Overview of Automatic Section Control Technology - Alabama ...

Overview of Automatic Section Control Technology - Alabama ...

Overview of Automatic Section Control Technology - Alabama ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

BIOSYSTEMS ENGINEERING SERIES<br />

TIMELY INFORMATION<br />

Agriculture, Natural Resources & Forestry<br />

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------<br />

Department <strong>of</strong> Biosystems Engineering, Auburn University, AL 36849-5626<br />

BSEN‐PA‐08‐02 JULY, 2008<br />

<strong>Overview</strong> <strong>of</strong> <strong>Automatic</strong> <strong>Section</strong> <strong>Control</strong> <strong>Technology</strong><br />

Introduction<br />

<strong>Automatic</strong> section control is a precision agriculture technology that has been readily adopted by<br />

producers over the past couple years. Currently, equipment manufacturers and third‐party companies<br />

are <strong>of</strong>fering systems that control sections, nozzles, and rows on sprayers and implements. Simply, the<br />

technology turns application equipment OFF in areas that have been previously covered or ON and OFF<br />

at headland turns, point rows, terraces, and/or waterways. Many farmers have implemented the<br />

technology for use on sprayers with popularity growing for planters.<br />

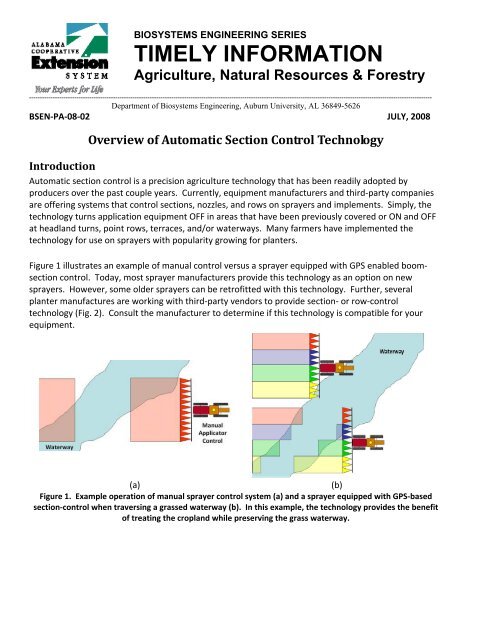

Figure 1 illustrates an example <strong>of</strong> manual control versus a sprayer equipped with GPS enabled boomsection<br />

control. Today, most sprayer manufacturers provide this technology as an option on new<br />

sprayers. However, some older sprayers can be retr<strong>of</strong>itted with this technology. Further, several<br />

planter manufactures are working with third‐party vendors to provide section‐ or row‐control<br />

technology (Fig. 2). Consult the manufacturer to determine if this technology is compatible for your<br />

equipment.<br />

(a)<br />

(b)<br />

Figure 1. Example operation <strong>of</strong> manual sprayer control system (a) and a sprayer equipped with GPS‐based<br />

section‐control when traversing a grassed waterway (b). In this example, the technology provides the benefit<br />

<strong>of</strong> treating the cropland while preserving the grass waterway.

Components<br />

The cost for this technology generally starts around $2000 but depends upon existing technology and<br />

equipment you may already be using on your farm. At minimum, you must have a:<br />

• GPS receiver<br />

• <strong>Control</strong>ler with s<strong>of</strong>tware capable <strong>of</strong> automatic section/row control<br />

• Proper boom valves for sprayers or row clutches for planters<br />

Other components can include a flow meter/control or other sensors to maintain the desired application<br />

rate when turning rows or sections ON/OFF. Please consult manufacturers for the necessary<br />

components and cables.<br />

Benefits<br />

Our calculations have shown input savings from 5% to over 30% for each pass across a field using<br />

automatic section control. However, these savings are dependent upon field shape and size with higher<br />

benefits occurring in large, irregular shaped fields or fields containing conservation management<br />

structures such as grass waterways and terraces.<br />

Benefits <strong>of</strong> this technology can include:<br />

1. Improved overall sprayer and planter accuracy<br />

2. Reduced overlap thus reducing overall input costs<br />

3. Improved environmental stewardship<br />

4. Reduced crop damage from over‐application<br />

5. Improved application efficiency<br />

6. Optimized operator efficiency<br />

Figure 2. Example benefits <strong>of</strong> planter individual row control to reduce overlap and skipped areas. The<br />

technology improves planting efficiency while savings on the amount <strong>of</strong> planted seed.<br />

Utilizing a guidance system in conjunction with automatic section control, can significantly improve<br />

field efficiency while providing input savings. Generally, automatic section control technology can pay<br />

for itself over 1 to 2 growing seasons.<br />

Prepared by<br />

Daniel Mullenix, Research Engineer, John Fulton, Assistant Pr<strong>of</strong>essor, Christian Brodbeck, Research<br />

Engineer Biosystems Engineering Department, Auburn University and Amy Winstead and Shannon<br />

Norwood, <strong>Alabama</strong> Cooperative Extension System.<br />

ALABAMA A&M AND AUBURN UINVERSITIES, AND TUSKEGEE UNIVERSITY, COUNTY GOVERNING BODIES AND USDA COOPERATING<br />

The <strong>Alabama</strong> Cooperative Extension System <strong>of</strong>fers educational programs, materials, and equal opportunity employment<br />

to all people without regard to race, color, national origin, religion, sex, age, veteran status, or disability.<br />

2

Available Systems and <strong>Technology</strong><br />

The following table provides a partial list <strong>of</strong> companies either providing complete systems or technology<br />

for these systems (last updated July 2008). Mention <strong>of</strong> trade names and commercial products is for<br />

informational purposes and does not necessarily imply endorsement by Auburn University or the<br />

<strong>Alabama</strong> Cooperative Extension System.<br />

Company System Name No. <strong>of</strong> <strong>Section</strong> <strong>Control</strong>s Website<br />

Topcon X20 Auto‐<strong>Section</strong> <strong>Control</strong> Up to 30 1<br />

John Deere Swath <strong>Control</strong> Pro TM Up to 12 2<br />

Relevant <strong>Control</strong>ler<br />

GreenStar TM 2 (GS2)<br />

Raven AccuBoom (CAN) Up to 10 3<br />

AccuBoom (Parallel) Up to 7 3<br />

SmartBoom Up to 7 3<br />

Relevant <strong>Control</strong>lers<br />

SCS 330 Up to 3<br />

SCS 400 Series 3, 6, or 7<br />

SCS 600 Series Up to 7<br />

SCS 4000 Series Up to 10<br />

TeeJet / Mid‐Tech Swath Manager Up to 5 4<br />

Boom Pilot Up to 15 4<br />

Centerline® 230BP Up to 15 4<br />

Relevant <strong>Control</strong>lers<br />

Legacy 6000<br />

ARC‐TASC Series Rate <strong>Control</strong>lers<br />

844 and 854 Rate <strong>Control</strong>lers<br />

Trimble AgGPS® EZ‐Boom TM Up to 10 5<br />

AgLeader <strong>Technology</strong> EZ‐Boom TM Up to 10 6<br />

AutoSwath TM Up to 10 6<br />

Relevant <strong>Control</strong>lers<br />

Insight<br />

SeedCommand<br />

DirectCommand<br />

Farmscan Farmlap ABS 5210 up to 10 7<br />

Farmlap Spray <strong>Control</strong> with Auto Boom<br />

Switching<br />

Up to 14 7<br />

Canlink 3500 Spray Guidance with TWIN<br />

Spray Line <strong>Control</strong><br />

5, 7, or 9 7<br />

Rinex AutoSPRAY AS7500 Up to 32 8<br />

Tru‐Count Air Clutch 9<br />

Capstan PWM Individual Nozzle Solenoids 10<br />

Related Websites<br />

1 www.topconpositioning.com 4 www.teejet.com or www.mid‐tech.com 7 www.farmscan.net 10 www.capstanag.com<br />

2 www.deere.com 5 www.trimble.com 8 www.rinex.com<br />

3 www.ravenprecision.com 6 www.agleader.com 9 www.trucount.com<br />

3