SUPERSEED® INOCULANT - Elkem

SUPERSEED® INOCULANT - Elkem

SUPERSEED® INOCULANT - Elkem

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

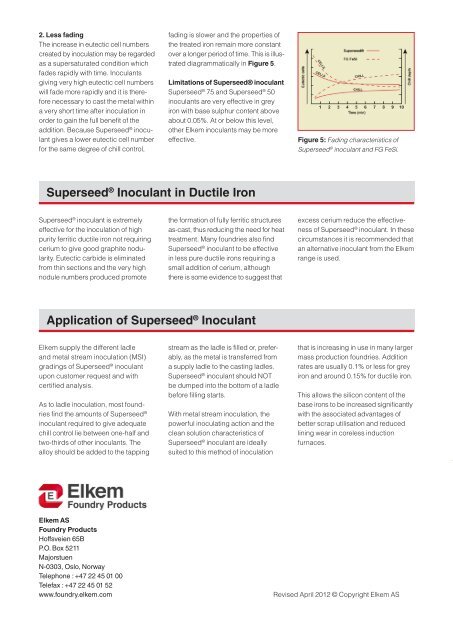

2. Less fading<br />

The increase in eutectic cell numbers<br />

created by inoculation may be regarded<br />

as a supersaturated condition which<br />

fades rapidly with time. Inoculants<br />

giving very high eutectic cell numbers<br />

will fade more rapidly and it is therefore<br />

necessary to cast the metal within<br />

a very short time after inoculation in<br />

order to gain the full benefit of the<br />

addition. Because Superseed ® inoculant<br />

gives a lower eutectic cell number<br />

for the same degree of chill control,<br />

fading is slower and the properties of<br />

the treated iron remain more constant<br />

over a longer period of time. This is illustrated<br />

diagrammatically in Figure 5.<br />

Limitations of Superseed® inoculant<br />

Superseed ® 75 and Superseed ® 50<br />

inoculants are very effective in grey<br />

iron with base sulphur content above<br />

about 0.05%. At or below this level,<br />

other <strong>Elkem</strong> inoculants may be more<br />

effective.<br />

Figure 5: Fading characteristics of<br />

Superseed ® inoculant and FG FeSi.<br />

Superseed ® Inoculant in Ductile Iron<br />

Superseed ® inoculant is extremely<br />

effective for the inoculation of high<br />

purity ferritic ductile iron not requiring<br />

cerium to give good graphite nodularity.<br />

Eutectic carbide is eliminated<br />

from thin sections and the very high<br />

nodule numbers pro duced promote<br />

the formation of fully ferritic structures<br />

as-cast, thus reducing the need for heat<br />

treatment. Many foundries also find<br />

Superseed ® inoculant to be effective<br />

in less pure ductile irons requiring a<br />

small addition of cerium, although<br />

there is some evidence to suggest that<br />

excess cerium reduce the effec tive -<br />

ness of Superseed ® inoculant. In these<br />

circumstances it is recommended that<br />

an alternative inoculant from the <strong>Elkem</strong><br />

range is used.<br />

Application of Superseed ® Inoculant<br />

<strong>Elkem</strong> supply the different ladle<br />

and metal stream inoculation (MSI)<br />

gradings of Superseed ® inoculant<br />

upon customer request and with<br />

certified analysis.<br />

As to ladle inoculation, most foundries<br />

find the amounts of Superseed ®<br />

inoculant required to give adequate<br />

chill control lie between one-half and<br />

two-thirds of other inoculants. The<br />

alloy should be added to the tapping<br />

stream as the ladle is filled or, preferably,<br />

as the metal is transferred from<br />

a supply ladle to the casting ladles.<br />

Superseed ® inoculant should NOT<br />

be dumped into the bottom of a ladle<br />

before filling starts.<br />

With metal stream inoculation, the<br />

power ful inoculating action and the<br />

clean solution characteristics of<br />

Superseed ® inoculant are ideally<br />

suited to this method of inoculation<br />

that is increasing in use in many larger<br />

mass production foundries. Addition<br />

rates are usually 0.1% or less for grey<br />

iron and around 0.15% for ductile iron.<br />

This allows the silicon content of the<br />

base irons to be increased significantly<br />

with the associated advantages of<br />

better scrap utilisation and reduced<br />

lining wear in coreless induction<br />

furnaces.<br />

<strong>Elkem</strong> AS<br />

Foundry Products<br />

Hoffsveien 65B<br />

P.O. Box 5211<br />

Majorstuen<br />

N-0303, Oslo, Norway<br />

Telephone : +47 22 45 01 00<br />

Telefax : +47 22 45 01 52<br />

www.foundry.elkem.com<br />

Revised April 2012 © Copyright <strong>Elkem</strong> AS