at</strong>a or taught from the<br />

hand-box<br />

• The ability to cre<strong>at</strong>e CMM programs using multiple probe<br />

types to achieve the best CMM inspection routine for your<br />

applic<strong>at</strong>ion.<br />

• Easy to use programming functions to suit all levels of user.<br />

• Reduced programming time.<br />

Comprehensive off-line programming capability<br />

Comprehensive graphical reporting<br />

• CAMIO7 planning provides the capability cre<strong>at</strong>e new or open<br />

existing inspection plans direct from CAD d<strong>at</strong>a including the<br />

import of part axis and GD&T tolerance d<strong>at</strong>a.<br />

• Full machine simul<strong>at</strong>ion and collision avoidance.<br />

• Cre<strong>at</strong>es CMM programs in true DMIS output without<br />

transl<strong>at</strong>ion.<br />

• CAMIO7 can be used as a stand-alone solution to cre<strong>at</strong>e<br />

programs to run in comp<strong>at</strong>ible 3rd party DMIS software*<br />

including PC-DMIS ® and Metrolog XG ® .<br />

Graphical reporting can combine GD&T tolerances and full part to CAD comparison<br />

* comp<strong>at</strong>ibility check to the DMIS standard is advised<br />

11