TENAX Kunststoffe GmbH - extrudierte Netze und Gitter aus Kunststoff

TENAX Kunststoffe GmbH - extrudierte Netze und Gitter aus Kunststoff

TENAX Kunststoffe GmbH - extrudierte Netze und Gitter aus Kunststoff

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>TENAX</strong> <strong><strong>Kunststoff</strong>e</strong> <strong>GmbH</strong> • Schloßstraße 13 • 88131 Lindau - Deutschland<br />

Tel (+49) 08382-93040 • Fax (+49) 08382-930430 • E-mail: info@tenax-net.de<br />

CASE HISTORY<br />

Railroad line Trieste Vienna: railway<br />

ballast stabilization by means of<br />

geosynthetics<br />

PRODUCT<br />

<strong>TENAX</strong> LBO 401 SAMP<br />

bi-oriented geogrids<br />

PROBLEM<br />

The railroad line Trieste Vienna, is<br />

crossing the Slovenian territory on<br />

very poor fo<strong>und</strong>ation soils (soil<br />

fo<strong>und</strong>ation modulus always lower<br />

than 20 MPa and locally equal to 5-<br />

10 MPa). On such conditions of<br />

excessive settlements, a drastic<br />

reduction of the trains were forced<br />

to travel at a low speed of 40-50<br />

km/h) until major reconstruction<br />

was completed. Since it was<br />

necessary to substitute only one<br />

track at a time, increasing the traffic<br />

on the adjoining track, the<br />

possibilities to remove poor<br />

superficial soil (clayey silt and clay)<br />

were very little (limited to the first<br />

0.60 m). In order to assure the<br />

minimum soil elastic modulus<br />

required by the Slovenian Railway,<br />

it was necessary to stabilize the<br />

fo<strong>und</strong>ation layers (50 MPa) by using<br />

<strong>TENAX</strong> geogrids.<br />

SOLUTION: ŠENTJUR-CELJE<br />

Specifically, in the track section<br />

between the cities of Sentjur and<br />

Celie, bioriented geogrids in PP<br />

<strong>TENAX</strong> LBO 401 SAMP were used to<br />

stabilize the railways fo<strong>und</strong>ation.<br />

<strong>TENAX</strong> LBO 401 SAMP geogrids are<br />

manufactured from polypropylene<br />

(PP) by a patent extrusion process<br />

and successively oriented in both<br />

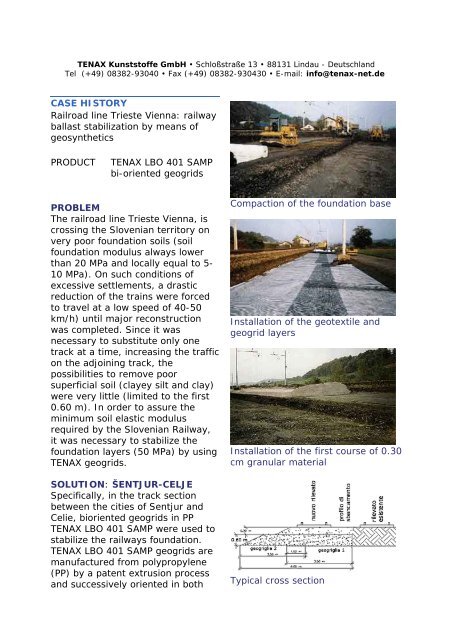

Compaction of the fo<strong>und</strong>ation base<br />

Installation of the geotextile and<br />

geogrid layers<br />

Installation of the first course of 0.30<br />

cm granular material<br />

Typical cross section

MD and TD directions thus creating<br />

biaxial geogrids.<br />

After the removal of the ballast and<br />

partial fo<strong>und</strong>ation soil, the<br />

fo<strong>und</strong>ation was compacted by<br />

means of a compactor roller (photo<br />

n. 1); then a geotextile, a <strong>TENAX</strong><br />

LBO 401 SAMP geogrid (photo n. 2)<br />

and 60 cm layer of granular<br />

material were placed (laid and<br />

compacted in two different lifts)<br />

(photo n. 3) and successively<br />

covered with 30 cm of ballast. A<br />

nonwoven geotextile below the<br />

bioriented geogrid in PP to has been<br />

installed at the base of the ballast.<br />

The geotextile provides the filtering<br />

effects between the fo<strong>und</strong>ation soil<br />

and the ballast, while the geogrid<br />

prevents the geotextile from<br />

excessive deformation and stiffening<br />

the subbase (reinforcement and<br />

separation functions).<br />

In this way the so called risk of<br />

"pumping" of fine particles of the<br />

fo<strong>und</strong>ation inside the granular<br />

material of the ballast, due to the<br />

compression and decompressing<br />

cycles c<strong>aus</strong>ed by the rapid passage<br />

of trains, was avoided.<br />

The grain size variation, due to the<br />

increasing portion of the fine<br />

fraction, generates a progressive<br />

water retention within the ballast,<br />

with consequent greater<br />

settlements. Besides, the separation<br />

layer at the toe of the ballast allows<br />

a filtering action between the ballast<br />

and the fo<strong>und</strong>ation soil, avoiding the<br />

capillary raise from fo<strong>und</strong>ation.<br />

CONCLUSIONS<br />

The embankment was completed in winter of 1996 and the railway line is<br />

fully operative. The geogrids installed were monitored by means of<br />

extensometers to verify the local shear stresses acting on the<br />

reinforcement. The low mobilised geogrid strains show that the geogrid is

fully performing within the reinforced section as a rigid load transfer<br />

platform; thus minimizing the shear displacement and consequent loss of<br />

bearing capacity and settlements.<br />

<strong>TENAX</strong> <strong><strong>Kunststoff</strong>e</strong> <strong>GmbH</strong> • Schloßstraße 13 • 88131 Lindau - Deutschland<br />

Tel (+49) 08382-93040 • Fax (+49) 08382-930430 • E-mail: info@tenax-net.de