Download - Norton

Download - Norton

Download - Norton

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Looking for Savings?<br />

Look to <strong>Norton</strong> Advanced Technology.<br />

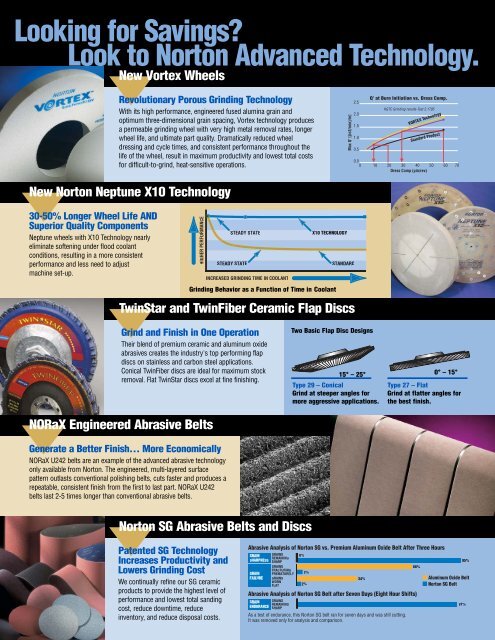

New Vortex Wheels<br />

Revolutionary Porous Grinding Technology<br />

With its high performance, engineered fused alumina grain and<br />

optimum three-dimensional grain spacing, Vortex technology produces<br />

a permeable grinding wheel with very high metal removal rates, longer<br />

wheel life, and ultimate part quality. Dramatically reduced wheel<br />

dressing and cycle times, and consistent performance throughout the<br />

life of the wheel, result in maximum productivity and lowest total costs<br />

for difficult-to-grind, heat-sensitive operations.<br />

Max Q' [(in3/min)/in]<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

Q' at Burn Initiation vs. Dress Comp.<br />

HGTC Grinding results-Test 2.1795<br />

VORTEX Technology<br />

Standard Product<br />

0.0<br />

0 10 20 30 40 50 60 70<br />

Dress Comp (µin/rev)<br />

New <strong>Norton</strong> Neptune X10 Technology<br />

30-50% Longer Wheel Life AND<br />

Superior Quality Components<br />

Neptune wheels with X10 Technology nearly<br />

eliminate softening under flood coolant<br />

conditions, resulting in a more consistent<br />

performance and less need to adjust<br />

machine set-up.<br />

HIGHER PERFORMANCE<br />

STEADY STATE<br />

STEADY STATE<br />

INCREASED GRINDING TIME IN COOLANT<br />

X10 TECHNOLOGY<br />

Grinding Behavior as a Function of Time in Coolant<br />

STANDARD<br />

TwinStar and TwinFiber Ceramic Flap Discs<br />

Grind and Finish in One Operation<br />

Their blend of premium ceramic and aluminum oxide<br />

abrasives creates the industry's top performing flap<br />

discs on stainless and carbon steel applications.<br />

Conical TwinFiber discs are ideal for maximum stock<br />

removal. Flat TwinStar discs excel at fine finishing.<br />

NORaX Engineered Abrasive Belts<br />

Generate a Better Finish… More Economically<br />

NORaX U242 belts are an example of the advanced abrasive technology<br />

only available from <strong>Norton</strong>. The engineered, multi-layered surface<br />

pattern outlasts conventional polishing belts, cuts faster and produces a<br />

repeatable, consistent finish from the first to last part. NORaX U242<br />

belts last 2-5 times longer than conventional abrasive belts.<br />

Two Basic Flap Disc Designs<br />

15° – 25°<br />

Type 29 – Conical<br />

Grind at steeper angles for<br />

more aggressive applications.<br />

0° – 15°<br />

Type 27 – Flat<br />

Grind at flatter angles for<br />

the best finish.<br />

<strong>Norton</strong> SG Abrasive Belts and Discs<br />

Patented SG Technology<br />

Increases Productivity and<br />

Lowers Grinding Cost<br />

We continually refine our SG ceramic<br />

products to provide the highest level of<br />

performance and lowest total sanding<br />

cost, reduce downtime, reduce<br />

inventory, and reduce disposal costs.<br />

Abrasive Analysis of <strong>Norton</strong> SG vs. Premium Aluminum Oxide Belt After Three Hours<br />

GRAIN<br />

SHARPNESS<br />

GRAIN<br />

FAILURE<br />

GRAINS<br />

REMAINING<br />

SHARP<br />

GRAINS<br />

FRACTURING<br />

PREMATURELY<br />

GRAINS<br />

WORN<br />

FLAT<br />

0%<br />

3%<br />

2%<br />

GRAIN GRAINS<br />

REMAINING<br />

ENDURANCE SHARP<br />

As a test of endurance, this <strong>Norton</strong> SG belt ran for seven days and was still cutting.<br />

It was removed only for analysis and comparison.<br />

66%<br />

95%<br />

34% Aluminum Oxide Belt<br />

<strong>Norton</strong> SG Belt<br />

Abrasive Analysis of <strong>Norton</strong> SG Belt after Seven Days (Eight Hour Shifts)<br />

91%