english - STEAG

english - STEAG

english - STEAG

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Power and heat for the future<br />

Efficient energy supply for the<br />

Leuna refinery complex<br />

As fifth biggest electricity producer in Germany, with ultramodern<br />

power plants in and outside Germany and a variety of<br />

services, <strong>STEAG</strong> GmbH safeguards the energy supply of the<br />

future – reliably, efficiently, and with low environmental impact.<br />

<strong>STEAG</strong> blazes the trail for the energy sources biomass,<br />

biogas, mine gas, geothermics, wind and solar thermics. The<br />

engineers of <strong>STEAG</strong> Energy Services GmbH develop, build<br />

and operate power plants all over the world and are experts<br />

for the modernization of existing plants and for made-tomeasure<br />

energy supply which goes easy on the climate and<br />

at the same time is economical.<br />

Power plants at home and abroad<br />

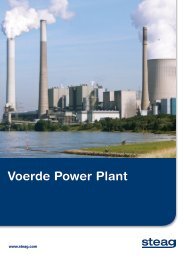

<strong>STEAG</strong> operates eleven power plants at ten locations in<br />

Germany with an installed capacity of about 7,500 MW; nine<br />

of these plants use hard coal as primary energy source. At<br />

two sites, each of which integrates an industrial power plant,<br />

refinery by-products also are used to produce steam, compressed<br />

air and electricity. Most of the electricity from hard<br />

coal is supplied to industrial and public utilities. The customers<br />

include RWE, EnBW and Deutsche Bahn, the German<br />

Railways. Where there is a demand for it, cogeneration –<br />

the simultaneous production of power and useful heat – is<br />

practiced. This heat either is used for heating purposes or<br />

is purchased by industrial enterprises in the form of process<br />

heat for their production processes. Outside Germany, too,<br />

the company contributes to public power supply with three<br />

hard-coal-fired power plants, capacity about 1,700 MW, in<br />

Turkey, Colombia and the Philippines. The efficient power<br />

plants of <strong>STEAG</strong> make an active contribution to a secure and<br />

sustainable supply of energy.<br />

The Leuna refinery power plant is located on the grounds of<br />

the Leuna chemical park, one of the biggest industrial chemicals<br />

sites in Germany. The power plant supplies the refinery<br />

at the site with electricity, process steam, compressed air,<br />

process water, feedwater and cooling water. The supply of<br />

energy to the refinery in Leuna was the first project of its kind<br />

worldwide. Up until then, the oil companies had financed,<br />

built and operated their power plants themselves. In Leuna,<br />

for the first time an external partner, <strong>STEAG</strong>, was given a<br />

chance. Thanks to <strong>STEAG</strong>’s longstanding know-how, it was<br />

and is possible to use refinery residues as fuel despite stiffer<br />

environmental protection regulations.<br />

Symbiosis of power plant and refinery<br />

The smooth cooperation between power plant and refinery is<br />

important for supplying the site. This symbiosis has functioned<br />

almost without a hitch since 1996. One chief reason<br />

for this is the close coordination between power plant and<br />

refinery concerning current energy consumption and operative<br />

measures.<br />

Via online links each party is well informed about the current<br />

operating data of the other party. This coordination is backed<br />

up by long-term and medium-term planning. Power plant<br />

and refinery begin at midyear to draw up the schedule for the<br />

coming year.<br />

<strong>STEAG</strong> also continually invests in the power plant site in order<br />

to meet the changing needs of the refinery. For example,<br />

paralleling the expansion of the refinery processing capacity<br />

from just under 10 million tons of crude to 12 million tons<br />

annually, investments were made in 30 projects at the power<br />

plant to increase its reliability and energy efficiency. In refinery<br />

power plants, capacity is not as important as availability, because<br />

the refinery is dependent on an uninterrupted supply<br />

of energy.