Biofuel Co-Products as Livestock Feed

Biofuel Co-Products as Livestock Feed

Biofuel Co-Products as Livestock Feed

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

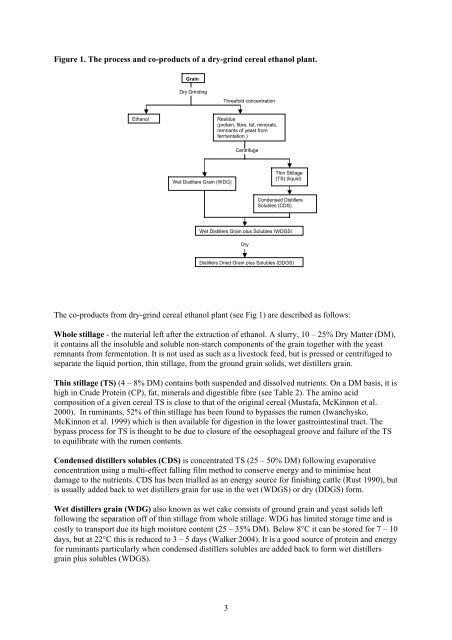

Figure 1. The process and co-products of a dry-grind cereal ethanol plant.<br />

Grain<br />

Dry Grinding<br />

Threefold concentration<br />

Ethanol<br />

Residue<br />

(protein, fibre, fat, minerals,<br />

remnants of ye<strong>as</strong>t from<br />

fermentation )<br />

Centrifuge<br />

Wet Distillers Grain (WDG)<br />

Thin Stillage<br />

(TS) (liquid)<br />

<strong>Co</strong>ndensed Distillers<br />

Solubles (CDS)<br />

Wet Distillers Grain plus Solubles (WDGS)<br />

Dry<br />

Distillers Dried Grain plus Solubles (DDGS)<br />

The co-products from dry-grind cereal ethanol plant (see Fig 1) are described <strong>as</strong> follows:<br />

Whole stillage - the material left after the extraction of ethanol. A slurry, 10 – 25% Dry Matter (DM),<br />

it contains all the insoluble and soluble non-starch components of the grain together with the ye<strong>as</strong>t<br />

remnants from fermentation. It is not used <strong>as</strong> such <strong>as</strong> a livestock feed, but is pressed or centrifuged to<br />

separate the liquid portion, thin stillage, from the ground grain solids, wet distillers grain.<br />

Thin stillage (TS) (4 – 8% DM) contains both suspended and dissolved nutrients. On a DM b<strong>as</strong>is, it is<br />

high in Crude Protein (CP), fat, minerals and digestible fibre (see Table 2). The amino acid<br />

composition of a given cereal TS is close to that of the original cereal (Mustafa, McKinnon et al.<br />

2000). In ruminants, 52% of thin stillage h<strong>as</strong> been found to byp<strong>as</strong>ses the rumen (Iwanchysko,<br />

McKinnon et al. 1999) which is then available for digestion in the lower g<strong>as</strong>trointestinal tract. The<br />

byp<strong>as</strong>s process for TS is thought to be due to closure of the oesophageal groove and failure of the TS<br />

to equilibrate with the rumen contents.<br />

<strong>Co</strong>ndensed distillers solubles (CDS) is concentrated TS (25 – 50% DM) following evaporative<br />

concentration using a multi-effect falling film method to conserve energy and to minimise heat<br />

damage to the nutrients. CDS h<strong>as</strong> been trialled <strong>as</strong> an energy source for finishing cattle (Rust 1990), but<br />

is usually added back to wet distillers grain for use in the wet (WDGS) or dry (DDGS) form.<br />

Wet distillers grain (WDG) also known <strong>as</strong> wet cake consists of ground grain and ye<strong>as</strong>t solids left<br />

following the separation off of thin stillage from whole stillage. WDG h<strong>as</strong> limited storage time and is<br />

costly to transport due its high moisture content (25 – 35% DM). Below 8°C it can be stored for 7 – 10<br />

days, but at 22°C this is reduced to 3 – 5 days (Walker 2004). It is a good source of protein and energy<br />

for ruminants particularly when condensed distillers solubles are added back to form wet distillers<br />

grain plus solubles (WDGS).<br />

3