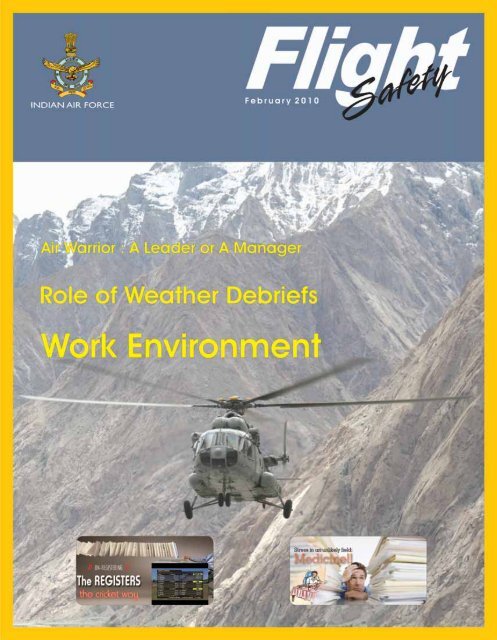

February 2010 - Indian Airforce

February 2010 - Indian Airforce

February 2010 - Indian Airforce

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Sqn Ldr RR Senthil kumar<br />

Statistical Highlights<br />

<br />

Total number of runs scored on the ground<br />

Almost all die-hard fans of cricket usually read the<br />

‘statistical highlights’ of any ODI, test or twenty20 at<br />

the start of the match. All leading newspapers publish<br />

statistical highlights on the day of the match or a day<br />

prior to the match, if its an important one.<br />

Facts Highlighted<br />

‘Statistical highlights’ bring out various facts about<br />

the match, the players, the venue and so much more. The<br />

data published in such columns would usually include<br />

the following: -<br />

<br />

<br />

<br />

Total no of centuries on the ground<br />

No of sixes, fours scored and wickets taken<br />

No of centuries and the runs scored in the<br />

venue by a particular batsman.........<br />

The list could be endless, but the intriguing thing<br />

about such amazing fact list is that how do they get<br />

such a lot of data? Do they do it the Air Force way i.e.<br />

maintaining registers of the data for all the fields? For<br />

example: -<br />

2 Flight Safety F e b r u a r y 2 0 10<br />

INDIAN AIR FORCE

Total no of runs register<br />

Centuries register<br />

data management need to be commended and they<br />

also deserve a mention in the Guinness book of world<br />

records.<br />

<br />

Total number of sixes register<br />

Total number of sixes by a particular batsman<br />

register.<br />

Brain behind the Statistical Highlights<br />

The list of registers seems to be never ending, isn’t it?<br />

The number of data entries will also be close to infinity. If<br />

that be the case, the personnel behind such mammoth<br />

However, that is not the way the whole gamut of data<br />

management works in cricket. The data is manipulated<br />

using customised software in such a way that the required<br />

report is generated for the requested query. This way the<br />

data entry is kept to the minimum and the ways in which<br />

information can be extracted numerous.<br />

It is also pertinent to mention that the person<br />

entering the data, ball after ball in the cricket match is<br />

the key person. The human link with the data entry<br />

INDIAN AIR FORCE 2 01 0 F e b r u a r y Flight Safety 3

“The quantum of<br />

data handled by<br />

sections like DSS,<br />

Refuelling, Bomb<br />

dump, armoury<br />

etc is huge and is<br />

nothing less than<br />

the quantity handled<br />

by the pundits of<br />

the game of cricket.<br />

Data management<br />

in these sections is<br />

even more necessary<br />

because it is an every<br />

day affair unlike ODI’s<br />

or Tests.<br />

starts and ends there. Rest is taken care by the computer,<br />

programmed with the database management software.<br />

Data Management at Unit/Section Level<br />

<br />

<br />

Daily flying progress register / file<br />

Concession/ limitation register<br />

Now, let us apply the same fundamentals in different<br />

units/sections of our Air Force. The quantum of data<br />

handled by sections like DSS, Refuelling, Bomb dump,<br />

armoury etc is huge and is nothing less than the quantity<br />

handled by the pundits of the game of cricket. Data<br />

management in these sections is even more necessary<br />

because it is an every day affair unlike ODI’s or Tests.<br />

Let us study the data load on the co-ordinator<br />

working in a DSS. The co-ordinator maintains a record of<br />

all the servicings due and rectification of the aircraft. He<br />

also keeps track of the daily flying activities. In order to<br />

discharge these duties he maintains a host of registers<br />

like: -<br />

The registers mentioned above are just the tip of<br />

the iceberg. The number of registers maintained in a<br />

flying unit would be close to 100. The common problem<br />

with such numbers of registers is that though we have<br />

the data available but the process of extracting relevant<br />

information is time consuming.<br />

Classical Example of Data Management at Unit /<br />

Section Level<br />

If we study the activities carried out on an aircraft<br />

in a typical squadron, it can be fathomed that the<br />

following parameters decide the servicing schedule on<br />

the aircraft.<br />

<br />

Forecast register<br />

<br />

Servicing based on the Flying hours<br />

<br />

Daily Dues register<br />

<br />

Servicing based on Calendar dues<br />

4 Flight Safety F e b r u a r y 2 0 10<br />

INDIAN AIR FORCE

What if we have a database that has all the data<br />

regarding each type of servicing due on the aircraft?<br />

Only the progress of flying is then required to be entered<br />

every day in to the database software. Once this is done,<br />

the programme should generate reports for all possible<br />

queries.<br />

Some of the queries commonly required are as<br />

follows<br />

<br />

<br />

<br />

<br />

Dues for next 25 hrs, 50 hrs, 100 hrs etc.<br />

Dues for next 30 days, 60 days etc.<br />

No of a particular component changed in a<br />

financial year.<br />

Daily dues aircraft wise, component wise etc.<br />

Presently, the reports for such queries would engage<br />

the co-ordinator for a minimum of three hours, maybe<br />

more. This time is required by the co-ordinator to go<br />

through all these registers and patiently pen down all the<br />

requisite information, and he being a human may miss<br />

some !<br />

If a software was programmed to generate results<br />

for such queries it would reduce the burden on the coordinator<br />

to a greater extent and if designed correctly<br />

would generate accurate results. Software of similar<br />

nature is also required in sections like refuelling, bomb<br />

dump, armoury etc.<br />

Standardised Software (The only Solution)<br />

Availability of locally written software merits a<br />

mention here. Thanks to the initiative of some dedicated<br />

officers and airmen, such software is being used in few<br />

units but since it is not standardised it doesn’t encompass<br />

all activities and finds limited use.<br />

Generally, such software remains in vogue only<br />

till the person who designed it remains in the unit. The<br />

only solution lies in the development of an open-ended<br />

software required in these sections by a central agency<br />

with inputs from the field personnel. Such software<br />

developed with the user inputs should be standardised<br />

and should be disseminated to all the units. Similarly we<br />

can have software designed for use at Command and Air<br />

HQ’s in the operations, maintenance and administration<br />

branches to increase efficiency and reduce paper work.<br />

Auditing of the Software Generated Reports<br />

To meet the requirements of audit, certain reports<br />

could be generated and filed.<br />

The Flight Safety Angle<br />

Such professionally developed and standardised<br />

software in various sections of the air force will definitely<br />

enhance flight safety. For example, in case of a snag in an<br />

aircraft, the software could be used to analyse the snag,<br />

repetition rate, if any, and the rectification done previously.<br />

This will help the EO and technicians in rectifying the<br />

aircraft faster and accurately. Study of repetitive snags<br />

would also bring out the preventive measures to be<br />

adopted to prevent recurrences of such snags.<br />

Such an e-enabled data base management system in<br />

every unit/section of the IAF would help in reducing the<br />

work burden on the air warriors. This would contribute<br />

towards increased work efficiency and act as an effective<br />

counter for depleting manpower in sections.<br />

Points to Ponder:<br />

The time required to calculate the total runs scored<br />

by Sachin Tendulkar during 1997-2000 at home excluding<br />

the matches against Australia would invariably be less<br />

than a few seconds by the data handlers.<br />

Most of us can appreciate the time it would take to<br />

calculate the number of aircraft sent back by the tyre<br />

checkers from the runway end during the period say Jan<br />

2008 to Jun 2009.<br />

Need I say more !!!<br />

Sqn Ldr RR Senthil Kumar AE(L) is posted to 33 Wing AF.<br />

Psychiatrists say girls tend to<br />

marry men like their fathers. That<br />

is probably the reason mothers cry at<br />

weddings.<br />

Safety Journal <strong>February</strong> 1978<br />

INDIAN AIR FORCE 2 01 0 F e b r u a r y Flight Safety 5

Wg Cdr MK Sharma<br />

WE have the fourth largest air force in the world and an inventory of around twenty-five different types of<br />

aircraft including helicopters, which are designed by six different nations. Imagine the complexities of<br />

maintenance, overhauling and logistic problems that this staggering variety poses.<br />

Aircraft & aero engine Base Repair Depots (BRDs) are like factories where in, the aeroplane/aero engines are<br />

dismantled completely and re-assembled after overhauling each item/component. Needless to mention one can<br />

imagine the kind of infrastructure w.r.t various disciplines of engineering, technology and support services a BRD<br />

possesses to accomplish this ‘Herculean task’.<br />

6 Flight Safety F e b r u a r y 2 0 10<br />

INDIAN AIR FORCE

The air warriors (including me)<br />

were compelled to compromise on<br />

set procedures and conditions of<br />

work environment to a certain extent<br />

in order to continue with production<br />

and meet the task.<br />

Repair and Overhaul (ROH) of an aero engine is<br />

one of the most challenging fields in aviation industry<br />

involving precision work of very high order and thorough<br />

professionalism. Majority of the aero engine assembly<br />

process and the Micrometry checks (it is the process<br />

of taking measurement of aero engine internal parts/<br />

subassemblies/components, etc using digital scientific<br />

measuring instruments) are required to be undertaken in<br />

a dust free and controlled environment of temperature,<br />

airflow and relative humidity to achieve conformity of<br />

product’s requirements. Universally, it is an accepted<br />

norm that for any accurate and steady measurement of<br />

a physical entity, a controlled temperature of 20 o C + 2 o<br />

is ideal.<br />

Importance of correct working conditions and<br />

environment can never be undermined. I would like<br />

to bring to light two interesting cases related to the<br />

working conditions at a BRD wherein, minute dust<br />

particles (foreign objects) contributed to the rejection<br />

of aero engines during operation/testing. During my<br />

tenure as the Squadron Commander of an aero engine<br />

and Gear Box overhaul line at the BRD we had a chronic<br />

problem in the air conditioning system of the building.<br />

Despite best efforts put in by the MES and C Adm O, there<br />

seemed no solution. To make matter worse, the summers<br />

were approaching and non availability of a suitable<br />

ventilation system with adequate air flow in the building<br />

was to complicate the working conditions further. The<br />

entrance doors to the assembly hall were partially kept<br />

open to avoid suffocation and allow inflow of some fresh<br />

air. The air warriors (including me) were compelled<br />

to compromise on set procedures and conditions<br />

of work environment to a certain extent in order to<br />

continue with production and meet the task.<br />

Case I An aero engine was received for DI with a<br />

snag of overheating marks on the torsion shaft driving<br />

the main gearbox from the aero engine. It appeared to be<br />

a clear case of oil starvation, albeit in the initial stages. As<br />

per SOP, the necessary checks on the oil pump assembly,<br />

scavenge pump, oil filters, flow rate of oil jets, circulation<br />

check of lubrication system etc. was undertaken. All<br />

the parameters checked were found within permissible<br />

limits. Subsequently, the bearing support assemblies<br />

(fourth & fifth support) were also dismantled for signs<br />

of malfunction/blockage and their micrometric checks<br />

were undertaken, which were again within the specified<br />

tolerance limits as given in the repair manual.<br />

After spending close to six days on the Defect<br />

Investigation (DI), I gave up and decided to approach<br />

my boss, “The Chief of Engines” (Gp Capt Mr. Right,<br />

always believed in doing the right things the right way<br />

and, possessed immense knowledge on aero engines<br />

overhauling procedures & processes). After patiently<br />

listening to us and our approach in tackling the defect<br />

investigation, we were questioned about the condition<br />

of the oil jet spraying oil in the affected area. When told<br />

that the jet was functioning normally (based on the<br />

spray obtained from it) he asked us to get it cut open by<br />

the Wire Cutting Machine. All of us were taken aback<br />

as this was the first instance when somebody in the<br />

engine division was asking for an oil jet to be cut open<br />

to view its internal passage. Reluctantly, we took up the<br />

cutting process of the oil jet as advised by Mr. Right. To<br />

our dismay we found a very minute solid dust particle<br />

sitting prettily at the curved portion of the oil passage in<br />

the oil jet (seen using a high magnification microscope).<br />

The dust particle must have entered the lubrication<br />

system during the assembly process of the aero engine<br />

INDIAN AIR FORCE 2 01 0 F e b r u a r y Flight Safety<br />

7

During brainstorming with the experienced<br />

technicians of the overhaul line, an idea was mooted<br />

that, the bearings must be re-checked for their radial and<br />

axial play on all the support assemblies. (It is pertinent to<br />

note that all support assemblies were fitted with Cat ‘A’<br />

bearings during the process of repair on the aero engine<br />

and their plays were within specified limits.)<br />

in the hall and must have positioned itself in the fourth/<br />

fifth support assembly oil jet eventually, thereby causing<br />

intermittent blockage of the oil passage. The aero engine<br />

had completed only about hundred hours of operation<br />

since the last repair/overhaul. Had it not been for our Mr.<br />

Right, we would have probably rejected the complete<br />

support assembly instead of only the oil jet.<br />

Case II An engine was vibrating beyond<br />

permissible limits when tested on the test bed after<br />

necessary repairs in the overhaul line. In fact, it was<br />

rejected twice on the test bed and now posed a serious<br />

challenge to our technical knowledge, practices and snag<br />

analysis capability. All the rotating major assemblies like<br />

the compressor assembly, drum, turbine assembly, NGVs<br />

etc where re-balanced but no imbalance was noticed.<br />

Any imbalance in the rotating components is capable of<br />

causing vibration & stresses, which increase as square of<br />

rotational speed. As nothing unusual was noticed from<br />

the previous readings during repair, the compressor<br />

blades were slightly re-distributed (within same weight<br />

range). Further, all other assemblies were checked for<br />

correct tightness and torque, but nothing abnormal was<br />

noticed and the engine was sent for testing. However,<br />

the engine failed for vibration again on the test bed.<br />

During the critical examination of the bearings in<br />

the ‘Micrometry Bay’ it was seen that there was a fine<br />

mirror like groove of about 1mm all around the outer<br />

surface of the inner race of the first support bearing.<br />

Initially, this appeared like some fine machining process<br />

on the bearing surface. However, in comparison with<br />

other first support bearings (Cat ‘A’ and ‘B’) it was<br />

seen that, such a pattern was noticed on a few other<br />

Cat B bearings as well. Thorough examination of<br />

these bearings was carried out which revealed that<br />

probably very small contaminant particles on the<br />

bearing surface or in the oil (lubricant) could have<br />

caused this “Polishing Wear” on the bearing. Across<br />

the globe about 14% bearing failure have been attributed<br />

to “Contamination” viz, foreign material entering the<br />

bearing and components such as moisture and solid<br />

particles.<br />

Subsequent analysis established that the foreign<br />

dust particles had damaged the bearing during the<br />

course of its operation. This bearing was contributing<br />

to the onset of vibration in the aero engine. There are<br />

a lot of rotating parts in the vicinity of the first support<br />

of the aero engine which also get their drives directly<br />

or indirectly from it. The damaged bearing had to be<br />

replaced which entailed the complete dismantling of<br />

the aero engine and wastage of previous man-hours<br />

and spares.<br />

8 Flight Safety F e b r u a r y 2 0 10<br />

INDIAN AIR FORCE

Another associated aspect that merits attention in<br />

connection with controlled working conditions while<br />

taking very small and accurate measurement is the<br />

temperature prevailing in the premises. It is a known<br />

fact that as temperature increases there is a tendency for<br />

expansion of physical metallic entities. The overhauling<br />

procedures of an aero engine entail taking measurement<br />

in microns. One micron is equal to one millionth of a meter<br />

and the thickness of a human hair is around 80 microns.<br />

For every degree increase in the room temperature<br />

there is a likelihood of variation in measurements being<br />

taken and their consistency. Therefore, maintaining the<br />

specified temperature conditions is also a mandatory<br />

requirement in the hall.<br />

The two cases mentioned above clearly indicate<br />

that, had the controlled conditions of environment been<br />

provided and maintained, the chances of ingress of the<br />

foreign dust particles into the internal parts of the aero<br />

engine could have been avoided and the engines would<br />

not have been prematurely withdrawn. Luckily both<br />

the failures did not result in an accident/incident but<br />

nevertheless could have manifested into serious defects<br />

in air. These cases and many such defects, therefore,<br />

bring forth the importance and criticality of maintaining<br />

the desired conditions of humidity, temperature, lighting<br />

and airflow in the work place, which have a direct bearing<br />

on Flight & Maintenance Safety.<br />

Today, Quality has become the most important<br />

force to organizational success and growth. The fact that<br />

quality increases productivity has now been well accepted<br />

contrary to the general belief that it hinders production.<br />

Though there is an excellent system of ensuring quality<br />

at our BRDs, there is still a scope for improving upon<br />

and further enhancing the various processes and<br />

activities that go into product realization including work<br />

environment. It is therefore important that the Admin<br />

and Support services must also understand their role<br />

towards Flight & Maintenance Safety and undertake a<br />

pro-active approach in all activities contributing towards<br />

safe & conducive working environment.<br />

WG Cdr MK Sharma AE(M) is posted at 19 Wg AF.<br />

There is more to Murphy !<br />

Lorenz’s Law of Mechanical Repair<br />

After your hands become coated with<br />

grease, your nose will begin to itch.<br />

INDIAN AIR FORCE 2 01 0 F e b r u a r y Flight Safety<br />

9

JWO P Sriram<br />

While we have a host of<br />

input channels for medium and<br />

long-range forecasts, for nowcasting,<br />

there is no substitute<br />

to an air report that is given<br />

by a pilot in real time.<br />

10 Flight Safety F e b r u a r y 2 0 10<br />

INDIAN AIR FORCE

ONE day I was performing D Met O duties. In the<br />

morning briefing I had forecasted convective weather<br />

activity and thunderstorms in the afternoon/early<br />

evening hours based on the synoptic chart inputs.<br />

However, at around 1000 h, I noticed some dark patches<br />

appearing west of the base. I immediately requested the<br />

GCA for a weather report. In addition, I requested the DATCO<br />

to obtain air report from the pilots who were airborne.<br />

The GCA weather report confirmed that there were many<br />

cumulus patches in the SW direction. As the BADC missions<br />

were in air, I was told that the air report would be provided<br />

after landing of the first ac. While I was waiting for the aircraft<br />

to land, taxi-in, switch off and then obtain pilot’s weather<br />

debrief, the cumulus patches in the southwest grew in size<br />

and extent.<br />

I was now getting impatient by the second, in the<br />

absence of actual prevailing weather around the airfield and<br />

its actual build up. When I could no longer bear the threat of<br />

an occurrence of a thunderstorm over the airfield, I issued a<br />

weather warning giving a 30 mts warning time for the aircraft<br />

to recover. All aircraft in the local flying area were recalled<br />

by the DATCO citing deterioration in the weather conditions.<br />

Only when the first aircraft had landed and switched off in<br />

dispersal, I could talk to the pilot on the weather build up<br />

and its movement. By this time, all the aircraft had landed<br />

safely after having abandoned their missions.<br />

The pilot gave me a detailed debrief about the weather<br />

conditions. I, then learnt that the cumulus patches were<br />

growing but were moving in a northerly direction; thus,<br />

would have been clear of the base. I realized, I was wrong in<br />

estimating the direction of movement of the CB clouds, had<br />

issued the weather warning too early and now it was too<br />

late to retract the warning. Had I known that useful weather<br />

input 15 mts early, may be there would not have been loss of<br />

valuable flying training of the pilots.<br />

I am sure meteorologists face this kind of experience<br />

quite often. The importance of weather debriefs has been<br />

emphasized on numerous occasions. Meteorology is a<br />

growing science and brings about collateral benefits to<br />

us. Its importance ranges from utility services to space<br />

missions, from satellites to super computers and so on. Its<br />

role is ubiquitous. Such is its ubiquity that a day does not<br />

pass in most people’s life, when they directly or indirectly,<br />

consciously or subconsciously want to know the next day’s<br />

weather. Be it a flyer, farmer or a mere weekender.<br />

Despite its significance, it is the only science that is most<br />

ridiculed and at the same time respected. Generally, the<br />

reasons for failures in accurate forecasting are attributed to<br />

improper analysis. This is partly true, but most of the time it is<br />

lack of timely inputs in a rapidly changing weather situation<br />

that causes the failure in predictions.<br />

While we have a host of input channels for medium and<br />

long-range forecasts, for now-casting, there is no substitute<br />

to an air report that is given by a pilot in real time. All the<br />

conventional forms of input reception systems like land<br />

line channels, satellite products and internet sites provide<br />

us rather ‘stale’ data. We have not yet imbibed real time<br />

data reception methodology.<br />

At the time of need of real time input, it is from a pilot<br />

alone, that we get the best status of current meteorological<br />

conditions. In marginal weather conditions, the first sortie<br />

is usually carried out for weather reconnaissance at our<br />

flying bases. That amply proves the significance of such an<br />

input.<br />

By providing weather debriefs, the pilots can make the<br />

weathermen work in real time. Weather debriefs enlarges<br />

the scope of forecasting ability of the forecaster. It brings out<br />

distinct perceptional change among the weather brethren.<br />

In the sense, the weather debrief gives a meteorologist the<br />

most needed reaction time in ‘now-casting’. It has a learning<br />

value too. The weather debrief provides a forecaster the<br />

much needed confidence to either back his forecast or to<br />

amend it as necessary.<br />

Like wise, a true forecaster cannot become a master<br />

in his profession without having done some real time data<br />

analysis. The real time weather debrief input provides<br />

enough data to supercede the synoptic chart that is<br />

prepared at the end of a three/ six hour synoptic period<br />

(atleast for local forecasts).<br />

Recently there was a policy circulated by Air HQs<br />

regarding enlarging the observational envelope around the<br />

airfield for more accurate and timely short range forecasts.<br />

Field units were asked to conduct surveys of nearby civil/<br />

military establishments and liaise to establish a larger<br />

weather observation network. Whether shine or shower, let<br />

us institutionalize gathering of the pilot debrief even if it is<br />

a single sentence report about general weather conditions,<br />

as soon as the aircraft takes off, which would immensely<br />

help in providing a more conducive environment for flying<br />

operations. During flying, if pilots are busy, other aircrew<br />

like navigators, flight gunners etc can give debrief on the<br />

general weather conditions. This would immensely help<br />

the weathermen in understanding the intricacies of nature<br />

more objectively. Adherence to this would definitely<br />

increase the quality of the forecasts issued by the Met Flight<br />

significantly. I hope that the passing of weather debriefs by<br />

the aircrew become a routine in near future.<br />

JWO P Sriram Met Asst is posted to 414 AF Station.<br />

INDIAN AIR FORCE 2 01 0 F e b r u a r y Flight Safety 11

Wg Cdr Indranil Chakraborty<br />

IT was the first day of the Maha-Guj Raj Exercise and we<br />

were all geared up to meet the contingencies that were<br />

likely to come up during the week. The time was early<br />

morning and I was discussing some issues with my JWO<br />

I/C in front of the SMC. Suddenly, I saw a coach coming<br />

to a stop in front of us and three Air Warriors emerged<br />

from it carrying a colleague in their arms. They shouted<br />

that the person, a young Cpl, has been caught between<br />

a tractor and a GPU and was injured. We put him in the<br />

emergency room and carried out the necessary treatment<br />

to him. Luckily, there were no internal injuries and further<br />

follow up did not reveal any long term damage. The<br />

young Cpl was anxious as he was getting married the<br />

next month and I hope he is well settled by the time this<br />

article appears!<br />

What Happened?<br />

Cpl X, age 25 yrs, was a PMF (M) and belonged to<br />

the visiting fighter squadron. On the day of the incident<br />

he was in the process of attaching a GPU to a tractor. He<br />

was holding the tow arm of the GPU and the tractor was<br />

slowly backing towards him, so that the tow arm could<br />

be attached to the tractor. When the tractor was within<br />

comfortable distance, Cpl X called out to stop the tractor.<br />

To his horror, the tractor kept on moving towards him. Sgt<br />

Y, the MTD of the tractor, was desperately trying to stop<br />

the vehicle by applying the brakes hard but his efforts<br />

seemed to have no effect on the motion of the tractor.<br />

By this time, Cpl X was trapped between the tow arm and<br />

the tractor and was getting crushed. Sgt Y then applied<br />

the forward gear so that the tractor started moving in the<br />

opposite direction. Cpl X, though injured in the lower part<br />

of the body, was able to free himself and got saved from<br />

almost certain death. Other Air Warriors then put him in a<br />

coach and brought him to SMC.<br />

Why it Happened?<br />

Apparently, there was no human error involved. It<br />

was the brakes of the tractor that had failed. The tractor<br />

involved was of BEML make. The brakes were pneumatic<br />

in nature. A follow up in the MT section revealed a<br />

pneumatic leak in the brakes of the tractor. Luckily, the<br />

tractor was at a very slow speed and so life saving action<br />

could be taken by the MTD. Had he been backing at a<br />

high speed, the damage would have been beyond one’s<br />

imagination.<br />

Medical Advice<br />

Through this article I would like to intimate my<br />

readers that life saving procedures are very simple but<br />

must be carried out in a professional manner. In this<br />

particular case, when it was suspected that Cpl X had<br />

sustained crush injury in the lower abdomen and<br />

back, he should NOT have been evacuated to SMC in a<br />

coach and neither should he been carried in the arms<br />

while coming out of the vehicle. He should have been<br />

laid on the tarmac and ambulance should have been<br />

12 Flight Safety F e b r u a r y 2 0 10<br />

INDIAN AIR FORCE

equisitioned for transferring him to SMC. Patients with<br />

such injuries should be carried on a flat stretcher, as any<br />

unnecessary movement of the injured back would have<br />

led to spinal injury.<br />

Similar Incident in the Base<br />

During my interaction with the MT Section and other<br />

personnel I came to know that a major accident had<br />

occurred some years ago in the same base involving a<br />

tractor. The COI revealed that the accelerator mechanism<br />

of the tractor had got stuck which led to the tractor<br />

suddenly moving on the tarmac and ultimately damaging<br />

one MiG 21 aircraft. The entire airframe had to be written<br />

off! Thus, there is a past record of tractors getting involved<br />

in accidents on the tarmac.<br />

Lessons Learnt<br />

Vehicles operating on the tarmac must be thoroughly<br />

checked daily so that defective vehicles are not put in use<br />

for tarmac operations.<br />

Operators must know that accidents do happen on<br />

the tarmac and they must remain vigilant to prevent such<br />

accidents.<br />

Such accidents and incidents must be recorded and<br />

disseminated to the users so that at least they are aware<br />

of such mishaps.<br />

First Aid procedures must be taught and practiced<br />

by all personnel working on the tarmac. Wrong First Aid<br />

procedures can further aggravate an injury.<br />

Conclusion<br />

The incident could have happened on any day and<br />

at any time in a flying station. The Unit was lucky not<br />

to have a damaged GPU, a runaway tractor and injured<br />

Air Warrior. The Station was lucky that it did not have to<br />

hold a COI. We were lucky that we did not have to start<br />

the exercise with an actual contingency. Efforts must<br />

be made to compliment the Sgt who saved not only a<br />

human life, but managed to save all the equipment and<br />

the vehicle.<br />

It is my endeavour to spread the awareness amongst<br />

my readers to be alert while working on the tarmac.<br />

You are handling tools and equipment which have the<br />

potential to injure you. Disasters happen without prior<br />

notice. BE ALERT SO THAT YOU DO NOT TRANSFORM<br />

A GIVEN SITUATION IN A DISASTER.<br />

Wg Cdr Indranil Chakraborty (Med) is posted to Air Force<br />

Station Utarlai.<br />

INDIAN AIR FORCE 2 01 0 F e b r u a r y Flight Safety 13

BLAST FROM THE PAST<br />

SAFETY JOURNAL NOVEMBER 1977<br />

FLT LT AK SINGH 49 SQN<br />

THE Flight Commander called me into his office<br />

– “AK, I want you to take an aircraft to Hakimpet<br />

tomorrow morning. Some bonedomes are to be<br />

brought from there; the Logistic Officer will give you all<br />

the briefing”.<br />

“Yes Sir”. Cross-country of the month! In fact it<br />

sounded fine. A pleasant day’s flying around Southern<br />

India – not too strenuous at all. A welcome break from<br />

circuits and bumps with a constant yammering to the<br />

cadets. Better inform the DSS to keep the air-craft ready.<br />

“What’s the score on X-1010? CI’s aircraft reserved<br />

for X-country flights and CI’s standardization checks<br />

only (‘Cause it had a booster pump – the only one in the<br />

fleet’).<br />

“You are to carry sufficient fuel. No passenger because<br />

you will have to carry all the bonedomes in the rear cockpit,<br />

keep a check on weather as you may have to divert to<br />

Begumpet.“<br />

Hmm! I thought, I mustn’t do what the other chap did,<br />

by force landing on his wayback due to insufficient fuel.<br />

So sitting back, I drew a straightline on the map, the HT-2<br />

does not require any flight planning, or so I thought with<br />

supreme confidence.<br />

Morning dawned grey and foreboding with a slight<br />

drizzle and low clouds. All aircraft were in the hangar, cadets<br />

were given a quiz to work on and the QFIs were exchanging<br />

banter in the verandah. By 1130 hrs the weather had lifted<br />

sufficiently and the Flt Cdr said that I was to go.<br />

14 Flight Safety F e b r u a r y 2 0 10<br />

INDIAN AIR FORCE

I picked up the parachute, rang up the ATC that I was<br />

proceeding to Hakimpet, kicked the tyres and jumped<br />

into the front cockpit. As I started taxying out, I saw<br />

young sleepy Dopey, walking towards the aircraft with<br />

a parachute slung on his back, since there was no other<br />

aircraft on the flight line, I had no choice but to wait for<br />

him.<br />

Dopey got into the rear cockpit despite all my yelling<br />

that I wasn’t supposed to carry any passengers. Once in,<br />

I heard his sleepy voce telling me to taxi out as he had<br />

some accounts problems to be sorted out at Begumpet.<br />

We had an uneventful trip to Hakimpet, landed there<br />

at 1300 hrs. The Logistic officer was boiling mad because<br />

we would keep him after working hours to sign various<br />

vouchers.<br />

We left Hakimpet for Begumpet with ten bonedomes<br />

in Dopey’s lap and some all over the floor, the rear hood<br />

couldn’t even be closed. As we landed in Begumpet the<br />

sky split, there was a thunder storm so we sat it out in<br />

the cafeteria and every few minutes asked the met for<br />

clearance.<br />

In the quite period over the next half-an-hour or so, I<br />

pondered. A great number of people take a great deal of<br />

time and care at a great expense compiling things like ASIs,<br />

briefing notes, pilot orders and they just don’t do it for fun.<br />

I should have paid attention to all these things that were<br />

wrong :-<br />

I hadn’t briefed Dopey for the sortie or for any<br />

emergency.<br />

We were in such a hurry that, we were not even strapped<br />

up, adding insult to injury was the fact that we were using<br />

our parachutes like cushions and hadn’t strapped them<br />

on ! Sheer luck a field was there and we did not go into<br />

any obstructions else, I shudder to think what would have<br />

happened.<br />

This incident still gives me the jitters to think that with<br />

a little less luck we might have lost quite a lot more – more<br />

than just the undercarriage, may be two pilots and an<br />

aircraft.<br />

At 1600 hrs, Bidar sent a message that their airfield<br />

would close down at 1800 hrs. Prospects of staying the<br />

night without even a tooth brush were staring at us in<br />

the face. The Almighty probably heard the prayers of two<br />

sinners and the storm abated at 1700 hrs. We dashed<br />

down to the aircraft, jumped into the cockpit and were<br />

off. Dopey yelled, “level out we’ll go back at 200 ft only,<br />

why climb through clouds ?”<br />

Fifteen minutes out, I gave a call to Bidar, “ETA 1745”.<br />

Our flying time was 45 mins and we got airborne at 1720,<br />

so the earliest we would make Bidar was 1805. If we told<br />

them that they wouldn’t accept us. HT-2 R/T being what<br />

it is, the only person who could hear us was an Avro flying<br />

overhead and the message was relayed to Bidar.<br />

Happy with ourselves that all jobs were done,<br />

Bonedomes had been collected. Dopey came on R/T, “Yaar<br />

Goodwala trip what say you” before I could say anything,<br />

the aircraft vibrated. I reduced throttle, vibrations<br />

subsided, but once again set in, shaking the aircraft like a<br />

fish out of water. Dopey closed the throttle and we saw a<br />

white streak curving to our right, realizing simultaneously<br />

that our propeller had taken wings. Thank God, I saw a<br />

field to my right and put the aircraft down, no damage,<br />

we rolled for 50 yds and stopped. Didn’t even have time<br />

to give a call to Bidar.<br />

This Pilot couldn’t be<br />

bothered to strap himself in.<br />

INDIAN AIR FORCE 2 01 0 F e b r u a r y Flight Safety 15

Wg Cdr Arvind Kumar<br />

16 Flight Safety F e b r u a r y 2 0 10<br />

INDIAN AIR FORCE

MANY people use the terms ‘leadership’ and<br />

‘management’ interchangeably. However, these<br />

words imply a number of different things in<br />

spite of being quite similar. Management in the simplest<br />

words means getting the job done through others.<br />

Hence a manager is a person who gets work done. From<br />

the functional perspective, a manager is the one who<br />

plans, organises, controls and directs. Leadership can be<br />

defined as the art of inspiring and influencing people<br />

so that they work willingly towards achieving goals laid<br />

down by their leader. Thus every manager is a leader to<br />

that extent. But the question is, “Does the Air Force need<br />

leaders or managers?”<br />

Often it is said that so and so leader has brought a<br />

dramatic change e.g. Lee Lacocca credited with turning<br />

around the loss making American<br />

auto giant Chrysler. Thus leadership<br />

is associated with change or<br />

transformation. A manager on<br />

the other hand is identified<br />

more with ensuring stability<br />

and predictability in the<br />

organisation. In the Air<br />

Force context, if we say<br />

‘so and so person was<br />

instrumental in the<br />

smooth conduct of<br />

the Op exercise’, we are<br />

referring to the person<br />

as a manager rather than a<br />

leader.<br />

Leadership is visionary<br />

whereas management is rational. A<br />

leader can see the ‘big picture’ and lay<br />

down the goal which the organisation<br />

should reach in the future. Personal vision of Ratan Tata<br />

could be summarised as “I will build a motor car that<br />

will cost not more than one lakh rupees so that the<br />

<strong>Indian</strong> masses can enjoy a four wheeler ride.” It was the<br />

managers in TELCO who through rational planning and<br />

other activities implemented the vision of their leader<br />

and produced the Nano car. The leadership of the Royal<br />

Singapore Air Force has the vision of “Zero Accident” and<br />

has laid it down as its primary goal. Thus, a leader creates<br />

vision and a manager implements it.<br />

A leader is warm, radiant and inspiring. A manager is<br />

often seen as cool and reserved. A leader relates himself<br />

with people who in turn identify themselves with him<br />

or her. A leader reaches out to people, penetrates their<br />

hearts and touches their soul. People start considering<br />

A leader can see<br />

the ‘big picture’ and lay<br />

down the goal which the<br />

organization should reach<br />

in the future. Personal vision of<br />

Ratan Tata could be summarized as<br />

“I will build a motor car that will cost<br />

not more than one lakh rupees so that<br />

the <strong>Indian</strong> masses can enjoy the four<br />

wheeler ride.” It was the managers<br />

in TELCO who through rational<br />

planning and other activities<br />

implemented the vision of<br />

their leader and produced<br />

the Nano car.<br />

the vision and ideas of the leader as their own. In contrast,<br />

a manager is often seen as a person sitting in his chamber<br />

who maintains a distance from his subordinates. Field<br />

Marshal Rommel used to fight along with his soldiers<br />

in the trenches. A leader can be a source of inspiration<br />

to millions. We often hear many great men saying, “I am<br />

inspired by Mahatma Gandhi and his ideology of nonviolence.”<br />

We talk of the Mahatma as being one of the<br />

greatest leaders (not the managers) of the world.<br />

A leader needs to be innovative and imaginative<br />

whereas a manager is more deliberate and analytical. A<br />

leader often uses simple but new and creative approaches<br />

to solve the profoundest of the problems. A manager<br />

on the other hand uses the existing framework of tools<br />

and practices for his day to day work. Leaders love<br />

experimentation but managers hesitate<br />

in doing that. It can be safely said<br />

that a manager uses the existing<br />

framework, approach and ideas<br />

whereas the leader creates new<br />

framework, approach and<br />

ideas.<br />

Now the question<br />

arises “Should the air<br />

warriors be leaders<br />

or managers?” The<br />

Air Force has a well<br />

designed system of rules<br />

and regulations in the form<br />

of various orders, instructions,<br />

policies and directives. Rules<br />

and<br />

regulations are needed<br />

to maintain<br />

order, stability and<br />

predictability in the system. In this<br />

context, the Air Force needs ‘managers’.<br />

A commanding officer or a flight commander has to lead<br />

his team to fight the enemy or accomplish a mission. In<br />

this context, the Air Force needs ‘leaders’. We are often<br />

reminded of many of our great leaders like the Marshal of<br />

the Air Force Arjan Singh who led the IAF outstandingly<br />

during the 1965 air operations.<br />

The IAF still has a long way to reach the ultimate goal<br />

of ‘Zero Accident Rate or ZAR’. To achieve such goals we<br />

need leaders who can bring a dramatic change in the<br />

attitude and working culture of our air warriors and make<br />

them really believe and follow the motto ‘Perfection and<br />

Zero Defect in whatever we do” so that ZAR becomes a<br />

reality.<br />

Wg Cdr Arvind Kumar AE(L) is posted to 5 Wg AF.<br />

INDIAN AIR FORCE 2 01 0 F e b r u a r y Flight Safety 17

Gp Capt Narinder Taneja<br />

DMO duties on weekend will<br />

be part<br />

“<br />

of you for the rest of your<br />

career. You will get respite only<br />

if there are three or more MOs<br />

at the base”. Some, enthusiastic<br />

SMO may offer, “Listen, if you<br />

want to go out for couple of<br />

hours, I can cover up for you.”<br />

Frustrated he discusses this with<br />

all his friends, who may or may<br />

not sympathize with him. No<br />

one does at the station eitherbecause<br />

we can see only see his<br />

comforts and luxury.<br />

18 Flight Safety F e b r u a r y 2 0 10<br />

INDIAN AIR FORCE

I<br />

read with interest a recent article in the Flight Safety<br />

Magazine and the line /phrase that caught my<br />

attention was ‘Flying is a stressful profession’. I cannot<br />

but wholly agree with this statement. Over the past fourfive<br />

years, I have in some way or the other acknowledged<br />

this in my articles in this magazine, when I have discussed<br />

about fatigue in aviation, about low backache, spine,<br />

about critical incident Stress Management and even<br />

Ejection.<br />

However, every time I have discussed ‘stress’ in<br />

aircrew, deep inside there has been a desire to write<br />

about stress in another branch in the Air Force, which<br />

has neither been discussed nor acknowledged in any<br />

form. I am pointing towards the stress of the Doc’s in the<br />

‘Medical Profession’ which is the noblest of all professions<br />

and in our parlance –the ‘Medical Branch’. I can already<br />

hear certain sighs of disbelief –Wow! Do you think Doc’s<br />

are stressed? They are the luckiest of all-pack up on<br />

time; sharp 2 pm-lunch, bang on time don’t you see our<br />

young bachelor Doc always at the dining table at 2.10,<br />

he is the first one to have his lunch and first to leave the<br />

dining room–when others are still trickling in. You will see<br />

him at 5 pm, regular with his walk or jog or his game of<br />

squash, or his dancing classes. You will again see him at<br />

the appropriate time for dinner. That was no doubt, the<br />

comfort part. We need to go beyond this.<br />

Let’s chart the progress/careers of a Medical Officer<br />

in the IAF<br />

Young straight after internship, a 24 yr something,<br />

doctor from the civil reports to an Air Force Base close to<br />

his hometown and gets commisioned. Generally this will<br />

not be a single MO unit, so that the young commissioned<br />

MO gets groomed by some seniors in the SMC or he may<br />

be commissioned from AFMC and then may be posted<br />

any where. Life is beautiful for most of these newly<br />

commissioned officers. If they worked in the civil prior<br />

to joining the AF, it is a welcome change. See about 20<br />

patients in the morning and another 25 families later in<br />

the day, unless he is at an extremely busy base with a<br />

relative shortage of medical officers where he may see<br />

a little more. Rarely would there be a MO seeing more<br />

than these no of patients regularly. He has time to read a<br />

newspaper/ may be his medical books, have his breakfast<br />

at leisure and enjoy a cup of tea, may be twice. He will also<br />

find someone to respond to his other needs such as odd<br />

work at the post office, bank, canteen etc. After working<br />

hours, he realizes he has enough time to pursue his extra<br />

curricular activities, and he suddenly finds facilities which<br />

he had until now only heard of : billiards, TT, badminton,<br />

gym, squash and may be swimming pool, all at one place,<br />

without any membership charges, without any waiting<br />

period to become members. Carry home pay 30 grand – a<br />

quantum jump to the measly 5000/- he was getting after<br />

slogging for hours in the local nursing home in the civil.<br />

He couldn’t have asked for a better life. No two doubts<br />

about life as discussed till here.<br />

However, he soon realises that all is not so rosy. The<br />

manning situation suddenly becomes SMO plus two.<br />

SMO being a veteran with 20+ years of service does not<br />

do DMO duties. Left are the two MOs including the young<br />

Flt Lt. The base works 5 days a week. This Flt Lt, who is<br />

an extrovert, has already made a whole lot of bachelor<br />

friends-from fighter boys to the ground duty officers-<br />

But come Thursday all his friends would start planning<br />

for a weekend. Suddenly our Flt Lt realizes that every<br />

weekend he is on duty – either Thu and Sat or Fri and<br />

Sun - which means, that he is stuck. He packs up on time<br />

everyday but weekend he is stuck! He is any day willing<br />

to trade longer working hours on week days to get an<br />

entire weekend off. But there is no option /solution in<br />

sight. Mumbles his predicament to the SMO, who, as<br />

all veterans do, tells him “See, young boy, we all have<br />

grown up in the organization like this. DMO duties on<br />

weekend will be part of you for the rest of your career.<br />

You will get respite only if there are three or more MOs<br />

at the base”. Some, enthusiastic SMO may offer, “Listen, if<br />

you want to go out for couple of hours, I can cover up for<br />

you.” Frustrated he discusses this with all his friends, who<br />

may or may not sympathize with him. No one does at the<br />

station either- because we can see only see his comforts<br />

and luxury. For one desperate full weekend, he offers his<br />

colleague a brilliant idea- “Sir, I will do 3-4-5 duties the<br />

entire week –just give me the full weekend off- sir my<br />

friends are going to a place-x –sir, couple of lady officers<br />

are also going for this trek, sir, please” and eventually he<br />

gets a full weekend off! So much for the joy of packing up<br />

on time on a week day.<br />

Given these rosy working hours with abundance<br />

of time at his disposal every evening, he enrolls for<br />

certain classes in the evening -Swimming, may be<br />

dancing. Life is stressful Whosoever said that military<br />

life is stressful? Whosoever said that Air Force Medical<br />

Officers are stressed? Not here. Hardly has he learnt the<br />

first steps of dancing that he gets a rude awakening - 4<br />

weeks TD! Whatever happened to his 5000/- enrolment<br />

fee- frantically contacts his teacher to request her to<br />

be considerate for a month. “I will be back”, he assures.<br />

Little does he realize that being the youngest, a bachelor,<br />

he fits the optimum bill to be on relief pool so to say.<br />

Four weeks later, another TD is already planned for him.<br />

He can only dream of his dancing classes, teacher and<br />

INDIAN AIR FORCE 2 01 0 F e b r u a r y Flight Safety 19

fellow colleagues. All of his other friends have since then<br />

progressed and are flaunting their newly learnt skills on<br />

the dance floor, where as our young Flt Lt DOC is on TD<br />

replacing a MO in a single MO unit. Life of a MO –Stressful<br />

-possibly Yes.<br />

Another MO is posted to a fighter Sqn, a missile Sqn<br />

or any other sqn for that matter. COs anniversary being<br />

celebrated with great zeal at COs house. Liquor and<br />

snacks! Have no time for dinner : the dance floor ablaze;<br />

the music rocking. The party continues well into the wee<br />

hours. When the ‘guys’ eat the food, it is close to breakfast<br />

time. The Doc is enjoying his drinks (if he takes alcohol) or<br />

cursing his day (if he is a teetotaler). He also knows from<br />

past experiences of such occasions that the Squadron<br />

will have a stand down the next day.<br />

The sole ‘guy’ out of this Sqn gathering working<br />

and expected to be at his office on time is the poor<br />

DOC. Imagine his plight, if he was the DMO that day and<br />

drinking or not drinking – he got two calls from the SMC<br />

during these extended celebrations while the entire sqn<br />

is enjoying and looking forward to the stand down the<br />

next day. The poor Doc is STRESSED, being DMO that day,<br />

not drinking, getting called twice at SMC, and having to<br />

report on time at work after packing up at 0300 hrs. Some<br />

one of you may well say the DOC should have packed up<br />

early- he need not have stayed there that long. But does<br />

that happen? After all COs anniversary is next only to<br />

the Sqns anniversary. Has anyone sympathized with the<br />

DOC on such occasions? To top it all, let’s say one of these<br />

calls to the SMC was an emergency call; a tough one at<br />

that- does the DOC come and enjoy the party- No, Can<br />

he ever switch off from the SMC on call duty, say along<br />

with a social evening ? No never. Yes, he has taken up the<br />

profession by choice! He knows that doctor will forever<br />

remain on call –but dear friends, in no other organisation,<br />

would he be on so much call duties for so many years<br />

the way we have. No where, not even in the Army is a<br />

medical officer on call duty so frequently, in particular<br />

when a hospital is located so nearby.<br />

Lets look at a medical officer with 18-19 years of<br />

service; still not a Gp Capt. He is the senior Wg Cdr in a<br />

big base - may be no 3-4 with 3 Gp Capt above him, or he<br />

is the SMO in a medium base with 2 more MOs. He will do<br />

DMO duties at the same frequency as does a Flt Lt with<br />

6 months of service- because the young Flt Lt now has<br />

the guts to ask for transparency and equality in duties<br />

and temporary duties. Add to this a lady officer, gender<br />

as an issue is added. On the other hand in the smaller<br />

base, he may or may not get a replacement for one of his<br />

MOs. Leaves him with one more MO. For one month he<br />

cannot put the other MO on continuous DMO duty. So<br />

perforce he does alternate DMO duty with his other MO.<br />

Which other branch expects’ officers with 18 -19 year of<br />

service to be on 24 hrs call duty every alternate day and<br />

expect error, free prompt response round the clock. Yes<br />

COs, COOs … are on call everyday but they do not have<br />

to respond every time, they do not have to wake up in the<br />

middle of the night every alternate day, change and come<br />

to the working place and perform at their peak. No other<br />

branch can compare to the STRESS the DOC goes through<br />

and believe you me, as we age, all this gets more and more<br />

difficult; sleep once disturbed gets lighter - less refreshing<br />

adding to your physical and mental well being.<br />

Research has also documented that sleep of<br />

physicians on call is less ‘sound’, given the constant<br />

expectancy of a call in the might. The difference between<br />

medical and other branches is that while you switch off<br />

for the day, or for the weekend once you pack up from<br />

office, a medical officer could well be starting the second<br />

half of his working day. A lot of my seniors sitting at higher<br />

echelons may take a high moral ground- what’s wrong in<br />

senior SMO doing DMO duties- after all that is our primary<br />

work. I do not agree with this moralistic sermon.<br />

This was only the medical officer’s stress. Does it<br />

affect the family? When the phone rings up in the night<br />

at 0400 hrs it’s your wife who possibly shakes you up to<br />

tell you that it is a call from the SMC. It used to be the call<br />

bell at home in the early days with no telephones. Does<br />

your baby in arm get up when the phone rings? Duties<br />

are so busy that you start sleeping in the other room less<br />

your infant wakes up and then disturbs the already tired<br />

mother. STRESS? Does anyone else face this situation?<br />

No.<br />

Let’s talk of office life! Medical Service is only a support<br />

service and the only one that is internally dependant for<br />

everything on everyone-starting from office table, table<br />

cloth (blazer cloth not authorised), glass top (gone are<br />

the days-again not authorised), curtains, office chair, pen<br />

stand, pen, pencil. Nothing that you control! At every base<br />

you start from ground zero for all these things. Lets talk<br />

of stationary –A4 paper, Computer paper, to computer,<br />

from cup saucers, glasses to trays from cleaning material<br />

to paint – it is an end less struggle-demanding – N/A or<br />

partial supply and then resorting to personal request, or<br />

the famous approach of give and take.<br />

On a bigger front let’s talk of vehicle. What does the<br />

DMO get? Gypsy ambulance – a Flt Lt may get a Swaraj<br />

Mazda ambulance! A young Flt Lt holding a portfolio may<br />

well be driving a reasonably good Gypsy or Sumo. Leave<br />

alone the Flt Lt or DMO, what about the SMO, in my 23<br />

years of service till now , I have yet to see a SMO driving<br />

20 Flight Safety F e b r u a r y 2 0 10<br />

INDIAN AIR FORCE

The question will be asked, what<br />

about Preflight Medicals or medical<br />

cover during afternoon/ evening<br />

flying. That can be arranged between<br />

the MO/ SMO. The whole concept<br />

of preflight medicals itself needs an<br />

honest introspection. Similarly, if the<br />

MO from a single MO Unit goes on<br />

leave, and there is a local hospital<br />

available in the civil, the unit should<br />

accept medical care without the MO<br />

for short durations. Such a paradigm<br />

change in our approach could bring<br />

much needed relief.<br />

a Gypsy which could have been considered good to be<br />

offered to any Sqn Cdr, or Branch head, leave alone other<br />

small Section Cdrs. This STRESS is unique only to the<br />

Medical Branch.<br />

Let’s talk of some solutions.<br />

Why should a Medical officer be on DMO duty at an<br />

SMC when military hospital is located at 10, 15 or even<br />

20 minute driving distance. Why couldn’t the patients<br />

be seen at the SMC by the Duty Medical Asst, and those<br />

requiring the attention of Medical officer be seen at the<br />

Hospital. Such a system has many feasible benefits. Two<br />

Med offrs at a base doing alternate DMO duties will no<br />

longer be ‘stressed’, as they will share DMO duties in the<br />

hospital with a larger MO pool. No doubt, the DMO will<br />

be busy in the hospital, but then in turn will enhance<br />

his skills and experience. The question will be asked,<br />

what about Preflight Medicals or Medical cover during<br />

afternoon/ evening flying. That can be arranged between<br />

the MO/ SMO. The whole concept of preflight medicals<br />

itself needs an honest introspection. Similarly, if the MO<br />

from a single MO unit goes on leave, and there is a local<br />

hospital available in the civil, the unit should accept<br />

medical care without the MO for short durations. Such<br />

a paradigm change in our approach could bring much<br />

needed relief. After all, what happens in big metros like<br />

Bangalore and Delhi. There is no 24x7 MO in colonies like<br />

MP Camp, Akash Vihar, Vishwa Vihar in Bangalore, similar<br />

may be the case in Shankar Vihar in Delhi. They all go to<br />

Command Hospital/ Base Hospital and the driving time<br />

could well be 30-40 minutes.<br />

Other baby steps in this direction.<br />

Lets make the SMO/Medical a group head at the field<br />

level, a PSO at the Command and Air Headquarters level.<br />

A lot of things that do cause stress will automatically fall<br />

into place. Sounds a tough one! All changes appear tough<br />

when first proposed.<br />

Does this all make sense? Did you ever think or<br />

visualize the other side of life of a Medical officer?<br />

Possibly not! Let’s take small steps in this direction.<br />

These small steps will then chart a path that will possibly<br />

minimize working stress in the Medical branch without<br />

compromising patient care in the AF.<br />

Gp Capt Narinder Taneja (Med) is posted to 20 Wing AF.<br />

A weather forecast of 1934<br />

“Dust and or thunderstorm with<br />

or without percipitations likely,<br />

occasionally, temporarily and locally in<br />

your area”.<br />

- From “Birth of an Air Force”<br />

Memoirs of the late AVM Harjinder Singh.<br />

INDIAN AIR FORCE 2 01 0 F e b r u a r y Flight Safety 21

Wg Cdr A Mudgal<br />

THIS incident happened with me in the year 2003<br />

when I was posted to Halwara. A fighter formation<br />

was visiting my base for an operational commitment.<br />

The weather during winters at this time of the year in the<br />

entire Punjab belt is generally bad with poor visibility and<br />

low clouds and this day was no exception. The departure<br />

from the launch base kept getting delayed due to marginal<br />

weather. Finally, the formation got airborne in the late<br />

afternoon hours amidst low clouds and poor visibility.<br />

We were eagerly waiting for the formation’s arrival. I was<br />

in the GCA (Ground Control Approach) looking out for<br />

the formation on the SRE. The radarscope was filled with<br />

weather clutter. The enroute and base weather was bad<br />

with lot of low clouds and poor visibility.<br />

Soon, the formation leader established R/T contact<br />

with the SRE and asked for descent from their cruising<br />

level to 02 kms. I requested for the inbound distance,<br />

as I could not see the ac blips. The leader informed me<br />

that they were 45 miles inbound. I looked for the blips in<br />

the expected direction correlating with the homing but<br />

could not see any. Considering the prevailing weather,<br />

I could not clear the descent and accordingly informed<br />

the leader. After a while, there was another call from the<br />

formation that the distance was 35 miles with a request<br />

for descent. In the absence of a pick up on the radar, I<br />

cleared the descent but restricted it to a safe level.<br />

The performance of the radar was proven. Two-way<br />

R/T contact with the formation meant that they were<br />

within the radar range, however, we were unable to<br />

pick them up on our scope. Soon there was another call<br />

requesting for further descent at an inbound distance of<br />

25 miles. This made me restless. In the absence of a pick<br />

up at that altitude and distance, I started suspecting the<br />

equipment. I once again declined the request for further<br />

descent. I am sure, this must have made the formation<br />

pilots restless and irritated which was evident by their<br />

language like ‘Is your radar working, Do you have DRDF,<br />

and so on”. The formation leader insisted that his distance<br />

was accurate and shortly they will be overhead.<br />

Now, I was losing confidence on myself and on the<br />

equipment. This manifested in my shouting at the radar<br />

technicians. We tried all possible combinations for best<br />

pickup but somehow were unsuccessful in tracking the<br />

formation ac. In the given circumstances, I perforce had to<br />

deny them further descent. I had almost given up on the<br />

22 Flight Safety F e b r u a r y 2 0 10<br />

INDIAN AIR FORCE

“<br />

Soon there was another call requesting for further<br />

descent at an inbound distance of 25 miles. This made<br />

me restless. In the absence of a pick up at that altitude<br />

and distance, I started suspecting the equipment. I<br />

once again declined the request for further descent.<br />

“<br />

situation and wished the pilots would not call up again.<br />

Suddenly, I saw blips south of base on the radarscope.<br />

This boosted my confidence and I asked the formation<br />

to turn to a particular heading for positive identification.<br />

As soon as I saw the initiation of the formation’s turn, I<br />

felt greatly relieved. I informed the formation that the<br />

distance was now 45 miles and cleared them for further<br />

descent. Thereafter, the ac were recovered smoothly at<br />

our base. I wonder what would have happened if the<br />

formation would not have been picked up in marginal<br />

weather on the radar that day. Though a small incident,<br />

some valuable lessons can be derived out of it.<br />

equipment and more so in difficult times like weather or<br />

external pressures from the air traffic.<br />

Rules and procedures must be followed meticulously.<br />

Never succumb to pressures internal or external, as it can<br />

precipitate in a totally unwarranted situation.<br />

Discuss such incidents without bothering about<br />

rank and appointment, pride and ego for own and others<br />

professional improvement.<br />

Wg Cdr A Mudgal Adm/ATC is posted to 45 Wing AF.<br />

Lessons learnt<br />

I wonder if the CRM of the formation had functioned<br />

efficiently. I could not understand why no one piped<br />

up in the air with actual bearing and distance from the<br />

base. Bad weather could have become a catalyst for an<br />

altogether different outcome.<br />

Anyone can make mistake irrespective of experience.<br />

One must acknowledge his/her mistake and take<br />

corrective actions to avoid recurrence.<br />

A doctor giving prescription to<br />

patient ‘Let me know if this stuff<br />

works.‛ I ‘m having the same trouble<br />

myself !<br />

Safety Journal Febuary 1978<br />

<br />

For all radar controllers. Have faith on your<br />

INDIAN AIR FORCE 2 01 0 F e b r u a r y Flight Safety 23

ON 26 Mar 2009, Wg Cdr Ajay Koul (19960-L) F(P) was authorized to fly a bird reccee and<br />

handling sortie on a microlight aircraft. During the sortie, the pilot experienced increasing<br />

engine vibrations at 60 Kts. He reduced throttle and commenced a left turn towards base. The<br />

engine vibrations reduced to 2000 RPM. After ensuring engine parameters within limits, he<br />

smoothly opened power to 3500 RPM. At this stage, there was a mild bang and engine RPM<br />

dropped to zero. He immediately selected a force landing field and landed the aircraft safely on a<br />

rocky terrain with minimal damage to the aircraft. He immediately alerted the Air Traffic Services<br />

and guided the search and rescue helicopter to the accident site.<br />

Wg Cdr A Koul displayed a keen sense of observation, exceptional flying skills in emergency<br />

and recovered the aircraft with minimum damage.<br />

Good Show Wg Cdr Ajay Kaul<br />

(TP Singh)<br />

Air Cmde<br />

PDFS<br />

ON 25 Sep 09, Sqn Ldr G Kumar (26697-R) F(P) was detailed to fly as captain of Sarang 4 with<br />

Sqn Ldr S Bhopi (27221-R) F(P) as co-pilot on the Sarang Display.<br />

During the profile, the four helicopters were positioned in opposite pairs heading towards<br />

each other for the Synchro cross. For this manoeuvre Sarang 4 formates abeam Sarang 2<br />

and crossed between Sarang 1 and Sarang 3. While running in for the manoeuvre, Sarang 4<br />

experienced severe vertical oscillations. The amplitude of the oscillations was initially divergent<br />

and subsided later. The crew displayed an excellent presence of mind, despite the fact that other<br />

helicopters were coming head on and gave a prompt call for the formation to break up. The crew<br />

controlled the aircraft and landed safely.<br />

Sqn Ldr G Kumar and Sqn Ldr S Bhopi displayed an extremely high degree of situational<br />

awareness and averted a possible disastrous situation.<br />

Good Show Sqn Ldr G Kumar & Sqn Ldr S Bhopi<br />

(TP Singh)<br />

Air Cmde<br />

PDFS<br />

28 Flight Safety F e b r u a r y 2 0 10<br />

INDIAN AIR FORCE

O N 20 29 Apr Jul 09, 09, Flt 769828-T Lt Sandeep Sgt Sunil Shetty Kumar Adm/ATC Eng Fit was was detailed detailed as a to radar see off controller. the aircraft A formation No U-2165<br />

during of two night Mig-21 flying. aircraft The was aircraft planned. could The not pair start got and airborne cold cranking and changed also failed. over After to SU. giving The<br />

N2 visibility stop, he in checked the LFA the was condition 4000 meters of jet in pipe dust and haze. noticed The Radar flame controller inside jet pipe. observed Immediately a weather fire<br />

spread patch very on radar fast and scope started north engulfing of base at rear approximately fuselage area 30 and NM. the As fire SRE was is brought not meant under to detect control<br />

due weather, to alertness a patch of appears the individual. when weather is severe. He quickly informed about weather. He kept<br />

a close watch on the movement of weather. Within a few minutes, he realized that the patch<br />

might Sgt hit Sunil the Kumar base. He displayed immediately a high informed degree of the professionalism formation on and R/T his and prompt instructed action them further to<br />

helped rejoin. in Eventually, controlling both fire the without aircrafts any landed damage safely. to aircraft and service property.<br />

Flt Lt Shetty displayed a proactive approach and situational awareness, that resulted in a<br />

controlled timely recovery of the formation.<br />

Good Show Sgt Sunil Kumar<br />

Good Show Flt Lt SandeepShetty<br />

(TP Singh)<br />

Air Cmde<br />

PDFS<br />

O N 18 13 May Sep 09, 08, 767262-G Sqn Ldr Rosha Sgt Anand (24241) Singh F(P) was Engine authorized Fitter was detailed a supervisor to carry for an out instrument FFS on a<br />

flying Mi-35 sortie. at Goma, During Democratic the execution Republic of a Congo. turn on During instruments, FFS, the airwarrior the main hydraulic observed a failure steel<br />

warning pin of 10mm light X came 4mm ‘ON”. dia lying He under realized the the firewall gravity between of the the emergency engines. and He reported aborted the matter exercise to<br />

immediately. WO i/c Engine He Section. co-ordinated Subsequent the actions investigations by his other revealed crew that members the IOD for was an the immediate locating dowel visual<br />

descent, pin ( inserted direct between finals and the landing air starter at the body airfield. and flange A safe of landing the oil was level carried check pipe). out using Had standby the pin<br />

hydraulic gone undetected, system and it could without have the lodged autopilot. itself Post on the flight V/IGU inspection actuating revealed rings of hydraulic the engine, fluid causing on the<br />

MG serious bed. problems The main to hydraulic the engine fluid power. tank was empty.<br />

Sqn Sgt Ldr Anand Rosha Singh’s displayed keen sense a high of degree observation, of situational professional awareness, competence prompt and decision diligence making to<br />

and duty professional prevented a handling possible of accident/ the emergency incident. and averted a potentially hazardous situation.<br />

Good Good Show Show Sgt Sqn Anand Ldr Rosha Singh<br />

(TP Singh)<br />

Air Cmde<br />

PDFS<br />

INDIAN AIR FORCE 2 01 0 F e b r u a r y Flight Safety<br />

29

ON 06 Sep 09, Sqn Ldr KPS Dham (24514-R) F(P) was authorized to fly a Bison aircraft as a<br />

CAP in 4 + 3 Vs 3 mission. The aircraft was in 3 D/T configuration and also modified with<br />

SPP system (Anti Surge System). During initial engagement at an altitude of 3.5 KM on pressing<br />

missile firing button he experienced loss of thrust. On checking engine parameters, he noticed<br />

RPM winding down to flight idle and then again building up to 100% after a delay of 6 seconds<br />

with throttle lever stationary at full dry power. He also noticed ignition light illuminated on the<br />

failure warning panel. The sequence of RPM dropping and then rising again repeated. The pilot<br />

correctly identified this as a malfunction of Anti Surge System and promptly switched off the Anti<br />

Surge CB. He called off the mission and recovered the aircraft safely on priority.<br />

Sqn Ldr KPS Dham, despite his limited experience on type, displayed a keen sense of<br />

observation and a high degree of professionalism in preventing a possible incident/accident.<br />

Well Done Sqn Ldr KPS Dham<br />

(TP Singh)<br />

Air Cmde<br />

PDFS<br />

ON 30 Aug 09, Flt Lt Ankur Singh (28776A) Adm/ATC was detailed to activate ATC with an aim<br />

to recover a lost Cessna-152 aircraft which was low on fuel around at Hakimpet airfield. He<br />

tried to contact the aircraft on various channels. Finally, he could make a two way R/T contact<br />

when the aircraft was approx 15 NM east of Hakimpet. On airport radar inputs, the DATCO<br />

passed the pin-point to the pilot. At 2-3 NM from the airfield the pilot reported engine failure.<br />

While the pilot was looking for a force landing field the engine re-started and subsequently, on<br />

appropriate guidance from the controller, the pilot was able to spot the runway and make a safe<br />

landing with negligible fuel.<br />

Flt Lt Ankur Singh displayed a great dedication to duty and a high degree of professionalism<br />

in averting an accident / incident.<br />

Well Done Flt Lt Ankur Singh<br />

(TP Singh)<br />

Air Cmde<br />

PDFS<br />

30 Flight Safety F e b r u a r y 2 0 10<br />

INDIAN AIR FORCE

O N Feb 04 Aug 09, 766124-S 09, 913424-L Sgt LAC PR Prasad G Singh was Struct detailed Fit was to take detailed up structural as a take repair off inspector on a MiG-27 for night ML<br />