Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Zirconia Layering Ceramic<br />

Specifically designed for Lava TM Plus and <strong>Jensen</strong> HT

Table of Contents<br />

Content<br />

Page<br />

Company Overview<br />

Material and Indications<br />

Technical Data<br />

Color Chart<br />

Framework Recommendation<br />

Liner Application<br />

Dentin/Enamel 1 st firing<br />

Dentin/Enamel 2 nd firing<br />

Glaze Firing<br />

3<br />

3<br />

4-5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

2

Company Profile<br />

Over the last 30 years, <strong>Jensen</strong> <strong>Dental</strong> has grown from an alloy company into a comprehensive provider of<br />

quality products and services. We pride ourselves on our world-class products, personalized customer service<br />

and exceptional education and technical support. <strong>Jensen</strong> <strong>Dental</strong> is committed to quality in every aspect of our<br />

business as well as providing efficient, cost effective solutions for your laboratory.<br />

Quality Products<br />

<strong>Jensen</strong> has the consistent and proven products you have come to know and trust and our emphasis on testing<br />

and quality is a key component of our commitment to you.<br />

Performance and Value<br />

We strive for true relationships with our customers, and we are committed to the success of their businesses.<br />

Personalized Support<br />

We understand that your deadlines will not wait, and our highly trained staff is here waiting to help you when<br />

you need it.<br />

World Class Education<br />

From our famed <strong>Jensen</strong> Education Day in Chicago and hands-on courses to our newest online webinars and<br />

study clubs, <strong>Jensen</strong> offers a full suite of educational opportunities to provide you with the technical and<br />

business insights to succeed.<br />

Commitment to the Future<br />

Our commitment to our customers continues into the future as evidenced by our recent acquisition of Chemichl, a<br />

leader in the manufacturing of dental ceramics. In addition, our partnerships with 3M ESPE and DEKEMA were<br />

designed to help our customer realize relevant digital and furnace solutions. We are hard at work on exciting<br />

initiatives to provide our customers with the next generation of innovative products and services.<br />

Material & Indications<br />

The low-fusing layering material of <strong>InSync</strong> <strong>Zr</strong> is a versatile and reliable dental ceramic for layering and characterizing<br />

framework materials made of sintered zirconium dioxide (<strong>Zr</strong>O₂). The materials exhibit great optical<br />

properties and natural esthetics. <strong>InSync</strong> <strong>Zr</strong> delivers a problem free build up, is easy to handle and fires at lower<br />

temperatures. The <strong>InSync</strong> <strong>Zr</strong> dental ceramic features a highly stable CTE even after multiple firings. The <strong>InSync</strong> <strong>Zr</strong><br />

system includes all of the VITA TM Classic shades. The highly translucent and fluorescent material exhibits highly<br />

esthetic natural results.<br />

3

Technical Data<br />

CTE CTE Tg (*) Chem. Solubility 3 Point – Flexural<br />

Technical Data<br />

TYP<br />

CLASS<br />

2x fired<br />

(25-500°C)<br />

4x fired<br />

(25-500°C)<br />

2x / 4x<br />

fired<br />

Ceramic<br />

acc. to<br />

ISO 6872<br />

Keramik<br />

acc. to<br />

ISO 6872<br />

[*10 -6 K -1 ]<br />

± 0,5<br />

[*10 -6 K -1 ]<br />

± 0,5<br />

[°C] ± 20 [µg/cm 2 ] [µg/cm 2 ] [MPa] [MPa]<br />

<strong>Zr</strong> Liner I 1a 9.8 9.8 640 ≤ 20 < 100 ≥ 80 > 50<br />

Margin I 1a 8.5 8.5 570 ≤ 20 < 100 ≥ 70 > 50<br />

Dentine I 1a<br />

Incisal, Modifier I 1a<br />

Transpa, Clear, Opal I 1a<br />

8.5 8.5 530 ≤ 20 < 100 ≥ 70 > 50<br />

Correction I 1a 8.5 8.5 500 ≤ 20 < 100 ≥ 70 > 50<br />

Stain I 1a 7.5 - 490 < 100 < 100 ≥ 50 > 50<br />

Glaze <strong>Zr</strong> I 1a 7.3 (1x)<br />

- 485 1x)<br />

< 100 < 100 ≥ 50 > 50<br />

NEWLY DEVELOPED LINER<br />

An important component within the entire product system is the innovative liner, which guarantees a<br />

reliable and homogeneous bond between the zirconium oxide framework and the layering materials.<br />

The liner is fluorescing and translucent which enables high transmission of light. In addition to the neutral<br />

liner recommended for use with Lava TM Plus and <strong>Jensen</strong> HT, <strong>InSync</strong> <strong>Zr</strong> also includes 5 different color liners<br />

to help achieve your desired shade. Therefore, white as well as shaded frameworks can be matched to the<br />

respective layering material.<br />

4

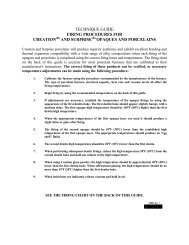

Firing Chart for <strong>InSync</strong> <strong>Zr</strong> Layering<br />

Entry Time<br />

(min)<br />

Low Temp<br />

°C<br />

Vac start<br />

°C<br />

Heat rate<br />

°C/min<br />

High temp<br />

°C<br />

Hold time<br />

(min)<br />

Liner 1 6 400 450 60 970 1 (air)<br />

Liner 2 6 400 450 60 960 1 (air)<br />

Shoulder/Margin 1 4 400 450 40 810 1 (air)<br />

Shoulder/Margin 2 4 400 450 40 800 1 (air)<br />

Dentin 1 4 400 450 40 765 1 (air)<br />

Dentin 2 4 400 450 40 760 1 (air)<br />

Correction powder 4 400 450 45 700 1 (air)<br />

Stain Paste for Layering 6 400 600 45 730 1 (air)<br />

Glaze Paste for Layering 6 400 600 45 730 1 (air)<br />

Stain Powder 4 400 450 45 730 1 (air)<br />

Glaze w/ Powder 4 400 450 45 720 1 (air)<br />

Natural Glaze 4 400 --- 45 730 1<br />

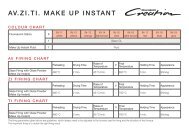

Color Combination Chart<br />

Opaque<br />

Liner<br />

A1<br />

1<br />

A2<br />

2<br />

A3<br />

2<br />

A3.5<br />

2<br />

A4<br />

4<br />

B1<br />

1<br />

B2<br />

1<br />

B3<br />

2<br />

B4<br />

2<br />

C1<br />

1<br />

C2<br />

3<br />

C3<br />

3<br />

C4<br />

4<br />

D2<br />

1<br />

D3<br />

5<br />

D4<br />

5<br />

Dentin<br />

A1<br />

A2<br />

A3<br />

A3.5<br />

A4<br />

B1<br />

B2<br />

B3<br />

B4<br />

C1<br />

C2<br />

C3<br />

C4<br />

D2<br />

D3<br />

D4<br />

Enamel<br />

57<br />

57<br />

58<br />

59<br />

59<br />

57<br />

58<br />

58<br />

59<br />

58<br />

59<br />

59<br />

59<br />

59<br />

59<br />

59<br />

Opaque Dentin<br />

A1<br />

A2<br />

A3<br />

A3.5<br />

A4<br />

B1<br />

B2<br />

B3<br />

B4<br />

C1<br />

C2<br />

C3<br />

C4<br />

D2<br />

D3<br />

D4<br />

Shoulder/Margin<br />

A1<br />

A2<br />

A3<br />

A3.5<br />

A4<br />

B1<br />

B2<br />

B3<br />

B4<br />

C1<br />

C2<br />

C3<br />

C4<br />

D2<br />

D3<br />

D4<br />

5

<strong>InSync</strong> <strong>Zr</strong> Color Chart<br />

Opaceous Dentin<br />

A1 A2 A3 A3.5 A4 B1 B2 B3<br />

B4 C1 C2 C3 C4 D2 D3 D4<br />

Dentin<br />

A1 A2 A3 A3.5 A4 B1 B2 B3<br />

B4 C1 C2 C3 C4 D2 D3 D4<br />

Enamel<br />

57 58 59 Yellow Orange Dark Light Molar Neutral Clear<br />

Orange Grey White<br />

6

Framework Recommendation<br />

Cleaning of Coping/Framework<br />

To ensure even coloring, the coping/ framework must be clean, free of oils, and completely dry prior to dyeing.<br />

• Touch the framework/restoration only with clean, non-oily hands.<br />

• Remove any milling dust completely from the entire framework/restoration, including the inner surfaces of the<br />

crown, e.g., using a soft brush for layered ceramic<br />

Dyeing/Shading Liquid Application Process<br />

1. Lava Plus Dyeing Liquids are recommended for use with Lava Plus High Translucency and <strong>Jensen</strong> HT Zirconia<br />

2. There is a Lava Plus High Translucency Zirconia Dyeing Liquid available corresponding to every tooth color (e.g.,<br />

tooth color Vita Classical A1 = dyeing liquid A1).<br />

• Use liquids undiluted with Lava Plus High Translucency Zirconia<br />

• Dilute liquids 8 parts liquid to 2 parts water with <strong>Jensen</strong> HT Zirconia (Frame only)<br />

3. Select the Lava Plus High Translucency Zirconia Dyeing Liquid corresponding to the tooth color and fill the<br />

immersion container.<br />

• Reseal the bottle immediately after use so that the concentration of the dyeing liquid does not change.<br />

4. Use plastic forceps to place the framework/restoration in the immersion container; the coping/bridge must be<br />

completely covered by the dyeing liquid.<br />

5. Carefully tilt the immersion container to allow any air bubbles trapped inside a coping to escape.<br />

6. Leave the framework/restoration in the dyeing liquid for 2 minutes, then use plastic forceps to remove it. Dye each<br />

coping/framework only once.<br />

7. Remove the excess dyeing liquid from the coping and from around the interdental connectors, e.g., using a<br />

cotton swab or an absorbent paper towel, to ensure even coloring. Make sure that no lint from the paper towel<br />

remains on the framework or restoration.<br />

8. Follow the manufacturers recommended sintering procedures as different heat rates and temperatures apply.<br />

• Sinter Lava Plus HT Zirconia and <strong>Jensen</strong> HT at 1450 C.<br />

7

Liner Selection and Application:<br />

• To achieve a homogenous bond and excellent esthetics the use of <strong>InSync</strong> Zirconia Liners is<br />

REQUIRED<br />

• <strong>InSync</strong> Neutral liner is recommended for use with pre-shaded zirconia and shaded Lava<br />

Plus and <strong>Jensen</strong> HT Zirconia<br />

• <strong>InSync</strong> liners 1-5 are recommended for use with un-shaded zirconia<br />

1. Mix liner powder with liner<br />

liquid to a creamy consistency.<br />

2. Apply selected liner to framework in a thin<br />

and even coat<br />

4. Start up temperature of 400°C<br />

5. Close furnace with a 6 minute dry time<br />

Heat to 970°C at a rate of 60°C per minute<br />

Start vacuum at 450°C<br />

Hold time: 1 minute without vacuum<br />

If first liner does not provide complete coverage,<br />

apply second coat and fire according to<br />

instructions on page 5<br />

3. Place crown or bridge on firing tray.<br />

Anterior:<br />

Posterior:<br />

Liner Firing Result:<br />

8

Basic Build Up Process for anterior and posterior restorations<br />

Dentin/enamel 1 st firing<br />

1. Mix the dentin & enamel powder with modeling liquid to a creamy consistency.<br />

2. Apply dentin/enamel to the restoration.<br />

3. After buildup, place crown or bridge into firing furnace.<br />

4. Start up temperature of 400° C.<br />

5. Close furnace with a 4 minute dry time.<br />

Heat to 765°C at a rate of 40°C per minute.<br />

Start vacuum at 450°C.<br />

Hold time: 1 minute without vacuum<br />

Anterior:<br />

Posterior:<br />

1 st Firing Result:<br />

9

Basic Build Up Process for anterior and posterior restorations<br />

Dentin/enamel 2 nd firing<br />

1. Prepare restoration for 2 nd firing by lightly sandblasting or steam cleaning.<br />

2. Second firing at 760°C.<br />

Anterior:<br />

Posterior:<br />

2 nd Firing Result:<br />

10

Basic Build Up Process for anterior and posterior restorations<br />

Glaze Firing<br />

1. Steam clean after final contouring.<br />

2. Place crown or bridge on firing tray.<br />

3. Start up temperature 400°C.<br />

4. Close furnace with a 4 minute dry time.<br />

5. For Natural Glaze<br />

(no extra powder or paste glaze):<br />

1. Heat to 730oC without vacuum<br />

2. Rate of 45oC per minute<br />

3. Hold Time: 1 minute<br />

For Over Glaze<br />

(using powder or paste glaze):<br />

1. Heat to 720oC with vacuum<br />

2. Rate of 40oC per minute<br />

3. Hold Time: 1 minute without vacuum<br />

Anterior:<br />

Posterior:<br />

Glaze Firing Result:<br />

11

Final Restoration<br />

Anterior:<br />

Posterior:<br />

12

<strong>Jensen</strong> <strong>Dental</strong><br />

50 Stillman Road<br />

North Haven, CT 06473<br />

Tel. (203) 239-2090<br />

www.jensendental.com<br />

0344<br />

Rev 1