VERIMATION TECHNOLOGY, Inc. - Directories - Quality

VERIMATION TECHNOLOGY, Inc. - Directories - Quality

VERIMATION TECHNOLOGY, Inc. - Directories - Quality

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

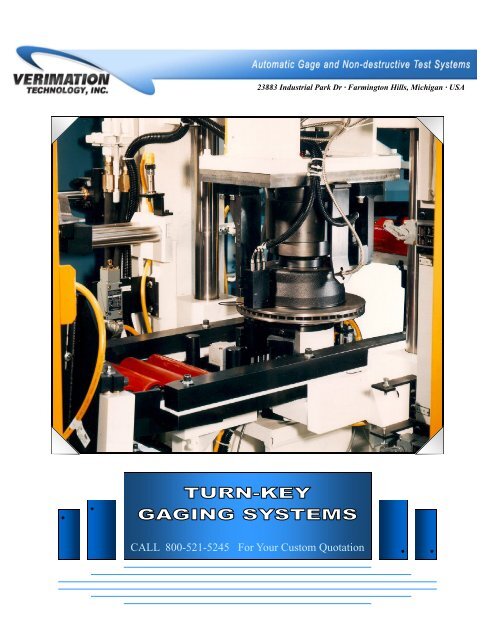

23883 Industrial Park Dr · Farmington Hills, Michigan · USA<br />

•<br />

•<br />

CALL 800-521-5245 For Your Custom Quotation<br />

•<br />

•

Verimation Technology, <strong>Inc</strong>.<br />

Inherits the Legacy of K. J. Law Engineers<br />

In 2002 Verimation Technology, <strong>Inc</strong>. acquired all of K. J Law's technology<br />

and inventory, and continues the K. J. Law tradition of high quality products and<br />

dependable service with all key former K. J. Law staff.<br />

Verimation's experienced and talented engineers maintain a robust and time proven<br />

catalog of products covering a wide range of inspection solutions. With over four decades<br />

of success inherited, Verimation continues to demonstrate the ability to deliver<br />

high quality products and services that meet or exceed customer needs.<br />

GAGING SYSTEMS:<br />

VERIMET® U1000 Universal Instrument<br />

In 2004, we began shipping systems utilizing Verimation’s advanced VERIMET U1000<br />

system to key customers. Verimet® represents the future of inspection instrumentation<br />

for Verimation. Built with modular software and hardware components, the VERIMET<br />

U1000 can handle the most challenging dynamic and / or static gaging applications<br />

with a single instrument built on standard Microsoft and industry-standard technology.<br />

Standard Features: Temp Comp, Tool Comp, GR&R Mode, Bias Mode, Unlimited and<br />

Flexible Data Storage, Up to 64 LVDT’s and Unlimited Test Formulas, Configurable Screens<br />

and …………………………………TOTALLY USER FRIENDLY<br />

TODAY & TOMORROW:<br />

Verimation Technology, <strong>Inc</strong>. continues to look to the future with a healthy percent of<br />

capital directed to advance planning and long range product development. Along the<br />

way the company is developing stronger partnerships and associations with tier one<br />

and two automotive parts suppliers, production line machine integrators, machine<br />

builders, fixture manufacturers, as well as in-process instrument systems for process<br />

monitoring and control. We feel the reputation we have established in our marketplace<br />

has gained the respect of our customers and competitors alike. We intend to maintain<br />

the high quality, reliability and good service attitude and capability that have always<br />

been provided to our customers.<br />

GAGING APPLICATIONS:<br />

Verimation routinely performs measurements such as:<br />

• DISTANCE<br />

• DIAMETER<br />

• THICKNESS<br />

• TAPER<br />

• RUN-OUT<br />

• FLATNESS<br />

• HARMONICS<br />

• ROUNDNESS<br />

• PARALLELISM<br />

• PERPINDICULARITY<br />

Email: info@verimation.com — www.verimation.com<br />

Verimet ® is a registered trademark of Verimation Technology, <strong>Inc</strong>.

23883 Industrial Park Dr · Farmington Hills, Michigan · USA<br />

The VERIMET® U1000 SYSTEM is a Modular Instrument designed to perform automatic<br />

gaging and nondestructive eddy current testing operations. The U1000 replaces all the eddy<br />

current and gaging instruments previously sold by K. J. Law Engineers over the years with a single<br />

modular instrument system. The U1000 can perform low frequency hardness verification<br />

and case depth prediction. Its gaging capabilities process input from LVDTs and Air Circuits to<br />

perform difficult dynamic and static measurements, and includes advanced filtering with temperature<br />

compensation and spindle compensation. The U1000 was developed using the latest<br />

hardware and software standards allowing integration with other devices and systems and the<br />

ability to evolve with emerging standards.<br />

•<br />

•<br />

CALL 800-521-5245 For Your Custom Quotation<br />

•<br />

•

Development Platform:<br />

Microsoft .NET Framework using C# language<br />

Operating Systems:<br />

Windows XP, Future Windows OS support<br />

Modularity<br />

Buy only the modules you need for the application at hand to support LVDTs, Air Circuits, Temperature Probes<br />

and Eddy Current probes and coils.<br />

Standards Support<br />

Compatibility with all Windows-supported standards (TCP/IP, Ethernet, Wireless 802.11b/g, USB, etc.) and<br />

standard devices such as Printers and CD-ROMs.<br />

Security<br />

Ability to define user logins and roles provides password-protected access to the various functions of the gage<br />

and related user-interface elements.<br />

Specific logins only see the menu items, screens, etc. they need to perform their tasks to keep training costs<br />

low and allow for plant-wide standards to be set.<br />

Additional Features<br />

The U1000 Program Editor allows end-users to set up any gage program from simple bench-gage applications<br />

to fully-automatic multi-station dynamic gages.<br />

Users may write their own equations and / or use the built-in library of common gage equations.<br />

The system is extendible and customizable: additional Screens and other UI elements, Datastores, and Control<br />

Interfaces (e.g. for PLCs, Tool Comp, etc.) may be added on a per-job basis or as new technologies emerge.<br />

Automatic Spindle Compensation records the slight imperfections in the gage spindle and removes that influence<br />

as each part is gaged.<br />

Integrated Temperature Compensation corrects for variations in part and fixture temperature on a per-feature<br />

basis.<br />

Integrated Tool Compensation establishes and maintains process control by automatically transferring tool offset<br />

data to the CNC to adjust for normal tool wear. A Trend Screen provides a visual history of any feature per<br />

source operation.<br />

Remote monitors may be placed at a specific operation (e.g. lathe) that show results only from that specific<br />

operation.<br />

Built-in GRR capability provides instant gage evaluation and data may be exported in Excel or .csv format for<br />

cataloging or further analysis.<br />

The Bias Test module provides for automatic periodic gage verification using known parts.<br />

A range of higher-level harmonics may be monitored in a single test and an optional datastore of the harmonic<br />

spectrum may be triggered when one or more harmonics exceed the limits.<br />

Any number of Data Attributes may be set up to tag part data (e.g. serial#, shift, part#).<br />

Any number of Datastores may be set up to store part data, mastering history, counter data, bias test results.<br />

A user-definable serial datastream allows definition of any output to most part marking systems.<br />

Integrated SPC for real-time process control allows monitoring of various features based on the specific source<br />

operation.<br />

A summary report may be printed to verify correctness of gage program configuration (e.g. validate formulas,<br />

spec limits, master values, etc.)<br />

Robust fault-handling to prevent invalid measurements.<br />

WARRANTY: All parts and workmanship are guaranteed for a full year from date of purchase. Email: info@verimation.com — www.verimation.com<br />

Verimet ® is a registered trademark of Verimation Technology, <strong>Inc</strong>.

<strong>VERIMATION</strong> GAGING<br />

<strong>VERIMATION</strong> <strong>TECHNOLOGY</strong>, <strong>Inc</strong>.<br />

Announces The Release Of It’s Newest Product !<br />

The<br />

MINI - U<br />

Portable Gaging Instrument<br />

Developed primarily for Static Gaging applications, the MINI-U carries all the sophistication of its big brother<br />

the U1000. The MINI-U is a perfect companion for bench top gages, utilizing DIGITAL PROBES.<br />

This is an UP-SCALE instrument for applications that demand more than the typical portable gages so popular<br />

today. Housed in a STEEL cabinet, this is a rugged instrument worthy of every day factory use !<br />

Specifications: width 21.5”- height 14.5” - depth 4.5”<br />

PH 1-800-521-5245 info@verimation.com www.verimation.com FAX 1-248-471-0055

Use of Microsoft .NET technology allows the Mini-U to provide the latest industry standards for the userinterface,<br />

data management, communication and security. All data, including setup program data and measurement<br />

result data, is managed internally as XML. The setup program is stored as an XML file and result data may be<br />

sent anywhere as XML or written to a RDMS (or exported in other formats through serial ports, via USB, etc.).<br />

Development Platform:<br />

Microsoft .NET Framework using C# language<br />

Operating Systems:<br />

Windows XP, Future Windows OS support<br />

Standards Support<br />

Compatibility with all Windows-supported standards (TCP/IP, Ethernet, Wireless 802.11b/g, USB, etc.) and<br />

standard devices such as Printers and CD-ROMs.<br />

Security<br />

Ability to define user logins and roles provides password-protected access to the various functions of the gage<br />

and related user-interface elements.<br />

Specific logins only see the menu items, screens, etc. they need to perform their tasks to keep training costs<br />

low and allow for plant-wide standards to be set.<br />

Additional Features<br />

The Mini-U Program Editor allows end-users to set up their gage programs utilizing digital probe technology.<br />

Users may write their own equations and / or use the built-in library of common gage equations.<br />

Integrated GRR capability provides instant gage evaluation and data may exported in Excel format if desired for<br />

cataloging or further analysis.<br />

The system is extendible and customizable: additional Screens and other UI elements, Datastores, and Control<br />

Interfaces (e.g. for PLCs, Tool Comp, etc.) may be added on a per-job basis or as new technologies emerge.<br />

Automatic Spindle Compensation records the slight imperfections in the gage spindle and removes that influence<br />

as each part is gaged.<br />

Integrated Temperature Compensation corrects for variations in part and fixture temperature on a per-feature<br />

basis.<br />

Built-in GRR capability provides instant gage evaluation and data may be exported in Excel or .csv format for<br />

cataloging or further analysis.<br />

The Bias Test module provides for automatic periodic gage verification using known parts.<br />

Any number of Data Attributes may be set up to tag part data (e.g. serial#, shift, part#).<br />

Any number of Datastores may be set up to store part data, mastering history, counter data, bias test results.<br />

Integrated SPC for real-time process control allows monitoring of various features based on the specific source<br />

operation.<br />

A summary report may be printed to verify correctness of gage program configuration (e.g. validate formulas,<br />

spec limits, master values, etc.)<br />

Robust fault-handling to prevent invalid measurements.<br />

WARRANTY: All parts and workmanship are guaranteed for a full year from date of purchase. Email: info@verimation.com — www.verimation.com<br />

Verimet ® is a registered trademark of Verimation Technology, <strong>Inc</strong>.