CMK-02 volume corrector - firsttech.ro

CMK-02 volume corrector - firsttech.ro

CMK-02 volume corrector - firsttech.ro

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

][][<br />

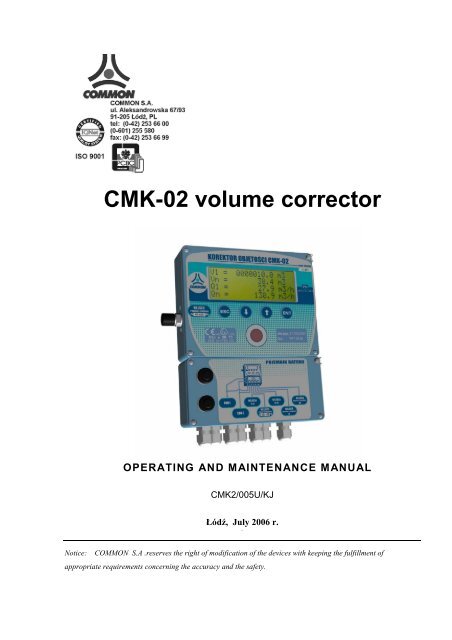

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng><br />

OPERATING AND MAINTENANCE MANUAL<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>2/005U/KJ<br />

Łódź, July 2006 r.<br />

Notice:<br />

COMMON S.A .reserves the right of modification of the devices with keeping the fulfillment of<br />

app<strong>ro</strong>priate requirements concerning the accuracy and the safety.

Contents<br />

1. INTRODUCTION ...................................................................................................................................................4<br />

2. CONSTRUCTION ..................................................................................................................................................5<br />

3. MAIN TECHNICAL AND METROLOGICAL DATA ......................................................................................6<br />

3.1. BASIC DATA OF THE MICROPROCESSOR SYSTEM. ................................................................................................6<br />

3.2. CONDITIONS FOR USE OF THE <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> VOLUME CORRECTOR. ...........................................................................6<br />

3.3. BASIC METROLOGICAL DATA..............................................................................................................................6<br />

4. ASSEMBLY AND INSTALLATION....................................................................................................................7<br />

4.1. CONNECTING THE CORRECTOR ...........................................................................................................................7<br />

4.2. MECHANICAL ASSEMBLY....................................................................................................................................9<br />

4.3. PARAMETERS OF USE ........................................................................................................................................16<br />

5. OPERATING THE CORRECTOR.....................................................................................................................17<br />

5.1. MAIN MENU......................................................................................................................................................18<br />

5.2. ALGORITHM CONSTANTS ..................................................................................................................................18<br />

5.3. CURRENT DATA ................................................................................................................................................19<br />

5.5. GAS COMPOSITION............................................................................................................................................24<br />

5.6. SERIAL CONNECTIONS.......................................................................................................................................25<br />

5.7. CONFIGURATION...............................................................................................................................................25<br />

5.8. NAMEPLATE .....................................................................................................................................................25<br />

5.9. CLOCK..............................................................................................................................................................26<br />

6.1. CONFIGURATION OF THE CORRECTOR OPERATING PARAMETERS ......................................................................28<br />

6.2. PROGRAMMING THE ALGORITHM CONSTANTS ..................................................................................................30<br />

6.3. MODIFICATION OF PARAMETER VALUE.............................................................................................................31<br />

6.4. SETTING THE OPERATING PARAMETERS. ...........................................................................................................31<br />

6.5. CONFIGURATION ACTIVATION ..........................................................................................................................48<br />

7. COMMUNICATION OF THE CORRECTOR WITH A COMPUTER. ........................................................50<br />

8. PACKING, STORAGE AND TRANSPORTATION.........................................................................................51<br />

9. TABLE OF AVAILABLE PARAMETERS .......................................................................................................52<br />

10. TABLE OF ALARMS.........................................................................................................................................56<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 3

1. Int<strong>ro</strong>duction<br />

The <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> is used for determination of the <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> and the gas flow in<br />

standard conditions. It is designed for installation in the reduction and the gas measuring<br />

stations. On the base of pulses generated by the reed contact sensor, placed in the gas meter,<br />

the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> counts the uncorrected gas <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng>. At the same time the temperature and the gas<br />

pressure measurement is taken. On the base of the taken measurements and the declared gas<br />

composition the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> calculates the compressibility coefficient, using the permissible<br />

method (in gas industry GERG 88), and converts the uncorrected gas <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> to standard<br />

conditions (in Poland: p=101,325 kPa; T=273,15 K).<br />

The <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> also calculates and logs:<br />

• correction coefficient,<br />

• real <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> flow,<br />

• standard <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> flow,<br />

• gas density in standard conditions,<br />

• energy and mass flow flowing th<strong>ro</strong>ugh the pipeline,<br />

• date, time and maximum number of pulses counted in one minute,<br />

• date, time and hourly peak values between completed hours ,<br />

• date, time and hourly peak values with sliding window.<br />

These data together with the temperature and the gas pressure and uncorrected and<br />

standard <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> are stored in nonvolatile <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>’s memory. They can be read on the fourline,<br />

twenty-character liquid crystal display or remotely via the serial transmission connections.<br />

The <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> is p<strong>ro</strong>vided with the transmission p<strong>ro</strong>tocol compliant with the GAZ-MODEM<br />

p<strong>ro</strong>tocol as well as with the functional subset of MODBUS p<strong>ro</strong>tocol (RTU and ASCII version).<br />

Each signal converter operating in theRS-GAZ2 standard can cooperate with the system. Its<br />

application is especially recommended for:<br />

• continuous reading: two-channel signal converter with the CZAK-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> power supply or the<br />

CBS-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> signalling barrier. These devices require the power supply connection.<br />

• periodical reading: the CAK-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> battery converter or the COG-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> optical connection.<br />

These devises do not require the power supply connection.<br />

The <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> is manufactured in two versions, depending on the way of supply of additional<br />

PC-70 pressure converter:<br />

1. In standard version – it is possible connection of one or two additional PC-70<br />

converters supplied via the external converter (i.e. the CZAK-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> converter, the CBS-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng><br />

barrier).<br />

2. In version „B” (on special order) – it enables connection of one PC-70 pressure<br />

converter supplied f<strong>ro</strong>m the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>’s internal battery (without necessity to connect the<br />

additional power supply). In this version after the factory number the „B” character is<br />

added. The <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> in the „B” version is equipped with two inputs and one digital<br />

output.<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 4

2. Construction<br />

The <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> has two-chamber construction. In the upper chamber it is located the<br />

mainboard with the p<strong>ro</strong>cessor, serial connection systems and measuring converters used for<br />

conversion of signals f<strong>ro</strong>m the measuring converters to digital signals. The absolute pressure<br />

sensor is also located there. The chamber is sealed by the manufacturer; tearing off the seal<br />

is equivalent to warranty loss and annulment of factory certificate!<br />

The lower chamber includes the terminal strip to which the data transmission circuits and<br />

the signalling and measuring circuits are connected. The batteries and the configuration<br />

selector switch used when manually configuring the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>’s operating parameters<br />

(discussed below) are also located there. This chamber should be sealed by the user (see the<br />

chapter „Assembly and installation”).<br />

Data transmission f<strong>ro</strong>m the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> may be performed with the use of RS-GAZ2/RS-232<br />

signal converter eg: CZAK-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>, CAK-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>, CBS-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> and via the OPTO-GAZ connection (COG-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng><br />

interface). After putting the OPTO-GAZ head against the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>’s f<strong>ro</strong>nt plate at the marked<br />

place, it is carried out the automatic switching over the COM1 line f<strong>ro</strong>m the RS1 permanent<br />

connection (connected to the terminal strip or to the TUCHEL socket). This enables direct<br />

reading of the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> without necessity to disconnect the remaining RS1 and RS2<br />

connections (in case when both are used). You can buy the COG-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> interface in COMMON<br />

S.A.<br />

Operating conditions of the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> are included in chapters „Basic<br />

technical and met<strong>ro</strong>logical data” and „Assembly and installation”. We recommend<br />

detailed acquainting with these chapters prior to assembly of the device.<br />

The <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> can operate in two basic configurations:<br />

a) Battery operation – the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> operates in accounting mode with possibility of<br />

connecting two inputs and two pulse outputs with the p<strong>ro</strong>grammable function (standard<br />

version); possibility of reading data after connecting the external signal converter of<br />

app<strong>ro</strong>ved type; calculation of the Qn flow is performed on the base of low frequency<br />

pulses LF.<br />

b) Mains operation (with external supply) – all functions as in the battery operation and<br />

additional possibility of connecting the high frequency pulse transmitter HF of app<strong>ro</strong>ved<br />

type and possibility of connecting two additional PC-70 pressure converters.<br />

The <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> has the possibility of logging up to 32768 samples of accounting<br />

data, that ensures permanent logging the device’s operation for 142 days with the set 10<br />

minute logging interval. The daily data memory ensures permanent logging for 5 years, the<br />

monthly data memory – for the whole period of the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> operation, the list of events<br />

may contain up to 4000 logs.<br />

With the assumption of 2 hour daily operation without the external power supply with the<br />

LCD display switched on, the battery supply system ensures the 5 year permanent operation of<br />

the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>.<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 5

3. Main technical and met<strong>ro</strong>logical data<br />

3.1. Basic data of the mic<strong>ro</strong>p<strong>ro</strong>cessor system.<br />

- P<strong>ro</strong>cessor: INTEL 386<br />

- Memory: 256kB – Static RAM, 2MB or 4MB – FLASH ROM,<br />

- A/C converter: 24-bit sigma-delta<br />

- Clock: Internal real time clock RTC<br />

- Communication: Two independent serial transmission channels<br />

RS-GAZ2 (up to 115200 baud)<br />

- Display: LCD – four lines, twenty characters each; maintaining<br />

contract in the whole range of ambient temperatures (-<br />

25 O C ÷ +55 O C)<br />

- Keyboard: foil keyboard, four keys<br />

- Technology: 2,7-Volt<br />

- Power supply: 2 lithium batteries SL-780 3,6V/13,5Ah (p<strong>ro</strong>tected by<br />

resistors and insulating sleeve)<br />

3.2. Conditions for use of the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>.<br />

- Ambient temperature: -25 O C ÷ +55 O C<br />

- Relative humidity: max. 95% at 55 O C<br />

- Casing degree of p<strong>ro</strong>tection: IP54<br />

- EMI disturbances: character and disturbances level fulfils the requirements<br />

of company standard PGNiG ZN-G-4007 z 2001r.<br />

- Marking of the explosion p<strong>ro</strong>of casing: II 2G EEx ia IIB T3<br />

- Certificate number: KDB 1453 04 ATEX 220<br />

- Compliance with standards: PN-EN 50014 , PN-EN 50<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>0<br />

3.3. Basic met<strong>ro</strong>logical data<br />

Pressure measurement:<br />

For the measurement it is used the absolute pressure sensor operating in one of the<br />

following measuring ranges:<br />

0,09÷0,7 MPa, 0,25÷2 MPa, 0,5÷4 MPa, 1÷8 MPa , 1,3÷10 MPa.<br />

The limiting relative er<strong>ro</strong>r of pressure measurement related to the measured value amounts to<br />

δ=0,3% in the whole range of the operating pressure and temperature. The pressure measuring<br />

range is p<strong>ro</strong>grammable within the sensor measuring range. The pressure sensor is mounted<br />

inside the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>’s casing.<br />

Temperature measurement:<br />

The gas temperature measurement is performed by the PT1000 class A sensor with the<br />

measuring range -25 O C ÷ +50 O C. The limiting relative er<strong>ro</strong>r of the measurement related to the<br />

measured value (in Kelvin scale) amounts to δ=0,2% in the whole range of ambient<br />

temperature. The temperature measuring range is p<strong>ro</strong>grammable within the PT1000 sensor<br />

measuring range. The sensor is fixed in the measuring section or in the gas meter.<br />

NOTICE:<br />

The P and T er<strong>ro</strong>r values are compliant with OIML SP6 Sr9 recommendations on the<br />

subject: „Elect<strong>ro</strong>nic instruments for <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng>tric gas meters” and with the company standard<br />

PGNiG ZN-G-40001 f<strong>ro</strong>m 2001r.<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 6

4. Assembly and installation<br />

The <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> is adapted to direct mounting on the <strong>ro</strong>tor gas meter, on the<br />

measuring section or directly on e.g. the wall of the station. The temperature sensor is fixed in<br />

the measuring section of the assembly kit in the temperature measurement stub pipe. The<br />

pressure f<strong>ro</strong>m the gas meter impulse aperture is led by the impulse piping to the internal<br />

pressure sensor. When making connection it is recommended to use the three-way manometer<br />

cock (eg. CKMT of COMMON).<br />

4.1. Connecting the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng><br />

The electrical connection of the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> with the remaining system elements should be<br />

done by the multi-core cables with conductors made in form of stranded wires. The following<br />

cables should be used:<br />

a) for connecting the supply and the „RS-GAZ2” data transmission to the terminal strip or the<br />

„Tuchel” type connector – the unscreened four-core cable; required parameters R p ≤30Ω,<br />

L p ≤3mH.<br />

When selecting the cable one should strictly take into account the presumed distance<br />

between the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> and the cooperating device (i.e. CZAK-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> converter,<br />

CBS-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>, etc.).<br />

The examples of cable selection:<br />

Distance<br />

The example of cable type<br />

up to 100m LIYY 4x0,25mm 2<br />

up to 200m LIYY 4x0,5mm 2<br />

up to 400m LIYY 4x1mm 2<br />

over<br />

Loop parameters must meet:<br />

R p ≤30Ω, L p ≤3mH<br />

R p = 2 * R Cu ; L p + L it ≤ L O<br />

where: L it - output inductance of the connected accompanying device,<br />

L O - maximum inductance connected to the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>’s terminals (L O =3mH).<br />

l<br />

R Cu<br />

ρ ;<br />

S<br />

The resistance of copper conductor (one core): = [ Ω]<br />

where: ρ [Ωm] – copper resistivity (at 20°C ρ Cu = 0,0168*10 -6 [Ωm]),<br />

l [m]<br />

- length,<br />

S (m 2 ) - c<strong>ro</strong>ss section.<br />

The <strong>ro</strong>ugh inductance of the LIYY cable amounts L p = 0,7mH/km (use the catalogue data of<br />

the applied cable manufacturer).<br />

b) for connecting the temperature sensor to the terminal strip – two wires in common screen<br />

i.e.: LIYCY 2x0,25mm 2 .<br />

The screen of the cable should be connected only f<strong>ro</strong>m the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> side to the<br />

casing earth – screw terminal on the lower right corner of the plate!<br />

c) for connecting the reed contact pulse transmitter to the terminal strip – two unscreened<br />

cores i.e.: LIYY 2x0,25mm 2 ;<br />

d) for connecting input signals (IN) to the terminal strip – four unscreened cores i.e.: LIYY<br />

4x0,25mm 2 ;<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 7

e) for connecting input signals (OUT) to the terminal strip – four unscreened cores i.e.: LIYY<br />

4x0,25mm 2 ;<br />

f) for connecting the HF internal pulses transmitter to the terminal strip – two unscreened<br />

cores i.e.: LIYY 2x0,25mm 2 ;<br />

NOTICE:<br />

• Owing to the used PG9 type cable glands the external cable diameter should be<br />

f<strong>ro</strong>m 5 to 8,5mm.<br />

• The <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> casing must be elect<strong>ro</strong>statically earthed with the help of R

4.2. Mechanical assembly<br />

Fig.1. Mounting the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>, version 1.<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 9

Fig. 2. Mounting the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>, version 2.<br />

.<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 10

Fig. 3. Mounting the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>, version 3.<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 11

The installation of the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> may be differentiated into few stages:<br />

1. Install of the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> nearby the gas meter at a place easily accessible for maintenance<br />

and service. To do this one should use a holder app<strong>ro</strong>priate for the gas meter and the<br />

mounting conditions in the measuring station. The offer of COMMON S.A. firm includes a few<br />

types of holders for fixing the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> on the measuring section or on the gas meter. When<br />

selecting the place for the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> take into account that the pressure sensor inside the<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> must not be located below the pressure measurement stub pipe of the gas meter.<br />

2. Connection of the pressure measurement. The pressure measurement stub pipe located<br />

on the gas meter should be connected with the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>’s pressure sensor with the help of<br />

impulse piping. It should also be installed the three-way cock to facilitate later servicing of the<br />

<st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> or connecting the cont<strong>ro</strong>l manometer. The offer of COMMON S.A. firm also<br />

includes the CKMT three-way cock (made by COMMON S.A.).<br />

3. The connection of basic measurements. To perform the basic function: the accounting<br />

operation, it is necessary to connect the low frequency (LF) transmitter circuit f<strong>ro</strong>m the gas<br />

meter head and the temperature sensor circuit. Below it is given the description of the<br />

terminal strip:<br />

Pt 1000<br />

1 2<br />

LF<br />

1 2<br />

The <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> is adapted for operation with the reed contact LF transmitter (every gas meter<br />

of COMMON firm is equipped with it as a standard). The polarity of the LF transmitter and<br />

the Pt 1000 sensor is of no importance.<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 12

Example of mounting the Pt 1000 temperature sensor<br />

1. outlet section,<br />

2. temperature sensor Pt 1000,<br />

3. thermometric sleeve<br />

4. seal<br />

4. Connecting the additional measurements. The description of the terminal strip is given<br />

below. Pay attention to the polarity of the connecting circuits (if the circuits of the connecting<br />

devices have the defined polarity). Because the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> is entirely an intrinsically safe<br />

device, all circuits must be connected to the circuits of the intrinsically safe devices; in other<br />

cases the explosion p<strong>ro</strong>of barriers should be used.<br />

IN 2 OUT 4<br />

- + - +<br />

IN 1 OUT 3<br />

- + - +<br />

HF<br />

- +<br />

The input circuits marked IN1 and IN2 can cooperate with the intrinsically safe circuits<br />

of the simply devices and in particular with contacts of the switching elements<br />

app<strong>ro</strong>ved for operation in the intrinsically safe circuits.<br />

The input circuits marked OUT3 and OUT3 can cooperate with the external intrinsically<br />

safe circuits of ia or ib category. Maximum value of capacitance and inductance for this<br />

circuit should be assumed according to the criterion of the connected circuit, taking into<br />

consideration the internal C i and L i parameters<br />

NOTICE:<br />

For the option with the digital PC-70 pressure transmitter supplied f<strong>ro</strong>m the<br />

<st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>’s battery the OUT3 is used for supplying it.<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 13

5. Connecting the power supply and data transmission in the RS-GAZ2 standard.<br />

The converter (e.g. CZAK-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>, CBS-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>, CAK-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>, and CAKGSM-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>) must be installed<br />

outside the explosion zone. The installation conditions are described in the converter<br />

documentation. The app<strong>ro</strong>priate terminals of the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>’s terminal strip<br />

should be connected to the adequately marked connectors in the converter. Attention<br />

should be paid to the description of the terminals because their location in the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng><br />

and the converter is not the same.<br />

The <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> terminal strip:<br />

A B A B<br />

TUCHEL connector on the casing:<br />

V+<br />

RS 1 RS 2<br />

V+ ┴ V+ ┴<br />

View f<strong>ro</strong>m the f<strong>ro</strong>nt of Tuchel male socket on<br />

the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>’s casing<br />

6. Connecting the PC-70 digital pressure converter. The <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> ensures<br />

the possibility of connecting and logging the additional pressure measurements with<br />

the help of the PC-70 digital pressure converters. Cooperation between the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng><br />

<st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> and the PC-70 converters is performed with two version of supply:<br />

• The <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> uses the external power supply. The supply can be<br />

transferred by a suitable transmission converter (recommended for the mains<br />

supply: two-channel converter with the CZAK-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> power converter, the CBS-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng><br />

signaling barrier; recommended for supply f<strong>ro</strong>m the battery and the solar battery:<br />

CAKGSM-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> converter) – possible connection of two sensors.<br />

• The <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> uses its own battery supply (only for the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> in „B”<br />

version) – possible connection of one sensor.<br />

The PC-70 pressure converter is placed in the casing with the stub pipe with the M20x1,5<br />

external thread and dimensions given below.<br />

Stub pipe dimensions of the PC-70 converter.<br />

2 1<br />

5<br />

3 4<br />

1 - RSGAZ 2 B<br />

2 - RSGAZ 2 A<br />

4 - + SUPPLY<br />

5 - ⊥ EARTH<br />

Description and designation of the PC-70 converter connector leads<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 14

Connection of the PC-70 converter with the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> and the power supply/ the<br />

CZAK-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> converter (mains supply):<br />

230 V<br />

RS232<br />

CZAK-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng><br />

E X zone<br />

4 x LIYY 0,25 mm 2<br />

(or 0,5 lub 1) mm 2<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng><br />

RS1 RS2<br />

4 x LIYY 0,25 mm 2<br />

(Notice! Supply to RS1)<br />

PC 70<br />

CZAK-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> PC-70 (1) PC-70 (2)<br />

A (COM1) A (RS 1)<br />

B (COM1) B (RS 1)<br />

A (RS 2) 2 2<br />

B (RS 2) 1 1<br />

V+ (COM1) V+ (RS 1) 4 4<br />

┴ (COM1) ┴ (RS 1) 5 5<br />

Maximum distance between the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> and the PC70 converter with the given<br />

cable c<strong>ro</strong>ss section (0,25 mm2) should be shorter than 25 meters.<br />

The cables supplying the PC-70 converter should be connected together with the supply<br />

f<strong>ro</strong>m the CZAK-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> converter (to the same terminals on the RS 1 port terminal strip in the<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng><st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>).<br />

Connect the second PC-70 converter to the same terminals as the first one.<br />

Connection of the PC-70 converter with the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> (battery supply):<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng><br />

RS1 RS2<br />

PC 70<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> PC-70<br />

A (RS 2) 2<br />

B (RS 2) 1<br />

– OUT 3 4<br />

┴ (RS 2) 5<br />

4 x LIYY 0,25 mm 2<br />

The circuits going out f<strong>ro</strong>m the explosion zone can be led in one bundle.<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 15

4.3. Parameters of use<br />

Below there are given the electrical parameters related to individual terminals and<br />

connectors of the device:<br />

RS-GAZ2:<br />

The V+, terminals of the RS1 and RS2 terminal strip and the 4-5 pins of TUCHEL<br />

connector on the casing have the following parameters:<br />

U i =7,5V, I i =0,45A, P i =0,85W, L i ≈0, C i

5. Operating the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng><br />

The communication of the user with the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> is performed by means of keyboard and<br />

four-line alphanumeric display. The keyboard consists of four keys Esc, Enter, and the ↓,<br />

↑ ar<strong>ro</strong>ws.<br />

The Enter key causes moving to the submenu, changing the active position in the editor<br />

or storing the entered value.<br />

The Esc key causes return to the upper menu or exit f<strong>ro</strong>m the value editing mode.<br />

The ↓ and ↑ keys cause changing the submenu, displaying the consecutive sequence of<br />

information, which do not hold on one screen and setting the parameters in case of<br />

modification of the settings.<br />

When the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> is fallen asleep (display is not active) it should be stimulated by<br />

pressing any key. The display is turned off automatically after 30 seconds since the<br />

moment one stopped using the keyboard (with the external supply the display remains<br />

switched on all the time).<br />

The following screens are displayed (moving to the consecutive screen is done after<br />

pressing the ↓ key):<br />

1) Main counters and <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> flows:<br />

• uncorrected <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> (V1),<br />

• standard <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> (Vn),<br />

• real flow (Q1),<br />

• standard flow (Qn).<br />

V1 = 0009543.0 m3<br />

Vn = 18520.0 m3<br />

Q1 =s 171.5 m3/h<br />

Qn = 188.9 m3/h<br />

NOTICE:<br />

The ‘s’ character on the right of the ‘=’ sign means that the simulation is switched<br />

on.<br />

2) Gas parameters and correction values:<br />

• compressibility coefficient (K1),<br />

• correction coefficient (F),<br />

• momentary gas temperature (t1),<br />

• momentary gas pressure (p1).<br />

Alarms:<br />

K1 = 0.997546<br />

F = 2.386054<br />

t1 =s 19.8 °C<br />

p1= 258.7 kPa<br />

• The ‘’ sign at the ‘t1’ or ‘p1’ labels means that the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> was not able to<br />

take the p<strong>ro</strong>per measurement of the given value – the value f<strong>ro</strong>m the previous<br />

measurement remains on the display.<br />

• The sign ‘!’ means c<strong>ro</strong>ssing of the defined alarm limits, flashing ‘!’ sign means<br />

c<strong>ro</strong>ssing the defined converter ranges and the NAN value – converter failure.<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 17

The measurements of the p1, t1 values and the calculations of correction coefficient in the<br />

battery supply mode are performed every 30 seconds, and with external supply every 2<br />

seconds.<br />

The calculation of the compressibility coefficient is performer every 30 seconds on the<br />

base of the mean temperature and the pressure values for the last 30 seconds.<br />

3) Gas consumption<br />

- value f<strong>ro</strong>m the beginning of the hour (ph),<br />

- expected consumption to the end of the hour (eph),<br />

-=- -=ph<br />

= 12.69 m3<br />

eph = 542.71 m3<br />

-=- -=-<br />

Expected hourly consumption – way of calculation<br />

The gas quantity that will be consumed to the end of the hour is calculated on the<br />

base of the standard flow current value, and with assumption of its invariability. Then<br />

the value is increased by the consumption since the beginning of the clock hour.<br />

4) The condition of the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>’s supply and the battery capacity.<br />

Mains operation<br />

Battery condition 85%<br />

˜˜˜˜˜˜˜˜˜˜˜˜˜•••<br />

Battery operation<br />

Battery condition 85%<br />

˜˜˜˜˜˜˜˜˜˜˜˜˜•••<br />

After reaching the state of 5% the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> starts logging the alarm ‘Low supply voltage’,<br />

and below 1% the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>’s and logger’s modules are switched off. The data<br />

transmission still can be performed by eg.: the OptoGAZ interface.<br />

5.1. Main menu<br />

After pressing the Enter key the main menu is displayed. The selection is done with the<br />

help of the ↑ and ↓ keys. The selection is confirmed by the Enter key.<br />

5.2. Algorithm constants<br />

→algorithm constants<br />

current data<br />

logged data<br />

gas composition<br />

serial connections<br />

configuration<br />

plate<br />

clock<br />

The presented information is split to the data concerning the <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> and the gas<br />

compressibility coefficient determination method.<br />

The following data are displayed: HF, LF pulse weight, moment of logging the logged data<br />

and the current source of Qr and Vr signal.<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 18

HF = 3228.10 imp/m3<br />

LF = 1.00 imp/m3<br />

Q:LF[] V:LF<br />

R+ [dt=10min] K+<br />

Information concerning the signal source used for determination of the Q flow:<br />

- Q : LF [LF] - the flow is calculated f<strong>ro</strong>m the low frequency reed contact transmitter LF,<br />

- Q : HF [HF] - the flow is calculated f<strong>ro</strong>m the high frequency transmitter HF.<br />

In case the setting is present in the square bracket (Q : HF []) the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> selects<br />

by itself the flow signal source depending on signal availability (eg. the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng><br />

determines the flow Q f<strong>ro</strong>m the HF transmitter, in case of failure in the external supply the<br />

<st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> automatically switches over to determination of Q f<strong>ro</strong>m the LF transmitter).<br />

The +/- signs at the R and K characters means the status of switching on/ switching off the<br />

<st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>’s (R) and data logger’s (K) modules.<br />

When the accounting data logging period is to be changed and it was chosen the<br />

synch<strong>ro</strong>nization with the beginning of the accounting day, the app<strong>ro</strong>priate information is<br />

displayed:<br />

HF = 3228.10 imp/m3<br />

LF = 1.00 imp/m3<br />

Q:LF[] V:LF<br />

R+ [dt=5→10min] K+<br />

After pressing the ar<strong>ro</strong>w key there are displayed:<br />

• standard temperature,<br />

• standard pressure,<br />

• applied calculation method,<br />

• type of gas mixture.<br />

tn = 273.15 K<br />

pn = 101325 Pa<br />

K1 wg GERG-88<br />

natural gas<br />

The calculation method matches with the selected gas composition. As a standard the<br />

<st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> is p<strong>ro</strong>vided with the GERG-88 algorithm, the following algorithms are also<br />

available on the order:<br />

Natural gas:<br />

GERG-91, AGA-NX19<br />

City gas/coke-oven gas:<br />

Beattie-Bridgeman,<br />

Others (CO 2 , hyd<strong>ro</strong>gen, nit<strong>ro</strong>gen, argon, air, p<strong>ro</strong>pane-buthanee and others):<br />

Peng-Robinson, Van der Waals, Redlich-Kwong, Soeve-Redlich-Kwong, virial equation.<br />

5.3. Current data<br />

In this menu there are displayed parameters currently determined by the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng><br />

<st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>. Pressing the ↓ key causes moving to the consecutive set of parameters.<br />

1) Main counters:<br />

- gas <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> in real conditions V1,<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 19

- gas <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> in standard conditions Vn,<br />

- energy counters for standard conditions E (the subscript adequately means:<br />

‘s’ – energy calculated with the use of heat of combustion, ‘i’ – calorific value).<br />

- mass for standard conditions M.<br />

V1 =<br />

Vn =<br />

Es =<br />

M =<br />

0010786.0 m3<br />

21139 m3<br />

142842 MJ<br />

15650 kg<br />

2) Flows:<br />

- gas flow in real conditions Q1,<br />

- gas velocity in the pipeline U1 (to calculate this value p<strong>ro</strong>perly it is required the<br />

information about cooperating gas meter and especially DN parameter),<br />

- normal energy flow,<br />

- mass flow<br />

Q1 =<br />

U1 =<br />

Eq =<br />

Mq =<br />

171.75 m3/h<br />

2.18 m/s<br />

7555.62 MJ/h<br />

140.34 kg/h<br />

3) Current correction values:<br />

- compressibility coefficient K1,<br />

- correction coefficient F,<br />

- gas real temperature,<br />

- gas real pressure.<br />

K1 = 1.000179<br />

F = 1.105173<br />

t1 = 19.8 °C<br />

p1 = 119.9 kPa<br />

3) Digital in/out:<br />

- HF pulse weight measured by the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> with reference to 1 m 3 - rHF,<br />

- calculated HF constant er<strong>ro</strong>r with reference to the p<strong>ro</strong>grammed value - eHF,<br />

- state of individual digital in/out, example:<br />

I1 - - I1 output inactive<br />

I1+ - I1 output active, input signal below the filtering threshold<br />

(described in the chapter algorithm constants | signalling),<br />

I1++ I1 output active, input signal above the filtering threshold<br />

(described in the chapter algorithm constants | signalling),<br />

-O4 - O4 output inactive,<br />

+O4- O4 output active, electrical state of the output - open,<br />

+O4+ O4 output active, electrical state of the output - closed<br />

- day, time and maximum number of pulses counted in one minute.<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 20

4) Real parameters of the mixture:<br />

rHF= 900.0 imp/m3<br />

eHF= 0.0000 %<br />

I1++ I2-- -O3- -O4-<br />

Imax 1/12:15 = 7<br />

- real gas density in measuring conditions ρ1,<br />

- relative gas density in measuring conditions d1,<br />

- real heat of combustion Hs1,<br />

- real calorific value Hi1,<br />

ρ1 =<br />

d1 =<br />

Hs1=<br />

Hi1=<br />

0.8306 kg/m3<br />

0.6424 kg/m3<br />

25.8587 MJ/m3<br />

23.3273 MJ/m3<br />

5) Peak consumption for standard values<br />

- values calculated for each day,<br />

- monthly values,<br />

With the Enter key we may change the peak value displaying mode. The following values<br />

will be displayed in turn:<br />

• for daily peak:<br />

− permanent window values (maximum consumption between completed hours),<br />

− slide window values (maximum consumption for the 60 minute period),<br />

− current value (consumption for the last 60 minutes).<br />

• for monthly peak:<br />

− permanent window values,<br />

− slide window values.<br />

The date, moment of the beginning and value of the adequate consumption are<br />

always given.<br />

Daily consumption – way of calculation<br />

The flowing gas standard <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> increase is calculated during every clock hour. The<br />

biggest of them, counting f<strong>ro</strong>m the beginning of the day (as a standard it is 22.00 hour) is<br />

stored in the database as hourly peak together with the signature of the moment of<br />

occurrence.<br />

This cycle is repeated independently for every day.<br />

Daily peak<br />

permanent widow<br />

qh = 482.82 m3/h<br />

06/01/2001 01:00<br />

Daily peak<br />

slide window<br />

qh = 578.71 m3/h<br />

06/01/2001 01:28<br />

Daily peak<br />

current value<br />

qh = 695.33 m3/h<br />

06/01/2001 06:51<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 21

Monthly consumption – way of calculation<br />

F<strong>ro</strong>m the maximum consumption values determined every day the maximum value for the<br />

month’s period is selected and stored in the database as a monthly peak.<br />

This cycle is repeated independently for each day.<br />

Monthly peak<br />

permanent window<br />

qh = 575.23 m3/h<br />

<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>/01/2001 05:00<br />

Monthly peak<br />

slide window<br />

qh = 578.71 m3/h<br />

06/01/2001 01:28<br />

6) Current value for external sensors:<br />

- pressure value,<br />

- calculated gradient value,<br />

- calculated percentage value of the change.<br />

Outlet pressure 1<br />

Pw = 338.1 kPa<br />

+ G= 7.79º Z= 2.01%<br />

Outlet pressure 2<br />

Lack of reading<br />

When the measurement f<strong>ro</strong>m the sensor is switched off or the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> detects the lack of<br />

communication with the transducer for 60 second period, the „Lack of reading” description<br />

is displayed.<br />

5.4. Logged values<br />

The four-item submenu is displayed:<br />

→alarm list<br />

daily data<br />

monthly data<br />

accounting data<br />

After selecting the item, the information about number of records written in the memory is<br />

displayed; the percentage of the memory available for recording is given in brackets.<br />

Number of logs<br />

629 (98%)<br />

↑ the most recent data<br />

↓ the oldest data<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 22

Alarm list contains:<br />

• date and the moment of the start of the event,<br />

• date and the moment of the end of the event or the identifier of the software or the<br />

user,<br />

• estimated gas standard <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> increase (if it was calculated),<br />

• shortened event description.<br />

The list can contain maximum up to 4000 logs.<br />

P: 6/01/01 00:33.35<br />

K: 6/01/01 00:34.09<br />

dVn = 11.5 m3<br />

P limit exceeded<br />

Daily data include:<br />

On each screen:<br />

• date of logging,<br />

On the first screen:<br />

• state of the counter at the end of the day (V1),<br />

• state of the main counter at the end of the day (Vn),<br />

On the second screen:<br />

• time and value of maximum hourly consumption (with the slide window) – (pm),<br />

• time and value of maximum hourly consumption (between completed hours) – (ph),<br />

It is always given the moment of the beginning of the peak.<br />

Switching over between screens is done after pressing the Enter key. The data f<strong>ro</strong>m the<br />

last 60 months are stored.<br />

V1 =<br />

Vn =<br />

Record 9/9<br />

1/01/2001<br />

00<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>500.0 m3<br />

208125.2 m3<br />

Record 9/9<br />

1/01/2001<br />

pm = 1678 m3 21:25<br />

ph = 1677 m3 22:00<br />

Monthly data include:<br />

On each screen:<br />

• date of logging,<br />

On the first screen:<br />

• state of the real counter at the end of the month (V1),<br />

• state of the main counter at the end of the month (Vn),<br />

On the second screen:<br />

• time and value of maximum hourly consumption (with the slide window) – (pm),<br />

• time and value of maximum hourly consumption (between completed hours)– (ph).<br />

It is always given the moment of beginning of the peak.<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 23

Switching over between screens is done after pressing the Enter key. The data f<strong>ro</strong>m the<br />

beginning of the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> use are stored.<br />

V1 =<br />

Vn =<br />

Record 4/2<br />

January 2000<br />

00<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>500.0 m3<br />

208125.2 m3<br />

Record 4/2<br />

January 2000<br />

pm = 1678m3 21:25/01<br />

ph = 1677m3 22:00/01<br />

Accounting data include:<br />

On each screen:<br />

• date and time of logging,<br />

On the first screen:<br />

• gas real <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> increase,<br />

• gas standard <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> increase,<br />

On the second screen:<br />

• mean gas temperature for the logging interval,<br />

• mean gas absolute pressure for the logging period ,<br />

On the third screen:<br />

• reserve 1 – pressure value f<strong>ro</strong>m the first PC-70 sensor,<br />

• reserve 2 – pressure value f<strong>ro</strong>m the second PC-70 sensor.<br />

Switching over between screens is done after pressing the Enter key.<br />

5.5. Gas composition<br />

Record 9/1<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>9<br />

1/01/2000 07:00<br />

dV1 = 00<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>500.0 m3<br />

dVn = 2501.7 m3<br />

Record 9/1<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>9<br />

1/01/2000 07:00<br />

t1 = 19.9 °C<br />

p1 = 99.8 kPa<br />

Record 9/1<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>9<br />

1/01/2000 07:00<br />

r1 = 23.6 °C<br />

r2 = 1.0007<br />

It is displayed the submenu including the following items:<br />

→ gas parameters<br />

gas coefficient<br />

gas composition<br />

Gas parameters (for GERG-88 calculation method):<br />

• molar heat of combustion (Hch),<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 24

• mole fraction CH<br />

• mole fraction N 2<br />

Hch 916.64100<br />

CH participation 0.981822<br />

N2 participation 0.015839<br />

Gas coefficients (for GERG-88 calculation method):<br />

• standard compressibility coefficient (Zn),<br />

• standard density (ρn),<br />

• heat of combustion (Hs),<br />

• calorific value (Hi).<br />

Zn 0.9975<br />

ρn 0.7533<br />

Hs 40.2542<br />

Hi 36.3136<br />

In gas composition menu it is displayed the percentage content (<st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng>tric or molar) of<br />

all gas components in the defined mixture.<br />

5.6. Serial connections<br />

gas composition<br />

natural gas<br />

<st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng>tric composition<br />

methane 95.520<br />

ethane 01.880<br />

p<strong>ro</strong>pane 00.490<br />

n-buthane 00.150<br />

....<br />

oxygen 00.000<br />

carbon dioxide 00.230<br />

sulfur dioxide 00.000<br />

air 00.000<br />

The option serial connection is discussed in chapter 6. Configuration of the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>.<br />

5.7. Configuration<br />

The option configuration is discussed in chapter 6. Configuration of the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>.<br />

5.8. Nameplate<br />

It displays the information of the p<strong>ro</strong>duct, manufacturer and version of internal software.<br />

Factory number 41059<br />

Year of p<strong>ro</strong>duction 2000<br />

Software version<br />

GM1/GM2 2xPC70/bat<br />

Common 91-205 Łódź<br />

Aleksand<strong>ro</strong>wska 67/93<br />

tel: /+4842/ 6135600<br />

fax: /+4842/ 6135698<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 25

5.9. Clock<br />

Software ID<br />

1.0.4.0a<br />

Build-time<br />

08-07-06 12:35:22<br />

After selecting this menu item the following information is displayed:<br />

On the first screen: current date, day of the week and time.<br />

2006-07-12<br />

Wednesday<br />

13:14:36<br />

On the second screen: date of changing the time to summer time and standard time.<br />

If the date has not been p<strong>ro</strong>grammed or the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> has changed the time, the<br />

description „not set” is displayed.<br />

summer time<br />

31/03/20<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>:00<br />

standard time<br />

28/10/2001 03:00<br />

On the third screen: the period of time during which the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> was activated without<br />

external supply.<br />

Total time of<br />

battery operation<br />

<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>:27:16<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 26

6. Configuration of the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng><br />

Before performing the remote configuration of the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> the transmission parameters<br />

of serial connections should be set. To do this the function serial connections should be<br />

selected f<strong>ro</strong>m the main menu. The following screen will appear:<br />

→port com1/opto<br />

port com2<br />

gazmodem<br />

modbus ascii/rtu<br />

NOTICE:<br />

Since the software version 1.0.2.20b after selecting this menu item the screen<br />

appears with collected information about serial connections parameters, as below.<br />

After pressing the Enter key we move to configuration of the communication ports<br />

parameters.<br />

Com1:<br />

GM:55<br />

Com2:<br />

GM:99<br />

9600,8,N,1<br />

Modbus:0<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng><br />

57600,8,N,1<br />

Modbus:0<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng><br />

The options port com1/opto and port com2 are used for setting the transmission<br />

parameters of adequate COM1 and COM2 ports. On the following drawing the following<br />

parameters are seen (f<strong>ro</strong>m the left): transmission speed, data bits, parity, stop bits.<br />

port com1/opto<br />

4800 08 N 01<br />

^^^^^<br />

↑↓ digit change<br />

The change of the selected parameter (distinguished by ^^^^^ signs) is done with the<br />

help of the ↑ and ↓ keys. Moving to the next modification field is performed after pressing<br />

the Enter key. The modification is finished after pressing the Esc key. If any changes had<br />

been entered it will appear the screen with the request for their confirmation, i.e.:<br />

port com1/opto<br />

9600 08 N 01<br />

ESC-No<br />

ENTER–Yes<br />

After pressing the Esc key the changes will be rejected; the Enter key confirms changes<br />

– the reconfiguration of the app<strong>ro</strong>priate port takes place.<br />

In gazmodem option the addresses of Gaz-Modem p<strong>ro</strong>tocol are set. The addresses are<br />

p<strong>ro</strong>grammed in turn for COM1 and COM2 port.<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 27

gazmodem<br />

1:00055 2:00099<br />

^<br />

↑↓ digit change<br />

In the modbus ascii/rtu option it is set the Modus p<strong>ro</strong>tocol address common for both<br />

communication connections.<br />

The configuration of the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> can be done in two ways:<br />

1. By the use of a computer and the p<strong>ro</strong>per service p<strong>ro</strong>gramme. Owing to the fact<br />

that the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> is the functional extension of the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-01 <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>, the<br />

same software may be used for configuration of both devices. But it should be taken<br />

into account that the older versions of the software may not enable configuration of<br />

some operating parameters. Because the <st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> stores the operating<br />

parameters in nonvolatile FLASHROM memory one should remember about the<br />

necessity to authorize the configuration, i.e. write the newly set parameters to the<br />

FLASHROM memory. The SERVICE.EXE p<strong>ro</strong>gramme for MS-DOS system version,<br />

as well as the older versions of the WService.exe p<strong>ro</strong>gramme for MS-Windows g<strong>ro</strong>up<br />

systems do not have this option, and due to this the parameters set by them will be<br />

stored only in RAM memory. This will cause that in case when e.g. the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> is<br />

st<strong>ro</strong>ngly disturbed, after restart by the „Watch Dog” function, it will return to the<br />

configuration written in FLASHROM memory.<br />

2. By the use of the selector switch. When there is no a software switch one should<br />

switch over the configuration switch, located between the connection terminal strips in<br />

the battery chamber, to ON position and then select the option configuration in the<br />

menu.<br />

6.1. Configuration of the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> operating parameters<br />

After selecting the option configuration f<strong>ro</strong>m the main menu the following screen is<br />

displayed with the information:<br />

-=- -=-<br />

Connect the hardkey<br />

-=- -=-<br />

After switching on the computer with the service p<strong>ro</strong>gramme, the p<strong>ro</strong>gramme will be<br />

automatically detected and the information about the identification is displayed:<br />

-=- -=-<br />

KeyID:64254<br />

Press ENTER<br />

-=- -=-<br />

Alternatively we can switch over the configuration switch located in the battery container<br />

to ON position. The software automatically identifies the state of the selector and the<br />

following screen is displayed:<br />

NOTICE:<br />

-=- -=-<br />

LocalUser:48254<br />

Press ENTER<br />

-=- -=-<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 28

The <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>s with the software number lower than 1.0.2.18 additionally require<br />

entering the password (the password is: Enter, ↓, ↑, Esc). Only 4 consecutive<br />

pressing are accepted, and every consecutive pressing is ignored and causes return<br />

to the main menu.<br />

After pressing the Enter key the submenu with the following items is displayed.<br />

→ real <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng><br />

current date/time<br />

algorithm constants<br />

The firs two options are used for the abacus synch<strong>ro</strong>nization and setting the conversion<br />

unit clock. The modifications of these settings cause automatic updating the app<strong>ro</strong>priate<br />

variables in the conversion unit.<br />

All modifications in the algorithm constants menu are buffered and written in FLASH<br />

ROM memory only after leaving this menu and appearance of the following screen.<br />

-=- -=-<br />

Configuration<br />

writing finished!<br />

-=- -=-<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 29

6.2. P<strong>ro</strong>gramming the algorithm constants<br />

The whole configuration menu shows itself as follow (the options necessary for minimal<br />

<st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> configuration are distinguished):<br />

real <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng><br />

current date/time<br />

algorithm constants<br />

gas meter<br />

abacus<br />

format abacus<br />

measuring inputs<br />

pulse weight LF<br />

coefficient HF<br />

measuring window Qr<br />

er<strong>ro</strong>r range HF/LF<br />

alarm limits<br />

alarm limits p<br />

alarm limits t<br />

alarm limits Q1<br />

alarm limits Qn<br />

gas composition<br />

model<br />

neutral high methane<br />

N9<br />

N43<br />

N48<br />

neutral nit<strong>ro</strong>negated<br />

molar composition<br />

<st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng>tric composition<br />

partial analysis<br />

standard density<br />

heat of combustion<br />

mole fraction CO2<br />

mole fraction H2<br />

clock<br />

accounting day<br />

logging interval<br />

summer time<br />

date of change<br />

automatic<br />

not set<br />

standard time<br />

date of change<br />

automatic<br />

not set<br />

serial connections<br />

port com1/opto<br />

port com2<br />

addressing<br />

set 1<br />

...<br />

set 4<br />

gazmodem<br />

modbus ascii/rtu<br />

SMS notification<br />

GSM modem<br />

message center<br />

phone numbers<br />

1)<br />

...<br />

4)<br />

Pwy measurement –battery<br />

device address<br />

calibration<br />

detection method<br />

limit value<br />

Pwy measurement –network 1<br />

device address<br />

calibration<br />

detection method<br />

limit value<br />

Pwy measurement –network 2<br />

device address<br />

calibration<br />

detection method<br />

limit value<br />

signalling<br />

line OUT1 (I1)<br />

line OUT2 (I2)<br />

line OUT3 (O1)<br />

operation mode<br />

configuration<br />

line OUT4 (O2)<br />

operation mode<br />

configuration<br />

converters<br />

value K1<br />

input Q1<br />

range of operation<br />

unit<br />

simulation<br />

input t<br />

range of operation<br />

unit<br />

simulation<br />

input p<br />

range of operation<br />

unit<br />

simulation<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 30

The serial ports configuration menu which does not require the operator<br />

authorization is placed additionally in the main menu of the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>.<br />

6.3. Modification of parameter value.<br />

The modification of the selected parameter (the whole value is distinguished by the ^^^^<br />

marks) or the specific figure (distinguished by the ^ mark) is done with the help of the ↓<br />

and ↑ keys. Moving to the next editing field is performed after pressing the Enter key. The<br />

end of modification takes place after pressing the Esc key.<br />

After finishing the modification it appears the screen with the newly set values, recognized<br />

as permissible ones (eg. non existing date 31/<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>/2005 will be automatically converted to<br />

28/<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>/2005) and with the request to accept or cancel the new settings.<br />

Pressing the Esc key causes the rejection of the modifications; the Enter key app<strong>ro</strong>ves<br />

the modifications. This pattern is valid when setting all operating parameters of the<br />

<st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>.<br />

NOTICE:<br />

The <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>s with the software version number 1.0.2.16 or higher do not show the<br />

screen for acceptance of the parameters’ modification in case when any<br />

modifications of the settings have been done..<br />

6.4. Setting the operating parameters.<br />

It is the best to start configuring the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> form setting the algorithm constants, the<br />

date, time and the real <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> counter are set at the end (last). The most important<br />

parameters, responsible for accounting work, are described below:<br />

real <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> – setting the real <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> counter<br />

current date/time – setting the date and hour<br />

algorithm constants<br />

gas meter –gas meter parameters should be set (f<strong>ro</strong>m the rating plate)<br />

abacus – it includes options for abacus configuration<br />

• abacus – it should be set the integer number of abacus’ digits (number of drums)<br />

and number of digits after the decimal point<br />

• LF pulse weight – it is expressed in m 3 per pulse.<br />

alarm limits – it should be set the alarm limits of the measured values<br />

gas composition – the p<strong>ro</strong>per gas composition should be entered. There are few<br />

ways of entering the gas composition. The details are discussed in the further part of<br />

the instruction.<br />

clock – the automatic change of the summer time and standard time should be set. All<br />

dates of time changing are implemented in the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>.<br />

The configuration menu includes the following options:<br />

→gas meter<br />

abacus<br />

alarm limits<br />

gas composition<br />

clock<br />

serial connections<br />

SMS notification<br />

Pwy measurement–battery<br />

Pwy measurement –network 1<br />

Pwy measurement –network 2<br />

signalling<br />

converters<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 31

algorithm constants | gas meter<br />

gas meter<br />

DN100 G<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>50 1:<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng>0<br />

^^^<br />

↑↓ digit change<br />

The parameters of the cooperating gas meter should be set: DN, G and the rangebility<br />

read f<strong>ro</strong>m the rating plate (the turndown ratio is equal to the Q min value read f<strong>ro</strong>m the<br />

rating plate and divided by the Q max e.g.: for the DN100 G250 gas meter the Q min =20m 3 /h,<br />

Q max =400m 3 /h and the turndown ratio is equal to 1:20).<br />

Modification of settings in this menu causes automatic change of the converter range Q1.<br />

In case the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> is connected to the gas meter not included in the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng>’s<br />

database, the Q1 range of the converter should be changed manually.<br />

The er<strong>ro</strong>neous setting may cause the imp<strong>ro</strong>per operation of the real flow monitoring<br />

system and the module calculating the HF coefficient er<strong>ro</strong>r as well as incorrect calculation<br />

of the gas velocity value.<br />

algorithm constants | abacus<br />

It is displayed the submenu including the functions:<br />

→ abacus format<br />

measuring inputs<br />

pulse weight LF<br />

coefficient HF<br />

measuring window Qr<br />

er<strong>ro</strong>r range HF/LF<br />

algorithm constants | abacus | abacus format<br />

abacus format<br />

8 : 1<br />

^<br />

↑↓ digit change<br />

abacus format<br />

0000000.0<br />

ESC-No ENTER-Yes<br />

We set two figures: the first is the integer number of digits (drums) of the gas meter<br />

mechanical abacus. The second – number of digits after the decimal point. The<br />

synch<strong>ro</strong>nization of the V1 counter resetting in concordance with the gas meter abacus<br />

depends on the correctness of these parameters setting.<br />

The format of the set abacus, displayed on acceptance, is in such a form that will be used<br />

for displaying the counter current value.<br />

At the same time the abacus format is used for setting the LF pulse weight. That means<br />

that the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> may not display the fractional digits even in case when the LF weight is<br />

set to e.g.: 0.01m 3 .<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 32

algorithm constants | abacus | measuring input<br />

measuring inputs<br />

Vr:LF Qr:Auto<br />

^^<br />

↑↓ digit change<br />

The first parameter determines which signal is to be used for the real <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> calculation.<br />

The possible settings are: LF, HF, Q1.<br />

The first parameter determines which signal is to be used for calculation of the real flow<br />

rate. The possible settings are: LF, HF, Auto (the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> automatically switches over to<br />

the active input).<br />

algorithm constants | abacus | LF pulse weight<br />

pulse weight LF<br />

1 imp = 01.000 m3<br />

^^^^^^<br />

↑↓ digit change<br />

We set the LF pulse weight in m 3 falls on r 1 input pulse. The following values are<br />

available: 10, 1, 0.5, 0.1, 0.05, 0.01, 0.005, 0.001 m 3 /imp.<br />

algorithm constants | abacus | HF coefficient<br />

HF coefficient<br />

1m3 = 0001000.00 imp<br />

^<br />

↑↓ digit change<br />

When the HF transmitter is connected to the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> it is recommended to set the weight<br />

of this input independently on the fact whether the external power supply is permanently<br />

connected to the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> or not. The weight is set as number of pulses falls on 1m 3 .<br />

Every digit of the coefficient is set separately. The digits and the decimal point are<br />

available for edition.<br />

algorithm constants | abacus | Qr measurement window<br />

measuring window<br />

Qr<br />

Q/LF=10 min HF=15 s<br />

^^<br />

↑↓ digit change<br />

This parameter defines the period of time in which the <st<strong>ro</strong>ng>volume</st<strong>ro</strong>ng> flows mean value will be<br />

calculated. In the above-mentioned example the flow calculated f<strong>ro</strong>m the LF input will be<br />

averaging for the last 10 minutes, but the one calculated f<strong>ro</strong>m the HF input – for the last<br />

15 seconds.<br />

In case of the external supply failure the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> automatically switches over the flow<br />

calculation f<strong>ro</strong>m the HF to LF input.<br />

<st<strong>ro</strong>ng>CMK</st<strong>ro</strong>ng>-<st<strong>ro</strong>ng>02</st<strong>ro</strong>ng> Operating and maintenance manual 33

algorithm constants | abacus | HF/LF er<strong>ro</strong>r range<br />

er<strong>ro</strong>r range F/LF<br />

-3.00 ÷ +3.00 %<br />

^<br />

↑↓ digit change<br />

During operation the <st<strong>ro</strong>ng>corrector</st<strong>ro</strong>ng> calculates the HF measuring er<strong>ro</strong>r in relation to the LF<br />

measurement and averages it taking into account the last 10 pulses. The abovementioned<br />

parameter defines when the information about er<strong>ro</strong>r is written in the list of<br />

events. These er<strong>ro</strong>rs can occur in the moment of external power supply failure or restoring<br />

or in case of pulsatory gas flow in both directions.<br />