Product Brochure - English - Martin Automatic Inc

Product Brochure - English - Martin Automatic Inc

Product Brochure - English - Martin Automatic Inc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

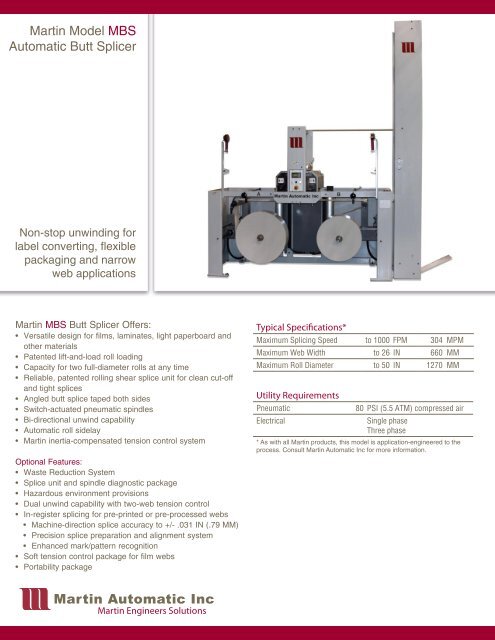

<strong>Martin</strong> Model MBS<br />

<strong>Automatic</strong> Butt Splicer<br />

Non-stop unwinding for<br />

label converting, flexible<br />

packaging and narrow<br />

web applications<br />

<strong>Martin</strong> MBS Butt Splicer Offers:<br />

• Versatile design for films, laminates, light paperboard and<br />

other materials<br />

• Patented lift-and-load roll loading<br />

• Capacity for two full-diameter rolls at any time<br />

• Reliable, patented rolling shear splice unit for clean cut-off<br />

and tight splices<br />

• Angled butt splice taped both sides<br />

• Switch-actuated pneumatic spindles<br />

• Bi-directional unwind capability<br />

• <strong>Automatic</strong> roll sidelay<br />

• <strong>Martin</strong> inertia-compensated tension control system<br />

Optional Features:<br />

• Waste Reduction System<br />

• Splice unit and spindle diagnostic package<br />

• Hazardous environment provisions<br />

• Dual unwind capability with two-web tension control<br />

• In-register splicing for pre-printed or pre-processed webs<br />

• Machine-direction splice accuracy to +/- .031 IN (.79 MM)<br />

• Precision splice preparation and alignment system<br />

• Enhanced mark/pattern recognition<br />

• Soft tension control package for film webs<br />

• Portability package<br />

<strong>Martin</strong> Engineers Solutions<br />

Typical Specifications*<br />

Maximum Splicing Speed to 1000 FPM 304 MPM<br />

Maximum Web Width to 26 IN 660 MM<br />

Maximum Roll Diameter to 50 IN 1270 MM<br />

Utility Requirements<br />

Pneumatic 80 PSI (5.5 ATM) compressed air<br />

Electrical Single phase<br />

Three phase<br />

* As with all <strong>Martin</strong> products, this model is application-engineered to the<br />

process. Consult <strong>Martin</strong> <strong>Automatic</strong> <strong>Inc</strong> for more information.

<strong>Martin</strong> Model MBS <strong>Automatic</strong> Butt Splicer<br />

The benefits of automatic splicing add up to significantly increased productivity, greater quality control and reduced waste.<br />

The MBS applies these benefits to label converting, flexible packaging and narrow web applications.<br />

The MBS is engineered for versatility, combining simplicity and reliability with feature<br />

flexibility. Design features of the MBS include:<br />

•<br />

•<br />

•<br />

•<br />

•<br />

•<br />

Reliable rolling shear splice unit. This patented butt splice unit simultaneously<br />

severs the web and irons tape across the splice, producing a tight bond. The<br />

precision shear wheel and anvil mechanism guarantees a clean cut and no<br />

overlap. A second rotary nip applies tape to the backside of the splice.<br />

Lift-and-load. A patented, built-in roll handling system lifts rolls up to 1500<br />

LBS/680 KGS from the aisle, without the need for<br />

auxiliary roll loading equipment.<br />

<strong>Automatic</strong> sidelay. This feature maintains the<br />

alignment of the running web to the prepared<br />

web in the splice unit. A sensor (ultrasonic shown<br />

here with a clear film) monitors the position of the<br />

running web, and the automatic sidelay system<br />

compensates to insure that the webs are<br />

aligned at the time of a splice.<br />

Inertia compensated tension control. The festoon<br />

features <strong>Martin</strong>’s inertia compensation technology for<br />

consistent, accurate tensioning of the web as it enters the<br />

process.<br />

<strong>Automatic</strong> splice initiation. The MBS monitors the<br />

diameter of the running roll and automatically makes<br />

a roll change at a pre-set diameter. Alternatively, the<br />

tail grabbing function initiates a splice as material<br />

separates from the core for maximum material usage<br />

and minimum waste.<br />

Soft tension features.<br />

The MBS can be<br />

equipped to handle a<br />

wide range of materials,<br />

including delicate film<br />

webs. Driven unwind<br />

packages are available<br />

for lightweight stocks<br />

requiring very low<br />

tension levels and<br />

strictest tension accuracy.<br />

1041 MM<br />

41 IN<br />

2997 MM<br />

118 IN<br />

Dimensions shown are representative of standard model MBS 05-16-40<br />

and are for planning purposes only.<br />

High Performance Splicing, Rewinding and Tension Control<br />

www.martinautomatic.com<br />

<strong>Martin</strong> <strong>Automatic</strong> <strong>Inc</strong> 1661 Northrock Court Rockford, Illinois 61103 tel 815.654.4800 fax 815.654.4810<br />

<strong>Martin</strong> <strong>Automatic</strong> Europe GmbH Sonnenbergstrasse 73 D-74626 Bretzfeld-Dimbach Germany tel +49.7946.942.881 fax +49.7946.942.396<br />

<strong>Martin</strong> <strong>Automatic</strong> Asia-Pacific 3F, No 8, Lane 6, Hsintung Street Taipei, Taiwan 105 tel +886.2.27609886 fax +886.2.27609887<br />

2641 MM<br />

104 IN