August Cooling pdf - Narsa

August Cooling pdf - Narsa

August Cooling pdf - Narsa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

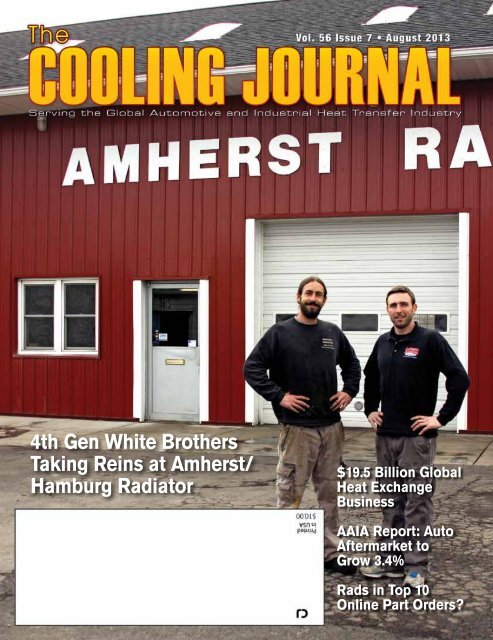

4th Gen White Brothers<br />

Taking Reins at Amherst/<br />

Hamburg Radiator<br />

$19.5 Billion Global<br />

Heat Exchange<br />

Business<br />

AAIA Report: Auto<br />

Aftermarket to<br />

Grow 3.4%<br />

Rads in Top 10<br />

Online Part Orders?

IN THIS MONTH’S… <strong>August</strong> 2013 • Vol. 56 issue 7<br />

EDITORIAL Staff<br />

Wayne Juchno, CAE<br />

Editor<br />

wjuchno@narsa.org<br />

Contributing Editors<br />

Thomas Coleman<br />

Doug Shymoniak<br />

Graphic Design<br />

Lucy Matyjaszczyk<br />

NARSA Officers<br />

Maarten Taal<br />

Chairman of the Board of Directors<br />

Patrick (Pat) O’Connor<br />

President<br />

<strong>Cooling</strong> Journal/NARSA<br />

3000 Village Run Rd.<br />

Ste 103, #221<br />

Wexford, PA 15090-6315 USA<br />

Phone: 724.799.8415<br />

Fax: 724.799.8416<br />

info@narsa.org<br />

www.narsa.org<br />

Printing<br />

Modern Litho<br />

Advertising<br />

Doug Shymoniak<br />

Sales and Business Development<br />

724-799-8415<br />

dshymoniak@narsa.org<br />

The <strong>Cooling</strong> Journal (CJ) is the official<br />

publication of NARSA – The International<br />

Heat Transfer Association. Material published<br />

in the <strong>Cooling</strong> Journal does not necessarily<br />

express the views of NARSA. Every attempt<br />

has been made to ensure the accuracy<br />

of the content of the publication. NARSA,<br />

however, will not be responsible for the<br />

accuracy of information published, nor<br />

will it be liable in any way for injury, labor,<br />

parts or other expenses resulting from use<br />

of information appearing in the <strong>Cooling</strong><br />

Journal. Publication of products, services,<br />

techniques, organizations, and firms does not<br />

constitute an endorsement of NARSA.<br />

The<br />

COOLING JOURNAL<br />

Features<br />

NARSA News<br />

HD Conference Details.............................................. 3<br />

Feature<br />

Heat Transfer Pavilion List at AAPEX ........................ 8<br />

Report on State of Logistics..................................... 20<br />

ATA Forecasts Trucking Growth............................... 22<br />

HEAVY DUTY<br />

Clean Diesels Make Up 1/4 of USA Fleet............... 18<br />

EPA Reports on Diesel Programs............................. 19<br />

DEPARTMENTS<br />

President’s Message........................................................ 2<br />

Today’s Special................................................................ 6<br />

Automotive..................................................................... 23<br />

For Release............................................................... 24, 26<br />

Classified......................................................................... 27<br />

Ad Index........................................................................ 27<br />

The Point........................................................................ 28<br />

Cover Photo:<br />

© iStockphoto/shaunll<br />

The <strong>Cooling</strong> Journal is published ten times<br />

yearly by NARSA and is sent to businesses<br />

engaged in the automotive, heavy<br />

equipment, trucking, and industrial heat<br />

exchange industries. In the USA single issues<br />

cost $10.00 and a one-year subscription is $75.<br />

Overseas subscriptions are available for $155<br />

per year.<br />

©NARSA – The International Heat Transfer<br />

Association, 2013<br />

1<br />

the cooling the cooling journal journal • august • august 2013 2013 1

President’s Message<br />

A Guide: How to Survive Life’s<br />

Unexpected Changes – The Merits of<br />

Building Your Own Personal Network<br />

Have you ever wondered how you arrived<br />

at this point in your life? What decisions<br />

made ten, 20, or even 30 years ago have<br />

had a direct impact on your career?<br />

Most of us start out young, ambitious<br />

and alone with very high expectations for<br />

a successful professional work life. Most<br />

of us have a desire for an above average<br />

earned income. Of course there are some<br />

starts and stops, career path changes, business<br />

changes. Let’s not forget some of<br />

those other very important trajectory<br />

changers like marriage and the blessings<br />

of children, grandchildren, and for some<br />

of us great grandchildren.<br />

Changes in our professional and personal<br />

lives are inevitable. Some life-partners<br />

turn out not to be true life-partners.<br />

Jobs change, companies change focus and<br />

direction. Other companies fold, some<br />

consolidate, and others are sold. The results<br />

are not pretty and often leave disillusioned<br />

employees in the wake of all of<br />

the sudden and unexpected change.<br />

When one suddenly becomes unemployed<br />

after ten, 20, or 30 years in the<br />

workforce, the next six months to a few<br />

years can be a very difficult period to survive.<br />

Making things comparable or even<br />

better seems way beyond reach.<br />

Associations benefit society in many<br />

ways, providing forums for like-minded<br />

people with common goals and allowing<br />

them to accomplish the mission of the<br />

group and promote growth and prosperity<br />

for their chosen business or profession.<br />

This is exactly what NARSA has done for<br />

the heat exchange business in the past and<br />

as it continues to evolve.<br />

Membership and involvement have<br />

been instrumental for those who work in<br />

the industry as business owners, employees<br />

and potential employees. These industry<br />

connections can be invaluable to the<br />

second and third generations of family<br />

members as they assume responsibility for<br />

the management of the family business<br />

after the original owners retire.<br />

It is never too late to build your own<br />

personal network and your contacts. If<br />

you have been networking within your<br />

industry and also in outside interests, both<br />

personal and civic, please continue to do<br />

so. No one is guaranteed a secure work<br />

future in their current position or even in a<br />

recession free economy where we all pretty<br />

much prosper and grow.<br />

Where to start? A logical starting point<br />

is to become a member of the industry<br />

association that represents your livelihood.<br />

Be active and involved, the more that you<br />

participate, the more opportunities you<br />

have to add contacts to your personal network.<br />

These connections can be invaluable<br />

to you when and if that terrible day<br />

arrives when you receive a termination<br />

notice due to no fault of your own.<br />

Does this personal networking always<br />

work? Well, not always, but more often<br />

than not, it does work and can enable you<br />

to move on, enabling you to provide for<br />

yourself and your family.<br />

Your personal network can serve as a<br />

great support system while you work towards<br />

finding your next opportunity. I<br />

speak from experience. I moved into our<br />

heat transfer industry back in 1985.<br />

Through my own network, I transitioned<br />

from automotive service and repair to the<br />

radiator and heater manufacturing sales area<br />

when I joined Fedders Automotive Radiator<br />

Mfg. Co, later to become FEDCO.<br />

Networking within my sales position<br />

for one year at Fedders, I was able to gain<br />

a national sales manager position with<br />

Detroit Radiator for two years and then<br />

returned to FEDCO in a national sales<br />

management position. This was possible<br />

from my networking during my tenure in<br />

the automotive parts industry.<br />

Thirteen years later, an unexpected sale<br />

of the company affected me once again.<br />

For the next five years I operated my<br />

own sales and consulting LLC serving<br />

many of the companies and individuals<br />

that I had been networking with for over<br />

Patrick (Pat) O’Connor<br />

NARSA President<br />

2012-2014<br />

twenty years. In 2007, my fortunes<br />

changed for the better once again as I was<br />

asked by Larry LePrevost, Executive Vice<br />

President at Johnson Mfg. Co. Inc. to<br />

work for Johnson as the Vice President<br />

Sales and Marketing for their newly acquired<br />

company, the S.A. Day Mfg. Co.<br />

located right here in my hometown of<br />

Buffalo, New York.<br />

Life and our travels can be very unpredictable.<br />

However, you can prepare yourself<br />

not only to survive and move on from<br />

an unexpected change – but to prosper and<br />

better your life. This networking and contact<br />

building strategy works in all industries<br />

and professions.<br />

You just have to make the positive decision<br />

to become a member in your industry<br />

association, be proactive, and work<br />

toward the common goals that will mean<br />

personal success for yourself and your<br />

family. Keep in mind that your<br />

Association network building also has a<br />

primary and positive effect on your business<br />

and employer.<br />

So, remember, maintain your NARSA<br />

membership, become involved, build your<br />

contacts through networking through<br />

NARSA and you will be as prepared as<br />

you can be to face whatever comes your<br />

way. Want to add a contact today? Call or<br />

email me today, we can learn from each<br />

other. Email: pat.oconnor@johnsonmfg.<br />

com, cell: 716-316-4710, or Linkedin.<br />

2 the cooling journal • august 2013

Board Bolsters Trademark and Logo Use Policy<br />

BUFFALO, N. Y. – At its most recent<br />

meeting, the NARSA Board of Directors<br />

shored up the organization’s policy on use<br />

of NARSA logos and trademarks. The<br />

move was made to preserve the integrity<br />

of the Association’s trademark property<br />

and to protect member rights for the intended<br />

use of those properties.<br />

According to policy effective July 1,<br />

2013, NARSA grants members in good<br />

standing the right to use NARSA’s trade<br />

names, trademarks, logos, and designations<br />

in their marketing, advertising and<br />

promotion. However there are several<br />

stipulations.<br />

Prior to using any of the marks, members<br />

are asked to supply to NARSA samples<br />

of any intended use or promotional<br />

materials for the purposes of inspection<br />

and written approval and to determine if<br />

the usage meets the standards of quality<br />

acceptable to NARSA. NARSA shall<br />

promptly review such materials and approve<br />

or disapprove them. It is important<br />

that any use does include that the firm or<br />

business identifies itself as a member of<br />

NARSA and not that it is the organization<br />

itself. Suggested terms would “member<br />

of,” “proud member of,” or “supporter of.”<br />

The new policy also reinforces that<br />

NARSA retains the sole and exclusive ownership<br />

of the trademarks (whether registered<br />

or not), and any abbreviations, and all goodwill<br />

and rights related to them. All members<br />

must understand that nothing in the<br />

policy confers any proprietary rights upon<br />

them with respect to the trademarks other<br />

than the certain and defined rights for use.<br />

Members may use the trademarks that<br />

are registered accompanied with the symbol<br />

“®” and all use of the trademarks that<br />

are not registered shall be accompanied<br />

with the symbol “TM” or “SM” as appropriate.<br />

Upon the expiration or termination of<br />

membership, the member must cease all<br />

NARSA News<br />

display, advertising, and use of all NARSA<br />

names, marks, logos, and designations, and<br />

will not thereafter use, advertise, or display<br />

any name, mark, or logo which is, or any<br />

part of which is, similar to or confusing<br />

with any such designation associated with<br />

any products. For a complete download of<br />

the policy go to: www.narsa.org.<br />

the cooling journal • august 2013<br />

3

*Compiled by the staff and members of NARSA<br />

NARSA News<br />

Register Now for the 4 th Annual HD<br />

Conference<br />

Book your rooms today and make your<br />

travel plans for the 4th Annual NARSA<br />

HD Heating and <strong>Cooling</strong> Conference. The<br />

Doubletree by Hilton Bloomington has<br />

been selected as the hotel for the 2013 HD<br />

Heating and <strong>Cooling</strong> Conference,<br />

September 12 to 14.<br />

Conference Activities<br />

The HD Conference will include: committee<br />

meetings, educational sessions, table<br />

top exhibits with reception on Thursday,<br />

September 12. Program content will cover<br />

soldering, brazing, airflow and fans for<br />

cooling systems, metal characteristics and<br />

alloys used in HD heat exchange, HD cooling<br />

options and technologies, and more.<br />

Conference features for 2013 include:<br />

• shorter sessions<br />

• more networking opportunities<br />

• breakfast included with hotel room<br />

• special immersion tour at Maas<br />

Radiator and Powder Coating Unlimited<br />

• Friday evening BBQ<br />

• virtual tour of Businesses from Around<br />

the World<br />

• optional Saturday activities including<br />

HD Technician Certification Testing,<br />

self tour of Caterpillar Visitor Center,<br />

or golf.<br />

Conference Sponsors<br />

Sponsors to date include: Platinum Level<br />

- ThermaSys Tubing-An API Heat<br />

Transfer Company; Silver Level - Johnson<br />

Mfg. Co. S.A. Day Buffalo Flux Facility;<br />

Bronze Level - AccuTech.<br />

Hotel Information<br />

Room rates at the Doubletree by Hilton<br />

Bloomington are $129 per night plus tax<br />

(includes breakfast). Hotel can be reached<br />

at 309-664-6446 and tell them you are<br />

with the NARSA HD Conference to get<br />

the NARSA room rate. You may also book<br />

online at www.narsa.org.<br />

Get Your News<br />

Out with the Press<br />

Release Benefit<br />

WEXFORD, PA – Good news! If you<br />

have news that you want to share with your<br />

local press, post at your website or send to<br />

national and international trade publications<br />

and organizations, then the new<br />

NARSA press release benefit is for you.<br />

Beginning this fiscal year, all<br />

NARSA members will have access to<br />

press release writing services for two<br />

press releases annually. Press releases<br />

can be about personnel, product and service<br />

additions, new brand management,<br />

company milestones, etc.<br />

If you have news that you want to<br />

make public with a professionally written<br />

release, send an email to wjuchno@narsa.<br />

org and include PR in the subject line.<br />

Virtual Industry Tour<br />

A unique opportunity for free promotion<br />

for your company and its products and<br />

services will also be available. Take a few<br />

minutes to make sure you are included in<br />

the virtual tour Industry Showcase at the<br />

2013 NARSA HD Heating and <strong>Cooling</strong><br />

Conference. Submit up to 10 pictures of<br />

your company to info@dbssquotes.com.<br />

There are people in this industry that are<br />

looking for you so be sure to give them<br />

the opportunity to see the all the highlights<br />

your company has to offer.<br />

HD Technician Certification<br />

Use your time at the<br />

NARSA HD Heating<br />

and <strong>Cooling</strong><br />

Conference to get HD<br />

Technician<br />

Certification. A special<br />

class has been scheduled<br />

for Saturday morning,<br />

September 14. The<br />

NARSA Heat Transfer<br />

Pavilion Correction<br />

Our Pavilion listing in the July issue for<br />

ThermaSys Tubing, an API Heat<br />

Transfer Company was incorrect. Please<br />

note the correct contact information and<br />

location. We apologize for any confusion<br />

or inconvenience.<br />

ThermaSys Tubing, an API Heat<br />

Transfer Company<br />

Booth# 5305<br />

2760 Gunter Park Drive West<br />

Montgomery, AL 36109<br />

T 334-420-7043<br />

F 334-420-7154<br />

www.apiheattransfer.com<br />

NARSA Heavy Duty<br />

Technician Certification<br />

Overhaul Procedures for Heavy Duty<br />

Radiators: A Study Guide<br />

class and test will run from 9 a.m. until<br />

noon. Cost for certification test and class<br />

is only $39 per person for NARSA<br />

Members. For additional information, go<br />

to www.narsa.org.<br />

4 the cooling journal • august 2013

NARSA News<br />

NARSA Restoration Session<br />

Debuts at AAPEX<br />

LAS VEGAS – New for the convention this<br />

year will be a discussion group session on<br />

Wednesday, November 6 from 8:00 a.m. to<br />

10:00 a.m. at Harrah’s. Members and<br />

friends are invited to attend and participate<br />

in order to share information on antique and<br />

custom radiator restoration. Bring slide<br />

shows and photos of your achievements in<br />

the craft of antique radiator restoration and<br />

be willing to share your experience with<br />

your fellow craftsmen and women.<br />

Other NARSA activities will include the Annual Membership<br />

Breakfast, Seekins Cup Challenge Golf Outing and the <strong>Cooling</strong><br />

System Industry Customer Appreciation Reception. The<br />

Membership Breakfast and Seekins Cup Challenge will take<br />

place on Monday, November, 4 and the Customer Appreciation<br />

Reception will be held Tuesday, November 5.<br />

A block of rooms has been reserved at Harrah’s Las Vegas for<br />

$135 per night. Rooms can be booked by calling 888-458-8471<br />

and using Group Code: SHNAC3.<br />

Remember to register for AAPEX in advance to get the reduced<br />

rate badge fee and to avoid long lines in Vegas. It’s simple,<br />

go to www.appexshow.com.<br />

Charge Air Cooler<br />

Tester Kit<br />

Made in the<br />

USA<br />

NARSA Calendar of Events<br />

HD Conference<br />

Bloomington, IL<br />

September 12-14, 2013<br />

Great Lakes Truck Expo<br />

Cleveland, OH<br />

September 18-19, 2013<br />

NARSA Board of Directors<br />

Meeting<br />

Las Vegas<br />

Sunday, November 3, 2013<br />

Seekins Golf Challenge<br />

Presented by Johnson<br />

Mfg. Co.<br />

Tuscany Golf Course,<br />

Henderson, NV<br />

Monday, November 4, 2013<br />

<strong>Cooling</strong> System Customer<br />

Appreciation Reception<br />

Harrah’s Las Vegas, NV<br />

Tuesday Nov. 5, 2013<br />

NARSA Convention/<br />

AAPEX Show<br />

Harrah’s/Sands Expo, Las<br />

Vegas, NV<br />

November 4 – 7, 2013<br />

NARSA Management<br />

Seminar<br />

February 6-7, 2014<br />

EdTech Meeting<br />

March 1, 2014<br />

CON EXPO-CON AGG<br />

Las Vegas<br />

March 4-8, 2014<br />

MATS<br />

Louisville, KY<br />

March 27-29, 2014<br />

EdTEch Meeting<br />

May 3, 2014<br />

NARSA Board of Directors<br />

Meeting<br />

Pittsburgh, PA<br />

May 16, 17, 2014<br />

HD Conference, Houma, LA<br />

September11-13, 2014<br />

TM<br />

TM<br />

the cooling journal • august 2013<br />

5

Health Watch<br />

Talking Turkey - Solder Pot Safety<br />

“No, it’s cool man. I saw it on you tube.” “I don’t know Dude, it<br />

doesn’t seem safe.” “No worries, I’m a professional.” “You’re a<br />

professional Mechanic, not a Chef!” “Chill out. If it works in hot<br />

oil, it will work in the solder pot.” “I don’t think so; I still say<br />

deep frying a turkey in the solder pot is a bad idea!”<br />

We interrupt this incredibly silly dialog to interject some sanity.<br />

Cooking a turkey in the solder pot is not recommended! DO<br />

NOT try this at home! Or the shop! But, the comparison of a hot<br />

deep oil fryer and a header dip solder pot is not that far-fetched.<br />

Both will result in a golden brown skin on the bird, and both harbor<br />

a similar danger during use.<br />

First, the obvious problem. Solder, especially tin/lead, has<br />

health hazards associated with its use. By now we all know that<br />

lead (and to lesser degree) other metals (tin, copper and silver<br />

being common) are all hazardous to our health if we are excessively<br />

exposed via inhalation and/or ingestion. While none of us<br />

would think of eating solder cooked food, remember to keep food<br />

out of the work area and wash thoroughly before eating, smoking<br />

or going home for the day. Lead poisoning and Metal Fume<br />

Fever can result from excessive inhalation exposure. So in addition<br />

to not using the pot for fondue, we need to provide adequate<br />

exhaust to pull the fumes from the open surface of the solder pot,<br />

away from workers.<br />

The methodology of solder pot use presents its own set of<br />

dangers. Solder pots are generally set low to the ground with a<br />

large, open surface area. There low placement and open surface<br />

area allows tin headers to be lowered into the pot permitting the<br />

solder to seal the tube to header joints. The area in front of, and<br />

around the solder pot needs to be accessible. As a result, they<br />

6 the cooling journal • august 2013<br />

by Dave Brown, Johnson Mfg. Co.<br />

rarely have guard rails to protect workers. Here the danger is<br />

pretty obvious. A large, molten, surface area with easy access.<br />

Workers must be trained in the hazards and kept aware of the trip/<br />

fall danger into a 600°F hot tub. Signage and a properly followed<br />

methodology can help. We have all ‘splashed’ a drip or<br />

two of solder on our arms while working. It stings like crazy as<br />

the solder solidifies. The large heat sink capacity of solder pots<br />

means there will be no ‘solidifying’ – rather a burn that keeps on<br />

burning. Very dangerous.<br />

The last solder pot danger we will bring up here, is the one<br />

that has you asking “Where is he going with that stupid turkey<br />

cooking story?” The danger of a boiling water induced explosion.<br />

Water boils at 212°F, turning from liquid to steam. As the water<br />

turns to steam it expands very rapidly, that’s why bubbles form<br />

and rise to the top. Both a turkey fryer and a solder pot run well<br />

above that temperature. A fryer runs about 300 - 400°F, while a<br />

solder pot normally runs at least 600°F or above. If you rapidly<br />

submerge a water-logged turkey in a deep fryer the water will<br />

boil and rise violently to the surface. It will push the oil above<br />

the bubbles up and out of the way. Meaning, hot oil flying out of<br />

the kettle, all over you, and perhaps hitting the burner flame and<br />

igniting. There’s a Thanksgiving from Hell. The situation with a<br />

solder pot is identical except its molten solder being blasted all<br />

over you and everything around. It won’t ignite but that is the<br />

least of your troubles if it explodes.<br />

That is why flux coated headers are lowered slowly and at an<br />

angle into the molten solder. As it is slowly lowered, the flux<br />

(water) boils and can escape at the surface. Using an angled entry<br />

keeps moisture from being trapped as the header is lowered.<br />

Use of an apron, gloves and a face shield are strongly encouraged.<br />

Some popping and spattering may occur. The trick is to<br />

keep it controlled and away from the operator.<br />

The same method is promoted for a turkey. It is lowered<br />

slowly, allowing the water in the bird, to boil in a controlled fashion.<br />

In the deep fryer, NOT the solder pot! Stay Safe.<br />

About the author: Dave Brown has been a valued contributing<br />

editor to the <strong>Cooling</strong> Journal for a number of<br />

years. His insight and humorous writing style have been<br />

invaluable in carrying the very serious message of safety<br />

and health in and outside of the workplace to CJ readers.<br />

He is the chief engineer at Johnson Mfg. Co. where he administers<br />

the company’s health and safety programs in addition<br />

to his other duties. Johnson Mfg. Co. is a supplier of<br />

a variety of tools, materials and products for the service<br />

and manufacture of heat exchangers.<br />

NARSA Phone: 724.799.8415<br />

NARSA Fax: 724.799.8416<br />

Email: info@narsa.org

An LKQ Company<br />

877-rad-wOrK<br />

radiatOrwOrKS.COm<br />

eXtended liFe <br />

trUCK radiatOrS<br />

IndustrIal strength glass fiber polyamide resin<br />

composition tank material provides unsurpassed durability.<br />

heavIer gauge tubes reduce vibration and thermal<br />

expansion failure at the tube to header joints.<br />

thIcker heavy duty alumInIum headers with<br />

hardening additive reduces tube to header joint failures.<br />

aIr sIde header stIffenIng plate is added for<br />

additional durability.<br />

addItIonal staInless steel outer crImp strIps<br />

increase burst pressure by up to 40%.<br />

thIcker tank materIal in seating area virtually<br />

eliminates stress crack failure common in OE radiators.<br />

tabbed headers with extra deep tank seating area.<br />

sIde members protrude through the header and<br />

brazed in place to form a unibody which resists failure<br />

due to vibration or twisting of the core.<br />

heavy duty extruded tubes on the end rows<br />

extends the service life of the radiator.<br />

2 year limited warranty<br />

Over 80 mOdelS<br />

available

feature<br />

This Family Means Business – Four<br />

Generations in the Business and Counting<br />

BUFFALO, NY – Bursting with energy and reflecting a quiet confidence,<br />

Jesse White says for four generations they have done<br />

what they do for one primary reason. “We are in it for our family.”<br />

Jesse is the first among equals that represents the fourth generation<br />

radiator business that has its roots in this western New<br />

York metropolitan area. He is the spokesman. He is the face of<br />

the business. He is the master of the phones. However, he does<br />

so with the generous support and encouragement of his other<br />

family members including his grandmother Mary Wilson, his<br />

father David and mother, XXXX, and the other two members of<br />

the newest generation brothers Dan and Jody.<br />

The core of the business is much the same as it had been in the<br />

mid ‘80s; two service shop locations aligned with regional distribution.<br />

However, the Wilson and now the White family traditions<br />

are steeped in many other facets of the radiator industry.<br />

In speaking with Jesse White about today’s business conditions,<br />

you get an upbeat feeling about a young, driven entrepreneur<br />

who sees opportunities where others either fail to do so or<br />

do not have the energy and vision to pursue them.<br />

Amherst Radiator and Hamburg Radiator continue to operate<br />

under different names but they are joined together by the family<br />

that owns and operates them. Amherst is more automotive and<br />

distribution; Hamburg is more heavy duty.<br />

In order to understand the deep commitment Jesse and his brothers<br />

hold for family and this business, it helps to know something of<br />

the rich business heritage their predecessors provided them.<br />

Wilson’s Garage (and Radiators)<br />

In 1940, George D. Wilson Sr., a father of six girls and one boy,<br />

was working seasonally as a grain scooper to support his family.<br />

He looked around for opportunities and decided to open an automotive<br />

repair shop close to his home in Hamburg, New York.<br />

Wilson’s Garage was born.<br />

At the time, radiator work was very specialized as each repair<br />

or re-core was handcrafted. Whenever George needed radiators<br />

The Hamburg Radiator location is the HD and commercial center for the<br />

business. An adjacent building also provides additional space for product<br />

storage.<br />

repaired for Wilson’s Garage he had to travel to the only radiator<br />

shop in the area and that was in the city of Buffalo. That shop<br />

was Chimera Radiator that had been owned by Joe Chimera.<br />

In addition to radiator and heater repair, Chimera was also a<br />

distributor for G&O Mfg. Co., the New Haven, Connecticutbased<br />

manufacturer of radiator cores for automobiles and trucks.<br />

G&O’s heritage went back to WWI during which they supplied<br />

radiator and cores for the Mack Trucks used by the military.<br />

Over the years, G&O (Guggenheim and Oppe) was to be incorporated<br />

in the industry roll-up and consolidations that was to become<br />

Proliance. Today, Thermal Solutions Manufacturing<br />

(TSM) can claim lineage tied to G&O.<br />

Back in the ‘40s, radiator and heater cores were the staples<br />

of the aftermarket with re-cores handily done in a specialty<br />

radiator shop.<br />

After watching the men in the downtown shop at Chimera,<br />

George Wilson decided to try it himself. He bought what little<br />

equipment he could afford and find and had to build whatever<br />

else he needed by himself. In 1945, he opened the doors to<br />

Wilson Radiator.<br />

Pictured left to right are: Dan White, Rick Alvarez, Jesse White and Larry<br />

Hornberger. Amherst Radiator is the central location for much of the<br />

automotive and light duty work.<br />

Several repair bays in the main building house their automotive retail<br />

service operation and that includes general automotive service and A/C.<br />

8 the cooling journal • august 2013

EGR COOLERS<br />

OE QUALITY,<br />

PERFECT FIT<br />

BEHR HELLA SERVICE - THE EXPERTS IN THERMAL MANAGEMENT<br />

BHS is proud to announce its range<br />

of Exhaust Gas Recirculation (EGR)<br />

coolers for the ISX, ISM and ISB<br />

Cummins engines. These German<br />

made, OE quality EGRs are brand<br />

new and not re-manufactured.<br />

Coming from one of the leading<br />

thermal management producers<br />

in the world, these EGRs meet<br />

all the cooling specifications and<br />

emission standards. These products<br />

are available off the shelf<br />

for immediate delivery and come<br />

with all the necessary gaskets to<br />

professionally replace each unit.<br />

For more information on our<br />

EGRs please contact one of our<br />

distributors for your needs.<br />

HELLA, Inc,<br />

1.877.224.3552<br />

www.hellahd.com<br />

www.hellausa.com<br />

the cooling journal • august 2013<br />

9

feature<br />

The only photo available of family<br />

patriarch and the business founder<br />

George Wilson Sr. is a photo of a<br />

photo.<br />

Another photo of a photo shows the original shop<br />

location. The Hamburg Radiator location sits across the<br />

street from the original site.<br />

Jesse White is not one to complain about what may<br />

have been. He is more intent on using the tools and<br />

resources that he currently has to move the business<br />

forward. He always speaks about the wonderful<br />

opportunities he and his brothers have had growing up<br />

in the business and learning from his father and mother,<br />

David and Linda White, and his grandfather and<br />

grandmother George Wilson Jr. and Mary.<br />

Since George was the only person south of Buffalo fixing radiators<br />

and Bethlehem Steel was big at the time, there was no<br />

shortage of work fixing all kinds of heat exchangers and the business<br />

grew quickly.<br />

George’s successor, his son George Jr. grew up in the shop<br />

learning the trade – tricks and all – while working in his spare<br />

time from school. In 1951, George Jr. met Mary Willis and they<br />

were married two years later. George Jr. left the business briefly<br />

to become an iron worker, and during his absence, the business<br />

was sold to Harold Swain Jr.<br />

Jesse and Dan White genuinely like the family business and the radiator<br />

repair roots. They have an old school attitude and work the business hard.<br />

The small shop in Amherst is used for light duty radiator benchwork. It is on<br />

the radar for an upgrade but the brothers relish the old school feel as they<br />

do their heritage.<br />

Pat O’Connor, NARSA president and VP of sales for S.A. Day Buffalo Flux<br />

Facility of Johnson Mfg. Co., has tapped Jesse to help with building NARSA<br />

membership. Jesse thinks there is great benefit for young people to bond<br />

with other younger generations to continue to build their businesses.<br />

George, Jr. Begins Anew<br />

Upset over what transpired and determined to start fresh George<br />

Jr. started construction of his own radiator shop in the spring of<br />

1957 right across the street from the now named Swain Radiator,<br />

the original location of Wilson Radiator.<br />

Once he embarked on building the new business from the<br />

ground up, George Jr. made ends meet repairing radiators at night<br />

while framing and building what was to become his home on top<br />

of the shop. Mary and George would raise their family here<br />

above the shop. In 1960, the building was finished and Hamburg<br />

Radiator officially opened its doors. Mary Wilson, the family<br />

matriarch, still lives in their original home above the shop.<br />

The industry in the 1960s was dominated by small, regional<br />

radiator and heater core makers. It seemed as if each metro area<br />

had its own home town core manufacturer. Firms like Lake Auto<br />

Radiator Mfg. Co. in Cleveland; Beacon Auto Radiator in<br />

Boston; Liberty in San Francisco; Eskimo Radiator Mfg. Co. in<br />

Los Angeles; Daniel Radiator in Houston; Chromalloy in St.<br />

Louis; U.S. Auto Radiator and Detroit Radiator in Michigan and<br />

Mangum Mfg. Co. in Dallas and others supplied the aftermarket.<br />

It was during this time that Pittsburgh Auto Radiator was<br />

pushing east and north from its roots in western Pennsylvania.<br />

George and Neal Fry visited George at Hamburg Radiator and<br />

like what they saw. Hamburg would become their distributor in<br />

the Buffalo area.<br />

Also pushing out and expanding from smaller regional bases<br />

during that same time was NARSA (National Automotive<br />

10 the cooling journal • august 2013

feature<br />

David White and Steve Adplanalp with a radiator from<br />

a gen set from Niagara Memorial Hospital.<br />

They have stockpiled an impressive inventory of<br />

reconditioned fuel sending units. The family spends<br />

part of the winters salvaging the units and fuel tanks<br />

from locations in the South. Winters in western New York<br />

are hard on vehicles because of the corrosive nature of<br />

road de-icing chemicals. Typically parts from the South<br />

will not have been subject to that corrosion.<br />

Jody White is the youngest and<br />

most recent addition to the family<br />

business.<br />

Radiator Service Assn.). George and Mary Wilson would become<br />

members and they attended many of the events across the<br />

country and met many great people in the industry with whom<br />

they formed lasting relationships – business and personal.<br />

Manufacturing Cores<br />

In the early ‘70s, George met a man named Tony Narog at a<br />

NARSA meeting. Tony built and maintained core making<br />

equipment. George saw another opportunity that would help<br />

him grow the business. He bought some machines and brought<br />

them back to New York and began making cores for himself.<br />

Rumor has it he used the family kitchen over to bake his very<br />

first core. The first cores produced for sale by Hamburg<br />

Radiator were in 1972.<br />

With George running the shop and Mary running the office, the<br />

business to continued to grow at a steady pace. The manufacturing<br />

side quickly outgrew the Hamburg location. The Wilson’s looked<br />

towards central Buffalo for expansion and ended up striking a deal<br />

to purchase the repair end of Chimera Radiator which had been<br />

sold years earlier by a nephew of the original owner Joe Chimera.<br />

Joe still held onto the distribution side of the business until the<br />

‘80s. Chimera-Hamburg Radiator Mfg. Co. was launched.<br />

George and Mary had two children, Linda and Bill. Both<br />

were raised in the business and it was no surprise that both of<br />

them helped the family business in any way they could. Linda<br />

joined the office shortly after the move to the downtown<br />

“Cobblestone District” was complete. While working for the<br />

business, she married David White who in early 1978 after working<br />

on locomotives for the railroad company and joined the family<br />

business also. Dave was to run the manufacturing end of the<br />

business. Their son, Bill Wilson, joined the company after graduating<br />

Northwestern University and ran the sales division.<br />

The business kept evolving other smaller repair shops opened<br />

throughout the area. In the late ‘70s early ‘80s, industry estimates<br />

had the number of repair shops in the U.S. and Canadian markets<br />

at about 12,000. The Wilson family expanded opening one shop<br />

east of the city called Parker Radiator and one in the north called<br />

Amherst Radiator which they still own today.<br />

By the mid ‘80s it was still business as usual at the manufacturing<br />

plant but some of the family shops were having problems.<br />

Changes and hard decisions had to be made. They closed Parker<br />

down and Dave White moved out to the Amherst location and<br />

assumed ownership of it as well in 1985.<br />

Chimera Radiator continued to operate for just under decade<br />

using other names such as Mr. Radiator and LBG Radiator. But<br />

the times were changing and so was the family. George and<br />

Mary were getting older. Bill had other interests outside of the<br />

radiator industry. Boxes started to make inroads and everything<br />

started to change rapidly.<br />

They saw an out and took it. The Buffalo Sabres National<br />

Hockey League team wanted to build a new arena on the property<br />

on which the manufacturing business sat. Then timing was<br />

right to get out of manufacturing. The property and equipment<br />

were sold and the inventory was sent back out to Hamburg<br />

Radiator which Mary continued to operate.<br />

From the time David White assumed ownership of Amherst<br />

Radiator he started a grass roots campaign to rebuild the small<br />

repair location.<br />

Located on a dead-end street, he needed to really push hard to<br />

make a difference. He grew the business by growing a reputation<br />

for quality work and good customer service. With only himself<br />

and a delivery driver he slowly worked up his client list and<br />

made a name for himself.<br />

A/C and Fuel Systems<br />

He diversified the service offering to include air conditioning<br />

and eventually general automotive service, specializing in fuel<br />

system repairs. He took that specialty one step further when he<br />

began salvaging fuel system parts like sending units and gas<br />

tanks in a big way. He would glean parts from salvage yards<br />

across the southern USA. Cars in these areas were not subject to<br />

ravages of the severe Buffalo winters that brought with them<br />

massive amounts of moisture and road salt. They would recondition<br />

the parts and maintain an extensive inventory which gained<br />

them a reputation as a “go-to” company for these items. They<br />

have a healthy fan base in the rust belt for these items.<br />

the cooling journal • august 2013<br />

11

FEATURE<br />

After a few years, Dave was able to move Amherst from its<br />

dead-end location to a much larger location on the heavily trafficked<br />

and retail-centered Niagara Blvd. His wife, Linda, has been<br />

a vital part of the operation as a business partner who has done<br />

the bookkeeping and office management for years. Today, Linda<br />

is grooming Jesse’s wife Kelly to take over these responsibilities.<br />

Linda also has a sideline. Every Easter Season she opens and operates<br />

a temporary candy store for a notable local maker of fine<br />

candies. Linda has used the profits from this business to put her<br />

children and now grandchildren through private Catholic school.<br />

The New Generation<br />

In 1996, Hamburg Radiator was sold to Dave White as George Jr.<br />

became ill. He was ultimately diagnosed with cancer. Mary did<br />

not have time to spend on the business as she spent it with<br />

George taking care of him through his struggles. George succumbed<br />

to cancer in November 1998.<br />

Dave is now moving closer to full time retirement and the<br />

sons are moving closer to full time control on the fourth generation<br />

family business. They have a passion for the business and a<br />

reverence for their ancestors who started it all.<br />

Jesse, Dan and Jody compete on daily basis. They stock inventory.<br />

They stay on top on customer service. They know what<br />

they sell. They know their customers.<br />

Last year, Jesse alone made 750 sales calls on their customer<br />

base. Jesse sees opportunity all throughout western New York.<br />

He and his brothers are positioning their business with general<br />

automotive service, air conditioning service and parts, and cooling<br />

system parts using Amherst as this base. Hamburg has become<br />

the repair center and specializes in heavy duty, industrial/<br />

commercial and fuel tanks.<br />

As the sons ramp up, they know they are well positioned to add<br />

new tools and processes to the extensive arsenal of technical<br />

knowledge and business acumen their family history has provided.<br />

Their generation is one typically enthralled with the here and<br />

now – with little regard for the past. Not so for this family. They<br />

know and honor the past and those who paved the way for their<br />

future. They speak reverently of positive influences on their family’s<br />

business by such industry veterans like Jack Silver of<br />

Canfield Solder, Carl Voss of Voss Mfg., John Fields of ARSCO,<br />

Paul Shapiro of Lake Auto Radiator, Barry Bartlett of Canadian<br />

Auto Radiator Mfg Exchange and Manufacturing and A. Jay<br />

Damon of Damon Industries.<br />

As Jesse White said, “We are in this for family. We fight for<br />

this because we are family.”<br />

EDITOR’s NOTE: A special thank you to Jesse White who compiled<br />

the family history which serve as the basis of this story.<br />

12 the cooling journal • august 2013

NARSA Heavy Duty Heating<br />

and <strong>Cooling</strong> Conference<br />

September 12-14, 2013<br />

Doubletree by Hilton Bloomington<br />

Bloomington, IL 61701<br />

Room rates at the Doubletree by Hilton are $129 per night plus<br />

applicable taxes. Rate includes full breakfast buffet. You may<br />

make your reservations by calling the hotel direct: 309-664-6446<br />

or 800-222-8733 and tell them you are with NARSA. You may<br />

also go online to www.narsa.org for links to the hotel website to<br />

make reservations. You will also find the latest information about<br />

the conference and links to online registration, virtual tour info,<br />

and HD technician certification. Be sure to register before July 31<br />

to get the early the bird cooling discount. journal • august 2013 13<br />

For details go to: www.narsa.org

NARSA Heavy Duty Heating<br />

and <strong>Cooling</strong> Conference<br />

Air Travel<br />

Air service from American, Delta, Frontier<br />

and Allegiant is available directly into Central<br />

Illinois Regional Airport. Free shuttle service<br />

is available to and from the Doubletree to<br />

this airport.<br />

Other possibilities for air travel include:<br />

Chicago O’Hare International Airport which<br />

is 141 miles from Bloomington (2 hours and<br />

36 minutes) or Chicago Midway International<br />

Airport that is 132 miles from Bloomington<br />

(2 hours and 20 minutes). Note: if planning<br />

to use the Chicago airports be sure to plan<br />

around rush hour traffic in the Chicago<br />

metropolitan area which can be very heavy.<br />

Current HD Conference Sponsors:<br />

Platinum SPonSor<br />

Silver SPonSor<br />

Bronze SPonSor<br />

Sponsorships and table tops available. Call<br />

NARSA at 724-799-8415.<br />

Virtual Tour: Submit up to 10 photos to have<br />

your business included in the Friday night virtual<br />

tour. Send photos to: Darlene Barlow at info@<br />

dbssquotes.com.<br />

HD Technician Certification: On site HD technician<br />

certification will be held at the Doubletree on<br />

Saturday from 9:30 a.m. to noon. This will be a<br />

classroom review followed by a written test. For<br />

HD Technician Certification registration send an<br />

email to: info@narsa.org and include HD Tech Cert<br />

in the subject line or call NARSA at 724-799-8415.<br />

14 the cooling journal • august 2013<br />

The NARSA Heavy Duty Heating<br />

and <strong>Cooling</strong> Conference is<br />

a unique educational event<br />

for professionals in the<br />

heat exchange service and<br />

products business. In its fourth<br />

year, the event brings people<br />

from throughout the world<br />

together to discuss issues and<br />

solutions about the business<br />

of heat exchange repair,<br />

remanufacturing, fabricating,<br />

design, maintenance,<br />

manufacturing, and distribution.<br />

CONFERENCE AGENDA<br />

thurSday, SePtemBer 12<br />

10:00 AM Heavy Duty Conference Committee<br />

Meeting<br />

12:00 PM Conference Registration Opens<br />

General Session: 1:00 PM – 4:45 PM<br />

1:00 PM NARSA HD Conference Welcome Remarks<br />

and Introductions<br />

1:30 PM Metallurgy and Characteristics of Metals<br />

Used in Heat Exchanger Applications<br />

Mitch Ingram, Principal Metallurgist and<br />

Technical Center Manager, API Heat<br />

Transfer, Montgomery, AL.<br />

Mitch Ingram is the Principle Metallurgist<br />

and Technical Center Manager for API<br />

Heat Transfer in Montgomery, Alabama. He<br />

is a 1990 graduate of the Auburn University Mechanical<br />

Engineering Department and holds a Master of Science<br />

(1998) from the Auburn University Materials Engineering<br />

Program. He began his career with ThermaSys<br />

Corporation and maintains his present position since<br />

its merger as part of API Heat Transfer. He has served<br />

as Tech Center Manager, Heat Exchanger Operations<br />

Manager and Director of Quality. Mitch is married to<br />

Anne (25 years); has four children ranging in age from<br />

10 - 24; and loves to talk football, in particular, regarding<br />

his Auburn Tigers.<br />

Presentation Description: The presentation analyzes<br />

basic heat exchanger construction materials; material<br />

selection methodology; the metallurgy of brazing and<br />

soldering; the compatibility of certain materials; and<br />

the practical methods of alloy identification. Material<br />

enhancements to improve heat exchanger functionality<br />

and corrosion resistance will also be addressed. An<br />

overview of the recognized alloy designation systems<br />

and material properties in both the copper/brass and<br />

aluminum systems is also surveyed.<br />

If your business serves over the<br />

road trucking, mining, construction,<br />

agriculture, military, energy and<br />

manufacturing industries with service<br />

and product sales for heat exchangers<br />

than this meeting is for you.<br />

The conference includes technical<br />

presentations, networking events,<br />

tours, and product displays. Join with<br />

other business and technical decision<br />

makers and leaders to experience this<br />

unique niche meeting for the specialty<br />

markets for heavy duty heat exchanger<br />

service for transportation and industry.<br />

3:00 PM Coffee Break<br />

3:15 PM Brazing Update: Materials, Techniques,<br />

Common Mistakes and Suggestions<br />

W. Daniel Kay, Principal, Kay & Associates,<br />

Simsbury, CT<br />

Mr. Kay is an M.B.A., Metallurgical Engineer,<br />

consultant and trainer. Dan is the leading<br />

independent consultant/trainer to the<br />

brazing industry on all aspects of brazing<br />

engineering, business development, strategic planning,<br />

and development of in-house technical expertise for<br />

brazing problem solving and problem prevention.<br />

Presentation Description: Brazing is an important<br />

metals-joining process used today for all kinds of metals,<br />

from aluminum to titanium. The transportation industry<br />

uses it extensively in radiators, fuel-transmission lines,<br />

EGR coolers, etc., and many companies, both large and<br />

small, use the brazing process (be it torch braze, or a<br />

furnace braze) to join these components. But unless<br />

it is done properly, significant problems, leaks, and<br />

shut-downs can result. A number of common mistakes<br />

will be discussed, and their often simple solutions will<br />

surprise you!<br />

Items to be covered include:<br />

• What is brazing, and how does it differ from<br />

soldering or welding?<br />

• What fundamental issues must be understood for<br />

correct use of brazing?<br />

• What common mistakes are made by many brazers,<br />

and how can they be avoided?<br />

• What is the future of brazing in the transportation<br />

industry?<br />

4:45 PM General Session Adjourns<br />

5:30 to 7:30 PM Reception and Table Top Exhibit

CONFERENCE AGENDA<br />

Friday, SePtemBer 13<br />

7:30 to 9:30 AM Conference Registration<br />

General Session<br />

8:00 AM NARSA Announcements<br />

8:30 AM Understanding and Optimizing <strong>Cooling</strong><br />

System Heat Transfer<br />

Dave Thompson, Engineering Manager,<br />

Thermal Solutions Manufacturing, Inc.<br />

Mr. Thompson began his career with<br />

G&O Manufacturing as a lab technician<br />

in 1985 and moved to the engineering<br />

department several years later. He<br />

worked through the many company name changes<br />

(G&O, GDI, Transpro, Proliance) before serving<br />

several years as Engineering Manager at Rocore and<br />

then moving to Vista-Pro Automotive in early 2010.<br />

Currently with Thermal Solutions Manufacturing in<br />

Nashville, Dave has cooling package design and<br />

optimization experience in both aftermarket & OEM<br />

applications. He earned his BSME Mechanical<br />

Engineering degree from the University of New Haven.<br />

Presentation Description: Mr. Thompson’s<br />

presentation will cover the following points:<br />

• Heat transfer basics<br />

• Core types & replacement options<br />

• Radiator/aftercooler combinations<br />

• Airflow management<br />

10:00 AM Coffee Break<br />

10:15 AM Fans and Shrouds: their Performance<br />

Implications<br />

Shawn Beauchamp, Operations and<br />

Sales Manager, WingFan, Charlotte, NC<br />

Shawn Beauchamp is the North<br />

American Operations Manager<br />

of WingFan, a modular axial fan<br />

manufacturer with its headquarters in<br />

Hamburg, Germany. Prior to joining WingFan in 2006,<br />

Shawn spent over 10 years in OEM heat exchanger<br />

sales in the on-highway and off-highway markets<br />

working for Dana Corp (Long Manufacturing) and<br />

Serck (now Rocore). His degree is in Metallurgical<br />

Engineering Technology from Fleming College,<br />

Peterborough Ontario, Canada.<br />

Presentation Description:<br />

Learn how to help customers collect the right<br />

information to give to a fan supplier and educate them<br />

regarding airflow related cooling issues and noise.<br />

Key Topics to be covered include:<br />

• fan technology and terminology<br />

• interpreting fan curves<br />

• fan noise<br />

• finding a replacement fan<br />

11:00 AM Speaker’s Panel Discussion<br />

Conference speakers will participate in an interactive<br />

panel discussion featuring questions from the<br />

audience to which each speaker may respond.<br />

Question cards will be used to record and organize<br />

audience questions.<br />

12:05 PM NARSA HD Awards Luncheon<br />

1:30 PM Evolution of a Radiator Shop<br />

Mark Hicks, owner of Maas Radiator, and Powder<br />

Coating Unlimited, will provide a history of the<br />

development of his businesses. In addition he will<br />

brief the conference on what they will see and what<br />

they can look forward during the tour of his facility. He<br />

grew the business from a tiny 675 sq ft shop to more<br />

than 65,000 sq ft in three different locations. Along the<br />

way, he has reinvented his business while staying<br />

true to its core services and technologies – metals<br />

cleaning and joining. In addition to the standard<br />

radiator repair shop services, they also provide<br />

industrial/commercial heat transfer product services,<br />

extreme metals cleaning and powder coating for<br />

industry and transportation.<br />

2:15 PM Travel to Maas Radiator<br />

Attendees will travel by car or shuttle bus to Maas<br />

Radiator and Powder Coating Unlimited which<br />

provides comprehensive engine cooling and<br />

air conditioning systems sales and services for<br />

automotive, light truck and heavy diesel markets<br />

2:30 – 5:00 PM Open House at Maas Radiator<br />

and Powder Coating Unlimited<br />

The Open House provides a unique opportunity to<br />

see specialized metals cleaning and processing as<br />

well as more traditional processes for HD radiator<br />

repair. The staff of Maas Radiator and Power Coating<br />

Unlimited will be on hand to demonstrate and to<br />

inform attendees regarding their processes, services<br />

and products. Batch cleaning, blast cleaning, heat<br />

extraction and powder coating are among the<br />

processes to be demonstrated.<br />

FRIDAY EVENING SPECIAL EVENT<br />

(5:30 PM to 9:00 PM)<br />

BBQ Cookout and Virtual Tours of Member<br />

Businesses<br />

Mark Hicks, Owner of Maas Radiator and Vice<br />

President of NARSA, has graciously invited all<br />

conference attendees, speakers and exhibitors to his<br />

home for an evening of networking and refreshments.<br />

Table Top Exhibitors will have the option of presenting<br />

their booths. A virtual tour featuring promotional<br />

slide shows and photos of shops and businesses<br />

from around the world is being organized. Attendees<br />

will be invited to submit their promotional slide<br />

presentations in total or they may submit photos<br />

in advance to Darlene Barlow of D Barlow Sales<br />

Solutions LLC, who will create a special inclusive<br />

show. Slides will be shown on a big screen.<br />

Saturday, SePtemBer 14<br />

Optional Activities<br />

9:30 AM to noon HD Technician Certification<br />

Class and Test<br />

Take advantage of this unique opportunity to earn<br />

NARSA HD Technician Certification by attending class<br />

and taking the test. Fee for the certification is $49 per<br />

person and includes work booklet, class instruction<br />

and proctored written exam. For more information and<br />

registration email NARSA: info@narsa.org and include<br />

HD Cert in the subject line.<br />

9:30 AM Self Tour to Caterpillar Welcome Center<br />

Attendees may want to travel to the Caterpillar<br />

Welcome Center in Peoria, IL. It is approximately 50<br />

minutes from Bloomington and allow 90 to two hours<br />

to tour the center. Other activities in the Peoria river<br />

front area include a regional historic museum, some<br />

shopping and restaurants. The Center is open from<br />

10 AM to 5 PM (last ticket sale and entry is 3:30 PM).<br />

General admission fee is $7 per person.<br />

Each year, Caterpillar brings about 25,000 visitors<br />

to the region to visit the world headquarters, tour<br />

factories and operate machines. Those who visit the<br />

50,000-square-foot, interactive facility on the Peoria<br />

Riverfront will get to:<br />

• Hold on to their rumble seat in the bed of a lifesize<br />

mining truck and take a virtual ride with Cat<br />

customers onto a number of remote job sites<br />

• Design their own piece of Cat equipment…and<br />

email it to themselves<br />

• Hop on a simulator and operate a dozer or an<br />

excavator<br />

• Sit in the seat of an antique tractor, pull the levers<br />

and feel what it was like to operate a Cat D8<br />

tractor in the 1930s<br />

• Step into a 3-D world and be transported into the<br />

cab of a machine on a job site<br />

• Feel the excitement of the race track and get an<br />

up-close look at the Caterpillar NASCAR race car<br />

• Take a picture in front of a life-size mining truck<br />

that stands two stories tall<br />

• Settle into the cab of a dozer, a loader or a<br />

compactor and get the feel of the road.<br />

For more information on the Caterpillar Visitors Center,<br />

please go to www.caterpillar.com/visitors-center.<br />

GolF<br />

There are three golf courses in the immediate vicinity<br />

of the hotel. If you are interested in golfing with others<br />

from the conference, please send an email to info@<br />

narsa.org and put HD Golf in the subject line and we<br />

will arrange a golf outing.<br />

hotel<br />

Room rates at the Doubletree by Hilton Bloomington<br />

are $129 per night plus tax and it includes breakfast.<br />

To book rooms contact the hotel direct at 309-664-6446<br />

and tell them you are with the NARSA HD Conference.<br />

Doubletree by Hilton Bloomington<br />

10 Brickyard Drive<br />

Bloomington, IL 61701<br />

(309) 664-6446<br />

the cooling journal • august 2013<br />

15

Saturday Optional Activities<br />

NARSA Heavy Duty Heating and <strong>Cooling</strong> Conference<br />

September 12–14, Bloomington, IL<br />

Registration Information<br />

Conference Fee<br />

The conference registration fee includes access to all sessions, Thursday table-top exhibit and reception, Friday awards lunch, Friday evening BBQ<br />

and shuttle service, coffee breaks, and copies of the technical presentation materials.<br />

Members<br />

Nonmembers<br />

Individual Additional Registrants Individual Additional Registrants<br />

May – July 31 $295 $245 $395 $395<br />

Aug. 1 – Sep. 20 $365 $315 $465 $465<br />

Individual tickets are available for family members or business colleagues of any registration, sponsorship or table top. Cost for Thursday reception: $35;<br />

Cost for Friday BBQ: $35. Both events for$65. Registration is required for individual tickets.<br />

9:30 AM to noon HD Technician Certification Class and Test<br />

Take advantage of this unique opportunity to earn NARSA HD Certification by attending class and taking the test. Fee for the certification is $49 per person<br />

and includes work booklet, class instruction and proctored written exam. For more information and registration email NARSA: info@narsa.org and include<br />

HD Cert in the subject line.<br />

9:30 AM Self Tour to Caterpillar Welcome Center<br />

Attendees may want to travel to the Caterpillar Welcome Center in Peoria, IL. It is approximately 50 minutes from Bloomington and allow 90 to two hours to<br />

tour the center. Other activities in the Peoria river front area include a regional historic museum, some shopping and restaurants. The Center is open from<br />

10 AM to 5 PM (last ticket sale and entry is 3:30 PM). General admission fee is $7 per person. Tickets are available at the Caterpillar Visitors Center.<br />

For more information on the Caterpillar Visitors Center, please go to www.caterpillar.com/visitors-center.<br />

Attendee Information<br />

Name: ___________________________________________________________________________________<br />

Attendee Information<br />

Fee: $ _____________________________________<br />

Company: _________________________________________________________________________________<br />

Street Address: ____________________________________________________________________________<br />

City:_______________________________________ State: ________________ Zip: ______________________<br />

Phone:_____________________________________ Email _________________________________________<br />

Attendee Information<br />

Name: ___________________________________________________________________________________<br />

Name: ___________________________________________________________________________________<br />

Name: ___________________________________________________________________________________<br />

Fee: $ _____________________________________<br />

Fee: $ _____________________________________<br />

Fee: $ _____________________________________<br />

Attendee Information<br />

o Check: _________________________________________________________________________________<br />

Total:_____________________________________<br />

o Bill Me: _________________________________________________________________________________<br />

Credit Card<br />

Name on Card: _____________________________________________________________________________<br />

Card No._____________________________________________________ Exp. Date _____________________<br />

Signature: 16 ________________________________________________________________________________<br />

the cooling journal • august 2013

www.thermalsolutionsmfg.com<br />

Our lower baffle retro-fit kit included with the radiator eliminates<br />

the need to modify the original baffle bracket. Modifications to<br />

the lower small hose connection allow for a better fit for vehicles<br />

with plow mountings.<br />

• Copper/brass construction<br />

• High-density core for optimal heat transfer; 3 row VTH style fin<br />

with tight .385 centers<br />

• Ultra-Fused welded tube-to-header joints.<br />

• Heavy wall, welded core tubes<br />

• .040˝ thick brass tanks with deep ribs for exceptional stiffness.<br />

• “Thru-tank” mounting sleeves for added strength<br />

SouthPOINTE Radiator INC Adds<br />

Surge Tanks to Tube Line<br />

TAYLOR, MI -- SouthPOINTE<br />

Radiator INC now has available<br />

aluminum and steel surge tanks<br />

to complement their stainless<br />

steel coolant tubes for more than<br />

200 applications. According to<br />

the company, all tubes and tanks are OEM fit. They also offer<br />

custom fabrication services. For more information contact: Adam<br />

Purdy, SouthPOINTE Radiator Inc. 734-941-1460.<br />

BorgWarner Supplies EGR Cooler<br />

with New Hybrid Tube Technology<br />

AUBURN HILLS, MI – BorgWarner supplies<br />

its latest exhaust gas recirculation<br />

(EGR) cooler for Renault’s 1.6-liter diesel<br />

engine, available on the European Scenic<br />

and Megane as well as Nissan’s crossover<br />

Qashqai.<br />

BorgWarner’s advanced EGR cooler with integrated hybrid<br />

tube technology helps improve fuel economy up to three percent<br />

while helping to achieve upcoming Euro 6 emissions standards.<br />

The combination of BorgWarner’s optimized turbocharger and its<br />

latest compact EGR technology fulfills future engine requirements<br />

with improved durability.<br />

“BorgWarner’s advanced EGR solutions, combined with our<br />

optimized turbocharging technology, is a major step in enabling<br />

diesel engines to meet future emissions regulations while improving<br />

fuel economy,” said Brady Ericson, President and General<br />

Manager, BorgWarner Emissions Systems. “With our many years<br />

of experience, BorgWarner offers customers the latest compact,<br />

low-pressure EGR technology. We expect this effective, fastgrowing<br />

technology to drive engine advancements in the future.”<br />

Renault’s powertrain strategy included a low-pressure, compact<br />

EGR system. Although low-pressure EGR systems offer<br />

lower emissions and better fuel economy than high-pressure systems,<br />

components in low-pressure EGR systems must withstand<br />

extreme loads and damaging particles.<br />

BorgWarner’s EGR cooler technology employs highly corrosion-resistant<br />

stainless steel hybrid tubes inside the cooler to<br />

quickly reduce the temperature of hot exhaust gases. The specially<br />

shaped hybrid tubes keep exhaust gases moving at high speeds to<br />

increase EGR rates as well as avoid soot and hydrocarbon buildup.<br />

The system also features an integrated hydro-formed EGR tube<br />

to guide exhaust gases into the cooler and a metallic EGR filter<br />

with optimized permeability to protect the turbocharger compressor<br />

wheel by filtering out any remaining particulates. Built for<br />

durability and performance, BorgWarner’s advanced EGR cooler<br />

offers a compact, cost-effective and easy-to-install technology<br />

engineered to reduce emissions and improve fuel economy.<br />

Product News<br />

TSM All Metal Complete Crank<br />

Box Radiators for Mack Trucks<br />

NASHVILLE, TN – Thermal Solutions<br />

has announced the availability of its new<br />

Tame tough jobs with the toughest<br />

cooling parts in the industry<br />

“all metal” HD Mack Crank Box<br />

Complete Radiators. According to the<br />

company, the line has been enhanced to<br />

better ensure maximum performance in<br />

Features and benefits<br />

rough terrain applications.<br />

Product features include: copper/brass<br />

construction; high-density core for optimal<br />

TSM: The hottest name in Heat Transfer!<br />

heat transfer, 3-row VTH 17fpi with tight<br />

.385 centers; Ultra-Fused welded tubeto-header<br />

joints; heavy wall, welded core tubes; 0.040” thick<br />

brass tanks with deep ribs for exceptional stiffness; deep tank ribs<br />

for increased durability; “Thru-tank” mounting sleeves for added<br />

strength; lower baffle retro-fit kit included with radiator eliminates<br />

the need to modify the original baffle bracket; and modifications<br />

for lower small hose connection allowing better fit for vehicles<br />

with plow mounting.<br />

For more information, TSM invites you to reach out to the<br />

TSM sales team or your closest Thermal Solutions Mfg. Branch<br />

or go to: www.thermalsolutionsmfg.com.<br />

the cooling journal • august 2013<br />

17

Heavy Duty<br />

Report: Heat Exchanger Market Worth $19,505.8 Million By 2018<br />

DALLAS, TX – A report from MarketsandMarkets pegs the<br />

global heat exchanger market at “$19,505.8 Million” within the<br />

next five years. The report, “Heat Exchanger Market by Types<br />

(Shell & Tube, Plate & Frame, Air Cooled), By Applications<br />

(Chemical, Petrochemical, Oil & Gas, HVAC & Refrigeration),<br />

Classifications (MoC, Temperature Range & Fluid Types ) &<br />

Geography - Forecasts to 2018” define and segment the global<br />

Heat Exchanger Market with analysis and forecasting of the<br />

global consumption revenue. Some highlights from the<br />

MarketsandMarkets press release:<br />

Europe - the Biggest Heat Exchanger Market<br />

Europe has always been a strong market for heat exchangers and<br />

globally, this market has been a leader for heat exchangers with<br />

respect to demand as well as production capacity. The region has<br />

the presence of most of the global leaders in heat exchanger manufacturing.<br />

Heat exchanger consumption in the region is estimated to<br />

grow at a CAGR (Compound Annual Growth Rate) of around<br />

4.7% from 2013 to 2018. This region has a relatively slow<br />

growth rate as a result of its dominant market size and slow economic<br />

activity as compared to the other regions. The demand in<br />

this region is boosted mainly due to the increased replacement<br />

demand for the heat exchangers.<br />

Asia-Pacific – the Fastest Growing Market<br />

Asia-Pacific, being the fastest growing heat exchanger market<br />

globally, is estimated to grow at a CAGR of 10.6 percent for the<br />

next five years. Asia-Pacific is witnessing high industrial growth,<br />

which hints at an ever-increasing demand of heat exchangers for<br />

its diverse applications.<br />

China dominates the Heat Exchanger Market in the Asia-<br />

Pacific region, being a major consumer and the fastest growing<br />

country in terms of heat exchanger demand. Currently, a high<br />

share of heat exchangers are consumed by the chemical industry<br />

and the demand of heat exchangers in the chemical industry is<br />

expected to grow in the next five years at a CAGR of more than<br />

11.5% from 2013 to 2018.<br />

After China, countries, including India and other Asian countries,<br />

are showing increasing growth in demand for heat exchangers.<br />

Moreover, increasing number of heat exchanger manufacturers<br />

from Asian countries are making vigorous efforts for developing<br />

a strong base within the heat exchanger market, with a target<br />

of reducing heat exchanger imports.<br />

The report includes: 89 market data tables and 33 figures in its<br />

289 pages. Listed price for the report is $4,650.00. For more information,<br />

go to: http://www.marketsandmarkets.com/Market-<br />

Reports/heat-exchanger-market-750.html.<br />

MarketsandMarkets is a global market research and consulting<br />

company based in the U.S. They publish strategically analyzed<br />

market research reports and serve as a business intelligence partner<br />

to Fortune 500 companies across the world.<br />

MarketsandMarkets also provides multi-client reports, company<br />

profiles, databases, and custom research services.<br />

MarketsandMarkets covers thirteen industry verticals; including<br />

advanced materials, automotives and transportation, banking and<br />

financial services, biotechnology, chemicals, engineering equipment<br />

& devices, consumer goods, telecommunications and IT,<br />

energy and power, food and beverages, industrial automation,<br />

medical devices, pharmaceuticals, semiconductor and electronics,<br />

aerospace and defense.<br />

18 the cooling journal • august 2013

Wabtec Acquires Turbonetics, A<br />

Manufacturer Of Turbochargers<br />

For Industrial Markets<br />

WILMERDING, PA – Wabtec Corporation acquired Turbonetics<br />

Holdings, Inc., a manufacturer of turbochargers and related components<br />

for various industrial markets. Turbonetics has annual<br />

sales of about $15 million. Wabtec expects the transaction to be<br />

accretive in the first year.<br />

Based in Moorpark, CA, Turbonetics designs and manufactures<br />

turbochargers and pressure-control products for engines<br />

used mainly in various industrial markets, including energy, aerospace,<br />

marine and high-performance applications. Turbonetics’<br />

customers include a variety of original equipment engine manufacturers<br />

and end-users. The company has about 40 employees.<br />

Albert J. Neupaver, Wabtec’s chairman and chief executive<br />

officer, said: “With its technology focus and strong aftermarket<br />

presence, Turbonetics is a good fit for Wabtec and a strategic<br />

complement to our recently acquired Napier Turbocharger business.<br />