3.1 computer applications in mechanical engineering

3.1 computer applications in mechanical engineering

3.1 computer applications in mechanical engineering

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

61<br />

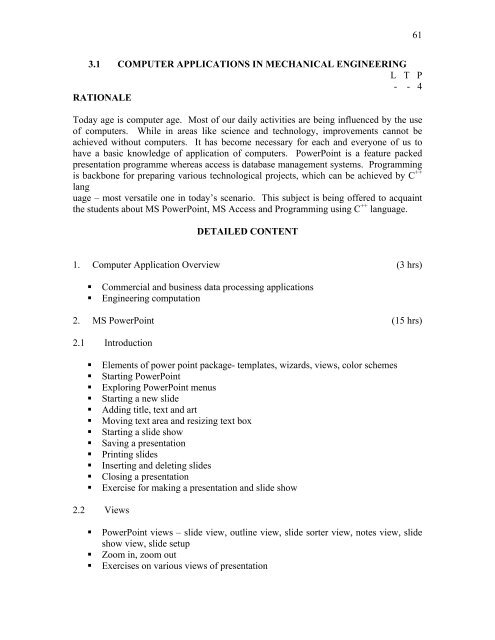

<strong>3.1</strong> COMPUTER APPLICATIONS IN MECHANICAL ENGINEERING<br />

L T P<br />

- - 4<br />

RATIONALE<br />

Today age is <strong>computer</strong> age. Most of our daily activities are be<strong>in</strong>g <strong>in</strong>fluenced by the use<br />

of <strong>computer</strong>s. While <strong>in</strong> areas like science and technology, improvements cannot be<br />

achieved without <strong>computer</strong>s. It has become necessary for each and everyone of us to<br />

have a basic knowledge of application of <strong>computer</strong>s. PowerPo<strong>in</strong>t is a feature packed<br />

presentation programme whereas access is database management systems. Programm<strong>in</strong>g<br />

is backbone for prepar<strong>in</strong>g various technological projects, which can be achieved by C ++<br />

lang<br />

uage – most versatile one <strong>in</strong> today’s scenario. This subject is be<strong>in</strong>g offered to acqua<strong>in</strong>t<br />

the students about MS PowerPo<strong>in</strong>t, MS Access and Programm<strong>in</strong>g us<strong>in</strong>g C ++ language.<br />

DETAILED CONTENT<br />

1. Computer Application Overview (3 hrs)<br />

• Commercial and bus<strong>in</strong>ess data process<strong>in</strong>g <strong>applications</strong><br />

• Eng<strong>in</strong>eer<strong>in</strong>g computation<br />

2. MS PowerPo<strong>in</strong>t (15 hrs)<br />

2.1 Introduction<br />

• Elements of power po<strong>in</strong>t package- templates, wizards, views, color schemes<br />

• Start<strong>in</strong>g PowerPo<strong>in</strong>t<br />

• Explor<strong>in</strong>g PowerPo<strong>in</strong>t menus<br />

• Start<strong>in</strong>g a new slide<br />

• Add<strong>in</strong>g title, text and art<br />

• Mov<strong>in</strong>g text area and resiz<strong>in</strong>g text box<br />

• Start<strong>in</strong>g a slide show<br />

• Sav<strong>in</strong>g a presentation<br />

• Pr<strong>in</strong>t<strong>in</strong>g slides<br />

• Insert<strong>in</strong>g and delet<strong>in</strong>g slides<br />

• Clos<strong>in</strong>g a presentation<br />

• Exercise for mak<strong>in</strong>g a presentation and slide show<br />

2.2 Views<br />

• PowerPo<strong>in</strong>t views – slide view, outl<strong>in</strong>e view, slide sorter view, notes view, slide<br />

show view, slide setup<br />

• Zoom <strong>in</strong>, zoom out<br />

• Exercises on various views of presentation

62<br />

2.3 Formatt<strong>in</strong>g and Enhanc<strong>in</strong>g text<br />

• Formatt<strong>in</strong>g<br />

• Chang<strong>in</strong>g format with a new layout<br />

• Alignment of text and text spac<strong>in</strong>g<br />

• Enhanc<strong>in</strong>g text formatt<strong>in</strong>g – use of bullets, chang<strong>in</strong>g text font and size<br />

• Select<strong>in</strong>g text style and color<br />

• Apply<strong>in</strong>g design template<br />

• Clos<strong>in</strong>g and apply<strong>in</strong>g the transition<br />

• Spell check<strong>in</strong>g<br />

• To set header and footer<br />

• Exercise on formatt<strong>in</strong>g text and apply<strong>in</strong>g design template.<br />

2.4 Slide with graphs<br />

• Creat<strong>in</strong>g a graph<br />

• Add<strong>in</strong>g graphic objects<br />

• Add<strong>in</strong>g clipart pictures<br />

• Add<strong>in</strong>g movies and sounds<br />

• Add<strong>in</strong>g multimedia to presentation<br />

• Insert<strong>in</strong>g excel worksheet or word table<br />

• Exercise on <strong>in</strong>sert<strong>in</strong>g graphs, tables, movies and clipart.<br />

3 MS - Access (16 hrs)<br />

<strong>3.1</strong> Introduction to Microsoft access<br />

• Components of access<br />

3.2 Table creat<strong>in</strong>g<br />

• Start<strong>in</strong>g access, creat<strong>in</strong>g tables, tool bars and views of tables<br />

• Edit<strong>in</strong>g the design and contents of the table<br />

• Creat<strong>in</strong>g relationship between tables<br />

• Add<strong>in</strong>g OLE objects to a table<br />

• Use of import and export facility<br />

• Exercise on table creat<strong>in</strong>g<br />

3.3 Query Handl<strong>in</strong>g<br />

• Creat<strong>in</strong>g a new query, use of criteria, expressions and operation<br />

• Edit<strong>in</strong>g a query, pr<strong>in</strong>t a query<br />

• Exercise on creat<strong>in</strong>g and edit<strong>in</strong>g query<br />

3.4 Form design<strong>in</strong>g<br />

• Introduction, creat<strong>in</strong>g a form, modify a form design, design<strong>in</strong>g a form us<strong>in</strong>g<br />

design view.<br />

• Sub – forms, pr<strong>in</strong>t<strong>in</strong>g the forms, exercise on form design<strong>in</strong>g.

63<br />

3.5 Report design<strong>in</strong>g<br />

• Creat<strong>in</strong>g a report, manag<strong>in</strong>g the different controls of the records, sav<strong>in</strong>g and<br />

pr<strong>in</strong>t<strong>in</strong>g the report, use of graphs <strong>in</strong> reports<br />

• Exercise on report design<strong>in</strong>g<br />

4 Programm<strong>in</strong>g fundamentals (6 hrs)<br />

• Algorithm, pseudo language, flow charts: advantages and disadvantages<br />

• Decision table – type, advantages and disadvantages<br />

• Structured programm<strong>in</strong>g: structur<strong>in</strong>g the control flow, modular programm<strong>in</strong>g<br />

• Exercise on mak<strong>in</strong>g algorithm and flow charts.<br />

5 C ++ programm<strong>in</strong>g (24 hrs)<br />

5.1 Fundamentals<br />

• Introduction, oop, character set, C ++ tokens, keywords, identifiers, constants,<br />

basic data type, declaration of variables, def<strong>in</strong><strong>in</strong>g symbolic constants, assignment<br />

statement, comments <strong>in</strong> a programme, structure of C ++ programme, output us<strong>in</strong>g<br />

COUT, output us<strong>in</strong>g CIN, manipulators.<br />

5.2 Operators and Expressions<br />

• Arithmetic operators, relational operators, logical operators, shorthand assignment<br />

operator, <strong>in</strong>crement and decrement operators, conditional operators, bit wise<br />

operators, precedence <strong>in</strong> C ++ operators, cast<strong>in</strong>g of data, standard mathematical<br />

functions.<br />

5.3 Control structures<br />

• IF statements, IF---ELSE statements, nested IF statements, switch statements, Go<br />

To statements, repetitive structures, while statements, do statement, for loop,<br />

break statement, cont<strong>in</strong>ue statement, nested loops.<br />

5.4 Programs<br />

• Write a program to check if a number is even or odd.<br />

• Write a program to f<strong>in</strong>d the smallest of 3 numbers.<br />

• Write a program to f<strong>in</strong>d largest of 4 numbers<br />

• Write a program to f<strong>in</strong>d the roots of quadratic equation.<br />

• Write a program to f<strong>in</strong>d the sum of the first N natural numbers us<strong>in</strong>g a for - do<br />

loops.<br />

• Write a program that reads <strong>in</strong> N numbers and f<strong>in</strong>ds the smallest number among<br />

them.<br />

• Write a program to f<strong>in</strong>d the sum of squares of the digits of a number.<br />

6. Demonstration of CNC mach<strong>in</strong>e.

64<br />

RECOMMENDED BOOKS<br />

1. MS Office 2000 for everyone by Sanjay Saxena; Vikas Publish<strong>in</strong>g House Pvt. Ltd.<br />

2. MS Office 2000 by Steve Hill; BPB Publications.<br />

3. Programm<strong>in</strong>g <strong>in</strong> C++ by B. Subharamanayam.<br />

4. Programm<strong>in</strong>g <strong>in</strong> C by Abdul Khader; Ajanata Publications

65<br />

3.2 THERMODYNAMICS<br />

L T P<br />

3 1 2<br />

RATIONALE<br />

A diploma holder <strong>in</strong> Mechanical Eng<strong>in</strong>eer<strong>in</strong>g is supposed to ma<strong>in</strong>ta<strong>in</strong> steam generators,<br />

turb<strong>in</strong>es and other power plant equipment. In addition he is required to ma<strong>in</strong>ta<strong>in</strong> various<br />

types of automobiles. Therefore, it is essential to teach him concepts, pr<strong>in</strong>ciples and<br />

<strong>applications</strong> of basic thermodynamics, steam generators, steam turb<strong>in</strong>e and other power<br />

plant equipment; non-conventional energy sources and about IC eng<strong>in</strong>es. Hence this<br />

subject.<br />

DETAILED CONTENTS<br />

1. Fundamental Concepts (4 hrs)<br />

Thermodynamic state and system, boundary, surround<strong>in</strong>g, universe,<br />

thermodynamic systems – closed, open, isolated, adiabatic, homogeneous and<br />

heterogeneous, macroscopic and microscopic, properties of system – <strong>in</strong>tensive<br />

and extensive, thermodynamic equilibrium, quasi – static process, reversible and<br />

irreversible processes, Zeroth law of thermodynamics, def<strong>in</strong>ition of properties like<br />

pressure, volume, temperature, enthalpy, <strong>in</strong>ternal energy<br />

2. Laws of Perfect Gases (4 hrs)<br />

Def<strong>in</strong>ition of gases, explanation of perfect gas laws – Boyle’s law, Charle’s law,<br />

Avagadro’s law, Regnault’s law, Universal gas constant, Characteristic gas<br />

constants, derivation<br />

Specific heat at constant pressure, specific heat at constant volume of gas,<br />

derivation of an expression for specific heats with characteristics, simple<br />

problems on gas equation<br />

3. Thermodynamic Processes of Gases (4 hrs)<br />

Types of thermodynamic processes – isochoric, isobaric, isothermal, hyperbolic,<br />

isentropic, polytropic and throttl<strong>in</strong>g processes, equations represent<strong>in</strong>g the<br />

processes<br />

Derivation of work done, change <strong>in</strong> <strong>in</strong>ternal energy, change <strong>in</strong> entropy, rate of<br />

heat transfer for the above processes

66<br />

4. Laws of Thermodynamics (6 hrs)<br />

Laws of conservation of energy, first law of thermodynamics (Joule’s<br />

experiment), Application of first law of thermodynamics to non-flow systems –<br />

Constant volume, constant pressure, Adiabatic and polytropic processes, steady<br />

flow energy equation, Application of steady flow energy to equation, turb<strong>in</strong>es,<br />

pump, boilers, compressors, nozzles, evaporators, limitations<br />

Heat source and heat s<strong>in</strong>ks, statement to second laws of thermodynamics; Kelv<strong>in</strong><br />

Planck’s statement, Classius statement, equivalence of statements, Perpetual<br />

motion Mach<strong>in</strong>e of first k<strong>in</strong>d, second k<strong>in</strong>d, (PMM1, PMM2), Carnot eng<strong>in</strong>e,<br />

Introduction of third law of thermodynamics, concept of irreversibility, entropy<br />

5. Steam Boiler (4 hrs)<br />

Water and fire tube boilers, construction and work<strong>in</strong>g of lancashire, babcock and<br />

Wilcox boilers. Various mount<strong>in</strong>g and accessories of boilers.<br />

6. Ideal and Real Gases (4 hrs)<br />

Concept of ideal gas, enthalpy and specific heat capacities of an ideal gas, P – V –<br />

T surface of an ideal gas, triple po<strong>in</strong>t, real gases, Vander-Wall’s equation,<br />

Amagat’s experiment, equation of states<br />

Mass fraction, mole fraction, partial pressure, <strong>in</strong>troduction to compressibility of<br />

gases<br />

7. Properties of Steam (4 hrs)<br />

Formation of steam and related terms, thermodynamics properties of steam, steam<br />

tables, <strong>in</strong>ternal latent heat, <strong>in</strong>ternal energy of stream, entropy of water, entropy of<br />

steam, T- S diagrams, Mollier diagram (H – S Chart), Expansion of steam,<br />

Hyperbolic, reversible adiabatic and throttl<strong>in</strong>g processes<br />

Quality of steam (dryness fraction), measurement of dryness fraction, throttl<strong>in</strong>g<br />

calorimeter, separat<strong>in</strong>g and throttl<strong>in</strong>g calorimeter<br />

8. Fuels and Combustion (8 hrs)<br />

Def<strong>in</strong>ition of fuel, types – solid, liquid and gaseous fuels, examples, uses of<br />

different types of fuels<br />

Calorific values of fuels, Dulong’s formula for calorific value, calculation of<br />

calorific values, chemical composition of a fuel

67<br />

Bomb calorimeter unit – description, procedure for determ<strong>in</strong>ation of C.V. of solid<br />

or liquid fuel us<strong>in</strong>g bomb calorimeters, calculation of CV with test data<br />

Junker’s gas calorimeter unit – description, determ<strong>in</strong>ation of gas us<strong>in</strong>g Junker’s<br />

calorimeter, Problems on CV determ<strong>in</strong>ation with Junker’s calorimeter test data<br />

Balance chemical equations for the comb<strong>in</strong>ation of C, H, S, CH 4 , and ethane<br />

Calculation of m<strong>in</strong>imum air requirement for the complete combustion of unit<br />

mass/unit volume of fuel hav<strong>in</strong>g a given composition, Conversion of volumetric<br />

analysis to gravimetric analysis and vice versa, calculation of percentage<br />

composition (by weight and volume) of fuel gas. Calculation of weight of fuel<br />

gases obta<strong>in</strong>ed by combustion of fuel with and without excess air, simple<br />

problems<br />

Description of Orsat apparatus and use, procedure for determ<strong>in</strong>ation of flue gas<br />

analysis, chemicals used for absorption of different gases <strong>in</strong> flue gases<br />

Description and work<strong>in</strong>g of a <strong>mechanical</strong> type of CO 2 recorder.<br />

9. Air Standard Cycles (4 hrs)<br />

Mean<strong>in</strong>g of air standard cycle – its use, condition of reversibility of a cycle<br />

Description of Carnot cycle, Otto cycle, Diesel cycle, simple problems on<br />

efficiency, calculation for different cycles<br />

Comparison of Otto, Diesel cycles for same compression ratio or same peak<br />

pressure developed<br />

Reasons for highest efficiency of Carnot cycle and all other cycles work<strong>in</strong>g<br />

between same temperature limits<br />

10. Air Compressors (4 hrs)<br />

Functions of air compressor – uses of compressed air, type of air compressors<br />

S<strong>in</strong>gle stage reciprocat<strong>in</strong>g air compressor, its construction and work<strong>in</strong>g,<br />

representation of processes <strong>in</strong>volved on P – V diagram.<br />

Multistage compressors – advantages over s<strong>in</strong>gle stage compressors, use of air<br />

cooler – condition of m<strong>in</strong>imum work <strong>in</strong> two stage compressor (without proof),<br />

simple problems

68<br />

Rotary compressors – types, descriptive treatment of centrifugal compressor, axial<br />

flow compressor, vane type compressor<br />

11. Introduction to Heat Transfer (2 hrs)<br />

Modes of heat transfer, Fourier’s law, steady state conduction, composite<br />

structures, Natural and forced convection, thermal radiation<br />

LIST OF PRACTICALS<br />

1. To f<strong>in</strong>d out the dryness fraction of steam by throttl<strong>in</strong>g calorimeter.<br />

2. Determ<strong>in</strong>ation of calorific value of fuel by bomb calorimeter.<br />

3. To f<strong>in</strong>d out specific fuel consumption by gravimetric or volumetric fuel<br />

equipment.<br />

4. To f<strong>in</strong>d out the viscosity <strong>in</strong>dex of lubricant by Orsat Apparatus.<br />

5. To f<strong>in</strong>d out CO 2 value of exhaust from eng<strong>in</strong>e by CO 2 recorder (Smokemeter).<br />

6. To study the construction and work<strong>in</strong>g of s<strong>in</strong>gle stage air compressor.<br />

7. To f<strong>in</strong>d out the flash po<strong>in</strong>t of fuel by flash po<strong>in</strong>t apparatus.<br />

8. Study of various fire tube and water tube boiler by models or by visits.<br />

9. Study of various mount<strong>in</strong>g and accessories of boilers.<br />

RECOMMENDED BOOKS<br />

1. Eng<strong>in</strong>eer<strong>in</strong>g Thermodynamics by PK Nag; Tata McGraw Hill, Delhi<br />

2. Basic Eng<strong>in</strong>eer<strong>in</strong>g Thermodynamics by Roy Chaudhary; Tata McGraw Hill,<br />

Delhi<br />

3. Basic Thermodynamics by PB Joshi and US Tumne; Pune Vidyarthi Grah<br />

Prakashan<br />

4. Eng<strong>in</strong>eer<strong>in</strong>g Thermodynamics by CP Arora; Tata McGraw Hill, Delhi<br />

5. A Treatise on Heat Eng<strong>in</strong>eer<strong>in</strong>g by VP Vasandani and DS Kumar; Metropolitan<br />

Book Company.

69<br />

3.3 BASICS OF ELECTRICAL AND ELECTRONICS ENGINEERING<br />

RATIONALE<br />

L T P<br />

3 - 2<br />

The objective of the course is to impart basic knowledge and skills regard<strong>in</strong>g electrical<br />

eng<strong>in</strong>eer<strong>in</strong>g, which diploma holders will come across <strong>in</strong> their professional life<br />

DETAILED CONTENTS<br />

1. Application and Advantage of Electricity (4 hrs)<br />

Difference between AC and DC, various <strong>applications</strong> of electricity, advantages of<br />

electrical eng<strong>in</strong>ergy over other types of energy<br />

2. Basic Quantities of Electricity (4 hrs)<br />

Def<strong>in</strong>ition of voltages, current, power and energy with their units, name of<br />

<strong>in</strong>struments used for measur<strong>in</strong>g above quantities, connection of these <strong>in</strong>struments<br />

<strong>in</strong> an electric circuit<br />

3. Electromagnetic Induction (4 hrs)<br />

Production of e.m.f., idea of a transformer and its work<strong>in</strong>g pr<strong>in</strong>ciple<br />

4. Distribution System (8 hrs)<br />

Difference between high and low voltage distribution system, identification of<br />

three-phase wire, neutral wires and earth wire <strong>in</strong> a low voltage distribution<br />

system. Identification of voltages between phases and between one phase and<br />

neutral. Difference between three-phase and s<strong>in</strong>gle-phase supply<br />

5. Domestic Installation (7 hrs)<br />

Dist<strong>in</strong>ction between light and fan circuits and s<strong>in</strong>gle phase power circuit, subcircuits,<br />

various accessories and parts of electrical <strong>in</strong>stallation. Identification of<br />

wir<strong>in</strong>g systems. Common safety measures and earth<strong>in</strong>g<br />

6. Electric Motor (9 hrs)<br />

Def<strong>in</strong>ition and various <strong>applications</strong> of s<strong>in</strong>gle-phase and three-phase motors.<br />

Connection and start<strong>in</strong>g of three-phase <strong>in</strong>duction motors by star-delta starter.<br />

Chang<strong>in</strong>g direction of rotation of a given 3 phase <strong>in</strong>duction motor

70<br />

7. Electrical Safety (5 hrs)<br />

Electrical shock and precautions aga<strong>in</strong>st shock, treatment of electric shock,<br />

concept of fuses and their classification, selection and application, concept of<br />

earth<strong>in</strong>g and various types of earth<strong>in</strong>g, <strong>applications</strong> of MCBs and ELCBs<br />

8. Basic Electronics (7 hrs)<br />

Basic idea of semiconductors – P and N type; diodes, zener diodes and their<br />

<strong>applications</strong>, transistor – PNP and NPN, their characteristics and uses,<br />

characteristics and application of a thyristor, characteristics and <strong>applications</strong> of<br />

servo motors.<br />

LIST OF PRACTICALS<br />

1. Connection of a three-phase motor and starter with fuses and revers<strong>in</strong>g of<br />

direction of rotation<br />

2. Connection of a s<strong>in</strong>gle-phase <strong>in</strong>duction motor with supply and revers<strong>in</strong>g of its<br />

direction of rotation<br />

3. Charg<strong>in</strong>g of a lead – acid battery<br />

4. Troubleshoot<strong>in</strong>g <strong>in</strong> domestic wir<strong>in</strong>g system<br />

5. Connection and read<strong>in</strong>g of an electric energy meter<br />

6. Study of a distribution board for domestic <strong>in</strong>stallation<br />

7. Use of ammeter, voltmeter, wattmeter, energy meter and multi-meter<br />

8. Ohm’s Law verification<br />

9. Verification of law of resistance <strong>in</strong> series<br />

10. Verification of law of resistance <strong>in</strong> parallel<br />

11. Study of different types of fuses<br />

12. Study of earth<strong>in</strong>g pratices

71<br />

RECOMMENDED BOOKS<br />

1. Basic Electrical Eng<strong>in</strong>eer<strong>in</strong>g by PS Dhongal; Tata McGraw Hill Publishers, New<br />

Delhi<br />

2. A Text Book of Electrical Technology, Vol. I and II by BL Thareja; S Chand and<br />

Co., New Delhi<br />

3. Basic Electricity by BR Sharma; Satya Prakashan, New Delhi<br />

4. Basic Electrical Eng<strong>in</strong>eer<strong>in</strong>g by JB Gupta, S Kataria and Sons, Delhi<br />

5. Experiments <strong>in</strong> Basic Electrical Eng<strong>in</strong>eer<strong>in</strong>g by SK Bhattacharya and KM Rastogi,<br />

New Age International Publishers Ltd., New Delhi<br />

6. Basic Electronics by VK Mehta; S Chand and Co., New Delhi<br />

7. Electrical Mach<strong>in</strong>es by SK Bhattacharya; Tata McGraw Hill, New Delhi

72<br />

3.4 WORKSHOP TECHNOLOGY - I<br />

RATIONALE<br />

L T P<br />

3 - -<br />

Diploma holders are responsible for supervis<strong>in</strong>g production processes to achieve<br />

production targets and for optimal utilization of resources. For this purpose, knowledge<br />

about various mach<strong>in</strong><strong>in</strong>g processes, modern mach<strong>in</strong><strong>in</strong>g methods, process<strong>in</strong>g of plastic,<br />

CNC mach<strong>in</strong><strong>in</strong>g, tool, jigs and fixtures is required to be imparted. Hence the subject of<br />

workshop technology.<br />

DETAILED CONTENTS<br />

1. Weld<strong>in</strong>g Process (2 hrs)<br />

- Pr<strong>in</strong>ciple of weld<strong>in</strong>g<br />

- Weld<strong>in</strong>g positions and techniques, symbols.<br />

2. Gas Weld<strong>in</strong>g (3 hrs)<br />

- Types of gas weld<strong>in</strong>g flames and their <strong>applications</strong><br />

- Gas weld<strong>in</strong>g equipments- Gas weld<strong>in</strong>g torch, Oxy – acetylene cutt<strong>in</strong>g torch,<br />

Blowpipe, Pressure regulators, Filler rods and fluxes.<br />

3. Arc Weld<strong>in</strong>g (3 hrs)<br />

- Arc weld<strong>in</strong>g mach<strong>in</strong>es and equipment<br />

- A.C. and D.C. arc weld<strong>in</strong>g<br />

- Effect of polarity, current regulation and voltage regulation<br />

- Electrodes: Classification, B.I.S. specification and selection<br />

- Flux for arc weld<strong>in</strong>g<br />

4. Other Weld<strong>in</strong>g Processes (3 hrs)<br />

- Pr<strong>in</strong>ciple of resistance weld<strong>in</strong>g, work<strong>in</strong>g and <strong>applications</strong> of spot weld<strong>in</strong>g,<br />

seam weld<strong>in</strong>g, projection weld<strong>in</strong>g and percussion weld<strong>in</strong>g.<br />

- Weld<strong>in</strong>g defects and <strong>in</strong>spection of welded jo<strong>in</strong>ts.<br />

5. Modern Weld<strong>in</strong>g Methods (4 hrs)<br />

Pr<strong>in</strong>ciple of operation, advantages, disadvantages and <strong>applications</strong> of:<br />

- Tungsten <strong>in</strong>ert gas (TIG) weld<strong>in</strong>g<br />

- Metal <strong>in</strong>ert gas (MIG) weld<strong>in</strong>g<br />

- Thermit weld<strong>in</strong>g<br />

- Electro slag weld<strong>in</strong>g

73<br />

6. Pattern Mak<strong>in</strong>g (3 hrs)<br />

- Types of pattern<br />

- Pattern material<br />

- Pattern allowances<br />

- Pattern codes as per B.I.S.<br />

- Introduction to cores, core boxes and core materials<br />

- Core mak<strong>in</strong>g procedure<br />

- Core pr<strong>in</strong>ts, position<strong>in</strong>g of cores<br />

7. Mould<strong>in</strong>g Sand (2 hrs)<br />

- Properties of mould<strong>in</strong>g sand, their impact and control of properties viz.<br />

permeability, refractor<strong>in</strong>ess, adhesiveness, cohesiveness, strength, flow<br />

ability, collapsibility.<br />

- Various types of mould<strong>in</strong>g sand.<br />

8. Mould Mak<strong>in</strong>g (3 hrs)]<br />

- Introduction to mould<strong>in</strong>g tools<br />

- Types of moulds<br />

- Step <strong>in</strong>volved <strong>in</strong> mak<strong>in</strong>g a mould<br />

- Mould<strong>in</strong>g boxes, hand tools used for mould mak<strong>in</strong>g<br />

- Mould<strong>in</strong>g processes: Bench mould<strong>in</strong>g, floor mould<strong>in</strong>g, pit mould<strong>in</strong>g and<br />

mach<strong>in</strong>e mould<strong>in</strong>g.<br />

9. Special Cast<strong>in</strong>g Processes (2 hrs)<br />

Pr<strong>in</strong>ciples, work<strong>in</strong>g and <strong>applications</strong> of<br />

- Dies cast<strong>in</strong>g: hot chamber and cold chamber<br />

- Centrifugal cast<strong>in</strong>g<br />

10. Gat<strong>in</strong>g and Riser<strong>in</strong>g System (2 hrs)<br />

- Elements of gat<strong>in</strong>g system<br />

- Pour<strong>in</strong>g bas<strong>in</strong>, sprue, runner, gates<br />

- Types of risers, location of risers<br />

- Directional solidification<br />

11. Cast<strong>in</strong>g Defects (3 hrs)<br />

- Different types of cast<strong>in</strong>g defects<br />

- Test<strong>in</strong>g of defects: radiography, magnetic particle <strong>in</strong>spection, and<br />

ultrasonic <strong>in</strong>spection.

74<br />

12. Lathe (8 hrs)<br />

- Description and function of various parts of a lathe<br />

- Classification and specification of various types of lathe<br />

- Work hold<strong>in</strong>g devices<br />

- Lathe operations: - Pla<strong>in</strong> and step turn<strong>in</strong>g, fac<strong>in</strong>g, part<strong>in</strong>g off, taper turn<strong>in</strong>g,<br />

eccentric turn<strong>in</strong>g, drill<strong>in</strong>g, ream<strong>in</strong>g, bor<strong>in</strong>g, thread<strong>in</strong>g and knurl<strong>in</strong>g.<br />

- Cutt<strong>in</strong>g parameters – Speed, feed and depth of cut for various materials and<br />

for various operations, mach<strong>in</strong><strong>in</strong>g time.<br />

- Lathe accessories:- Centers, dogs, chucks, collets, face plate, angle plate,<br />

mandrel, steady rest, taper turn<strong>in</strong>g attachment, tool post gr<strong>in</strong>der<br />

13. Drill<strong>in</strong>g (4 hrs)<br />

- Classification of drill<strong>in</strong>g mach<strong>in</strong>es and their description.<br />

- Various operations performed on drill<strong>in</strong>g mach<strong>in</strong>e – drill<strong>in</strong>g, spot fac<strong>in</strong>g,<br />

ream<strong>in</strong>g, bor<strong>in</strong>g, counter bor<strong>in</strong>g, counter s<strong>in</strong>k<strong>in</strong>g, hole mill<strong>in</strong>g, tapp<strong>in</strong>g.<br />

- Speeds and feed dur<strong>in</strong>g drill<strong>in</strong>g, impacts of these parameters on drill<strong>in</strong>g,<br />

mach<strong>in</strong><strong>in</strong>g time.<br />

- Types of drills and their features, nomenclature of a drill<br />

- Drill hold<strong>in</strong>g devices.<br />

- Types of reamers.<br />

14. Bor<strong>in</strong>g (3 hrs)<br />

- Pr<strong>in</strong>ciple of bor<strong>in</strong>g<br />

- Classification of bor<strong>in</strong>g mach<strong>in</strong>es and their brief description.<br />

- Specification of bor<strong>in</strong>g mach<strong>in</strong>es.<br />

- Bor<strong>in</strong>g tools, bor<strong>in</strong>g bars and bor<strong>in</strong>g heads.<br />

- Description of jig bor<strong>in</strong>g mach<strong>in</strong>e.<br />

15. Cutt<strong>in</strong>g Tools and Cutt<strong>in</strong>g Materials (3 hrs)<br />

- Various types of s<strong>in</strong>gle po<strong>in</strong>t cutt<strong>in</strong>g tools and their uses.<br />

- S<strong>in</strong>gle po<strong>in</strong>t cutt<strong>in</strong>g tool geometry, tool signature.<br />

- Properties of cutt<strong>in</strong>g tool material.<br />

- Study of various cutt<strong>in</strong>g tool materials viz. High speed steel, tungsten carbide,<br />

cobalt steel, cemented carbides, satellite, ceramics and diamond.<br />

- Cutt<strong>in</strong>g fluid – their types, importance, properties & advantages and<br />

<strong>applications</strong>.

75<br />

REFERENCE BOOKS<br />

1. A Text Book of Weld<strong>in</strong>g Technology by O.P. Khanna.<br />

2. Weld<strong>in</strong>g Technology by R.L. Agarwal and Tahil Maghanani; Khanna Publishers,<br />

Delhi.<br />

3. A Text Book on Foundry Technology by M.Lal and O.P.Khanna.<br />

4. Foundry Eng<strong>in</strong>eer<strong>in</strong>g by Tahil Maghnani.<br />

5. Workshop Technology by B.S. Raghuwanshi; Dhanpat Rai and Sons, Delhi.<br />

6. Manufactur<strong>in</strong>g Technology by M.Adithan and AB Gupta; New Age International<br />

(P) Ltd, Delhi.<br />

7. Workshop Technology by RC J<strong>in</strong>dal; Ishan Publication Ambala city.<br />

8. Elements of Workshop Technology by S.K.Choudhary and Hazara; Asia<br />

Publish<strong>in</strong>g House.

76<br />

RATIONALE<br />

3.5 MACHINE DRAWING<br />

L T P<br />

- - 6<br />

Diploma Holders are required to read and <strong>in</strong>terpret draw<strong>in</strong>gs. Therefore it is essential<br />

that they have competency <strong>in</strong> prepar<strong>in</strong>g draw<strong>in</strong>gs and sketches of various mach<strong>in</strong>e parts.<br />

Therefore this subject is essentially required.<br />

DETAILED CONTENT<br />

1. Introduction<br />

• Limits and Fits: Limit system – tolerance, limits, deviation, allowance,<br />

basic size, design size. Tolerances-fundamental tolerances, fundamental<br />

deviation, method of plac<strong>in</strong>g limit dimensions.<br />

Fits: Clearance fit, transition fit, <strong>in</strong>terference fit, hole basis system, shaft basis<br />

system, tolerance grades.<br />

Calculat<strong>in</strong>g values of clearance/<strong>in</strong>terference, hole tolerance and, shaft tolerance<br />

with given basic size for common assemblies like H7/g6, H7/m6, H8/u7.<br />

• Surface Roughness<br />

Introduction-actual profile, reference profile, datum profile, mean profile, peakto-valley<br />

height, mean roughness <strong>in</strong>dex, surface roughness number.<br />

Use of mach<strong>in</strong><strong>in</strong>g symbols <strong>in</strong> production draw<strong>in</strong>gs, <strong>in</strong>dication of surface<br />

roughness-<strong>in</strong>dication of special surface roughness characteristics, <strong>in</strong>dication of<br />

mach<strong>in</strong><strong>in</strong>g allowance, <strong>in</strong>dication of surface roughness, symbols on draw<strong>in</strong>gs,<br />

method of <strong>in</strong>dicat<strong>in</strong>g surface roughness on given components.<br />

Indicat<strong>in</strong>g roughness on a component for: -<br />

i) Surface to be obta<strong>in</strong>ed by any production method.<br />

ii) Surface to be obta<strong>in</strong>ed without removal of material.<br />

2. Shaft Coupl<strong>in</strong>gs (2 sheets)<br />

• Oldham coupl<strong>in</strong>g<br />

• Universal coupl<strong>in</strong>g

77<br />

3. Bear<strong>in</strong>gs (5 sheets)<br />

• Bush bear<strong>in</strong>g<br />

• Foot step bear<strong>in</strong>g<br />

• Plummer block<br />

• Self align<strong>in</strong>g bear<strong>in</strong>g<br />

• Brackets<br />

4. Pipe Jo<strong>in</strong>ts (5 sheets)<br />

• Symbols for pip<strong>in</strong>g and layout plan of pip<strong>in</strong>g<br />

• Flanged jo<strong>in</strong>t<br />

• Socket and spigot jo<strong>in</strong>t<br />

• Union jo<strong>in</strong>t<br />

• Expansion pipe jo<strong>in</strong>t<br />

5. I.C. eng<strong>in</strong>e parts (2 sheets)<br />

• I.C. eng<strong>in</strong>e connect<strong>in</strong>g rods<br />

• I.C. eng<strong>in</strong>e pistons<br />

6. Screw Jack (1 sheet)<br />

RECOMMENDED BOOKS<br />

1. Mach<strong>in</strong>e Draw<strong>in</strong>g by P.S. Gill; S.K. Kataria and Sons, Delhi.<br />

2. Mach<strong>in</strong>e Draw<strong>in</strong>g by R.K. Dhawan; S. Chand and Company, Delhi.<br />

3. Mach<strong>in</strong>e Draw<strong>in</strong>g by R.B. Gupta; Satya Parkashan, New Delhi.<br />

4. Mach<strong>in</strong>e Draw<strong>in</strong>g by N.D. Bhatt; Charotar Publish<strong>in</strong>g House.<br />

Note:<br />

1. The draw<strong>in</strong>gs should <strong>in</strong>clude dimensions with tolerances, wherever<br />

necessary, and material list accord<strong>in</strong>g to B.I.S. specifications as per<br />

SP46: 1988.<br />

2. 25% of the draw<strong>in</strong>g sheets should be drawn us<strong>in</strong>g AutoCAD.

78<br />

RATIONALE<br />

3.6 WORKSHOP PRACTICE I<br />

L T P<br />

- - 9<br />

Diploma holders are responsible for supervis<strong>in</strong>g production processes to achieve<br />

production targets and for optimal utilization of resources. For this purpose, skills <strong>in</strong><br />

various mach<strong>in</strong><strong>in</strong>g processes, modern mach<strong>in</strong><strong>in</strong>g methods, process<strong>in</strong>g of plastic, CNC<br />

mach<strong>in</strong><strong>in</strong>g, tool, jigs and fixtures is required to be imparted. Hence the subject of<br />

workshop practice.<br />

LIST OF PRACTICALS<br />

WELDING<br />

1. Mak<strong>in</strong>g follow<strong>in</strong>g types of jo<strong>in</strong>ts by gas weld<strong>in</strong>g<br />

- Prelim<strong>in</strong>ary jo<strong>in</strong><strong>in</strong>g practice<br />

- Vertical weld<strong>in</strong>g<br />

2. Exercises of gas weld<strong>in</strong>g on the follow<strong>in</strong>g<br />

- Alum<strong>in</strong>um<br />

- Brass<br />

- Copper<br />

- C.I.<br />

3. Gas cutt<strong>in</strong>g of the follow<strong>in</strong>g types<br />

- Prelim<strong>in</strong>ary gas cutt<strong>in</strong>g practice<br />

- Stock cutt<strong>in</strong>g by oxy acetylene<br />

- C.I. cutt<strong>in</strong>g<br />

4. Mak<strong>in</strong>g follow<strong>in</strong>g types of jo<strong>in</strong>ts by arc weld<strong>in</strong>g on M.S, C.I and alum<strong>in</strong>ium<br />

- Jo<strong>in</strong><strong>in</strong>g practice by arc weld<strong>in</strong>g<br />

- Butt and lap jo<strong>in</strong>t (<strong>in</strong> vertical position, travel up and down).<br />

- Weld<strong>in</strong>g of outside corner jo<strong>in</strong>t.<br />

- Inspection of the weld<strong>in</strong>g defects occurred <strong>in</strong> the job.<br />

5. Exercise on spot weld<strong>in</strong>g.<br />

6. Exercise on projection weld<strong>in</strong>g (<strong>in</strong>dustrial visit should be arranged).<br />

7. Exercise on braz<strong>in</strong>g.

79<br />

8. Exercise on TIG weld<strong>in</strong>g.<br />

9. Exercise on MIG weld<strong>in</strong>g.<br />

FOUNDRY<br />

10. Preparation of the follow<strong>in</strong>g types of moulds.<br />

- Floor mold<strong>in</strong>g<br />

.<br />

11. Mould<strong>in</strong>g and cast<strong>in</strong>g of<br />

- A solid pattern<br />

- A split pattern<br />

12. Test<strong>in</strong>g and <strong>in</strong>spection of cast<strong>in</strong>g defects visually.<br />

13. Study of constructional features of coupla furnace.<br />

TURNING<br />

14. Simple exercise on turn<strong>in</strong>g and step turn<strong>in</strong>g.<br />

15. A composite job <strong>in</strong>volv<strong>in</strong>g turn<strong>in</strong>g, taper turn<strong>in</strong>g, thread cutt<strong>in</strong>g and knurl<strong>in</strong>g and<br />

Eccentric turn<strong>in</strong>g.<br />

16. Exercise on <strong>in</strong>ternal thread<strong>in</strong>g on lathe.<br />

DRILLING AND FITTING<br />

17. Mark<strong>in</strong>g and drill<strong>in</strong>g practice us<strong>in</strong>g column and knee type drill<strong>in</strong>g mach<strong>in</strong>e and<br />

radial drill<strong>in</strong>g mach<strong>in</strong>e.<br />

18. A job on drill<strong>in</strong>g, thread<strong>in</strong>g, ream<strong>in</strong>g, counter bor<strong>in</strong>g and counter s<strong>in</strong>k<strong>in</strong>g.<br />

19. Exercise on bor<strong>in</strong>g with the help of bor<strong>in</strong>g bar.<br />

20. Dovetail fitt<strong>in</strong>g <strong>in</strong> mild steel piece<br />

21. Radius fitt<strong>in</strong>g <strong>in</strong> mild steel piece.<br />

22. Exercise on pipe bend<strong>in</strong>g on MS pipe and PVC pipe us<strong>in</strong>g pipe bend<strong>in</strong>g mach<strong>in</strong>e.<br />

PATTERN MAKING<br />

23. Preparation of solid pattern (s<strong>in</strong>gle piece)<br />

24. Preparation of split pattern<br />

25. Preparation of self cored pattern

80<br />

Note: 1. The Workshop Super<strong>in</strong>tendent will prepare & f<strong>in</strong>alize the specific<br />

draw<strong>in</strong>gs of all jobs <strong>in</strong> the beg<strong>in</strong>n<strong>in</strong>g of semester <strong>in</strong> consultation with staff<br />

2. The Institutions where foundry shop is not exist<strong>in</strong>g, they should arrange a<br />

visit to foundry <strong>in</strong>dustry <strong>in</strong> the nearby area.