Air cooled liquid chillers and reverse cycle air/water heat pumps ...

Air cooled liquid chillers and reverse cycle air/water heat pumps ...

Air cooled liquid chillers and reverse cycle air/water heat pumps ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

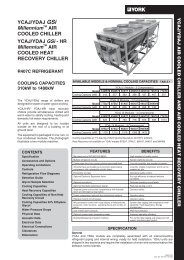

<strong>Air</strong> <strong>cooled</strong> <strong>liquid</strong> <strong>chillers</strong> <strong>and</strong> <strong>reverse</strong> <strong>cycle</strong> <strong>air</strong>/<strong>water</strong> <strong>heat</strong> <strong>pumps</strong><br />

Range: from 34 kW to 262 kW<br />

• R410A refrigerant<br />

• Scroll compressors<br />

• Part load efficiency<br />

• Range flexibility<br />

• IDRORELAX Network Unit

Climaveneta presents its new NECS (New Evolution Climaveneta System) range of <strong>chillers</strong> (<strong>heat</strong> <strong>pumps</strong>)<br />

fitted with R410A rotary scroll compressors.<br />

The range comprises one-circuit versions with due compressors <strong>and</strong> two-circuit versions with four<br />

compressors.<br />

Consistently with corporate culture, the NECS series exploits cutting-edge technology to achieve<br />

extremely high levels of quality, focusing on maximum energy efficiency <strong>and</strong> minimum noise emissions.<br />

WHY R410A<br />

Though R410A is a blend, it behaves just like a pure gas <strong>and</strong><br />

features a negligible temperature glide. Thanks to its outst<strong>and</strong>ing<br />

<strong>heat</strong> conductivity, R410A contributes towards achieving elevated<br />

system efficiency.<br />

R410A is also an ecological gas, both because its elevated<br />

efficiency reduces electricity consumption <strong>and</strong>, consequently,<br />

CO 2 , emissions <strong>and</strong> because it does not damage<br />

the ozone layer (ODP = 0).<br />

The scroll compressor has been expressly redesigned<br />

for use with the new gas <strong>and</strong> is now even more compact<br />

<strong>and</strong> silent than before.<br />

NECS, THE CLIMAVENETA R410A RANGE<br />

Scroll compressors,<br />

featuring high efficiency,<br />

low vibrations <strong>and</strong><br />

low noise emissions.<br />

R410A refrigerant,<br />

thanks to its enhanced <strong>heat</strong><br />

conductivity compared with R407C<br />

<strong>and</strong> the generous sizing of the<br />

<strong>heat</strong> exchange surfaces of the<br />

units, this refrigerant has<br />

considerably increased the EER<br />

<strong>and</strong> ESEER energy indices.<br />

Part load efficiency,<br />

part load efficiency has been improved<br />

(ESEER > 4.3) in the new single-circuit,<br />

dual-compressor version, with a 35%<br />

saving in seasonal electricity consumption<br />

compared with the previous R407C<br />

version.<br />

ESEER<br />

Range flexibility,<br />

the Climaveneta range has been designed<br />

to satisfy a wide variety of needs.<br />

For this reason, a good<br />

16 sizes <strong>and</strong> up to 5<br />

versions are<br />

available in<br />

the 34-262<br />

kW range.<br />

New controller, all the units can be connected<br />

to the new W3000 controller featuring a “user<br />

friendly” interface.<br />

Main functions:<br />

QuickMind, local <strong>and</strong><br />

remote FWS supervision,<br />

<strong>and</strong> dual setpoint<br />

management confirm<br />

Climaveneta's<br />

commitment to<br />

continually developing its<br />

electronics technology.<br />

IDRORELAX,<br />

the NECS range of<br />

<strong>chillers</strong> is available<br />

in the –IR configuration. This allows interfacing with<br />

the IDRORELAX system.

INTEGRATED HYDRONIC UNIT (Optional).<br />

Compact PLUG <strong>and</strong> PLAY units.<br />

NECS has been designed to reduce installation work to a minimum.<br />

The integrated hydronic unit incorporates all the hydraulic components, thus optimising installation space,<br />

time <strong>and</strong> costs.<br />

The integrated hydronic unit comprises:<br />

• storage tank<br />

• circulation pump with composite impeller<br />

• pre-mounted Y-shaped <strong>water</strong> filter with stainless steel mesh<br />

• <strong>water</strong> flow switch<br />

• pump inlet pressure gauge<br />

• output flow adjustment valve<br />

• safety valve<br />

• expansion tank<br />

• <strong>air</strong> vent<br />

• <strong>water</strong> drain.<br />

A circulation pump with a two-pole electric motor <strong>and</strong> an elevated useful static head is available<br />

for all sizes.<br />

Pumps with a low useful static head <strong>and</strong> a 2- or 4-pole electric motor are available for units with four<br />

compressors (NECS xxx4) in order to more fully adapt the unit to system requirements in terms of flow<br />

rate/head. On request, the hydronic assembly can be supplied with two circulation <strong>pumps</strong>, one of which<br />

backing up the other, featuring a programmed rotation schedule <strong>and</strong> automatic swap-over should the<br />

working pump fail.<br />

In this case, the hydronic assembly is fitted with a check valve in order to ensure the unit is installed <strong>and</strong><br />

operated correctly.<br />

Hydronic unit rendering

Comparison between NECS <strong>and</strong> traditional<br />

R407C units - Range from 34 to 262 kW<br />

The energy efficiency (EER) of these<br />

Climaveneta units is further enhanced thanks<br />

to the fact that the design of the <strong>heat</strong><br />

exchange surfaces, coils <strong>and</strong> plate exchangers<br />

was focused on minimising running costs.<br />

As well as achieving an EER close to 2.9,<br />

this design focus achieves very high levels<br />

of reliability <strong>and</strong> lengthens the working<br />

life of the compressor.<br />

EER<br />

2,90<br />

2,85<br />

2,80<br />

2,75<br />

2,7<br />

2,65<br />

2,60<br />

2,81<br />

2,63<br />

2,75<br />

2,61<br />

2,80<br />

2,82<br />

2,77<br />

+ 10%<br />

R407C unit<br />

2,89<br />

2,60 2,60<br />

2,55<br />

2,58<br />

2,54<br />

2,50<br />

ELEVATED PERFORMANCE AT ESEER PART LOADS<br />

Increasingly closer attention is being paid towards<br />

the power consumption of <strong>air</strong>-conditioning<br />

equipment, both at national <strong>and</strong> European level.<br />

An installed chiller reduces rated energy for<br />

extremely short periods of time, while most of the<br />

energy is produced with part loads ranging<br />

between 50% <strong>and</strong> 75%.<br />

The ESEER parameter proposed by Eurovent, takes<br />

part load operating conditions into account when<br />

assessing unit efficiency.<br />

It should be pointed out that units are only<br />

required to deliver 100% of their rated cooling<br />

power for 1.4% of their total running time,<br />

according to European calculations, <strong>and</strong> just 0.5%<br />

according to American calculations (IPLV).<br />

In these conditions, the energy produced by a unit<br />

accounts for respectively 3% <strong>and</strong> just 1% of the<br />

total energy produced during its working life.<br />

load - energy %<br />

125<br />

100<br />

75<br />

50<br />

25<br />

0<br />

ESEER<br />

carico<br />

peso<br />

18 20 22 24 26 28 30 32 34 36<br />

IPLV (American)<br />

carico<br />

peso<br />

12 14 16 18 20 22 24 26 28 30 32 34 36<br />

external <strong>air</strong> temperature (°C)<br />

external <strong>air</strong> temperature (°C)<br />

ESEER<br />

IPLV (American)<br />

Load <strong>Air</strong> temp. Time Energy <strong>Air</strong> temp. Time Energy<br />

100 % 35 °C 1,4 % 3 % 35 °C 0,5 % 1 %<br />

75 % 30 °C 19,9 % 33 % 26,7 °C 28,7 % 42 %<br />

50 % 25 °C 37,1 % 41 % 18,3 °C 46,2 % 45 %<br />

25 % 20 °C 41,6 % 23 % 12,8 °C 24,6 % 12 %<br />

Energy = percentage of total power produced in the various load conditions<br />

ESEER values of the new NECS units<br />

ESEER = Energy 100% * EER 100% + Energy 75% * EER 75% + Energy 50% * EER 50% + Energy 25% * EER 25%<br />

SINGLE-CIRCUIT<br />

NECS 302LN<br />

R410A UNIT<br />

EER 100% 2,59<br />

EER 75% 3,59<br />

EER 50% 4,45<br />

EER 25% 4,39<br />

TRADITIONAL TWO-CIRCUIT<br />

R407C UNIT<br />

WITH TWO SCROLL COMPRESSORS<br />

2,44 EER 100%<br />

2,71 EER 75%<br />

3,21 EER 50%<br />

3,27 EER 25%<br />

ESEER 4,10<br />

3,04 ESEER

NECS 0152-1004 Ver. 0152 0182 0202 0252 0302 0352 0412<br />

B 38,1 45,1 50,5 57,0 76,0 86,8 96,9<br />

Cooling capacity (1) LN 36,1 42,8 50,7 57,6 74,2 84,4 96,4<br />

SL 33,8 42,3 47,8 55,5 69,9 85,4 96,8<br />

B 14,4 15,6 19,1 21,5 27,8 31,9 36,3<br />

Total power input (1) LN 15,0 16,5 18,9 21,3 28,6 33,6 37,1<br />

SL 16,3 17,0 20,3 22,6 30,8 33,6 37,4<br />

B 2,65 2,89 2,65 2,65 2,73 2,72 2,67<br />

Total EER LN 2,40 2,60 2,68 2,71 2,59 2,51 2,60<br />

SL 2,07 2,49 2,35 2,46 2,27 2,54 2,59<br />

B 4,03 4,27 4,21 4,14 4,13 4,31 4,16<br />

ESEER LN 4,03 4,18 4,23 4,20 4,10 4,03 4,00<br />

SL 3,77 3,92 4,01 3,93 3,85 3,91 3,89<br />

B 84 84 84 84 85 86 86<br />

Sound power level (3) LN 79 79 80 80 81 83 83<br />

SL 76 77 77 78 78 81 81<br />

B 52 52 52 52 53 54 54<br />

Sound pressur level (4) LN 47 47 48 48 49 51 51<br />

SL 44 45 45 46 46 49 49<br />

NECS-N 0152-1004 Ver. 0152 0182 0202 0252 0302 0352 0412<br />

B 37,7 42,8 47,9 57,5 72,0 82,5 93,9<br />

Cooling capacity (1) LN 35,8 42,0 48,0 54,6 73,2 83,5 93,9<br />

SL - - - - - - -<br />

B 13,6 15,7 19,2 20,4 28,0 32,0 36,0<br />

Total power input (1) LN 14,3 16,2 19,1 21,3 27,2 32,0 36,0<br />

SL - - - - - - -<br />

B 42,6 47,8 53,8 64,8 80,6 92,9 105<br />

Heating capacity (2) LN 41,6 47,9 53,7 63,2 83,6 95,6 108<br />

SL - - - - - - -<br />

B 14,2 15,6 18,1 21,2 26,1 29,8 33,9<br />

Total power input (2) LN 13,8 15,3 18,1 20,7 26,0 30,4 34,2<br />

SL - - - - - - -<br />

B 2,99 3,07 2,97 3,06 3,09 3,12 3,09<br />

Total COP LN 3,01 3,14 2,97 3,06 3,21 3,14 3,17<br />

SL - - - - - - -<br />

B 84 84 84 84 85 86 86<br />

Sound power level (3) LN 79 79 80 80 81 83 83<br />

SL - - - - - - -<br />

B 52 52 52 52 53 54 54<br />

Sound pressure level (4) LN 47 47 48 48 49 51 51<br />

SL - - - - - - -<br />

NECS 0152-1004<br />

Dim. (5) Ver. 0152 0182 0202 0252 0302 0352 0412 0452 0512 0504 0524<br />

B 1695 1695 1695 1695 2195 2195 2745 2745 3245 3110 3110<br />

A LN 1695 1695 2195 2195 2745 2745 2745 2745 3245 3110 3110<br />

SL 1695 2195 2195 2745 2745 3245 3245 3245 3245 3110 3110<br />

B 1120 1120 1120 1120 1120 1120 1120 1120 1120 2220 2220<br />

B LN 1120 1120 1120 1120 1120 1120 1120 1120 1120 2220 2220<br />

SL 1120 1120 1120 1120 1120 1120 1120 1120 1120 2220 2220<br />

B 1420 1420 1420 1420 1420 1420 1420 1420 1620 1700 1700<br />

H LN 1420 1420 1420 1420 1420 1620 1620 1620 1620 1700 1700<br />

SL 1420 1420 1420 1420 1420 1620 1620 1620 1620 1700 2150<br />

B 370 410 410 420 620 650 730 780 930 1230 1450<br />

Operating<br />

LN 370 410 460 490 660 720 790 820 930 1230 1450<br />

weight<br />

SL 390 450 480 540 700 780 860 910 940 1360 1570<br />

NECS-N 0152-1004<br />

Dim. (5) Ver. 0152 0182 0202 0252 0302 0352 0412 0452 0512 0504 0524<br />

B 1695 1695 1695 2195 2195 2195 2745 2745 3245 3110 3110<br />

A LN 1695 1695 2195 2195 2745 2745 2745 2745 3245 3110 3110<br />

SL - - - - - - - - - 3110 3110<br />

B 1120 1120 1120 1120 1120 1120 1120 1120 1120 2220 2220<br />

B LN 1120 1120 1120 1120 1120 1120 1120 1120 1120 2220 2220<br />

SL - - - - - - - - - 2220 2220<br />

B 1420 1420 1420 1420 1420 1420 1420 1420 1620 1700 1700<br />

H LN 1420 1420 1420 1420 1420 1620 1620 1620 1620 1700 1700<br />

SL - - - - - - - - - 1700 2150<br />

B 400 410 420 500 630 690 770 850 950 1380 1570<br />

Operating<br />

LN 400 420 460 500 710 770 830 880 990 1380 1570<br />

weight<br />

SL - - - - - - - - - 1460 1700

0452 0512 0504 0524 0604 0704 0804 0904 1004<br />

112 127 113 136 154 177 200 223 255<br />

109 122 104 129 147 167 187 208 242<br />

106 118 113 130 147 162 193 211 235<br />

39,7 43,8 45,6 53,8 59,7 68,1 74,9 84,2 94,1<br />

41,4 46,0 47,9 53,5 60,0 69,6 77,6 87,8 95,3<br />

43,1 48,4 45,2 51,8 58,8 71,1 75,4 87,2 96,7<br />

2,83 2,90 2,48 2,53 2,58 2,60 2,67 2,65 2,71<br />

2,63 2,65 2,17 2,41 2,45 2,40 2,41 2,37 2,54<br />

2,46 2,44 2,50 2,51 2,50 2,28 2,56 2,42 2,43<br />

4,34 4,23 4,05 3,60 3,77 3,91 4,04 4,14 3,93<br />

4,21 4,04 3,92 3,85 3,92 4,02 3,98 4,07 4,01<br />

3,98 3,89 4,01 4,14 4,14 4,13 4,07 4,08 4,09<br />

86 87 91 92 92 92 92 93 94<br />

83 84 85 86 86 86 86 87 88<br />

81 82 82 82 82 82 83 83 83<br />

54 55 59 60 60 60 60 61 62<br />

51 52 53 54 54 54 54 55 56<br />

49 50 50 50 50 50 51 51 51<br />

0452 0512 0504 0524 0604 0704 0804 0904 1004<br />

107 120 111 129 147 166 189 211 240<br />

103 119 103 123 141 156 177 199 227<br />

- - 108 124 141 159 183 201 225<br />

39,9 44,0 43,7 54,0 60,0 68,9 75,9 85,1 95,6<br />

41,6 44,5 46,2 53,5 60,0 70,3 78,3 87,7 96,2<br />

- - 45,0 52,1 58,3 67,7 75,3 87,4 95,3<br />

121 135 127 145 167 185 209 234 267<br />

120 137 122 138 158 176 198 225 254<br />

- - 125 140 158 178 205 226 253<br />

38,1 42,3 43,6 52,7 58,0 64,7 72,1 79,9 92,1<br />

37,9 42,3 41,5 48,9 53,7 60,7 67,8 75,5 86,1<br />

- - 42,8 47,5 52,1 59,5 68,6 75,8 83,8<br />

3,18 3,19 2,91 2,75 2,88 2,86 2,90 2,93 2,90<br />

3,16 3,23 2,94 2,82 2,94 2,90 2,92 2,98 2,95<br />

- - 2,92 2,95 3,03 2,99 2,99 2,98 3,02<br />

86 87 91 92 92 92 92 93 94<br />

83 84 85 86 86 86 86 87 88<br />

- - 82 82 82 82 83 83 83<br />

87 55 59 60 60 60 60 61 62<br />

84 52 53 54 54 54 54 55 56<br />

- - 50 50 50 50 51 51 51<br />

0604 0704 0804 0904 1004<br />

3110 3110 3110 4110 4110<br />

3110 3110 3110 4110 4110<br />

3110 3110 4110 4110 4110<br />

2220 2220 2220 2220 2220<br />

2220 2220 2220 2220 2220<br />

2220 2220 2220 2220 2220<br />

1700 2150 2150 2150 2150<br />

1700 2150 2150 2150 2150<br />

2150 2150 2150 2150 2150<br />

1620 1780 1890 2070 2220<br />

1620 1780 1890 2070 2220<br />

1770 1860 2120 2180 2320<br />

Data referred to:<br />

Units fitted with a hydronic unit with one 2-pole high-head pump. Data<br />

referring to other configurations can be obtained from our sales department.<br />

1) Evaporator <strong>water</strong> (in/out) 12/7 °C<br />

Condenser <strong>air</strong> (in) 35 °C<br />

2) Condenser <strong>water</strong> (in/out) 40/45 °C<br />

Evaporator <strong>air</strong> (in) 7 °C<br />

3) Acoustic power measured according to ISO 3744 <strong>and</strong> Eurovent 8/1.<br />

4) Acoustic pressure measured in free field conditions on a reflecting plane.<br />

Average value on the condensing coil side, 10 metre from the outer surface <strong>and</strong><br />

10 metre above the base of the unit.<br />

4) Free space required around the unit:<br />

Electrical panel side 600 mm<br />

Opposite side from electrical panel 600 mm<br />

Condensation coil side 1000 mm<br />

The information contained in this document may be modified without notice<br />

<strong>and</strong> refers to units designed for the European Market.<br />

0604 0704 0804 0904 1004<br />

3110 3110 3110 4110 4110<br />

3110 3110 3110 4110 4110<br />

3110 3110 4110 4110 4110<br />

2220 2220 2220 2220 2220<br />

2220 2220 2220 2220 2220<br />

2220 2220 2220 2220 2220<br />

1700 2150 2150 2150 2150<br />

1700 2150 2150 2150 2150<br />

2150 2150 2150 2150 2150<br />

1750 1900 2080 2270 2410<br />

1750 1900 2080 2270 2410<br />

1900 2050 2310 2370 2520<br />

H<br />

H<br />

A<br />

A<br />

B<br />

B<br />

NECS / NECS-N 0152-0512 NECS / NECS-N 0504-1004

LOW-NOISE VERSIONS<br />

Two noise reduction versions are available<br />

for all sizes: low noise <strong>and</strong> super low noise.<br />

Low noise levels are achieved by reducing<br />

fan speed while the circuitry has been optimised<br />

<strong>and</strong> the coils generously sized to ensure<br />

the unit works correctly.<br />

Example of low-noise configuration<br />

NECS 0704 sound power levels:<br />

LN version =- 6<br />

dB(A)<br />

compared with the st<strong>and</strong>ard version<br />

SL version =-10 dB(A)<br />

compared with the st<strong>and</strong>ard version<br />

Climaveneta certifies <strong>and</strong> guarantees<br />

its noise parameters<br />

CONTROLLER WITH LCD INTERFACE<br />

All the units can be connected to the new W3000<br />

controller featuring a “user friendly” interface.<br />

(Std. for 4 compressors).<br />

The interface is also available in the remote version.<br />

Main functions: QuickMind, local <strong>and</strong> remote FWS<br />

supervision, dual setpoint management, etc.,<br />

confirm Climaveneta's commitment to continually<br />

developing its electronics technology.<br />

The <strong>heat</strong> <strong>pumps</strong>, moreover, are fitted with the original<br />

Climaveneta defrosting control system called “Autotuning<br />

Defrost” which considerably reduces defrosting times,<br />

thus improving the energy performance of the unit.<br />

Interfaces with BMS systems: METASYS ® , MODBUS ® ,<br />

LONWORKS ® , SYEMENS ® , TREND ® .<br />

QuickMind is a special control unit which monitors<br />

the main operating parameters, predicts system<br />

behaviour <strong>and</strong> anticipates unit settings in order<br />

to constantly optimise performance; it allows both<br />

return <strong>and</strong> delivery <strong>water</strong> temperatures to be chosen<br />

as adjustment parameters.<br />

Black Box logs data relative<br />

to 200 alarm events which<br />

can be printed with any kind<br />

of personal computer.<br />

IDRORELAX<br />

The NECS range of <strong>chillers</strong> with <strong>heat</strong> pump is available<br />

in the IR configuration; this allows units to be combined<br />

with IDRORELAX, a centralised hydronic system<br />

for managing cooling <strong>and</strong> <strong>heat</strong>ing requirements<br />

<strong>and</strong> producing hot running <strong>water</strong> for residential, hotel <strong>and</strong> office applications.<br />

Further information on the IDRORELAX system can be obtained by consulting<br />

the relative documentation.

A100HL_101_110D_CV_05_06_GB (V.02)<br />

CLIMAVENETA S.p.A.<br />

Via Sarson, 57/c<br />

36061 Bassano del Grappa (VI) - Italia<br />

Tel. +39 0424 509 500<br />

Fax +39 0424 509 509<br />

info@climaveneta.it<br />

www.climaveneta.it