Lätt från början, Bengt Nilsson, Lamera (PDF-dokument, 2,8 MB)

Lätt från början, Bengt Nilsson, Lamera (PDF-dokument, 2,8 MB)

Lätt från början, Bengt Nilsson, Lamera (PDF-dokument, 2,8 MB)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Lätt</strong> <strong>från</strong> <strong>början</strong>!<br />

Att bygga in lättvikt direkt i materialet<br />

<strong>Bengt</strong> <strong>Nilsson</strong><br />

Göteborg 2013-05-29

<strong>Lätt</strong> <strong>från</strong> <strong>början</strong>!<br />

Att bygga in lättvikt direkt i materialet<br />

Formbar metallsandwich<br />

ger 50% lättare produkter i serietillverkning

What if…<br />

…you could have all the<br />

goodies of solid metal…<br />

…at a weight less than half

Now you can.<br />

Ultralight metal sandwich materials.

Hybrix - Unique Patented Material<br />

The Company develops, manufactures and markets light weight materials and<br />

components made of metal. The material, called Hybrix, is produced using a<br />

unique and patented micro-sandwich technology.<br />

Hybrix<br />

5

Parameters<br />

• Material/Alloy<br />

• Mechanical properties<br />

• Thickness<br />

• Surface finish<br />

Hybrix<br />

• highly adaptable material<br />

• alloys, hardening, thickness of face plates and length of fibers<br />

• Type<br />

• Thickness<br />

• Pattern<br />

• Length<br />

• Thickness<br />

• Material/Alloy<br />

• Orientation<br />

• customize stiffness, formability, surface quality, surface weight and dent resistance

Hybrix - Product Characteristics<br />

Hybrix is a sandwich material - of two facing sheets of metal bonded<br />

together by an air-rich formable core consisting of fibres and adhesive.<br />

Hybrix looks and can be processed like solid sheet metal it has half the<br />

weight but the same bending stiffness.<br />

Hybrix<br />

7

Benchmark Hybrix vs. solid steel<br />

the technology<br />

8

Benchmark Hybrix vs. aluminium<br />

the technology<br />

9

Benchmark materials<br />

Konventionella materialparametrar<br />

E, Rp, Rm, A, n, R, Icke mekaniska egenskaper, Etc.<br />

Materialparametrar för alternativa material<br />

Isotropiska material / anisotropiska material<br />

10<br />

Lokal styrka<br />

Global styrka<br />

Lokal styvhet<br />

Planstyvhet<br />

Global styvhet<br />

Energiupptagningsförmåga<br />

Etc.

11<br />

Material & Egenskaps – Matris (MEM)

12<br />

Material & Egenskaps – Matris (MEM)

13<br />

Material & Egenskaps – Matris (MEM)

14<br />

Material & Egenskaps – Matris (MEM)

15<br />

Material & Egenskaps – Matris (MEM)

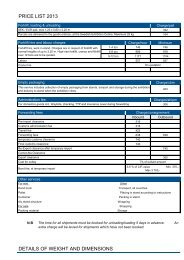

Benchmark materials<br />

Stainless<br />

steel<br />

Carbon steel Aluminium Magnesium<br />

Carbon fiber<br />

composite<br />

Sandwich<br />

Hybrix<br />

Density + + +++ ++++ +++++ ++++ ++++<br />

Bending stiffness / weight ++ ++ +++ +++ ++++ ++++ ++++<br />

Damping + + + ++ ++ +++ ++++<br />

Processing ++++ +++++ +++ +++ + + +++<br />

Recyclability ++++ ++++ ++++ ++ + + +++<br />

Cost ++ +++++ ++++ + - ++ +++<br />

+ Poor<br />

++ Acceptable<br />

+++ Average<br />

++++ Very good<br />

+++++ Best in class<br />

16

Hybrix<br />

Order och serieleveranser av Hybrix TM<br />

17<br />

<strong>Lätt</strong>viktslådor I Hybrix TM<br />

Varje låda har halva vikten jämfört<br />

med solid låda med samma<br />

bärighet.

Processing<br />

the technology<br />

18

Forming<br />

the processing<br />

Bending<br />

Deep Drawing<br />

19

Shearing<br />

the processing<br />

Water-jet Cuting Shear-cutting Laser Cutting<br />

20

Joining<br />

the processing<br />

SPR (Self Piercing Laser Welding Spot Welding<br />

Riveting)<br />

21

22<br />

Summary

Collaboration as enabler for light weight vehicles<br />

24<br />

A research project within the FFI-program where Volvo<br />

Cars, FKG, Innovatum and approximately 35 suppliers<br />

and academic partners have collaborated to develop<br />

systems for a virtual light weight Volvo V60. The target of<br />

the project was to demonstrate the potential of the<br />

Swedish automotive cluster in collaborating to develop<br />

innovative concepts to reach a cost efficient weight<br />

savings of 20-40%. Project homepage : www.sanatt.se

Door<br />

Underbody<br />

25

Collaboration as enabler for light weight vehicles<br />

Please be invited to the project presentation and<br />

exhibition in the Lindholmen Conference Hall on June 27 th<br />

between 13.30 – 16.00 (exhibition open until 19.00)<br />

26

Information<br />

27

Tack för visat intresse<br />

<strong>Bengt</strong> <strong>Nilsson</strong><br />

28

Kontaktuppgifter<br />

<strong>Lamera</strong> AB<br />

<strong>Bengt</strong> <strong>Nilsson</strong>, CEO<br />

Email: bengt.nilsson@lamera.se<br />

Phone: +46 738 53 65 08<br />

Address: A Odhners gata 17<br />

421 30 V. Frölunda<br />

Sweden<br />

Web: http://lamera.se/<br />

29