Mazzei Air Injectors (selection and installation)

Mazzei Air Injectors (selection and installation)

Mazzei Air Injectors (selection and installation)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Mazzei</strong> <strong>Injectors</strong><br />

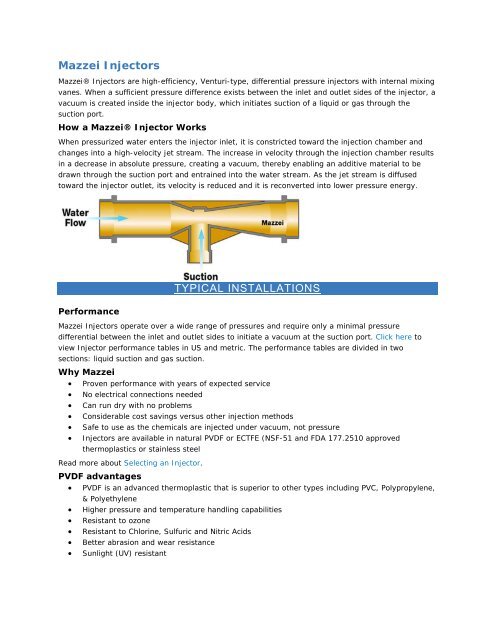

<strong>Mazzei</strong>® <strong>Injectors</strong> are high-efficiency, Venturi-type, differential pressure injectors with internal mixing<br />

vanes. When a sufficient pressure difference exists between the inlet <strong>and</strong> outlet sides of the injector, a<br />

vacuum is created inside the injector body, which initiates suction of a liquid or gas through the<br />

suction port.<br />

How a <strong>Mazzei</strong>® Injector Works<br />

When pressurized water enters the injector inlet, it is constricted toward the injection chamber <strong>and</strong><br />

changes into a high-velocity jet stream. The increase in velocity through the injection chamber results<br />

in a decrease in absolute pressure, creating a vacuum, thereby enabling an additive material to be<br />

drawn through the suction port <strong>and</strong> entrained into the water stream. As the jet stream is diffused<br />

toward the injector outlet, its velocity is reduced <strong>and</strong> it is reconverted into lower pressure energy.<br />

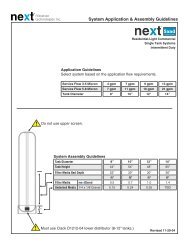

TYPICAL INSTALLATIONS<br />

Performance<br />

<strong>Mazzei</strong> <strong>Injectors</strong> operate over a wide range of pressures <strong>and</strong> require only a minimal pressure<br />

differential between the inlet <strong>and</strong> outlet sides to initiate a vacuum at the suction port. Click here to<br />

view Injector performance tables in US <strong>and</strong> metric. The performance tables are divided in two<br />

sections: liquid suction <strong>and</strong> gas suction.<br />

Why <strong>Mazzei</strong><br />

• Proven performance with years of expected service<br />

• No electrical connections needed<br />

• Can run dry with no problems<br />

• Considerable cost savings versus other injection methods<br />

• Safe to use as the chemicals are injected under vacuum, not pressure<br />

• <strong>Injectors</strong> are available in natural PVDF or ECTFE (NSF-51 <strong>and</strong> FDA 177.2510 approved<br />

thermoplastics or stainless steel<br />

Read more about Selecting an Injector.<br />

PVDF advantages<br />

• PVDF is an advanced thermoplastic that is superior to other types including PVC, Polypropylene,<br />

& Polyethylene<br />

• Higher pressure <strong>and</strong> temperature h<strong>and</strong>ling capabilities<br />

• Resistant to ozone<br />

• Resistant to Chlorine, Sulfuric <strong>and</strong> Nitric Acids<br />

• Better abrasion <strong>and</strong> wear resistance<br />

• Sunlight (UV) resistant

Selecting an Injector<br />

<strong>Mazzei</strong>® <strong>Injectors</strong> are of very high quality <strong>and</strong> are engineered for exact performance. Selecting the<br />

right injector simply requires that you refer to the performance tables found in the resource section<br />

(click here) <strong>and</strong> follow the guidelines.<br />

• Do want to inject a liquid or a gas<br />

• Injection Rate: How much do you want to inject per hour<br />

• Motive Flow Rate: How much water needs to run through the injector<br />

• Inlet Pressure: What is the water pressure available immediately upstream of the injector<br />

• Outlet Pressure: What pressure will the injector see downstream, after <strong>installation</strong><br />

From your answers above, use the <strong>Mazzei</strong> Injector performance tables to select an injector model able<br />

to exceed your desired injection (suction) rate. The total water flow of the system must be equal to or<br />

greater than the injector's motive flow capacity (water through the injector).<br />

1. Locate the injector inlet pressure on the performance table which most closely corresponds to<br />

your maximum available water pressure.<br />

2. Locate the injector outlet pressure which most closely corresponds to your system pressure<br />

downstream of the injector after <strong>installation</strong>.<br />

3. Review the performance table to locate an injector model which has a suction capacity that is<br />

greater than your desired suction capacity. Use a metering valve or orifice assembly to adjust<br />

the injector's suction rate to obtain the precise suction required.<br />

Remember, for the injector to operate properly, it must experience a higher inlet pressure than outlet<br />

pressure (called the differential pressure).<br />

There are several <strong>installation</strong> methods available to ensure the injector operates properly.<br />

NOTES:<br />

Using a metering valve on the suction line can accurately control the suction rate. Viscosity <strong>and</strong> weight<br />

of material will affect the suction rate.<br />

The water flow (motive flow) listed in the performance tables indicates the amount of water that the<br />

injector must be provided at a given pressure. Since the injector acts as a flow restrictor, this is the<br />

total amount of water that will pass through at this pressure.<br />

The outlet pressure is dependent on restriction to flow in the system downstream of the injector. For<br />

example, if pressurized water is flowing through an injector <strong>and</strong> runs down a short pipe <strong>and</strong> simply<br />

falls on the ground, the outlet pressure (back-pressure) is nearly zero. Any restrictions downstream in<br />

the form of piping, filters, valves, sprinklers, emitters, etc. cause the outlet pressure (or backpressure<br />

on the injector) to change.<br />

Should you have any questions, our experienced technical support staff is ready to help. Contact us<br />

with your requirements <strong>and</strong> allow us to assist you in designing your injection system.

Typical Installation Methods<br />

Fig 1 Fig 2<br />

The injector is installed around a point of restriction such as a regulator valve or a gate/ball valve to<br />

create a differential pressure across the injector. This allows the injector to produce a vacuum <strong>and</strong><br />

draw in material. (See Fig.1 <strong>and</strong> Fig.2)

Fig 3<br />

The injector is installed on the mainline <strong>and</strong> the pressure reducing device is on the bypass. Chemical<br />

injection can be turned on when the control valve is closed. When the valve is open, injection stops<br />

due to reduced pressure differential. (See Fig.3)

Fig 4<br />

The injector is installed on a bypass with a booster pump. When mainline pressure cannot be reduced,<br />

a small booster pump can be used to create sufficient differential pressure to operate the injector.(See<br />

Fig.4)<br />

Fig 5<br />

The injector is installed in the mainline. The injector must see a sufficient differential to operate. In<br />

other words, the inlet pressure must be sufficiently greater than the outlet pressure.