Download self-assembled monolayers lecture

Download self-assembled monolayers lecture

Download self-assembled monolayers lecture

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

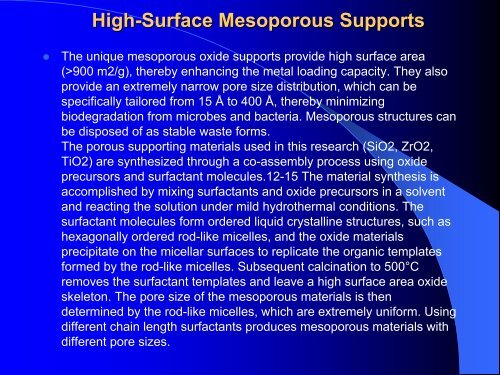

High-Surface<br />

Mesoporous Supports<br />

• The unique mesoporous oxide supports provide high surface area<br />

(>900 m2/g), thereby enhancing the metal loading capacity. They also<br />

provide an extremely narrow pore size distribution, which can be<br />

specifically tailored from 15 Å to 400 Å, thereby minimizing<br />

biodegradation from microbes and bacteria. Mesoporous structures can<br />

be disposed of as stable waste forms.<br />

The porous supporting materials used in this research (SiO2, ZrO2,<br />

TiO2) are synthesized through a co-assembly process using oxide<br />

precursors and surfactant molecules.12-15 The material synthesis is<br />

accomplished by mixing surfactants and oxide precursors in a solvent<br />

and reacting the solution under mild hydrothermal conditions. The<br />

surfactant molecules form ordered liquid crystalline structures, such as<br />

hexagonally ordered rod-like micelles, and the oxide materials<br />

precipitate on the micellar surfaces to replicate the organic templates<br />

formed by the rod-like micelles. Subsequent calcination to 500°C<br />

removes the surfactant templates and leave a high surface area oxide<br />

skeleton. The pore size of the mesoporous materials is then<br />

determined by the rod-like micelles, which are extremely uniform. Using<br />

different chain length surfactants produces mesoporous materials with<br />

different pore sizes.