Melcourt Industries - Forestry Journal

Melcourt Industries - Forestry Journal

Melcourt Industries - Forestry Journal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Barking up<br />

the right tree<br />

<strong>Melcourt</strong> <strong>Industries</strong><br />

Compared with timber and wood processing, the UK ‘conifer-bark business’ is relatively new. Until the 1970s, bark, a potentially<br />

valuable, natural, carbon-neutral co-product of sawmilling and wood processing, was simply dumped. “That’s hard to<br />

imagine today, given its value and breadth of use,” says Andy Chalmers, managing director of <strong>Melcourt</strong> <strong>Industries</strong> Limited,<br />

“but now at <strong>Melcourt</strong>, we exploit this high-value, carbon-neutral, natural resource to the fullest extent.”<br />

That’s something you quickly realise<br />

once inside <strong>Melcourt</strong>’s expansive<br />

screening, compost-mixing,<br />

bagging and distribution centre at<br />

Tetbury in Gloucestershire, when<br />

confronted by huge mounds of<br />

<strong>Melcourt</strong>’s branded products, each<br />

with their own unique specification<br />

and application.<br />

On site at Tetbury<br />

When I arrived on the Tetbury site,<br />

a mighty Doppstadt SM818<br />

tromell, in orange livery and ‘bright<br />

and beautiful’ on an otherwise<br />

murky, miserable day, was simultaneously<br />

screening and spewing out<br />

three entirely different grades, each<br />

with its own branded product<br />

specification.<br />

The Doppstadt was fed, and<br />

product piles were moved around,<br />

by a fleet of Volvo 190L loaders.<br />

“They are comparatively old but<br />

well maintained and serviced, and<br />

therefore doing the job,” said<br />

Andy. Also in operation was the<br />

company’s impressive Slootweg<br />

(Dutch) growing media (compost)<br />

mixing and bagging plant. It is<br />

anticipated that additional equipment<br />

will be installed soon.<br />

<strong>Melcourt</strong> also takes in conifer<br />

woodchip sourced within 100 miles<br />

of Tetbury and screens it for various<br />

markets, together with processed<br />

bark from <strong>Melcourt</strong>’s other site at<br />

Bishop’s Castle in Shropshire, for<br />

packing or mixing into growing<br />

media. The Bishop’s Castle site<br />

processes in excess of 150,000<br />

cubic metres of UK-grown, FSC<br />

mixed conifer and redwood bark<br />

per year. Bark is sourced from<br />

large sawmills like BSW and<br />

Pontrilas, wood panel manufacturer<br />

Kronospan and a number of<br />

other sawmills in the Welsh border<br />

region.<br />

<strong>Melcourt</strong> is clearly a dynamic<br />

business, but it would be wrong to<br />

view it as just another ‘chip it,<br />

heap it and sell it’ operation. I<br />

soon learned how this company is<br />

at the forefront of product innovation<br />

on the sustainable use of natural<br />

resources and maintaining the<br />

integrity of our environment,<br />

alongside self-sufficiency and longterm<br />

national prosperity.<br />

Birth of bark-based<br />

products<br />

I was fascinated by the thought<br />

that just four decades ago, before<br />

carbon awareness, when chimney<br />

sweeps were commonplace, hundreds<br />

of thousands of<br />

tonnes of British<br />

bark were<br />

dumped every<br />

year.<br />

According to<br />

Andy Chalmers,<br />

the ‘bark business’<br />

began in<br />

one of the most unlikely of places,<br />

St Anne’s Board mill in Bristol,<br />

which was manufacturing card<br />

and cardboard for Imperial<br />

Tobacco’s Bristol-based cigarette<br />

factory in the 1970s. “In those<br />

days,” he said, “surprisingly few<br />

fruits of forestry were being utilised.<br />

Trees were felled, snedded<br />

and topped; the pulpwood or sawlog<br />

element was transported to<br />

the mill where the wood was summarily<br />

stripped of bark, only for<br />

this potentially valuable resource<br />

to be thrown away.”<br />

That was until the arrival of Jack<br />

Aaren from the <strong>Forestry</strong><br />

Commission, who in one of those<br />

‘milestone moments’ in British forestry,<br />

came to Bristol to assess the<br />

potential for changing bark into a<br />

profitable forest co-product.<br />

Amongst potential uses he investigated<br />

was its use in the manufacture<br />

of building blocks (bark has<br />

natural insulation properties), horticultural<br />

products and equestrian<br />

surfacing. From this work<br />

evolved a product called ‘Forest<br />

Bark’, subsequently taken on<br />

board by ICI as the first retail bark<br />

mulch sold to gardeners.<br />

“In those days,” said Andy<br />

Chalmers, “most local authorities<br />

had their own in-house parks<br />

departments, spending lots of<br />

money on hoeing municipal flower<br />

beds. They were already starting<br />

to look for alternatives. Spraying<br />

herbicides to chemically control<br />

weeds, or using a thick layer of<br />

peat as mulch, were already raising<br />

eyebrows and frowned upon,<br />

but bark mulch suited the bill,<br />

both economically and environmentally.”<br />

<strong>Melcourt</strong> joins the market<br />

When <strong>Melcourt</strong><br />

started in<br />

1983<br />

<strong>Forestry</strong> <strong>Journal</strong> 9/12<br />

www.forestryjournal.co.uk<br />

53

(75% owned by<br />

Charles Ransford &<br />

Sons of Bishop’s<br />

Castle in Shropshire<br />

and 25% by John<br />

Latter), there were<br />

already two companies<br />

in the fledgling<br />

bark market: Bristol<br />

Bark Products, a<br />

spin-off from Jack<br />

Aaren’s pioneering<br />

work, selling three<br />

simple grades of<br />

bark (coarse, medium<br />

and fine) of variable<br />

quality. The other company<br />

was Camland Products Ltd, based<br />

in East Anglia. They were using<br />

bark from several species of conifer<br />

(mainly Corsican and Scots pine)<br />

sourced from Thetford Forest and<br />

FC’s Brandon Central Depot. The<br />

timber was processed into pit<br />

props and telegraph poles.<br />

Camland purchased the bark and<br />

screened it into dedicated products<br />

for specialist markets, including<br />

mulch and soil compost, for the<br />

Greater London Council and horticultural<br />

growers.<br />

<strong>Melcourt</strong>, as the ‘new kid on the<br />

block’, was faced with either copying<br />

these companies and selling at<br />

a cheaper price, or finding out<br />

exactly what the market wanted<br />

and manufacturing products to<br />

suit. They made enquiries of landscape<br />

contractors. “They came<br />

back with three core requirements,”<br />

said Andy Chalmers,<br />

“prompt telephone answering with<br />

delivered prices quoted while they<br />

were on the phone, guaranteed<br />

delivery times and consistent product<br />

quality, load after load.<br />

“They also told us that we needed<br />

to speak to landscape architects<br />

and garden designers, who were in<br />

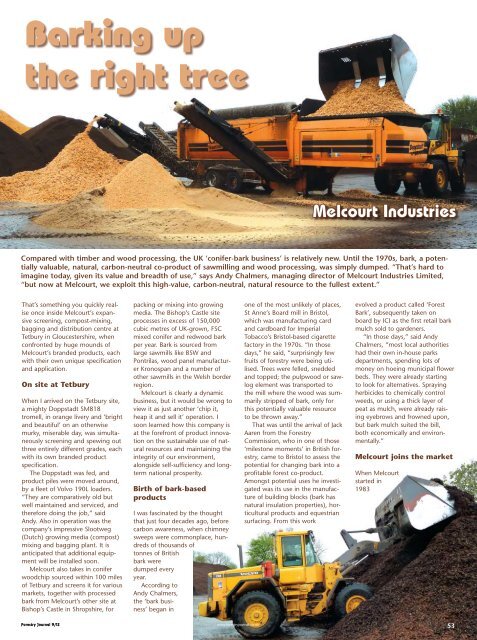

Bagging <strong>Melcourt</strong> ‘Topgrow’ tree and shrub planting compost.<br />

pole position in specifying the<br />

products to be used. What came<br />

back was a basic question: ‘What is<br />

bark’ There was no industry-wide<br />

specification and no British<br />

Standard for these new products.<br />

From this feedback <strong>Melcourt</strong><br />

identified the markets it wished to<br />

service and went on to develop a<br />

range of different grades of bark<br />

and woodchip products.<br />

In the rapid development that<br />

followed, <strong>Melcourt</strong> introduced<br />

product ranges to cover all applications,<br />

with brochures to assist in<br />

choosing the right product and<br />

specification. They also raised the<br />

industry profile by exhibiting at<br />

trade exhibitions.<br />

Ready for take off<br />

“There was an initial delay,” says<br />

Andy Chalmers, “as the market<br />

took time to gel, but it eventually<br />

took off in the early 1980s. Local<br />

authorities quickly became our biggest<br />

customers, each with its own<br />

parks and landscaping department,<br />

equipped with a substantial budget<br />

and a clerk of works who ensured<br />

that what was specified was actually<br />

done.<br />

“In those ‘halcyon days’, raw<br />

bark was quite cheap to source and<br />

this helped accelerate our market.<br />

Things began to change in the<br />

1990s. Local authority budgets<br />

were progressively cut, but new<br />

customers such as superstores and<br />

business/industrial parks stepped in<br />

to fill the breach.”<br />

Another key factor in <strong>Melcourt</strong>’s<br />

development was the formation of<br />

an efficient distribution network.<br />

“Most of our products are now<br />

supplied loose in quantities up to<br />

80 cubic metres” said Andy<br />

Chalmers, “but we additionally<br />

have a network of over 100 master<br />

stockists who split them into smaller<br />

quantities and sell them on to<br />

local users. We have also developed<br />

a range of bagged products aimed<br />

at the retail market.”<br />

Today, <strong>Melcourt</strong> offers 19 branded<br />

products covering mulches, soil<br />

ameliorants, planting composts<br />

and walk surfaces.<br />

Ups and downs<br />

Varying market conditions over the<br />

last three decades, as much, if not<br />

more, on the supply side, have<br />

The Doppstadt SM-818 was producing<br />

three different product<br />

specifications simultaneously.<br />

been ridden out by<br />

exploration and<br />

innovation. In the<br />

early days, bark was<br />

essentially free, the<br />

only cost being that<br />

of collection. But<br />

the forestry industry<br />

soon got wise and<br />

British bark, particularly<br />

pine bark,<br />

increased in price.<br />

<strong>Melcourt</strong> started to<br />

look abroad and in<br />

2005 started to<br />

import 40,000<br />

cubic metres of Maritime pine bark<br />

per annum from Spain. This worked<br />

fine for ten or more years until the<br />

credit crunch, some five years ago,<br />

when Spain’s economy, especially<br />

the construction sector, was<br />

blitzed. The market for timber collapsed,<br />

resulting in the closure of<br />

sawmills and a sudden dearth of<br />

bark.<br />

<strong>Melcourt</strong> took another look<br />

around the UK and secured a partnership<br />

with a company based in<br />

Norfolk to buy up to 50,000 cubic<br />

metres of processed bark, sourced<br />

from Corsican and Scots pine in<br />

the Thetford Forest area. All of the<br />

company’s haulage requirements<br />

are subcontracted out. Raw materials<br />

coming in are with AW<br />

Jenkinson which has a four-man<br />

team on site at Tetbury monitoring<br />

the movements of 70+ trucks.<br />

Loose products going out are also<br />

handled by AW Jenkinson, and<br />

packed products by Hacklings,<br />

which is part of the PalletLine<br />

Group.<br />

“Ninety five per cent of our<br />

business is in the UK,” said Andy<br />

Chalmers, “but we are moving forward<br />

with exports, mainly into the<br />

Far East (Malaysia, Vietnam, Hong<br />

Kong and China), especially for our<br />

Bio-Filtration Solutions range of<br />

products, including <strong>Melcourt</strong><br />

Heather, raw material for which is<br />

sourced from the North Yorkshire<br />

Moors.” Bio-Filtration Solutions is a<br />

range of peat-free, recyclable, natural<br />

air filtration materials used by<br />

industries such as sewage, sludge<br />

and waste-water treatment plants,<br />

abattoirs, animal by-product rendering<br />

and food processors, to cure<br />

the problem of ‘nasty niffs’.<br />

<strong>Melcourt</strong> <strong>Industries</strong> now turns<br />

over £5million a year and is 50%<br />

owned by Charles Ransford & Sons<br />

and 50% by Alan Jenkinson, whose<br />

business interests include half ownership<br />

of Berite Sawmills Limited, as<br />

well as the haulage company that<br />

carries his name.<br />

54<br />

www.forestryjournal.co.uk<br />

<strong>Forestry</strong> <strong>Journal</strong> 9/12

Down to earth<br />

Managing Director Andy Chalmers has many years of<br />

hands-on experience in forestry.<br />

In what was clearly a milestone<br />

moment for <strong>Melcourt</strong>’s product<br />

expansion and development, the<br />

company embarked on supplying<br />

peat-free growing<br />

media in the 1990s. Now<br />

they claim to be the only<br />

UK specialist providing<br />

bark- and wood-based<br />

compost ingredients and<br />

peat replacement growing<br />

media.<br />

These are clearly<br />

timely developments<br />

given<br />

Government-set<br />

targets are for all<br />

local authority and<br />

central government<br />

contracts to<br />

be peat free by<br />

2015, followed by<br />

all retail products<br />

in 2020 and professional<br />

growing<br />

media ten years<br />

later. “All <strong>Melcourt</strong><br />

barks originate<br />

from British or<br />

European forests managed on a<br />

fully sustained basis. We subscribe<br />

to both the FSC and the Soil<br />

Association and use products with<br />

these certifications wherever possible,”<br />

says Andy Chalmers.<br />

Supply and demand<br />

Whilst Andy Chalmers spends a lot<br />

of time with customers in the arb,<br />

amenity, landscape and leisure sectors,<br />

he is in fact a forester, having<br />

come up through the FC and private<br />

companies (including UPM<br />

Tilhill, Fountain <strong>Forestry</strong>, Forest<br />

Thinnings and EFG plc) both at<br />

home and abroad. He even<br />

remembers selling sawlogs to G<br />

Halsey’s Sawmill at London Colney<br />

(near St Albans) in Hertfordshire,<br />

where my grandfather worked for<br />

50 years before it was closed to<br />

make way for housing some 40<br />

years ago.<br />

As an experienced forester and MD<br />

of a company that needs British<br />

conifer bark, Andy Chalmers sees<br />

the need for UK forestry to replant<br />

all the conifers clearfelled and to<br />

massively extend planting. The<br />

industry needs to provide the<br />

resources required for timber and<br />

wood processes and associated<br />

natural materials like bark, on<br />

which his company relies.<br />

The impending shortfall of<br />

UK-grown conifer bark resources<br />

could set a ceiling on companies<br />

like <strong>Melcourt</strong>. The professional<br />

growing media market, for example,<br />

supplies 1 million cubic metres<br />

a year. “If needs be, I could access<br />

100,000 cubic metres of bark fines<br />

today,” said Andy Chalmers, “but I<br />

cannot import bark because it is<br />

too expensive for this market.”<br />

He dismisses some of the wilder<br />

claims over timber imports from<br />

markets as far afield as Canada,<br />

Brazil, South Korea and Australasia,<br />

especially those for industrial-scale<br />

biomass burning. He doubts<br />

whether these countries would be<br />

in position to sell the UK all it<br />

needs, even if they wanted to.<br />

He bemoans the fact that, in<br />

spite of all the expert advice,<br />

including the Read Report, UK forestry<br />

is failing to grasp the nettle,<br />

while the Government, like Nero,<br />

“Fiddles while Rome burns.”<br />

Dr Terry Mabbett<br />

Sign up today for free<br />

classified listings for 2012<br />

The online trading platform for the forestry and biomass industries<br />

Logshed offers an easy to use online trading platform for<br />

all those involved in the buying or selling of forestry and<br />

biomass products nationwide.<br />

We are a comprehensive and resourceful hub for all areas of the forestry and<br />

biomass sector designed by the industry for the industry<br />

Trading Platforms<br />

• Timber auctions<br />

• Biomass auctions<br />

• Machinery auctions<br />

• <strong>Forestry</strong> and Woodland auctions<br />

Directory<br />

• Timber<br />

• Biomass<br />

• Machinery<br />

• <strong>Forestry</strong> and Woodland<br />

Visit us online today to find out more<br />

Classified<br />

• Timber<br />

• Biomass<br />

• Machinery<br />

• <strong>Forestry</strong> and Woodland<br />

• Jobs<br />

Community<br />

• News<br />

• Events<br />

www.logshed.co.uk<br />

T: 01423 320749 E: info@logshed.co.uk