WELCOME SEA INSTALLER - A2SEA

WELCOME SEA INSTALLER - A2SEA

WELCOME SEA INSTALLER - A2SEA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

JACKING SYSTEM<br />

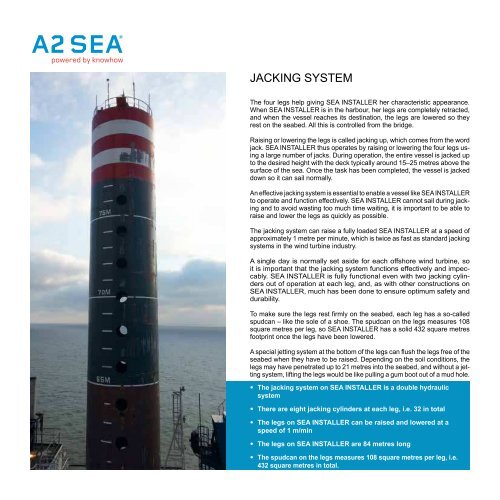

The four legs help giving <strong>SEA</strong> <strong>INSTALLER</strong> her characteristic appearance.<br />

When <strong>SEA</strong> <strong>INSTALLER</strong> is in the harbour, her legs are completely retracted,<br />

and when the vessel reaches its destination, the legs are lowered so they<br />

rest on the seabed. All this is controlled from the bridge.<br />

Raising or lowering the legs is called jacking up, which comes from the word<br />

jack. <strong>SEA</strong> <strong>INSTALLER</strong> thus operates by raising or lowering the four legs using<br />

a large number of jacks. During operation, the entire vessel is jacked up<br />

to the desired height with the deck typically around 15–25 metres above the<br />

surface of the sea. Once the task has been completed, the vessel is jacked<br />

down so it can sail normally.<br />

An effective jacking system is essential to enable a vessel like <strong>SEA</strong> <strong>INSTALLER</strong><br />

to operate and function effectively. <strong>SEA</strong> <strong>INSTALLER</strong> cannot sail during jacking<br />

and to avoid wasting too much time waiting, it is important to be able to<br />

raise and lower the legs as quickly as possible.<br />

• <strong>SEA</strong> <strong>INSTALLER</strong> has six<br />

3020 kilowatt engines<br />

• <strong>SEA</strong> <strong>INSTALLER</strong> has<br />

three Voight Schneider<br />

propellers for propulsion<br />

and three Bov propellers<br />

for satellite-based<br />

positioning<br />

• The vessel can<br />

manoeuvre with a precision<br />

of 25 cm under optimum<br />

weather conditions.<br />

The jacking system can raise a fully loaded <strong>SEA</strong> <strong>INSTALLER</strong> at a speed of<br />

approximately 1 metre per minute, which is twice as fast as standard jacking<br />

systems in the wind turbine industry.<br />

A single day is normally set aside for each offshore wind turbine, so<br />

it is important that the jacking system functions effectively and impeccably.<br />

<strong>SEA</strong> <strong>INSTALLER</strong> is fully functional even with two jacking cylinders<br />

out of operation at each leg, and, as with other constructions on<br />

<strong>SEA</strong> <strong>INSTALLER</strong>, much has been done to ensure optimum safety and<br />

durability.<br />

To make sure the legs rest firmly on the seabed, each leg has a so-called<br />

spudcan – like the sole of a shoe. The spudcan on the legs measures 108<br />

square metres per leg, so <strong>SEA</strong> <strong>INSTALLER</strong> has a solid 432 square metres<br />

footprint once the legs have been lowered.<br />

A special jetting system at the bottom of the legs can flush the legs free of the<br />

seabed when they have to be raised. Depending on the soil conditions, the<br />

legs may have penetrated up to 21 metres into the seabed, and without a jetting<br />

system, lifting the legs would be like pulling a gum boot out of a mud hole.<br />

• The jacking system on <strong>SEA</strong> <strong>INSTALLER</strong> is a double hydraulic<br />

system<br />

• There are eight jacking cylinders at each leg, i.e. 32 in total<br />

• The legs on <strong>SEA</strong> <strong>INSTALLER</strong> can be raised and lowered at a<br />

speed of 1 m/min<br />

• The legs on <strong>SEA</strong> <strong>INSTALLER</strong> are 84 metres long<br />

• The spudcan on the legs measures 108 square metres per leg, i.e.<br />

432 square metres in total.<br />

ENGINE ROOM<br />

No vessel is without an engine room. A huge amount of raw power is<br />

required on board <strong>SEA</strong> <strong>INSTALLER</strong>, so the engine room consists of three<br />

separate rooms, each equipped with two 3020 kilowatt diesel-electric engines.<br />

This gives a total of six engines with a combined capacity of more than<br />

18,000 kilowatt, generating high voltage power to propel the vessel, and<br />

for the jack-up system, the cranes and the many cooling, heating and<br />

ventilation systems on board. This is equivalent to the power required for<br />

2,5 million low energy light bulbs – if one should need that.<br />

Like the rest of <strong>SEA</strong> <strong>INSTALLER</strong>, the engine room is designed to optimise<br />

vessel operation. Even with two of the six engines out of operation, the<br />

vessel remains fully operational. In a worst case scenario, the vessel can<br />

sail with only one engine.<br />

The result is a large amount of raw power, not to mention a high degree<br />

of reliability of supply, which is essential when A2<strong>SEA</strong> counts on installing<br />

at least one wind turbine per day. While vessels in the oil and gas industry<br />

typically sail to a specific position, where they are jacked up and remain<br />

for shorter or longer periods of time, wind turbine installation vessels are<br />

constantly on the move, either to transport the turbines to their destination<br />

or in connection with installation.<br />

In addition to the engine power required to sail <strong>SEA</strong> <strong>INSTALLER</strong>, the engine<br />

room supplies power to a special satellite-based navigation system<br />

also called DP (Dynamic Positioning), which can maintain a given position<br />

during operation with a tolerance of only 25 cm.