Technical Note No.6 Trench Lining Systems - Design ... - Groundforce

Technical Note No.6 Trench Lining Systems - Design ... - Groundforce

Technical Note No.6 Trench Lining Systems - Design ... - Groundforce

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Technical</strong> <strong>Note</strong> <strong>No.6</strong><br />

<strong>Trench</strong> <strong>Lining</strong> <strong>Systems</strong> - <strong>Design</strong> Statement<br />

<strong>Trench</strong> Boxes<br />

<strong>Groundforce</strong> Shorco supplied trench boxes have been designed (in accordance with BS EN 13331-<br />

1: 2002) to support the worst ground conditions that can reasonably be expected to be encountered<br />

within the dimensional capabilities of the panels, including the upper panels. It is therefore not<br />

normally necessary to carry out site-specific soil pressure calculations. Exceptions to this<br />

however are in high surcharge applications, the proximity of sensitive structures, deep (greater than<br />

4m) excavations in very poor ground e.g. very soft clays and wide (greater than 3m) trenches.<br />

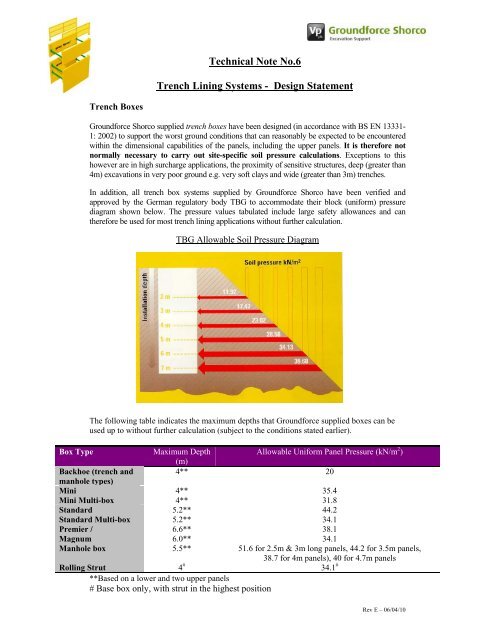

In addition, all trench box systems supplied by <strong>Groundforce</strong> Shorco have been verified and<br />

approved by the German regulatory body TBG to accommodate their block (uniform) pressure<br />

diagram shown below. The pressure values tabulated include large safety allowances and can<br />

therefore be used for most trench lining applications without further calculation.<br />

TBG Allowable Soil Pressure Diagram<br />

The following table indicates the maximum depths that <strong>Groundforce</strong> supplied boxes can be<br />

used up to without further calculation (subject to the conditions stated earlier).<br />

Box Type<br />

Maximum Depth<br />

Allowable Uniform Panel Pressure (kN/m 2 )<br />

(m)<br />

Backhoe (trench and<br />

4** 20<br />

manhole types)<br />

Mini<br />

Mini Multi-box<br />

4**<br />

4**<br />

35.4<br />

31.8<br />

Standard<br />

Standard Multi-box<br />

5.2**<br />

5.2**<br />

44.2<br />

34.1<br />

Premier /<br />

Magnum<br />

6.6**<br />

6.0**<br />

38.1<br />

34.1<br />

Manhole box 5.5** 51.6 for 2.5m & 3m long panels, 44.2 for 3.5m panels,<br />

38.7 for 4m panels), 40 for 4.7m panels<br />

Rolling Strut 4 # 34.1 #<br />

**Based on a lower and two upper panels<br />

# Base box only, with strut in the highest position<br />

Rev E – 06/04/10

<strong>Note</strong> that the allowable pressures at the maximum stated depths comfortably exceed the TBG<br />

pressure requirements.<br />

As a further guide for the selection of the best system, the tractive forces required to extract<br />

boxes can be considerable. The following table can be used as a guide for excavator sizing.<br />

<strong>Trench</strong> Box Extraction Forces<br />

Where the end wall of a trench requires support it is essential that no<br />

lateral load is applied to the box struts. Purpose made end closure panels<br />

are available for closing off the ends of boxes if required. Any contractor<br />

designed end support members must thrust off the ends of the box panels.<br />

The structural adequacy and integrity of non-standard end support<br />

members is the responsibility of the contractor.<br />

<strong>Note</strong>: <strong>Groundforce</strong> does not recommend the practice of “flying” trench boxes above the base<br />

of the excavation as this can potentially overload the lower struts.<br />

Drag Boxes<br />

Drag boxes as their name suggests are intended to be pulled or<br />

dragged through the excavation as the work proceeds. They are<br />

therefore designed to be used in pre-dominantly stable ground<br />

conditions in battered excavations.<br />

They therefore act as shields to protect the workforce rather that<br />

provide positive ground support as in the case of a trench box.<br />

Drag box plates do have a working load capacity commensurate<br />

with their height and would evidently provide support in the case of ground movement.<br />

However it is not industry policy to provide site-specific designs with this equipment<br />

type. Any assessment for the use of drag boxes should be carried out at site level where first<br />

hand knowledge of ground conditions and hence short-term ground stability is available.<br />

Rev E – 06/04/10

Chain attachment points on boxes<br />

All boxes are equipped with two types of chain attachment points.<br />

Handling points as the name suggests are provided at various locations around<br />

the box panels to enable them to be slung for assembly purposes in both<br />

horizontal and vertical planes.<br />

Lifting points are much heavier duty constructions designed to take the full weight<br />

of the box including extraction forces when pulling them out of the ground. These<br />

points are located in the top of the box panels and are denoted by red paint.<br />

<strong>Note</strong>s:<br />

1. Lifting points can be used for handling purposes but handling points must<br />

not be used for lifting assembled boxes.<br />

2. Chain attachment points have been designed in accordance with BS EN 13331-1:<br />

2002. clause 7.4.<br />

3. No separate certification is required for these points under LOLER<br />

MAP system boxes<br />

The modular aluminium panel box system is a lightweight yet high strength<br />

box system that can be assembled by hand and lifted and handled by backhoe<br />

type excavators. Using just three main components - panels, struts, and corner<br />

posts, the system provides great versatility by allowing 2, 3, and 4 sided<br />

support as the job demands. <strong>Note</strong> that MAP boxes do not fall within the scope<br />

of BS EN 13331-1:2002<br />

MAP Panel Length Maximum<br />

Depth (m)<br />

Allowable Uniform Panel<br />

Pressure (kN/m 2 )#<br />

990mm 4.8* 100.0<br />

1600mm 4.8* 60.0<br />

* Panels are 600mm high, posts are either 1200mm or 1800mm high.<br />

# assuming two struts per individual post<br />

Installation<br />

Installation and on-going inspection must be under the supervision of a competent person.<br />

User guides are available for all equipment referred to in this document.<br />

<strong>Note</strong>: A toolbox talk DVD is available for box installations. Ring 0800 000 345 for<br />

details.<br />

Rev E – 06/04/10