Optimizing water in the steam system - Endress+Hauser

Optimizing water in the steam system - Endress+Hauser

Optimizing water in the steam system - Endress+Hauser

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6<br />

<strong>Optimiz<strong>in</strong>g</strong> <strong>the</strong> <strong>water</strong>-/<strong>steam</strong> <strong>system</strong>s<br />

1<br />

Level measurement <strong>in</strong> <strong>the</strong> <strong>steam</strong> drum<br />

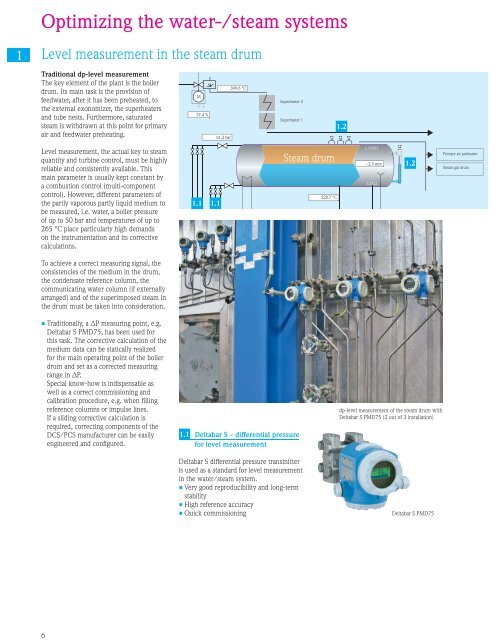

Traditional dp-level measurement<br />

The key element of <strong>the</strong> plant is <strong>the</strong> boiler<br />

drum. Its ma<strong>in</strong> task is <strong>the</strong> provision of<br />

feed<strong>water</strong>, after it has been preheated, to<br />

<strong>the</strong> external exonomizer, <strong>the</strong> superheaters<br />

and tube nests. Fur<strong>the</strong>rmore, saturated<br />

<strong>steam</strong> is withdrawn at this po<strong>in</strong>t for primary<br />

air and feed<strong>water</strong> preheat<strong>in</strong>g.<br />

M<br />

V L<br />

37.4 %<br />

61.2 bar 4<br />

399.6 °C<br />

Superheater 2<br />

Superheater 1<br />

1.2<br />

Level measurement, <strong>the</strong> actual key to <strong>steam</strong><br />

quantity and turb<strong>in</strong>e control, must be highly<br />

reliable and consistently available. This<br />

ma<strong>in</strong> parameter is usually kept constant by<br />

a combustion control (multi-component<br />

control). However, different parameters of<br />

<strong>the</strong> partly vaporous partly liquid medium to<br />

be measured, i.e. <strong>water</strong>, a boiler pressure<br />

of up to 50 bar and temperatures of up to<br />

265 °C place particularly high demands<br />

on <strong>the</strong> <strong>in</strong>strumentation and its corrective<br />

calculations.<br />

1.1 1.1<br />

Steam drum<br />

220.7 °C<br />

LZAHH<br />

-2.5 mm<br />

LZALL<br />

1.2<br />

Primary air preheater<br />

Steam gas drum<br />

To achieve a correct measur<strong>in</strong>g signal, <strong>the</strong><br />

consistencies of <strong>the</strong> medium <strong>in</strong> <strong>the</strong> drum,<br />

<strong>the</strong> condensate reference column, <strong>the</strong><br />

communicat<strong>in</strong>g <strong>water</strong> column (if externally<br />

arranged) and of <strong>the</strong> superimposed <strong>steam</strong> <strong>in</strong><br />

<strong>the</strong> drum must be taken <strong>in</strong>to consideration.<br />

• Traditionally, a P measur<strong>in</strong>g po<strong>in</strong>t, e.g.<br />

Deltabar S PMD75, has been used for<br />

this task. The corrective calculation of <strong>the</strong><br />

medium data can be statically realized<br />

for <strong>the</strong> ma<strong>in</strong> operat<strong>in</strong>g po<strong>in</strong>t of <strong>the</strong> boiler<br />

drum and set as a corrected measur<strong>in</strong>g<br />

range <strong>in</strong> P.<br />

Special know-how is <strong>in</strong>dispensable as<br />

well as a correct commission<strong>in</strong>g and<br />

calibration procedure, e.g. when fill<strong>in</strong>g<br />

reference columns or impulse l<strong>in</strong>es.<br />

If a slid<strong>in</strong>g corrective calculation is<br />

required, correct<strong>in</strong>g components of <strong>the</strong><br />

DCS/PCS manufacturer can be easily<br />

eng<strong>in</strong>eered and configured.<br />

1.1 Deltabar S – differential pressure<br />

for level measurement<br />

Deltabar S differential pressure transmitter<br />

is used as a standard for level measurement<br />

<strong>in</strong> <strong>the</strong> <strong>water</strong>/<strong>steam</strong> <strong>system</strong>.<br />

• Very good reproducibility and long-term<br />

stability<br />

• High reference accuracy<br />

• Quick commission<strong>in</strong>g<br />

dp-level measurement of <strong>the</strong> <strong>steam</strong> drum with<br />

Deltabar S PMD75 (2 out of 3 <strong>in</strong>stallation)<br />

Deltabar S PMD75

7<br />

Innovation: Higher plant availability<br />

with guided radar measurement<br />

As an alternative to differential pressure,<br />

levels can be determ<strong>in</strong>ed by Levelflex M<br />

FMP45 guided radar measurement.<br />

The <strong>in</strong>strument may be <strong>in</strong>stalled directly<br />

from <strong>the</strong> top us<strong>in</strong>g a coaxial tube <strong>in</strong> <strong>the</strong><br />

boiler drum or as a bypass variant next<br />

to exist<strong>in</strong>g local <strong>water</strong> reflex displays. In<br />

this application, Levelflex M FMP45 with<br />

EN12952-11/12953-9 approval is used as<br />

high level and low level limit.<br />

To complete <strong>the</strong> <strong>in</strong>stallation, <strong>the</strong> respective<br />

bypass as well as <strong>the</strong> high pressure tensile<br />

bolts/screws and serrated gaskets can also<br />

be supplied for Levelflex M FMP45.<br />

The gas phase compensation was particularly<br />

developed for <strong>the</strong>se special measurements,<br />

<strong>in</strong> which <strong>steam</strong> phases occur, to<br />

compensate <strong>the</strong> time-of-flight shift <strong>in</strong> <strong>steam</strong><br />

phases.<br />

A def<strong>in</strong>ed reference section at <strong>the</strong> probe<br />

comb<strong>in</strong>ed with an electronic software algorithm<br />

corrects <strong>the</strong> level value automatically<br />

and cont<strong>in</strong>ually thus offer<strong>in</strong>g correct and<br />

safe measurement.<br />

Fur<strong>the</strong>rmore, purg<strong>in</strong>g and fill<strong>in</strong>g of<br />

differential pressure pipes after stoppages is<br />

a th<strong>in</strong>g of <strong>the</strong> past.<br />

Level measurement <strong>in</strong> <strong>the</strong> <strong>steam</strong> drum with Levelflex M<br />

FMP45 (2 out of 3 <strong>in</strong>stallation) Level <strong>steam</strong> drum<br />

1.2 Levelflex M – guided microwave<br />

level measurement<br />

Levelflex provides level measurement of<br />

condensed <strong>steam</strong> <strong>in</strong> front of <strong>the</strong> turb<strong>in</strong>e<br />

<strong>in</strong> <strong>the</strong> ma<strong>in</strong> condenser (hotwell), as well<br />

as level measurement at <strong>the</strong> low pressure<br />

preheater, feed<strong>water</strong> tank, high pressure<br />

preheater and boiler drum. Levelflex<br />

provides cyclic automatic gas phase<br />

compensation, <strong>the</strong> ideal solution for precise<br />

level measurement <strong>in</strong> all <strong>steam</strong> applications.<br />

Levelflex is <strong>in</strong>dependent of:<br />

Visual <strong>steam</strong> drum level control through a sight glass<br />

• Density fluctuations<br />

• Chang<strong>in</strong>g dielectric numbers<br />

• Gas cover<strong>in</strong>g of <strong>steam</strong><br />

• Pressure and temperature changes<br />

• Vacuum (e.g. <strong>in</strong> ma<strong>in</strong> condenser hotwell)<br />

This results <strong>in</strong> a better solution than<br />

differential pressure for level measurement,<br />

provid<strong>in</strong>g:<br />

• More reliable measurement<br />

• Increased safety<br />

• Easier <strong>in</strong>stallation<br />

Levelflex M FMP45 as<br />

rod version up to 280 °C<br />

Levelflex M FMP45 as coax<br />

version up to 400 °C<br />

Levelflex is ideal as a displacer replacer.<br />

It has no mechanical mov<strong>in</strong>g parts and,<br />

<strong>the</strong>refore, no wear and tear. Levelflex is<br />

suitable for pressures up to 400 bar and<br />

temperatures up to 400 °C.

8<br />

1<br />

Level measurement <strong>in</strong>novation us<strong>in</strong>g guided radar<br />

The boiler feed<strong>water</strong> circulates with<strong>in</strong><br />

<strong>the</strong> <strong>water</strong>/<strong>steam</strong> circuit. This is <strong>the</strong> ma<strong>in</strong><br />

component <strong>in</strong> <strong>the</strong> power plant. After<br />

<strong>the</strong> <strong>steam</strong> has condensed <strong>in</strong> <strong>the</strong> ma<strong>in</strong><br />

condenser, pumps convey <strong>the</strong> feed<strong>water</strong><br />

through subsequent low and high pressure<br />

heaters <strong>in</strong>to <strong>the</strong> boiler. When it arrives at<br />

<strong>the</strong> boiler, <strong>the</strong> feed<strong>water</strong> is vaporized to<br />

saturated <strong>steam</strong> under high pressures (up<br />

to 110 bar) and high temperatures (up to<br />

318 °C). Pass<strong>in</strong>g through several levels<br />

of superheater, <strong>the</strong> <strong>steam</strong> is <strong>the</strong>n supplied<br />

to <strong>the</strong> turb<strong>in</strong>e to drive <strong>the</strong> generator.<br />

Condensation <strong>in</strong> <strong>the</strong> ma<strong>in</strong> condenser beg<strong>in</strong>s<br />

aga<strong>in</strong> and <strong>the</strong> entire procedure is repeated.<br />

Steam<br />

drum<br />

1.2<br />

Preheater<br />

Intermediate heater<br />

Superheater<br />

Vaporizer<br />

furnace<br />

To flue gas clean<strong>in</strong>g<br />

Boiler<br />

1.2<br />

Ma<strong>in</strong> condenser<br />

(hotwell)<br />

Steam turb<strong>in</strong>e<br />

Generator<br />

Monitor<strong>in</strong>g levels <strong>in</strong> <strong>the</strong> hotwell, low and<br />

high pressure preheater, feed<strong>water</strong> tank and<br />

boiler drum are of great importance for safe<br />

operation of <strong>the</strong> circuit.<br />

1.2<br />

High pressure<br />

preheater<br />

1.2<br />

Boiler feed pump<br />

Feed<strong>water</strong><br />

tank<br />

1.2<br />

Low pressure<br />

preheater<br />

Condensate<br />

pump<br />

Condensate<br />

Additional condensate<br />

from full<br />

desal<strong>in</strong>ation<br />

Hotwell (ma<strong>in</strong> condenser) Low pressure preheater Feed<strong>water</strong> tank<br />

High pressure preheater

9<br />

Pressure and temperature measurement <strong>in</strong> <strong>water</strong>-/<strong>steam</strong> <strong>system</strong>s<br />

2<br />

Overheated <strong>steam</strong> from <strong>the</strong> superheaters of<br />

<strong>the</strong> boiler enters <strong>the</strong> <strong>steam</strong> distributors. This<br />

<strong>steam</strong> is fed to different consumers from <strong>the</strong><br />

distribution station, e.g. turb<strong>in</strong>e, feed<strong>water</strong><br />

heater (degasser), process <strong>steam</strong> for<br />

chemical or pharmaceutical plants, warm<br />

<strong>water</strong> heat exchanger for utility-supplied<br />

heat, etc. In order to serve all processes, <strong>the</strong><br />

<strong>steam</strong> pressure has to be reduced to three<br />

levels:<br />

• High pressure <strong>steam</strong> 49 bar<br />

• Medium pressure <strong>steam</strong> 8.2 bar<br />

• Low pressure <strong>steam</strong> 1.7 bar<br />

A selection of <strong>in</strong>struments which measure<br />

this process with <strong>the</strong> highest degree of<br />

accuracy is:<br />

0.0 %<br />

8.4 bar<br />

HP Collector<br />

48.9 bar 401.0 °C<br />

V<br />

8.2 bar R<br />

V<br />

200.0 °C A<br />

178.6 °C<br />

178.7 °C<br />

A<br />

MP Collector<br />

0.1 % 12.4 t/h<br />

8.4 bar<br />

177.8 °C<br />

200.0 °C A<br />

178.0 °C<br />

178.0 °C<br />

0.2 %<br />

0.0 % 0.1 %<br />

V<br />

49.0 bar A<br />

140.0 °C A<br />

131.6 °C<br />

132.6 °C<br />

1.7 bar R<br />

LP Collector<br />

1.9 bar 1.9 bar<br />

0.0 %<br />

2.2 141.0 °C A 2.2<br />

132.5 °C<br />

2.1<br />

132.5 °C<br />

1.9 bar A<br />

132.2 °C<br />

2.1 Cerabar S<br />

• High pressure impact resistance <strong>in</strong> <strong>the</strong><br />

<strong>water</strong>-<strong>steam</strong> circuit<br />

• Fast commission<strong>in</strong>g via Quick Set up<br />

menu<br />

• Unique safety concept for your process<br />

application<br />

Cerabar S<br />

2.2 Omnigrad TC15 and TC88<br />

• Predom<strong>in</strong>ant use of D4 or D5 solid<br />

protect<strong>in</strong>g pipes<br />

• Preferred materials<br />

- 16Mo3/1.5415<br />

- 13CrMo4-5/1.7335<br />

• HART ® , head or DIN rail transmitter<br />

Redundant pressure monitor<strong>in</strong>g at <strong>the</strong> high and medium<br />

pressure distributor and redundant temperature monitor<strong>in</strong>g<br />

<strong>in</strong> <strong>the</strong> ma<strong>in</strong> pressure pipe by TC15 and <strong>the</strong> RIT261 display.<br />

The complete measur<strong>in</strong>g po<strong>in</strong>t <strong>in</strong>cludes <strong>the</strong><br />

<strong>the</strong>rmometer and <strong>the</strong> option of iTemp head,<br />

rail or field transmitters.<br />

TC15

10<br />

3<br />

Temperature measurement <strong>in</strong> <strong>the</strong> boiler<br />

The waste conveyed to <strong>the</strong> reciprocat<strong>in</strong>g grate is k<strong>in</strong>dled while<br />

apply<strong>in</strong>g primary and secondary air which also <strong>in</strong>fluences and<br />

controls <strong>the</strong> <strong>in</strong>c<strong>in</strong>eration. Temperature measurement <strong>in</strong> <strong>the</strong><br />

combustion chamber contributes decisively to <strong>the</strong> reduction of<br />

emissions and pollutants.<br />

Temperature measurement arranged directly <strong>in</strong> <strong>the</strong> lateral boiler<br />

walls at different levels or sensors located <strong>in</strong> <strong>the</strong> burn-up zone as<br />

well as <strong>in</strong> <strong>the</strong> passage of fur<strong>the</strong>r boiler flues provide <strong>in</strong>formation on<br />

<strong>the</strong> combustion temperature.<br />

The length and <strong>the</strong> material of <strong>the</strong> protect<strong>in</strong>g pipes as well as <strong>the</strong><br />

mechanical and chemical stra<strong>in</strong> are decisive for <strong>the</strong> corrosion and<br />

useful life of <strong>the</strong> <strong>the</strong>rmocouples. The aggressiveness of <strong>the</strong> flue gas<br />

must not be dismissed ei<strong>the</strong>r.<br />

Vessel ceil<strong>in</strong>g Superheater Electrostatic precipitator<br />

LAH<br />

LAH<br />

12392 Nm³/h<br />

5.8 mbar<br />

580.2 °C<br />

522.1 °C<br />

208.1 °C<br />

160.4 °C<br />

PSAL<br />

The follow<strong>in</strong>g materials are predom<strong>in</strong>antly used <strong>in</strong> furnaces:<br />

• Burn-up zones:<br />

Predom<strong>in</strong>antly 1.4762 / AISI446 or alternatively 1.4841 /<br />

AISI310, Type K respectively. The length of <strong>the</strong> <strong>the</strong>rmocouples<br />

is determ<strong>in</strong>ed by <strong>the</strong> l<strong>in</strong><strong>in</strong>g thickness and considerations such as<br />

avoidance of mechanical damage by slag or similar materials.<br />

• Boiler walls adjacent to <strong>the</strong> grate:<br />

S<strong>in</strong>ce <strong>the</strong> <strong>in</strong>stallation is mostly realized with a slight <strong>in</strong>cl<strong>in</strong>ation<br />

<strong>the</strong> protect<strong>in</strong>g pipes may bend downwards. The vic<strong>in</strong>ity to<br />

auxiliary burners and liquid <strong>in</strong>jections might have a negative<br />

<strong>in</strong>fluence <strong>in</strong> this situation.<br />

• Boiler combustion chamber ceil<strong>in</strong>g:<br />

S<strong>in</strong>ce <strong>the</strong> <strong>the</strong>rmocouples are directly mounted <strong>in</strong> <strong>the</strong> flue gas flow<br />

we recommend <strong>the</strong> use of a protective pipe of 1.4876 / Incoloy<br />

800HT with a solidly designed top or alternatively 1.4767 /<br />

Kanthal AF ® .<br />

• Superheater and economizer:<br />

The flue gases have now released <strong>the</strong>ir high temperatures to <strong>the</strong><br />

tube nests and o<strong>the</strong>r components <strong>in</strong>side of <strong>the</strong> <strong>steam</strong> generator.<br />

Thermocouples with protect<strong>in</strong>g pipes of 1.4762 / AISI446 are<br />

used at this po<strong>in</strong>t.<br />

Reciprocat<strong>in</strong>g grate<br />

Four-pass <strong>steam</strong> generator and electrostatic precipitator<br />

3<br />

Omnigrad S TAF16<br />

Temperature measurement at <strong>the</strong> superheater, horizontal flue<br />

Thermocouple with a protect<strong>in</strong>g tube of metal<br />

• Customized immersion length<br />

• Exchangeable measur<strong>in</strong>g <strong>in</strong>sert<br />

• Internal ceramic protective sheaths<br />

• Thermocouples with different<br />

diameters<br />

• 2-wire transmitter PC-programmable<br />

(4...20 mA), HART ® -, PROFIBUS ® - and<br />

FOUNDATION Fieldbus protocol<br />

• Double sens<strong>in</strong>g element<br />

• Various materials<br />

TAF16<br />

Temperature measurement on <strong>the</strong> boiler ceil<strong>in</strong>g

11<br />

Temperature measurement eng<strong>in</strong>eer<strong>in</strong>g<br />

Graphic configurator for temperature<br />

Today, <strong>the</strong> crucial factor of success is cost optimiz<strong>in</strong>g across <strong>the</strong><br />

whole life cycle of a plant. The eng<strong>in</strong>eer<strong>in</strong>g costs for a temperature<br />

measur<strong>in</strong>g po<strong>in</strong>t are frequently higher than <strong>the</strong> purchas<strong>in</strong>g costs of<br />

<strong>the</strong> product itself and eng<strong>in</strong>eer<strong>in</strong>g, commission<strong>in</strong>g and ma<strong>in</strong>tenance<br />

costs toge<strong>the</strong>r might amount to three times <strong>the</strong> purchas<strong>in</strong>g costs.<br />

For this reason, <strong>Endress+Hauser</strong> has developed <strong>the</strong> graphic<br />

configurator toge<strong>the</strong>r with its customers. The same supports<br />

eng<strong>in</strong>eer<strong>in</strong>g <strong>in</strong> particular with user-friendly navigation. It is thus a<br />

useful aid, from siz<strong>in</strong>g, to <strong>the</strong> operation of a temperature measur<strong>in</strong>g<br />

po<strong>in</strong>t.<br />

1 Safe siz<strong>in</strong>g of a temperature measur<strong>in</strong>g po<strong>in</strong>t with graphic trac<strong>in</strong>g<br />

and <strong>in</strong>tegrated calculation modules<br />

2 Fur<strong>the</strong>r <strong>in</strong>formation per click:<br />

Learn More area,<br />

Knowledge data base,<br />

Product sheet,<br />

Installation <strong>in</strong>struction,<br />

Technical documentation,<br />

Certificates,<br />

Spare part track<strong>in</strong>g tool <strong>in</strong>clud<strong>in</strong>g spare part list<br />

1<br />

The graphic configurator is part of <strong>the</strong> <strong>Endress+Hauser</strong><br />

Applicator as described on page 22.<br />

2<br />

View of <strong>the</strong> burn-up zone / grate

12<br />

4<br />

Deltatop dp-flow measurement <strong>system</strong> <strong>in</strong> <strong>steam</strong>, <strong>water</strong> and air<br />

Differential pressure flow devices - proven <strong>in</strong> practice. The way to<br />

avoid legal disputes on <strong>steam</strong> measurement.<br />

The ISO 5167 standard details <strong>the</strong> design and volume calculations for<br />

orifice plates, venturi tubes and nozzles. This gives significant advantages<br />

over o<strong>the</strong>r dp types (such as pitot type devices) where no specific standard<br />

exists. It is important <strong>in</strong> contractual or legal agreements to have a common<br />

calculation basis to avoid disputes about <strong>the</strong> volume measured.<br />

As an example, it is possible that a new power plant does not produce <strong>the</strong><br />

<strong>the</strong>rmal efficiency specified <strong>in</strong> <strong>the</strong> contract. The boiler supplier and <strong>the</strong><br />

turb<strong>in</strong>e manufacturer might disagree about <strong>the</strong> amount of <strong>steam</strong> actually<br />

supplied to <strong>the</strong> turb<strong>in</strong>e. The use of an agreed standard and a meter of fixed<br />

design ensures that third party experts can easily validate <strong>the</strong> meter, <strong>the</strong><br />

<strong>in</strong>stallation and <strong>the</strong> design calculations for <strong>the</strong> <strong>steam</strong> volume. This will<br />

elim<strong>in</strong>ate any potential dispute regard<strong>in</strong>g <strong>the</strong> energy conta<strong>in</strong>ed <strong>in</strong> <strong>the</strong> <strong>steam</strong><br />

flow so that <strong>the</strong>rmal efficiency can be accurately quantified.<br />

S<strong>in</strong>ce <strong>the</strong> primary element has to be eng<strong>in</strong>eered to specific customer or<br />

project requirements and sized correctly to provide <strong>the</strong> required meter<strong>in</strong>g<br />

accuracy laid down <strong>in</strong> ISO 5167, <strong>the</strong> follow<strong>in</strong>g <strong>in</strong>formation must be<br />

supplied:<br />

• Mass flow or volume flow range<br />

• Type of primary element preferred<br />

• Range of differential pressures required<br />

• Acceptable maximum permanent pressure loss<br />

• Nom<strong>in</strong>al pipe diameter<br />

• Operat<strong>in</strong>g temperature<br />

• Operat<strong>in</strong>g pressure<br />

• Standard base conditions used for reference calculations<br />

The choice of <strong>the</strong> primary element may be important if permanent pressure<br />

loss is an issue or is limited by process requirements. Reference texts show<br />

<strong>the</strong> permanent pressure drop as a function of <strong>the</strong> differential generated as:<br />

• Long pattern venturi tube 10...15 %<br />

• Short pattern venturi tube 10...20 %<br />

• Venturi nozzle 10...20 %<br />

• Nozzle 35...60 %<br />

• Orifice plates 35...70 %<br />

It is not just <strong>the</strong> primary element selection that is important. The <strong>in</strong>clusion<br />

of condensation chambers, valve manifolds, impulse l<strong>in</strong>e length and<br />

<strong>the</strong> location of pressure and temperature sensors is also important <strong>in</strong><br />

determ<strong>in</strong><strong>in</strong>g <strong>the</strong> overall <strong>system</strong> uncerta<strong>in</strong>ty as well as assur<strong>in</strong>g a reliable and<br />

safe measurement <strong>system</strong>.<br />

HP superheated <strong>steam</strong> <strong>in</strong>to<br />

turb<strong>in</strong>e<br />

Typical dp-flow applications<br />

Recommended primary elements<br />

Venturi tube/<br />

venturi nozzle<br />

➜<br />

For lowest pressure loss,<br />

meets ISO 5167 requirements<br />

Deltatop - dp flow measurement of secondary air with venturi tube long<br />

LP saturated <strong>steam</strong>/<br />

condensate return<br />

Primary- and secondary<br />

air flow<br />

Orifice plate ➜ Common standard,<br />

meets ISO 5167 requirements<br />

ISA or venturi nozzle ➜ Excellent long term stability,<br />

meets ISO 5167 requirements<br />

Vortex (Prowirl 73) ➜ Calibrated, easiest and cost<br />

effective solution up to 6<br />

Venturi tube ➜ For lowest pressure loss,<br />

reduces energy,<br />

meets ISO 5167 requirements<br />

In case ISO 5167 requirements are not important, pitot tubes can be <strong>in</strong>stalled <strong>in</strong> all mentioned<br />

applications as a cost effective solution for lowest possible pressure loss.<br />

Deltabar S dp-flow transmitter <strong>in</strong>stalled for convenient operation

13<br />

Typical cost sav<strong>in</strong>g case study*<br />

What are <strong>the</strong> sav<strong>in</strong>gs by us<strong>in</strong>g a venturi tube <strong>in</strong>stead of an orifice plate<br />

meter<strong>in</strong>g <strong>the</strong> <strong>steam</strong> <strong>in</strong>to <strong>the</strong> turb<strong>in</strong>e<br />

Steam parameters: 40 bar abs., 400 °C, 100 t/h<br />

Condensation turb<strong>in</strong>e with exhaust pressure 0.05 bar abs.<br />

Power generation: 21.25 MW<br />

Annual runtime 8.000 h<br />

Revenue per MWh produced: 100 €**<br />

Pressure loss of venturi tube = 0.12 bar<br />

Pressure loss of orifice plate = 1.2 bar<br />

Us<strong>in</strong>g a venturi tube <strong>in</strong>stead of an orifice plate <strong>in</strong>creases <strong>the</strong> power<br />

generation output from 21.19 MW to 21.25 MW due to <strong>the</strong> lower<br />

pressure loss at <strong>the</strong> meter<strong>in</strong>g po<strong>in</strong>t.<br />

This <strong>in</strong>creases <strong>the</strong> annual energy production by 543 MWh and leads to<br />

an <strong>in</strong>crease of revenue <strong>in</strong> excess of 54´000 € per year. The additional<br />

revenue is by far higher than <strong>the</strong> price adder of a venturi tube over an<br />

orifice plate.<br />

* Average figures at an <strong>in</strong>c<strong>in</strong>eration power plant<br />

** common local €uro zone price estimation<br />

Operat<strong>in</strong>g <strong>in</strong>structions for<br />

5-valve manifold<br />

Deltatop - <strong>steam</strong> flow measurement with Deltabar S<br />

and annular chamber orifice (49 bar/400 °C)<br />

Venturi nozzle with condensate pot<br />

and shut-off valves<br />

Deltabar S<br />

4 Deltabar S – <strong>the</strong> heart of any dp-flow<br />

measur<strong>in</strong>g <strong>system</strong><br />

• Clear on-site programm<strong>in</strong>g with display<br />

• Easy and fast commission<strong>in</strong>g via Quick Setup menu<br />

• The HistoROM memory module for fast recommission<strong>in</strong>g<br />

<strong>in</strong> case <strong>the</strong> transmitter needs to be replaced<br />

• S<strong>in</strong>gle side overload resistance of 420 bar (630 bar for<br />

both sides) provides unsurpassed process safety<br />

Our service:<br />

www.applicator.com gives you free of charge selection and siz<strong>in</strong>g of your flow<br />

measur<strong>in</strong>g <strong>system</strong> as per ISO 5167 standards.<br />

Fur<strong>the</strong>rmore, <strong>the</strong> dp-flow competence team at <strong>Endress+Hauser</strong> ensures<br />

that each custom-made Deltatop dp-flow solution fits correctly. This makes<br />

<strong>Endress+Hauser</strong> <strong>the</strong> right partner for dp-flow applications.

14<br />

5<br />

Liquid analyzer <strong>in</strong> feed<strong>water</strong><br />

The feed<strong>water</strong> of a <strong>steam</strong> generator must<br />

meet certa<strong>in</strong> requirements. It must be<br />

free of hardness which would cause <strong>the</strong><br />

formation of stones and sludge (scale) <strong>in</strong><br />

<strong>the</strong> boiler. The formation of scale on <strong>the</strong><br />

walls of <strong>the</strong> <strong>steam</strong> generator <strong>in</strong>creases <strong>the</strong><br />

sheet metal temperature thus impair<strong>in</strong>g <strong>the</strong><br />

stability of <strong>the</strong> boiler sheets.<br />

Preheater<br />

Intermediate heater<br />

To flue gas clean<strong>in</strong>g<br />

Boiler<br />

pH<br />

Conductivity<br />

Oxygen<br />

Steam turb<strong>in</strong>e<br />

Dissolved gases, e.g. carbonic acid and<br />

oxygen, as well as free acids are also not<br />

permitted <strong>in</strong> <strong>the</strong> <strong>water</strong>. They would cause<br />

corrosion of <strong>the</strong> boiler sheets and pipes.<br />

F<strong>in</strong>ally, <strong>the</strong> <strong>water</strong> must be free of mechanic<br />

contam<strong>in</strong>ation and colloidally dissolved<br />

substances like oils and greases to avoid<br />

foam<strong>in</strong>g of <strong>the</strong> boiler content.<br />

pH<br />

Conductivity<br />

Oxygen<br />

Steam<br />

drum<br />

High pressure<br />

preheater<br />

Superheater<br />

Vaporizer<br />

furnace<br />

Boiler feed pump<br />

Feed<strong>water</strong><br />

tank<br />

Low pressure<br />

preheater<br />

Condensate<br />

pump<br />

Condensate<br />

pH<br />

Conductivity<br />

Oxygen<br />

Generator<br />

Additional condensate<br />

from full<br />

desal<strong>in</strong>ation<br />

5.1<br />

Conductivity sensor CLS15D<br />

5.2<br />

pH-sensor CPS41D<br />

Why is conductivity measured <strong>in</strong> <strong>the</strong><br />

<strong>water</strong>-<strong>steam</strong> circulation <strong>system</strong><br />

The conductivity measurement detects<br />

<strong>the</strong> feed<strong>water</strong> concentration of ions<br />

and measures it <strong>in</strong> S/cm. A change <strong>in</strong><br />

conductivity dur<strong>in</strong>g operation <strong>in</strong>dicates<br />

impurity <strong>in</strong> feed<strong>water</strong> quality.<br />

Why is <strong>the</strong> pH-value measured <strong>in</strong> <strong>the</strong><br />

<strong>water</strong>-<strong>steam</strong> circulation <strong>system</strong><br />

The pH-value, i.e. <strong>the</strong> concentration of<br />

hydrogen ions, shows whe<strong>the</strong>r a solution<br />

is acid, neutral or alkal<strong>in</strong>e. The pH-value<br />

measurement thus monitors <strong>the</strong> feed<strong>water</strong><br />

to protect <strong>the</strong> pipes aga<strong>in</strong>st corrosion and<br />

build-up.<br />

Conductivity sensor CLS15D<br />

pH-sensor CPS41D<br />

5.3<br />

Oxygen sensor COS21D<br />

Why is O 2<br />

measured <strong>in</strong> <strong>the</strong> <strong>water</strong><strong>steam</strong><br />

circulation <strong>system</strong><br />

The feed<strong>water</strong> oxygen concentration is<br />

stated <strong>in</strong> mg/l. High oxygen concentrations<br />

promote corrosion of <strong>the</strong> steel pipes by<br />

electrochemical processes and must be<br />

cont<strong>in</strong>ually monitored.<br />

Oxygen sensor COS21D

15<br />

5.4 Liquil<strong>in</strong>e M<br />

Liquil<strong>in</strong>e is a modular two-wire transmitter for pH,<br />

conductivity and oxygen measurement <strong>in</strong> <strong>water</strong><strong>steam</strong><br />

circulation <strong>system</strong>s. Variants are available to<br />

connect Liquil<strong>in</strong>e to bus <strong>system</strong>s like FOUNDATION<br />

Fieldbus, PROFIBUS ® and HART ® protocol.<br />

• Easy commission<strong>in</strong>g with Quick Setup and Navigator<br />

button<br />

• Predictive ma<strong>in</strong>tenance <strong>system</strong> recognizes when a<br />

sensor has to be cleaned, calibrated or replaced<br />

• Comb<strong>in</strong>ed with Memosens cable breakage is<br />

<strong>in</strong>dicated on <strong>the</strong> display<br />

• User-guided commission<strong>in</strong>g, graphic display and pla<strong>in</strong><br />

text menue<br />

• Modular concept: Sensor module exchangeable.<br />

Liquil<strong>in</strong>e CM42<br />

5.5<br />

Digital sensor for pH-value, O 2<br />

and<br />

conductivity: Memosens<br />

Memosens, <strong>the</strong> first digital sensor worldwide, may be<br />

precalibrated at <strong>the</strong> laboratory. An <strong>in</strong>ductive plug-<strong>in</strong><br />

connection with bidirectional signal and energy transfer<br />

ensures perfect transmission of digital signals between<br />

sensor and transmitter. The calibration values are<br />

stored <strong>in</strong> <strong>the</strong> sensor. The <strong>in</strong>ductive plug-<strong>in</strong> connection<br />

is free of metal and excludes all impairments as <strong>the</strong>y<br />

might occur <strong>in</strong> conventional connections which are not<br />

without contact:<br />

• Safe, non-contact measurement also <strong>in</strong> case of<br />

humidity<br />

• Process data is stored directly <strong>in</strong> <strong>the</strong> sensor<br />

• Measured data cannot be falsified<br />

• Calibration possible at <strong>the</strong> laboratory<br />

• Significantly shorter downtimes of <strong>the</strong> measur<strong>in</strong>g<br />

po<strong>in</strong>t<br />

• Easier <strong>in</strong>stallation without special cable<br />

• Predictive diagnostics directly <strong>in</strong> <strong>the</strong> sensor<br />

<strong>system</strong><br />

Memosens technology

16<br />

<strong>Optimiz<strong>in</strong>g</strong> fur<strong>the</strong>r applications<br />

6<br />

Level and flow measurement at <strong>the</strong> scrubber<br />

Flue gas is washed <strong>in</strong> several stages <strong>in</strong> <strong>the</strong> scrubber. A noncontact<br />

<strong>system</strong> is recommended to measure <strong>the</strong> <strong>water</strong><br />

circulation of <strong>the</strong> scrubber sump and <strong>the</strong> r<strong>in</strong>g jet stage s<strong>in</strong>ce <strong>the</strong><br />

medium conta<strong>in</strong>s acid flue gas components and a dry content<br />

of 0.1-2 %. The pH-value of <strong>the</strong> scrubber sump usually ranges<br />

between pH 0.8-1.5. The <strong>in</strong>stallation of ultrasonic sensors<br />

is recommended with only one cross brace because of this<br />

dry content. Internal rubber l<strong>in</strong><strong>in</strong>g of a steel pipe also has a<br />

favorable effect on <strong>the</strong> strength of <strong>the</strong> signal if only one cross<br />

brace is used > ~70 dB. The response time of this measurement<br />

directly <strong>in</strong>fluences scrubber protection, i.e. after start<strong>in</strong>g<br />

<strong>the</strong> quench pumps a flow of more than 100 m3/h must be<br />

achieved with<strong>in</strong> less that 10 sec. - o<strong>the</strong>rwise <strong>the</strong> scrubber has<br />

to be restarted.<br />

54.9 °C<br />

Flue gas wash<strong>in</strong>g level 3<br />

70.5 %<br />

30.0 mbar A<br />

30.1 mbar<br />

7.0 pH A<br />

6.1<br />

3.0 bar<br />

7.1 pH<br />

59.8 %<br />

6.2<br />

Flue gas wash<strong>in</strong>g level 2<br />

2.0 bar<br />

R<strong>in</strong>g jet stage<br />

59.5 %<br />

6.2<br />

Flue gas wash<strong>in</strong>g level 1<br />

57.0 %<br />

6.2<br />

Quench <strong>water</strong> flow measurement <strong>in</strong> a pipe l<strong>in</strong>ed with rubber<br />

6.1<br />

Prosonic Flow Clamp On 93W – ultrasonic flow meter<br />

Prosonic Flow is an ultrasonic measur<strong>in</strong>g <strong>in</strong>strument<br />

<strong>in</strong>stalled directly on pipel<strong>in</strong>es via detect<strong>in</strong>g sensors. The<br />

transmitter, which is mounted separately, completes <strong>the</strong><br />

Prosonic Flow measur<strong>in</strong>g <strong>system</strong>.<br />

• External <strong>in</strong>stallation allow<strong>in</strong>g easy retrofit with no<br />

<strong>in</strong>trusion <strong>in</strong>to <strong>the</strong> pipe<br />

• Ma<strong>in</strong>tenance-free with no mov<strong>in</strong>g parts<br />

• No obstructions <strong>in</strong> <strong>the</strong> pipel<strong>in</strong>e and no pressure loss<br />

• Economical alternative for large diameters up to<br />

4000 mm<br />

• Portable ultrasonic transmitter for temporary meter<strong>in</strong>g<br />

Prosonic Flow Clamp On 93W

17<br />

To prevent <strong>the</strong> flue gases from flow<strong>in</strong>g unwashed<br />

through <strong>the</strong> scrubber, several stages<br />

with<strong>in</strong> <strong>the</strong> scrubber are filled with <strong>water</strong> and<br />

<strong>the</strong>ir levels are controlled.<br />

The acid stage or sump is located at <strong>the</strong><br />

scrubber <strong>in</strong>let, <strong>the</strong>n up to two packed bed<br />

stages follow, <strong>in</strong> which <strong>the</strong> flue gas is offered<br />

a large quantity of pack<strong>in</strong>g material, wetted<br />

by scrubb<strong>in</strong>g <strong>water</strong>. The solids stay on <strong>the</strong><br />

pack<strong>in</strong>g material, are washed out and moved<br />

downwards.<br />

To scrub <strong>the</strong> rema<strong>in</strong><strong>in</strong>g suspended solids, <strong>the</strong><br />

flue gas must pass spray<strong>in</strong>g nozzles on <strong>the</strong> r<strong>in</strong>g<br />

jet stage for <strong>the</strong> last time and is subsequently<br />

made neutral with a pH-value of 7.1.<br />

To monitor all differential pressures and gas<br />

wash<strong>in</strong>g levels, remote seal differential pressure<br />

transmitters of <strong>the</strong> FMD78 type with tantalum<br />

as wetted parts are used, partly <strong>in</strong> a redundant<br />

fashion.<br />

6.2<br />

Deltabar S FMD78<br />

• Very good reproducibility and long-term<br />

stability<br />

• High reference accuracy: up to ±0.075 %<br />

• Turn down 100:1, higher upon request<br />

• Applications for flow and differential pressure<br />

monitor<strong>in</strong>g up to SIL3, certified by TÜV SÜD<br />

accord<strong>in</strong>g to IEC 61508<br />

• Memory module HistoROM ® /M-DAT<br />

• Function controlled from <strong>the</strong> measur<strong>in</strong>g cell<br />

through to electronics<br />

Deltabar S FMD78,<br />

remote seal version