Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

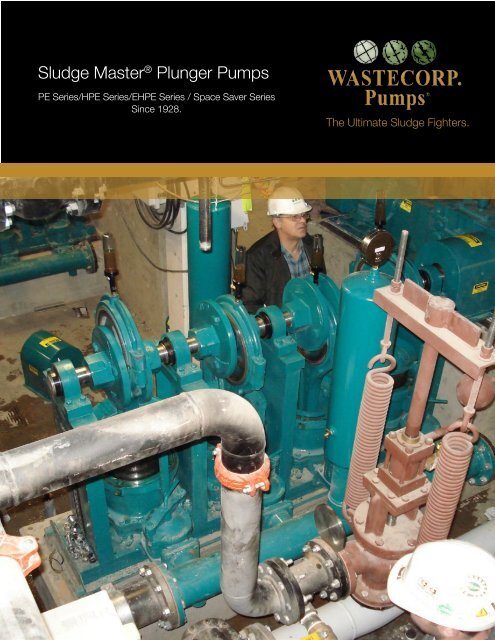

Sludge Master ® Plunger <strong>Pumps</strong><br />

PE Series/HPE Series/EHPE Series / Space Saver Series<br />

Since 1928.<br />

The Ultimate Sludge Fighters.

Municipal and Industrial Sewage Pump Manufacturer

The Original Plunger Pump...<br />

The Original Sewage Transfer Pump.<br />

2014 is a special year for the Sludge Master Plunger<br />

pump. This is the year over 20,000 installations will be<br />

surpassed worldwide. While 20,000 installations may<br />

only be a number, this represents thousands of satisfied<br />

customers spanning government, military, industrial<br />

wastewater treatment, food processing and more. When a<br />

pump technology has the proven quality and dependability<br />

over thousands of customers, its no wonder why<br />

consulting engineers have specified plunger pumps for<br />

over 85 years.<br />

technology designed to pump variations in solids and grit<br />

- the plunger pump. They won’t tell you that the plunger<br />

pump is one of the only pump technologies that can run<br />

dry without catastropic pump damage and they certainly<br />

won’t tell you that plunger pumps are easier to service and<br />

less expensive to own.<br />

Sludge Master Plunger <strong>Pumps</strong> consist of five product<br />

categories: the PE Series, HPE, EHPE Series, Space Saver<br />

Series and HPX engine driven plunger pumps. Sludge<br />

Master’s allow for custom options on any model including<br />

upgraded pump packing, plunger coating options and<br />

components available in bronze and stainless steel.<br />

Modern Solutions for Sludge Pumping<br />

A Google search on the internet for “sewage pumps”<br />

will yield results for plunger pumps, double disc pumps,<br />

rotary lobe pumps, progressive cavity pumps and more.<br />

All of these pump companies sell a story of “less mess”,<br />

“induced flow”, “technologically advanced” and more.<br />

What they don’t tell you is that their product offerings<br />

can’t compare to the orginal positive displacement pump<br />

The New Space Saver III<br />

Recent Customer surveys suggest that many sewage<br />

treatment plants consider space constraints when<br />

selecting new pumping equipment. <strong>Wastecorp</strong> responded<br />

with the introduction of the Space Saver III, a compact<br />

plunger pump which sheds over 20% off the footprint of a<br />

traditional plunger pump. Learn more inside.<br />

<strong>Wastecorp</strong> is a proud member and supporter of the water handling technology organizations above.<br />

<strong>Wastecorp</strong> exhibits Sludge Master Plunger <strong>Pumps</strong> yearly at the conferences held by these organizations.

What is a Plunger Pump?<br />

A plunger pump is a positive displacement pump which uses a<br />

plunger to force liquid from the suction side to the discharge side of<br />

the pump. <strong>Wastecorp</strong> Plunger <strong>Pumps</strong> are specified to move heavy<br />

municipal and industrial sludge up to 18-20% solids.<br />

<strong>Wastecorp</strong> Plunger <strong>Pumps</strong> operate essentially clog free because<br />

the pulsating motion of the plunger break up potential blockages.<br />

All <strong>Wastecorp</strong> Plunger Pump series’ are self-priming and capable of<br />

handling suction lifts up to 25 ft.<br />

Sludge Master Pump<br />

Applications<br />

• Raw and digested sewage<br />

sludge<br />

• Industrial and chemical<br />

waste and slurries<br />

• Lime putty and slurries<br />

• Pulp and paper stock<br />

• Settled oil solids<br />

• Oil refinery sludge<br />

• Distillation mashes<br />

• Lagoon Cleanup<br />

• Sugar bagasse<br />

• Gum and chicle slurries<br />

• Fish packaging wastes<br />

• Cannery wastes<br />

• Tannery wastes<br />

• Sump pumping<br />

• Textile and dye wastes<br />

• Unloading tank cars<br />

• Belt filter press feed pumps<br />

• Meat packing wastes<br />

Scan this QR code with your smart phone<br />

to see a video about <strong>Wastecorp</strong>’s Sludge<br />

Master Plunger <strong>Pumps</strong>.<br />

2<br />

3

The first plunger pump model produced in America<br />

circa 1928. The pump was manufactured by the<br />

founding engineers (shown) in Ridgewood, NJ USA.

More Innovation. More Options<br />

For Pumping Municipal or Industrial Sewage for The Long Haul.<br />

From replaceable connecting rod inserts to energy saving<br />

drive systems, you get more from Sludge Master Plunger<br />

<strong>Pumps</strong>. <strong>Wastecorp</strong> invests hundreds of engineering<br />

hours to perfect our industry leading design. Innovation<br />

never stops at <strong>Wastecorp</strong>. Our research has led to such<br />

breakthroughs as replaceable connecting rod inserts<br />

which allows you to replace the worn liner instead of<br />

the entire connecting rod. We also introduced 160,000<br />

psi strength shafts for extended wear life. Other pump<br />

types simply can’t stand up to punishing pumping<br />

conditions, likely at your facility. Rotary lobe, progressive<br />

cavity and double disc pumps all sell a story but only a<br />

Sludge Master can pump the gritty, heavy sewage that<br />

is common at modern sewage treatment plants. Most<br />

of these other pumps require 60% more maintenance<br />

hours compared to a plunger pump and much higher<br />

replacement parts costs. PE, HPE and EHPE pumps<br />

consistently rank among the top sludge pumps of choice.<br />

And there’s a reason for it. <strong>Wastecorp</strong> innovation keeps<br />

daily ownership costs lower.<br />

1. Sectionalized Construction<br />

With a cast iron sectionalized construction<br />

maintenance is easy and so is routine inspection<br />

of critical components. The Sludge Master<br />

is designed for variations in grit pumping and<br />

wastewater sewage pumping applications.<br />

2. Simple Design<br />

Positive displacement pumps don’t get much<br />

more simple than a plunger pump. And that’s a<br />

good thing, since the more complex a pump is<br />

engineered, the more difficult it is to service and<br />

more expensive to repair.<br />

4<br />

5

1<br />

2<br />

3<br />

4<br />

3. Smart Pump Innovations<br />

Sludge Master Plunger <strong>Pumps</strong> feature the<br />

latest innovations in sludge pump technology<br />

like guided plunger assemblies. This<br />

assembly helps to keep the wet section<br />

aligned when the facilitiy experiences higher<br />

than normal water concentration, particually<br />

after rain storms.<br />

4. Suction and Discharge Pressure Gauges<br />

Protect your pump from closed valves and<br />

blockages in your lines with suction and discharge<br />

pressure gauges. You’ll also be able<br />

to evaluate your pumps performance more<br />

closely and trouble shoot more easily.

Packing Options<br />

Improve The Seal and Reduce Leaks<br />

Your Sludge Master Plunger Pump is available with several<br />

packing arrangements to optimize pump performance and reduce<br />

leaks. You have a choice of three upgraded pump packing kits for<br />

your plunger pump.<br />

1. <strong>Wastecorp</strong> Graphite<br />

Flax Packing<br />

Your Sludge Master plunger<br />

pump ships standard with<br />

a graphite flax packing<br />

arrangement. Graphite flax is<br />

designed for pumping general<br />

municipal wastewater.<br />

2. <strong>Wastecorp</strong> Plunger Pac TM<br />

For added protection against<br />

leaks select <strong>Wastecorp</strong><br />

Plunger Pac with urethane<br />

and a braided Teflon lower<br />

ring. The urethane u-cup acts<br />

similar to a windshield wiper<br />

on the car moving sewage<br />

closely along the plunger with<br />

every stroke. The kit includes<br />

a urethane U-cup seal, top<br />

v-ring adapter, V-ring center<br />

(Quantity varies based on<br />

stuffing box height), Bottom<br />

v-ring adapter Braided Teflon<br />

ring.<br />

3. <strong>Wastecorp</strong> Graphite/<br />

Teflon® Set With U-cup Seal<br />

For the ultimate in longer<br />

term packing life cycles go<br />

with <strong>Wastecorp</strong> graphite or<br />

Teflon Packing sets with a<br />

u-cup seal. You will maximize<br />

fluid handling productivity<br />

while reducing overall need to<br />

check and replace packing.<br />

Set includes: Urethane<br />

U-cup seal Graphite or<br />

Teflon ring Graphite or Teflon<br />

ring Graphite or Teflon ring<br />

Graphite or Teflon ring.<br />

1 2 3<br />

6<br />

7

Plunger Coating Options<br />

Corrosion and Abrasive Fluid Resistance<br />

<strong>Wastecorp</strong> manufactures plungers with a superior cast iron classification<br />

of ASTM A48-64; Class 40. In addition to standard cast iron,<br />

consider the following coating options for your application:<br />

Corrosion Resistance<br />

• Stainless steel<br />

• Nickel alloy<br />

• Hard chrome<br />

Cast Iron<br />

• Cast iron is used for general<br />

municipal sewage handling<br />

applications and select industrial<br />

slurry applications<br />

Abrasion Resistance<br />

• Stainless steel<br />

• Nickel alloy<br />

• Hard chrome<br />

cast iron for higher volume<br />

wastewater treatment<br />

applications.<br />

Where fluid handling temperatures<br />

are higher.<br />

Stainless Steel<br />

• Ideal for USDA approved food<br />

processing applications<br />

• Safeguards plunger from<br />

chemicals, oils, alkalis, food<br />

acids, water immersion, abrasion<br />

and more<br />

Aluminum Oxide<br />

• Superior hardness of plunger<br />

• Used for pumping abrasive<br />

materials found in municipal and<br />

industrial sludge<br />

Hard Chrome<br />

• Reduces friction<br />

• Adds wear resistance<br />

• Extends plunger life by up to<br />

50%<br />

Nickel Chromium Oxide<br />

• Harsh pumping conditions with<br />

superior abrasion resistance<br />

• Use for higher than normal<br />

content of sand or salt.<br />

Tungsten Carbide<br />

• Offers up to three times<br />

the strength and durability of

8<br />

9<br />

PE Series<br />

Heavy Duty Sewage Transfer <strong>Pumps</strong><br />

Relentless Performance.<br />

Sludge Master PE Series plunger pumps manufactured by <strong>Wastecorp</strong> in North America are designed to handle the<br />

heavy, effluent viscous sludge encountered in sanitary and industrial waste treatment processes.<br />

PE Series plunger pumps are available with our standard V-Belt drive, constant speed direct drive, or variable speed/<br />

frequency drives. These pumps are capable of capacities up to 495 GPM and head levels up to 180 feet. Pump<br />

capacity can be permanently adjusted through the use of multiple eccentric positions established by an index pin.<br />

ensure operators stay comfortably productive.

1<br />

2<br />

3<br />

1. Overload Protection<br />

One of the great features of a plunger<br />

pump versus double disc pumps, progressive<br />

cavity or rotary lobe pumps is the standard<br />

overload protection. If a pin shears,<br />

the pump shuts down which may help<br />

reduce damage to critical components<br />

2. Advanced Shafting Material<br />

160,000 psi strength shafts will help to<br />

promote the long term reliability of your<br />

sewage pumps. Our premium shafting<br />

material is standard on all Sluddge Master<br />

Plunger <strong>Pumps</strong>.<br />

3. <strong>Pumps</strong> That Adapt to Your Needs<br />

A dual ball valve assembly is available on all<br />

PE Series models. This configuration allows<br />

facilities with heavy sewage to pump 18%<br />

solids and improve flow by 10%. See a<br />

video on how it works at:<br />

http://www.youtube.com/watch?v=JXW8YIZE-mw<br />

The PE Series is an industry rated alternative to Penn Valley Model 6DDSX76 Double Disc Pump. Did you know? Many<br />

facilities who have tried Penn Valley products find that the double disc pump cannot handle grit and thicker slurries. What<br />

this means is that when seasonal conditions produce thicker municipal sewage Sludge the double Master disc Plunger pump <strong>Pumps</strong> is known by <strong>Wastecorp</strong>. to fail. The so<br />

called new technology also is costly to maintain and the swan neck must be completely removed to service the pump. New<br />

technology is not always the best technology?

HPE Series<br />

Severe Duty Sewage Transfer <strong>Pumps</strong><br />

The world’s largest wastewater treatment facilities trust HPE Series heavy duty<br />

plunger pumps to pump the millions of gallons of raw sewage and wastewater<br />

critical to public sanitation and overall best practices for sewage transfer.<br />

productive.<br />

Where ever higher than usual working<br />

pressures are of prime consideration,<br />

<strong>Wastecorp</strong> provides the answer with the<br />

ruggedly-built HPE series. HPE Series<br />

plunger pumps are designed to meet<br />

the needs of the higher capacity plants<br />

with operating capacities to 600 GPM<br />

and heads to 240 feet. These pumps are<br />

similar to the PE units but incorporate<br />

heavier drive components, larger<br />

shafts and heavy duty connecting rod<br />

assemblies.<br />

With the HPE plunger pump series you<br />

get a team of skilled engineers and<br />

factory support representatives who<br />

review the specification and suggest<br />

pump design ideas to assist the facility<br />

in maximizing productivity for sewage<br />

handling solutions.<br />

Case in Point<br />

The <strong>Wastecorp</strong> Connecting Rod<br />

At the heart of plunger pump sewage transfer<br />

technology is the connecting rod assembly. The<br />

connecting rod connects to the pump shaft via<br />

eccentric and to the wet section through the<br />

crosshead and plunger.<br />

With a <strong>Wastecorp</strong> connecting rod, the operator<br />

need not replace the entire unit when performing<br />

maintenance. The bronze insert simply slides off<br />

and a new one put in place. This saves time and<br />

thousands of dollars in maintenance costs over the<br />

life cycle of the pump.<br />

10<br />

11<br />

What Borger rotary lobe pumps doesn’t tell you.<br />

Rotary lobe pumps have specific design issues<br />

such as stator & rotor wear effecting pump efficiency.<br />

As the rotors and stators wear on the<br />

pump, the pump becomes less able to productively<br />

1-888-829-2783<br />

transfer sewage. While they claim to be<br />

self priming, most rotary lobe pumps cannot<br />

respond well in such circumstances.

Sludge Master Plunger <strong>Pumps</strong> by <strong>Wastecorp</strong>.

EHPE Series<br />

Severe Duty Sewage Transfer <strong>Pumps</strong> for Higher Discharge<br />

Head Applications.<br />

Unhappy with yo<br />

if you weren’t cou<br />

with a modern pl<br />

sands of dollars w<br />

12<br />

13<br />

1-888-829-2783

1 2 3<br />

1. Pump Lubrication Options<br />

Sludge Master Plunger pumps are available with several oiler options to lubricate the<br />

connecting rod and eccentric. The most popular oiler option is the electric solenoid<br />

which automatically feeds SAE 30 oil to the critical rotating elements. At left, the<br />

standard drip feed oilers feed connecting rods individually.<br />

2. Stabilization Options<br />

<strong>Wastecorp</strong> recommends the guided plunger assembly for EHPE plunger pumps. The<br />

guided plunger assembly will help keep the plunger and connecting rod in line when<br />

pumping higher than normal concentrations of water or reduce wear on the plunger and<br />

stuffing box when packing becomes worn.<br />

3. Easy Maintenance Design<br />

The EHPE Series features an easy maintenance design which reduces downtime<br />

and makes maintenance quick and simple. To change the plunger or stuffing box,<br />

maintenance crews simply unbolt the stuffing box and swing the connecting rod<br />

assembly out. Maintaining the pump packing, ball valves and valve seats is just as easy.<br />

Learn more about the EHPE Series by scanning<br />

this QR code. Case studies and videos are available<br />

by visiting <strong>Wastecorp</strong>’s YouTube Channel at<br />

http://youtube.com/wastecorp1<br />

u Moyno 500 or Moyno 1000 Series?<br />

nting on the problems associated with progressive cavity pumps when you replaced your plunger pumps you can replace it<br />

unger pump. You see, the progressive cavity pump cannot run dry without damage. As you may no this damage is in the thouhen<br />

it happens. The EHPE Series plunger pump can run dry without damage.<br />

<strong>Wastecorp</strong> EHPE pumps, with capacities equal to the HPE are capable of discharge heads to 300 feet. These<br />

units incorporate a separate gear reducer and are offered with constant or variable speed drives depending on<br />

the individual application. Heavy duty shaft material and increased casting classifications make this series our<br />

extra heavy duty line of pumps.<br />

Sludge Master Plunger <strong>Pumps</strong> by <strong>Wastecorp</strong>.

14<br />

15<br />

1-888-829-2783

Space Saver Series<br />

Space Saving Sewage <strong>Pumps</strong><br />

The highly efficient Space Saver series has all of the rugged characteristics<br />

you have come to expect from Sludge Master Plunger <strong>Pumps</strong> within a<br />

compact integrated steel frame. At its widest point it measures less than 17”.<br />

These units are equipped with a uni-construction steel base that eliminates<br />

the need for a structural concrete pad.oductive.<br />

The <strong>Wastecorp</strong> Space Saver is the<br />

ideal replacement choice for an existing<br />

rotary lobe, progressive cavity<br />

or disc pump, since the suction and<br />

discharge piping configurations are<br />

very similar.<br />

Many WWTP’s with varying grit and<br />

solids pumping requirements have<br />

made the switch to the Space Saver<br />

with a versatility that other pump<br />

makes do not have. Plunger sizes<br />

are available in 7”, 9” and 11”.<br />

Standard Electric<br />

Engine Drive<br />

Hydraulic<br />

Air Driven<br />

Visit the Space Saver Plunger Pump’s official<br />

home on the web by scanning this QR code or<br />

visit: http://www.wastecorp.com/plungerpumps/<br />

space-saving-sewage-pumps.html

HPX Series<br />

Engine Driven Plunger <strong>Pumps</strong><br />

Take Your Plunger Pump Where Others Won’t Go.<br />

The severe duty <strong>Wastecorp</strong> trailer<br />

mounted plunger pump series<br />

takes the ultimate sludge fighter<br />

anywhere tough sludge needs to be<br />

pumped. From oil field applications<br />

to municipal sewage clean-ups and<br />

beyond, <strong>Wastecorp</strong>’s mobile plunger<br />

pumps can’t be beat for low cost<br />

of ownership and years of service.<br />

Standard features include galvanized<br />

air chambers, replaceable eccentric<br />

liner, 4” ANSI connections, belt driven<br />

or direct drive pump models and off<br />

road or DOT trailer options.<br />

1. Heavy Duty Diesel Engines<br />

When pumping oil slurry, raw sewage and other debris laden<br />

liquids you need a powerful engine to empower your pumping<br />

operation. That’s why all Sludge Master HPX Series plunger pumps<br />

feature Yanmar diesel engines with automatic start and oil alert.<br />

2. Component Selection for Select Corrosive Fluids<br />

<strong>Wastecorp</strong> offers several component options in stainless steel,<br />

bronze and cast iron to resist harsh pumping conditions. Plungers<br />

are available with chrome or nickel plated coatings with abrasion<br />

resistant oxide compounds.<br />

3. Easy Access Suction and Discharge Lines<br />

Located at the rear of the trailer, you can easily and quickly<br />

connect suction and discharge hoses to complete your pumping<br />

task.<br />

1<br />

4. Severe Duty Frame and Wheels<br />

With 13” wheels and a premium welded frame, your Sludge Master<br />

HPX Series can go anywhere you need to pump. Select from a<br />

forged eye key or standard ball hitch connection options.<br />

16<br />

17<br />

Did you know? The Sludge Master HPX Series can be used as an<br />

alternative to Godwin dry prime pumps, Gorman Rupp Super T<br />

Series, Thompson pump, Pioneer pump and others?

2<br />

3<br />

4

PE 61A-PE 741<br />

General Specifications<br />

Number of plungers 1<br />

Plunger dia. (in) 7<br />

Air chambers<br />

Simplex<br />

PE-61A/PE-741<br />

(2) 9”x30”<br />

Flanged connections 4” ANSI 125 #<br />

Driver speed, RPM 1200 | 1800<br />

Number of pin positions 12<br />

Max. strokes per min. 42 or 62<br />

Max. stroke length (in) 5.75<br />

Max. rec. suction lift (ft) 20<br />

Max. total head (ft) 100<br />

Max. capacity (GPM) 60<br />

Eccentric dia. (in) 8<br />

Eccentric shaft tensile strength (PSI) 160,000<br />

Approx. weight less driver (lbs) 750<br />

18<br />

19<br />

1-888-829-2783

Space Saver 7-Space Saver 11<br />

General Specifications<br />

Simplex<br />

PE-7SS<br />

Simplex<br />

PE-9SS<br />

Number of plungers 1 1 1<br />

Plunger dia. (in) 7 9 11<br />

Simplex<br />

PE-11SS<br />

Air chambers (1) 9”x30” (1) 9”x30” (1) 9”x30”<br />

Flanged connections 4” ANSI 125 # 4” ANSI 4” ANSI<br />

Driver speed, RPM 1200 | 1800 1200 | 1800 1200 | 1800<br />

Max. strokes per min. 50-62 50 50<br />

Max. stroke length (in) 5.75 6.56 6.56<br />

Max. total head (ft) 100 180 115<br />

Max. rec. suction lift (ft) 20’ 20’ 20’<br />

Max. capacity (GPM) 60 100 140<br />

Eccentric dia. (in) 8 10 10<br />

Eccentric shaft tensile<br />

strength (PSI)<br />

160,000 160,000 160,000<br />

Approx. weight (lbs) 400 600 800<br />

Sludge Master Plunger <strong>Pumps</strong> by <strong>Wastecorp</strong>.

PE 941-PE 944<br />

General Specifications<br />

Simplex<br />

PE-81W/PE-941<br />

Duplex<br />

PE-82W/PE-942<br />

Triplex<br />

PE-83W/PE-943<br />

Number of plungers 1 2 3 4<br />

Plunger dia. (in) 9 9 9 9<br />

Quadruplex<br />

PE-84W/PE-944<br />

Air chambers (2) 9”x30” (2) 9”x30” (2) 9”x30” (2) 9”x30”<br />

Flanged connections 4” ANSI 125 # 4” ANSI 125 # 6” ANSI 150 # 6” ANSI 150 #<br />

Driver speed, RPM 1200/1800 1200/1800 1200/1800 1200/1800<br />

Number of pin positions 11 11 11 11<br />

Max. strokes per min. 50 50 50 50<br />

Max. stroke length (in) 6.56 6.56 6.56 6.56<br />

Max. rec. suction lift (ft) 20 20 20 20<br />

Max. total head (ft) 180 180 180 125<br />

Max. capacity (GPM) 88 170 252 335<br />

Eccentric dia. (in) 10 10 10 10<br />

Eccentric shaft tensile strength<br />

(PSI)<br />

160,000 160,000 160,000 160,000<br />

Approx. weight less driver (lbs) 1200 1900 2650 3400<br />

20<br />

21<br />

1-888-829-2783

PE 1141-PE 1144<br />

General Specifications<br />

Simplex<br />

PE-111W/PE-1141<br />

Duplex<br />

PE-112W/PE-1142<br />

Triplex<br />

PE-113W/PE-1143<br />

Number of plungers 1 2 3 4<br />

Plunger dia. (in) 11 11 11 11<br />

Quadruplex<br />

PE-114W/PE-1144<br />

Air chambers (2) 9”x30” (2) 9”x30” (2) 9”x30” (2) 9”x30”<br />

Flanged connections 4” ANSI 125 # 4” ANSI 125 # 6” ANSI 150 # 6” ANSI 150 #<br />

Driver speed, RPM 1200/1800 1200/1800 1200/1800 1200/1800<br />

Number of pin positions 11 11 11 11<br />

Max. strokes per min. 50 50 50 50<br />

Max. stroke length (in) 6.56 6.56 6.56 6.56<br />

Max. rec. suction lift (ft) 20 20 20 20<br />

Max. total head (ft) 115 115 115 85<br />

Max. capacity (GPM) 136 247 371 495<br />

Eccentric dia. (in) 10 10 10 10<br />

Eccentric shaft tensile strength 160,000 160,000 160,000 160,000<br />

Approx. weight less driver (lbs) 1250 2000 2800 3600<br />

Sludge Master Plunger <strong>Pumps</strong> by <strong>Wastecorp</strong>.

HPE 81W-HPE-84 W<br />

General Specifications<br />

Simplex<br />

HPE-81W<br />

Duplex<br />

HPE-82W<br />

Triplex<br />

HPE-83W<br />

Quadruplex<br />

HPE-84W<br />

Number of plungers 1 2 3 4<br />

Plunger dia. (in) 9 9 9 9<br />

Air chambers (2) 9”x30” (2) 9”x30” (2) 9”x30” (2) 9”x30”<br />

Flanged connections 4” ANSI 125 # 4” ANSI 125 # 6” ANSI 150 # 6” ANSI 150#<br />

Driver speed, RPM 1200/1800 1200/1800 1200/1800 1200/1800<br />

Number of pin positions 11 11 11 11<br />

Max. strokes per min. 50 50 50 50<br />

Max. stroke length (in) 7.25 7.25 7.25 7.25<br />

Max. rec. suction lift (ft) 20 20 20 20<br />

Max. total head (ft) 240 240 180 140<br />

Max. capacity (GPM) 95 187 278 370<br />

Eccentric dia. (in) 12 12 12 12<br />

Shaft tensile strength (PSI) 160,000 160,000 160,000 160,000<br />

Approx. weight less driver<br />

(lbs)<br />

1250 2000 2800 3600<br />

22<br />

23<br />

1-888-829-2783

HPE 941-HPE-944<br />

General Specifications<br />

Duplex<br />

HPE-942<br />

Triplex<br />

HPE-943<br />

Quadruplex<br />

HPE-944<br />

Number of plungers 2 3 4<br />

Plunger dia. (in) 9 9 9<br />

Air chambers (2) 9”x30” (2) 9”x30” (2) 9”x30”<br />

Flanged connections 4” ANSI 125 # 6” ANSI 125 # 6” ANSI 125 #<br />

Driver speed, RPM 1800 1800 1800<br />

Number of pin positions 11 11 11<br />

Max. strokes per min. 50 50 50<br />

Max. stroke length (in) 7.25 7.25 7.25<br />

Max. rec. suction lift (ft) 20 20 20<br />

Max. total head (ft) 240 240 240<br />

Max. capacity (GPM) 187 278 378<br />

Eccentric dia. (in) 12 12 12<br />

Eccentric shaft tensile strength<br />

(PSI)<br />

160,000 160,000 160,000<br />

Approx. weight less driver (lbs) 1920 2650 3465<br />

Sludge Master Plunger <strong>Pumps</strong> by <strong>Wastecorp</strong>.

HPE 1141-HPE-1144<br />

General Specifications<br />

Simplex<br />

HPE-111W/HPE-1141<br />

Duplex<br />

HPE-112W/HPE-1142<br />

Triplex<br />

HPE-113W/HPE-1143<br />

Quadruplex<br />

HPE-114W/HPE-1144<br />

Number of plungers 1 2 3 4<br />

Plunger dia. (in) 11 11 11 11<br />

Air chambers (2) 9”x30” (2) 9”x30” (2) 9”x30” (2) 9”x30”<br />

Flanged connections 4” ANSI 125 # 4” ANSI 125 # 6” ANSI 150 # 6” ANSI 150#<br />

Driver speed, RPM 1200/1800 1200/1800 1200/1800 1200/1800<br />

Number of pin positions 11 11 11 11<br />

Max. strokes per min. 50 50 50 50<br />

Max. stroke length (in) 7.25 7.25 7.25 7.25<br />

Max. suction lift (ft) 20 20 20 20<br />

Max. total head (ft) 170 170 130 95<br />

Max. capacity (GPM) 142 280 418 556<br />

Eccentric dia. (in) 12 12 12 12<br />

Eccentric shaft tensile strength 160,000 160,000 160,000 160,000<br />

Approx. weight less driver (lbs) 1450 2400 3600 4400<br />

24<br />

25<br />

1-888-829-2783

EHPE 942-EHPE-944<br />

General Specifications<br />

Duplex<br />

EHPE-942<br />

Triplex<br />

EHPE-943<br />

Quadruplex<br />

EHPE-944<br />

Number of plungers 2 3 4<br />

Plunger dia. (in) 9 9 9<br />

Air chambers (2) 9”x30” (2) 9”x30” (2) 9”x30”<br />

Flanged connections 4” ANSI 125 # 6” ANSI 150 # 6” ANSI 150 #<br />

Driver speed, RPM 1200/1800 1200/1800 1200/1800<br />

Number of pin positions 11 11 11<br />

Max. strokes per min. 45 45 45<br />

Max. stroke length (in) 7.25 7.25 7.25<br />

Max. suction lift (ft) 20 20 20<br />

Max. total head (ft) 300 300 300<br />

Max. capacity (GPM) 187 278 370<br />

Eccentric dia. (in) 12 12 12<br />

Eccentric shaft tensile<br />

strength (PSI)<br />

160,000 160,000 160,000<br />

Sludge Master Plunger <strong>Pumps</strong> by <strong>Wastecorp</strong>.

Sludge Master ® Plunger <strong>Pumps</strong><br />

PE Series/HPE Series/EHPE Series / Space Saver Series<br />

Since 1928.<br />

http://www.wastecorp.com<br />

1-888-829-2783 info@wastecorp.com<br />

Specifications, literature and illustrative material are accurate at the time of publication but are<br />

subject to change without notice.<br />

Illustrations may include optional equipment and accessories and may not include all<br />

standard equipment. <strong>Wastecorp</strong> and globes are trademarks of WPCI Environmental Brands/<br />

<strong>Wastecorp</strong> <strong>Pumps</strong>. PE Series, HPE Series and EHPE Series are Trademarks of <strong>Wastecorp</strong>.<br />

<strong>Wastecorp</strong> <strong>Pumps</strong> is the exclusive manufacturer of these brands. Marks are protected in<br />

North America and worldwide.<br />

The Ultimate Sludge Fighters.<br />

© 2013 WPCI. All rights reserved. New York, NY 10024<br />

NYC/Brookl.Djs 6/2013. Lithographed in the United States of America<br />

For a complete engineering specification contact <strong>Wastecorp</strong> <strong>Pumps</strong><br />

at 1.888.829.2783 or by E -mail: info@ wastecorp.com