Pro-Lok Product Catalog - Locksmith Security Association of ...

Pro-Lok Product Catalog - Locksmith Security Association of ...

Pro-Lok Product Catalog - Locksmith Security Association of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Patented Tool Solutions<br />

<strong>Pro</strong>blem #1: The Tools Slide and Slip Along the Linkage<br />

It has been difficult at times to maneuver the locking linkage. Once the end <strong>of</strong> the tool is placed on the lock linkage, the<br />

tool wants to slip along the smooth surface <strong>of</strong> the linkage as opposed to moving the linkage to the unlocked position.<br />

The reason for this is simple. The round smooth surface <strong>of</strong> the car opening tool is being placed on the round smooth surface<br />

<strong>of</strong> the lock linkage. Two round, smooth surfaces, placed together do not work well. This works against your efforts to<br />

maneuver the linkage to the unlocked position.<br />

Solution: Knurl the part <strong>of</strong> the tool that makes contact with the lock linkage.<br />

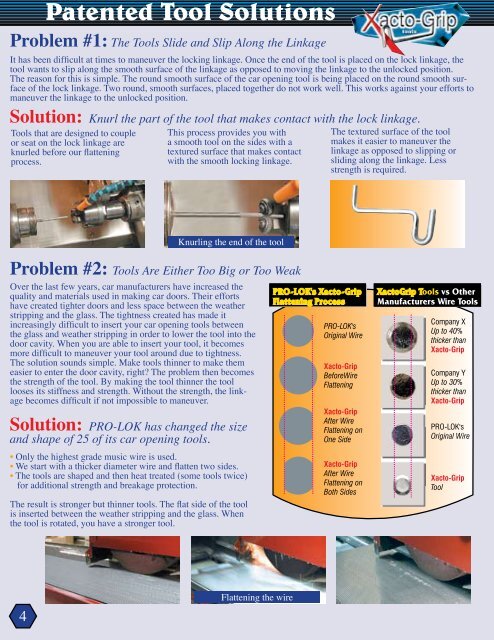

Tools that are designed to couple<br />

or seat on the lock linkage are<br />

knurled before our flattening<br />

process.<br />

This process provides you with<br />

a smooth tool on the sides with a<br />

textured surface that makes contact<br />

with the smooth locking linkage.<br />

The textured surface <strong>of</strong> the tool<br />

makes it easier to maneuver the<br />

linkage as opposed to slipping or<br />

sliding along the linkage. Less<br />

strength is required.<br />

Knurling the end <strong>of</strong> the tool<br />

<strong>Pro</strong>blem #2: Tools Are Either Too Big or Too Weak<br />

Over the last few years, car manufacturers have increased the<br />

quality and materials used in making car doors. Their efforts<br />

have created tighter doors and less space between the weather<br />

stripping and the glass. The tightness created has made it<br />

increasingly difficult to insert your car opening tools between<br />

the glass and weather stripping in order to lower the tool into the<br />

door cavity. When you are able to insert your tool, it becomes<br />

more difficult to maneuver your tool around due to tightness.<br />

The solution sounds simple. Make tools thinner to make them<br />

easier to enter the door cavity, right The problem then becomes<br />

the strength <strong>of</strong> the tool. By making the tool thinner the tool<br />

looses its stiffness and strength. Without the strength, the linkage<br />

becomes difficult if not impossible to maneuver.<br />

Solution: PRO-LOK has changed the size<br />

and shape <strong>of</strong> 25 <strong>of</strong> its car opening tools.<br />

• Only the highest grade music wire is used.<br />

• We start with a thicker diameter wire and flatten two sides.<br />

• The tools are shaped and then heat treated (some tools twice)<br />

for additional strength and breakage protection.<br />

The result is stronger but thinner tools. The flat side <strong>of</strong> the tool<br />

is inserted between the weather stripping and the glass. When<br />

the tool is rotated, you have a stronger tool.<br />

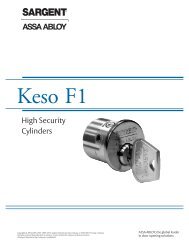

PRO-LOK's Xacto-Grip<br />

Flattening <strong>Pro</strong>cess<br />

PRO-LOK's<br />

Original Wire<br />

Xacto-Grip<br />

BeforeWire<br />

Flattening<br />

Xacto-Grip<br />

After Wire<br />

Flattening on<br />

One Side<br />

Xacto-Grip<br />

After Wire<br />

Flattening on<br />

Both Sides<br />

XactoGrip Tools vs Other<br />

Manufacturers Wire Tools<br />

Company X<br />

Up to 40%<br />

thicker than<br />

Xacto-Grip<br />

Company Y<br />

Up to 30%<br />

thicker than<br />

Xacto-Grip<br />

PRO-LOK's<br />

Original Wire<br />

Xacto-Grip<br />

Tool<br />

4<br />

Flattening the wire