Onkyo Brochure

Onkyo Brochure

Onkyo Brochure

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

DoveBid<br />

Worldwide<br />

Amsterdam<br />

Atlanta<br />

Bangkok<br />

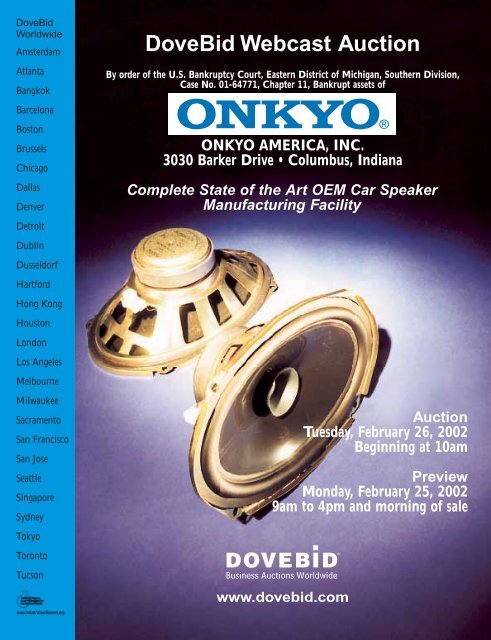

DoveBid Webcast Auction<br />

By order of the U.S. Bankruptcy Court, Eastern District of Michigan, Southern Division,<br />

Case No. 01-64771, Chapter 11, Bankrupt assets of<br />

Barcelona<br />

Boston<br />

Brussels<br />

Chicago<br />

Dallas<br />

Denver<br />

Detroit<br />

ONKYO AMERICA, INC.<br />

3030 Barker Drive • Columbus, Indiana<br />

Complete State of the Art OEM Car Speaker<br />

Manufacturing Facility<br />

Dublin<br />

Dusseldorf<br />

Hartford<br />

Hong Kong<br />

Houston<br />

London<br />

Los Angeles<br />

Melbourne<br />

Milwaukee<br />

Sacramento<br />

San Francisco<br />

San Jose<br />

Seattle<br />

Singapore<br />

Sydney<br />

Auction<br />

Tuesday, February 26, 2002<br />

Beginning at 10am<br />

Preview<br />

Monday, February 25, 2002<br />

9am to 4pm and morning of sale<br />

Tokyo<br />

Toronto<br />

Tucson<br />

www.industrialauctioneers.org<br />

www.dovebid.com<br />

®

DoveBid<br />

Webcast Auction<br />

Tues., February 26, 2002<br />

Beginning at 10am<br />

Preview<br />

Mon., February 25, 2002<br />

9am to 4pm and morning of sale<br />

Location & Preview<br />

By order of the U.S. Bankruptcy Court,<br />

Eastern District of Michigan,<br />

Southern Division, Case No. 01-64771,<br />

Chapter 11, Bankrupt assets of<br />

ONKYO AMERICA, INC.<br />

3030 Barker Drive<br />

Columbus, Indiana<br />

Directions<br />

From Indianapolis<br />

International Airport<br />

Exit airport by following<br />

I-465/I-70 signs. Proceed to<br />

I-465 South. Proceed on I-465<br />

South approximately 8-1/2 miles<br />

to I-65 South/Louisville Exit<br />

(Exit 53B). Proceed on I-65<br />

South approximately 42 miles to<br />

Route 58 West (Exit 64). After<br />

exiting expressway, turn left<br />

onto Route 58 (which becomes<br />

CR-450 S) and proceed approx.<br />

2/10 mile to Old Lake Drive<br />

(first traffic light) (Woodside<br />

Business Center). Turn left and<br />

proceed 1/10 mile to Inwood<br />

Drive. Turn left onto Inwood<br />

Drive (which becomes Interlake<br />

Drive) and proceed approximately<br />

1/2 mile to Barker Drive. Turn<br />

right and proceed to the sale site<br />

on the left side. Watch for auction<br />

and parking signs.<br />

For further information, please<br />

contact Steve Wolf in our<br />

Grand Rapids, Michigan Office<br />

at Phone (616) 458-7820<br />

or (248) 219-6113 (Cell)<br />

or Ray Welker at (248) 763-3278<br />

As a courtesy to our buyers, DoveBid<br />

can provide contact information for s<br />

hipping companies scheduled to attend<br />

this auction. For details, please visit the<br />

DoveBid Website at www.dovebid.com<br />

or call our customer care department at<br />

800-665-1042.<br />

A Buyer’s Premium Will Apply at this Sale<br />

Speaker Manufacturing Lines<br />

1998<br />

FUJI CONE SPEAKER MANUFACTURING LINE<br />

SPEAKER MANUFACTURING LINES<br />

1 – FUJI CONE SPEAKER MANUFACTURING LINE, (1998) A# OM-5,<br />

Pallet Style, I-Line Configuration, 4.9 Seconds/Cycle Time, 12.2<br />

Speakers/Minute Capacity, 13cm To 12” Diameter Driver Capacity,<br />

Round & Oval Style Speaker Shape Capacity, Overall Length 210’,<br />

For a complete list of all components in this line, please visit<br />

www.dovebid.com<br />

3 – IWANTANI SPEAKER MANUFACTURING LINES, (1) (1992) A# OM-3,<br />

(1) (1990) A# OM-2, (1) (1988) A# OM-1, Pallet Style, I-Line<br />

Configuration, 4.5 Seconds/Cycle Time, 13.3 Speakers/Minute Capacity,<br />

10cm To 8” Diameter Driver Capacity, Round & Oval Style Speaker<br />

Shape Capacity, Overall Length 210’, For a complete list of all<br />

components in these lines, please visit www.dovebid.com<br />

PLASTIC INJECTION MOLDERS<br />

1 – MITSUBISHI MODEL 500MJ-80 500-TON X 80-OZ HYDRAULIC<br />

CLAMP RECIPROCATING SCREW PLASTIC INJECTION MOLDING<br />

MACHINE, S/N 3G408130 (1997), Platen Size 45.3” X 45.3”, Tie Bar<br />

Spacing 31.9” X 31.9”, Maximum Daylight 55.1”, Minimum Mold Height<br />

13.8”, Clamping Stroke 41.3”, Hydraulic Core Pull & Ejection, Automatic<br />

Lubrication, Una-Dyn Hopper Loader & Drawer Magnet & Echo Systems<br />

Digital Programmable Station Control, Mitsubishi Model MAC-VI<br />

Programmable Control With Remote Tech Box<br />

1 – MITSUBISHI MODEL 320MJII-30C 320-TON X 30-OZ HYDRAULIC<br />

CLAMP RECIPROCATING SCREW PLASTIC INJECTION MOLDING<br />

MACHINE, S/N 3S29E108 (1997), Platen Size 37.4” X 37.4”, Tie Bar<br />

Spacing 25.98” X 25.98”, Maximum Daylight 41.7”, Minimum Mold<br />

Height 11.8”, Clamping Stroke 29.92”, Hydraulic Core Pull & Ejection,<br />

Automatic Lubrication, Una-Dyn Hopper Loader & Drawer Magnet,<br />

Mitsubishi Model MAC-VI Programmable Control<br />

2 – MITSUBISHI MODEL 210MJ11 210-TON X 17-OZ HYDRAULIC<br />

CLAMP RECIPROCATING SCREW PLASTIC INJECTION MOLDING<br />

MACHINES, S/Ns 3519D111, 3S19D112 (BOTH 1997), Platen Size<br />

32.28” X 32.28”, Tie Bar Spacing 22.44” X 22.44”, Maximum Daylight<br />

35.43”, Minimum Mold Height 10.6”, Clamping Stroke 24.80”, Hydraulic<br />

Core Pull & Ejection, Automatic Lubrication, Una-Dyn Hopper Loader &<br />

Drawer Magnet & Echo Systems Digital Programmable Station Control,<br />

Mitsubishi Model MAC-VI Programmable Control With Remote Tech Box<br />

1 OF 3 IWANTANI SPEAKER<br />

MANUFACTURING LINES<br />

HOPPER/DRYERS<br />

1 – UNA-DYN PROTEC MODEL 929020 200-LB.<br />

CAPACITY MODULAR HOPPER/DRYER,<br />

S/N 159989-1 (1997), Echo Systems Station<br />

Control, Una-Dyn Protec Model UDC-100 Auto<br />

Mini-Dryer, S/N 159989-08-0697 (1997),<br />

Cart-Mounted<br />

1 – UNA-DYN PROTEC MODEL 929020 150-LB.<br />

CAPACITY MODULAR HOPPER/DRYER,<br />

S/N 159989-4 (1997), Echo Systems<br />

Programmable Station Control, Una-Dyn<br />

Model UDC-55 Auto Mini-Dryer, S/N<br />

159989.01-03-0697 (1997), Cart-Mounted<br />

2 – UNA-DYN PROTEC MODEL 920916 100-LB.<br />

CAPACITY MODULAR HOPPER/DRYERS,<br />

S/Ns 159989-2, 159989-3 (BOTH 1997)<br />

2 – UNA-DYN PROTEC MODEL UDC-55 AUTO<br />

MINI-DRYERS, S/Ns 159989.01-02-0697,<br />

159989.01-01-0697 (BOTH 1997), Cart<br />

Mounted<br />

HOPPER LOADER<br />

1 – UNA-DYN VACUUM HOPPER LOADER, S/N<br />

159989-14-0697 (1997), Maxi-Vac 3-HP Power<br />

Pack, Echo Systems Programmable Master<br />

Control<br />

VIEW OF UNA-DYN PROTEC<br />

100-LB. TO 200-LB. CAPACITY<br />

MODULAR HOPPER/DRYERS<br />

See us<br />

1997<br />

@<br />

on the web<br />

www.dovebid.com<br />

1988<br />

To view a complete asset list, visit our website @ www.dovebid.com

Plastic Injection Molding Equipment<br />

®<br />

1997<br />

MITSUBISHI MODEL 500MJ-80 500-TON X 80-OZ<br />

HYDRAULIC CLAMP RECIPROCATING SCREW<br />

PLASTIC INJECTION MOLDING MACHINE<br />

CNC PARTS HANDLING ROBOTS<br />

3 – WHITTMAN 3-AXIS CNC PARTS HANDLING ROBOTS, (2) MODEL<br />

W-631, Maximum Lifting Weight 31-Lbs., 11.8-kVA Power Supply,<br />

(Both 2000), S/N 5122, Travels: X 19.68”, Y 55.11”,<br />

Z 118.11”, S/N 5128, Travels: X 19.68”, Y 55.11”, Z 98.42”, (1)<br />

MODEL W-430, S/N 5103/014 (1997), Travels: X 19.68”, Y 47.24”,<br />

Z 78.74”, Maximum Lifting Weight 22-Lbs., 3.6-kVA Power Supply<br />

TEMPERATURE CONTROLLERS<br />

4 – VAN DORN/DEMAG MODEL 1WT-9-1-.5-DS-460 TEMPERATURE<br />

CONTROLLERS, S/Ns 9700-302A, 9700-302B, 9700-302C,<br />

9700-302D (ALL 1997), Digital Temperature Control<br />

2 – INCOE MICROCOM 760 8-STATION TEMPERATURE<br />

CONTROLLERS, S/Ns N/A, 15-KVA Transformer<br />

CHILLERS<br />

1 – BUDZAR MODEL AC-15-FCB-92-00-002 CHILLER, S/N 8524-9703<br />

(1997), (2) 8-HP Compressor Motors, 3-HP Pump Motor, 7-1/2-HP<br />

Blower Motor, Maximum Working Pressure 380 PSIG, Partlow Digital<br />

Temperature Control<br />

1 – BUDZAR MODEL AC-10-FCB-48-00-004 CHILLER, S/N 970A-1041<br />

(1997), Maximum Working Pressure 395 PSIG, Partlow Digital<br />

Temperature Control, 10-HP Compressor Motor, 3-HP Pump Motor<br />

GRANULATORS<br />

4 – RAPID PLASTICS GRANULATORS, (1) MODEL 814 8” X 14”,<br />

S/N 380.28W (1998), 5-kW Motor, (1) MODEL 614-SR 6”<br />

X 14”, S/N 310.712 (1998), 2.2-kW Motor, (1) MODEL<br />

611-RS 6” X 11”, S/N 240.1696 (1998), 2.4-kW Motor,<br />

(1) MODEL 69-SR 8” X 8”, S/N 250.2526 (1998), 2.2-kW<br />

PARTICLE REMOVAL SYSTEM<br />

1 – ANALYTIC SYSTEMS LAB MODEL FPRS-40-ABH<br />

FINITE PARTICLE REMOVAL SYSTEM, S/N 5198<br />

(1998), 7-Amp<br />

1998<br />

RAPID PLASTICS GRANULATORS<br />

1997<br />

MITSUBISHI 320MJII-30C 320-TON X 30-OZ<br />

HYDRAULIC CLAMP RECIPROCATING SCREW<br />

PLASTIC INJECTION MOLDING MACHINE<br />

1997<br />

1 OF 2 MITSUBISHI MODEL 210MJ11<br />

210-TON X 17-OZ HYDRAULIC CLAMP<br />

RECIPROCATING SCREW PLASTIC<br />

INJECTION MOLDING MACHINES<br />

AND 1 OF 3 WHITTMAN 3-AXIS CNC<br />

PARTS HANDLING ROBOTS<br />

(2) INCOE MICROCOM 760 8-STATION<br />

TEMPERATURE CONTROLLERS;<br />

BUDZAR MODEL AC-15-FCB-92-00-002 AND<br />

MODEL AC-10-FCB-48-00-004 CHILLERS;<br />

ANALYTIC SYSTEMS LAB MODEL FPRS-40-ABH<br />

FINITE PARTICLE REMOVAL SYSTEM<br />

Can't make it to Columbus,<br />

Indiana With DoveBid's<br />

Webcast technology anyone<br />

around the world can bid on<br />

this auction through the<br />

Internet. Go to DoveBid.com:<br />

Register up to the day of the<br />

sale and download the free<br />

software. Bid in Real Time!<br />

All you need is a computer,<br />

Internet access and a<br />

touch-tone telephone to<br />

participate in this live auction.<br />

With Webcast technology,<br />

you are virtually there on the<br />

auction floor. The action is<br />

live and you are bidding with<br />

people in the room and<br />

around the world.<br />

The image of the current asset<br />

being sold will be displayed on<br />

your screen. You'll hear the<br />

auctioneer on your telephone.<br />

You press 1 on your telephone<br />

keypad to raise your paddle<br />

and press the # key to end<br />

your bid. It's easy. It's fun.<br />

It's the future. And it's here<br />

now at DoveBid!<br />

Terms & Conditions<br />

• Buyers are responsible for all shipping<br />

and rigging charges.<br />

• All items are sold AS IS, WHERE IS<br />

AND WITH ALL FAULTS.<br />

• DoveBid shall charge and collect from<br />

each successful bidder a 13% buyer’s<br />

premium for each sale at the auction, in<br />

addition to the purchase price as bid.<br />

Purchasers who pay in the form of<br />

certified funds or wire transfer shall<br />

receive a discount from the buyer’s<br />

premium equal to 3% of the purchase<br />

price (unless such purchasers bid over<br />

the Internet, in which case the discount<br />

shall be equal to 1% of the purchase<br />

price).<br />

• Each successful bidder must pay a 25%<br />

deposit toward the purchase price<br />

immediately following the successful bid.<br />

• Applicable taxes will be added to the<br />

purchase price of all taxable items.<br />

• Acceptable means of payment include<br />

certified funds, wire transfers, Visa’,<br />

American Express’ and Mastercard’.<br />

• The complete terms and conditions that<br />

govern this auction will be distributed<br />

at the auction site and/or are available<br />

on our website at www.DoveBid.com.<br />

The complete terms and conditions<br />

may include terms that are unique to<br />

this particular auction. Please read them<br />

carefully before you bid in the auction.<br />

If you participate in the auction, you<br />

will be deemed to have read and<br />

consented to all of the terms and<br />

conditions.<br />

To schedule an auction or appraisal call 800.665.1042

Speaker Manufacturing Equipment<br />

1 OF 2 NOVA TOOL & ENGINEERING<br />

8-STATION AUTOMATIC CONE<br />

SOLDERING MACHINES<br />

1996<br />

1 OF 3 SCHMIDT<br />

20-TON PNEUMATIC<br />

STAKING PRESSES<br />

ULTRASONIC WELDER<br />

1 – BRANSON 900 IW PLUS SERIES INTEGRATED ULTRASONIC WELDER,<br />

S/N YH700556 (1997), Programmable Controls<br />

CONE SOLDERING MACHINES<br />

2 – NOVA TOOL & ENGINEERING 8-STATION AUTOMATIC CONE SOLDERING<br />

MACHINES, S/N 5629-3 A# 00456, S/N 4419, S/N 5629-3 With Modicon Model Panel<br />

Mate Plus Programmable Logic Control<br />

STAKING PRESSES<br />

3 – SCHMIDT 20-TON PNEUMATIC STAKING PRESSES, S/Ns N/A A#s 00394, N/A, N/A<br />

(ALL 1996), Bed Size 12” X 14-1/2”, Throat 8”, Schmidt Model 50 Digital Press Control,<br />

STI Minisafe Safety Light Curtain<br />

1 – CUSTOM-BUILT MODEL ALP-10 10-TON PNEUMATIC STAKING PRESS, S/N 0598<br />

A# 00119, Digital Readout<br />

1 – CUSTOM-BUILT 2-STATION HEATED-PLATEN PNEUMATIC STAKING PRESS, Omron<br />

Digital Temperature & Time Controls<br />

PNEUMATIC PRESSES<br />

5 – MARUNI MODEL MP-200 200-KG PNEUMATIC PRESSES, S/Ns P199F01S (1999),<br />

2-0546, 2-0046 (1998), 2-0460, N/A (1999), Bed Size 5-1/2” X 10”, Stroke 75mm,<br />

Adjustment 25mm, Omron Digital Readout<br />

1 – CUSTOM-BUILT 2-STATION HEATED-PLATEN PNEUMATIC PRESS, S/N N/A, Platen<br />

Size 8” X 10”, Digital Temperature Controls, STI Safety Light Curtain<br />

1 – ELECTROPUNCH MODEL P1000 BENCH-TOP PNEUMATIC PRESS, S/N 6071<br />

HYDRAULIC PRESSES<br />

1 – AIR-HYDRAULICS MODEL AH20S-CF 20-TON DUAL-HEAD AIR-OVER-HYDRAULIC<br />

PRESS, S/N 5976A A# 00578, Ferguson Rotating Table Diameter 44”, Throat 8”, Ram<br />

Diameter 2-1/2”, Posi-Guard Safety Light Curtain, Hydraulic Unit<br />

1 – ENERPAC 5-TON 4-POST BENCH-TOP HYDRAULIC PRESS, S/N N/A A# 00996<br />

EYELET MACHINES<br />

6 – A.J. HORNE MODEL AF-500 EYELET MACHINES, S/Ns 389, 188, 299, 199, 392, 293,<br />

With Detect-A-Finger Safety Device<br />

2 – YAMAKOU MODEL YE3B EYELET MACHINES, S/Ns 2160596, 133, With<br />

Detect-A-Finger Safety Device<br />

1 – NITTO MODEL 601 EYELET MACHINE, S/N E1605 (1990)<br />

PARTIAL VIEW OF<br />

SPEAKER MANUFACTURING<br />

EQUIPMENT<br />

RIVETER<br />

1 – CHICAGO RIVET 912 PEDESTAL-TYPE RIVET<br />

MACHINE, S/N 11796-SS, With Touch-O-Matic<br />

Safety Device, 1/3-HP Motor<br />

MAGNETIZERS<br />

1 – ACOUSTIC DESIGN TOP & BOTTOM<br />

MAGNETIZER, S/N N/A, With 10”W X 10’L<br />

Motorized Belt Conveyor<br />

1 – NIHON DENJI SOKKI MODEL SCB-1510<br />

MAGNETIZER & POWER SOURCE, S/N 6783,<br />

Wire Size 3” X 10”, 73-Turn Capacity<br />

2 – MAGNAX MAG-1510-1A MAGNETIZERS,<br />

S/Ns 99066, 99065 (BOTH 1999), Digital Readout<br />

1 – TECHNOPHYSIK TECHNO TOWER 2000-30-D<br />

MAGNETIZER, S/N G971001 (1997)<br />

1 – MAGNETIC INSTRUMENTATION MODEL 33792<br />

MAGNETIZER, S/N 7500/900-8<br />

COIL WINDING MACHINE<br />

1 – NIPPON SERBIG SERIES PNS-250S COIL WINDING MACHINE, S/N 902520 (1990), Programmable Controls<br />

FOAM APPLICATION MACHINES<br />

2 – HI-STAR 3-AXIS FOAM APPLICATION MACHINES, Both With 3-Axis Robot, Dual Slide-In Speaker Foam Fixture<br />

Table, Computer Control, (1) S/N N/A (2000), With Nordson Model FM153 Hot Melt Foam Application Machine,<br />

S/N AA95L61859 (1995), (1) S/N N/A (1998), With Nordson Model FM153HO Hot Melt Foam Application Machine,<br />

S/N AA97L62945 (1997)<br />

HOT MELT MACHINES<br />

1 – NORDSON MODEL FM153 HOT MELT FOAM APPLICATION MACHINE, S/N AA97K61630 (1997)<br />

8 – HOT MELT TECH PRO-FLEX HOT MELT GLUE APPLICATORS, (5) BENCHMARK-205, S/Ns 14388, 19780,<br />

21735, 15840-1, 15840-2, (3) MODEL PF405-35-3-21L, S/Ns 14001, 13852, 15480<br />

SPEAKER ADHESION CELL<br />

1 – SPEAKER ADHESION CELL, Consisting of: Motoman Model YR-SV3-0000 6-Axis Robot, S/N RA9301-7082-6;<br />

Yasnac Model MRC11S-SB3 Power Supply; Yasnac Model MRC Computer Control, With Remote; Custom-Built<br />

Adhesion Fixture Table; STI Minisafe Safety Light Curtain<br />

MISCELLANEOUS SPEAKER MANUFACTURING EQUIPMENT<br />

2 – OVAL C 3-AXIS ADHESION MACHINE STATIONS, With Obostar MCA Series Power Supplies<br />

1 – BACK GASKET ADHESIVE & PRESS STATION<br />

7 – APPLICATION STATIONS, (1) MAGNET STRETCH & DUAL ADHESIVE, (3) GASKET, (2) DUST CAP, (1) 2-PART<br />

2 – ADHESIVE CONE PAPER, DAMPER & VOICE COIL ASSEMBLY STATIONS<br />

2 – CLEANING VOICE COIL PRE-ASSEMBLY FIXTURES<br />

1 – FY CAULKING STATION<br />

3 – ESTAR MODEL C-6 CUTTING STATIONS<br />

1 – MANUAL ACRYLIC DISPENSING STATION<br />

4 – 4-TRAY AIR DRYING STATIONS<br />

1 – PACE FUME EXTRACTOR<br />

1 – PRECISION VALVE & AUTOMATION 2-AXIS GLUE APPLICATION ROBOT<br />

2 – V & F MACHINE COPPER CAP GLUE MACHINE STATIONS<br />

2 – CU-CAP GLUE STATIONS<br />

9 – PAINTING STATIONS, (2) OVAL C, With Obostar MCA Series Power Supplies, (3) 3-POINT, (2) PO MG PAINTING<br />

MACHINE STATIONS, (2) D.A., (1) With Vacuum Cleaner & Cone Adhesion Machine<br />

1 – V & F MACHINE PNEUMATIC PRESS STATION<br />

1 – FCC MODEL ALP-10 CAULKING PRESS<br />

1 – DUAL STATION GASKET PRESS<br />

3 – CUSTOM-BUILT SOLDER STATIONS<br />

3 – SPEAKER STAMP STATIONS<br />

2 – APPLY WHIZZER STATIONS<br />

Fixtures, Handling Equipment, Solder & Assembly Tables, Etc.<br />

TO 2000<br />

1 OF 2 HI-STAR 3-AXIS<br />

FOAM APPLICATION MACHINES<br />

PAGE 4<br />

SPEAKER ADHESION CELL<br />

ALL<br />

THERMOTRON MODEL S-16C SINGLE-DOOR<br />

ENVIRONMENTAL TEST CHAMBERS

Speaker Manufacturing Equipment<br />

ENVIRONMENTAL<br />

TEST CHAMBERS<br />

3 – THERMOTRON S-16C SINGLE-DOOR ENVIRONMENTAL<br />

TEST CHAMBERS, S/N 24309 A# 00655, S/N 24308 A# N/A,<br />

S/N 24307 A# 06656 (ALL 1995), Chamber Size<br />

30” X 30” X 30”, Temperature Range 5°C to 85°C, Humidity<br />

Range 20% to 90%, Thermotron Model 2800 Programmable<br />

Controller, Thermotron Digital System Monitor, 2-HP Motor<br />

2 – TABAI ESPEC SINGLE-DOOR STAINLESS STEEL<br />

ENVIRONMENTAL TEST CHAMBERS, (1) MODEL<br />

PL-4FPH, S/N 12006132 (1993), (1) MODEL PL-4G,<br />

S/N 3139818 (1988) A# 00654, Both With Chamber Size<br />

100cm W X 100cm H X 80cm D, Temperature Range 40°C to<br />

150°C, Humidity Range 20% to 98%, 1.5 X 2-kW Heater, Tabai<br />

Model EY-101 Programmable Control & Chart Recorder<br />

1 – HARSHAW MODEL 21 SALT SPRAY ENVIRONMENTAL<br />

TEST CHAMBER, S/N 21E-005 A# 00653, Chamber Size<br />

30”W X 30”L X 38”D, Maximum PSI 25, Digital Temperature<br />

Controls, Chart Recorder<br />

SOUND CHAMBERS<br />

1 – ANECHOIC SOUND CHAMBER, Size 15’W X 20’L X 9’H,<br />

Wood Frame, Wire Mesh Floor, Lights & Insulation<br />

2 – BOLTED METAL SOUND BOOTHS, (1) Size 7’W X 7’L X 8’H,<br />

With Window, Door & Conveyor Entry & Exit Ways, (1) Size<br />

9’W X 9’L X 8’H, With Doors & Glass Windows<br />

OVENS<br />

1 – ASAHI KAGAKU DF-88 SINGLE-DOOR ELECTRIC OVEN,<br />

S/N 900936 A# 00813, Chamber Size 32” X 32” X 48”H,<br />

Maximum Operating Temperature 300°C, Digital Temperature<br />

Control<br />

4 – CUSTOM-BUILT TRAY-TYPE ELECTRIC OVENS, S/Ns N/A,<br />

Chamber Size 42”W X 55”H, Tray Width 27-1/2”, Chain Drive,<br />

Operating Temperature 46°C, (4) Circulating Fans, Digital<br />

Temperature Controls<br />

ULTRASONIC CLEANER<br />

1 – ZENITH MODEL STC201214 PORTABLE ULTRASONIC<br />

CLEANER, S/N 79992883, Chamber Size 20” X 12” X 14”D,<br />

Digital Timer, 1/3-HP Motor<br />

TENSILE TESTER<br />

1 – WEIGHT-TRONIX MODEL DTM 500-LB. CAPACITY<br />

TENSILE TESTER, S/N D95011 (1995) A# 01378, Magitronic<br />

486DX-33 Personal Computer Programmer<br />

CMM<br />

1 – MITUTOYO MODEL B504B 3-AXIS BRIDGE-TYPE CMM,<br />

S/N 0110006 A# 01376, Black Granite Surface Plate Size 34”<br />

X 34” X 10”, Travels: X 20”, Y 16”, Z 12”, Renishaw PH1 Probe,<br />

Mitutoyo MAG 1 Power Supply, IBM Personal Computer<br />

Programmer With Printer, Kaeser Compressed Air Dryer<br />

MEASURING SYSTEMS<br />

1 – MICRO-VU VECTOR 12X12 BRIDGE-TYPE VIDEO<br />

MEASURING SYSTEM, S/N 3606 (1994) A# 01377,<br />

RSF-Elektronik Model 82127205 12” X 12” Viewing Table,<br />

Travels: X 12”, Y 12”, Z 6”, Micro-Vu Model FD-10 Focus<br />

Detector, Panasonic Model CT-1030 10” Color Video Monitor,<br />

Panasonic Model CP-IOU Color Video Printer, Besq Personal<br />

Computer Programmer<br />

1 – FARO ARM ANTHRO CAM MODEL S12-05 PORTABLE<br />

PRECISION MEASURING SYSTEM, S/N S12059901593<br />

(1999), With Stand<br />

ELECTRONIC & TEST EQUIPMENT<br />

1 – AUDIO PRECISION DCX-127 MULTI-FUNCTION METER/POWER SUPPLY<br />

12 – TECRON 5530 AMPLIFIERS<br />

1 – SENCORE PA81 STEREO POWER ANALYZER<br />

3 – SIGNAL ANALYZERS, (1) BRUEL & KJAER 2032 DUAL CHANNEL, (2) HEWLETT-PACKARD 35665A DYNAMIC<br />

1 – LEADER LDC-824S DIGITAL COUNTER<br />

1 – KIKUSUI FC01120 FREQUENCY COUNTER<br />

1 – KIKUSUI 255 MULTI-COUNTER<br />

1 – HEWLETT-PACKARD 34970A DATA ACQUISITION/SWITCH UNIT<br />

1 – YEW 2786 DECADE RESISTANCE BOX<br />

1 – ASHLY PQX-572 SEVEN BAND PARAMETRIC EQUALIZER<br />

1 – KNOHN HITE 3750 FILTER<br />

2 – FUNCTION GENERATORS, (1) HEWLETT-PACKARD 3312A, (1) TENMA 72-5015<br />

3 – SWEEP GENERATORS, (1) BK PRECISION 3017A, (2) KIKUSUI MODEL 462S<br />

1 – N.F. DM-155B AUTOMATIC DISTORTION METER<br />

4 – MULTIMETERS, (1) ADVANTEST TR6848 DIGITAL, (1) FLUKE 45 DUAL DISPLAY,<br />

(1) HEWLETT-PACKARD 34401A, (1) HEWLETT-PACKARD 2478A<br />

1 – ONSOKU OMT-205 VOICE COIL TEMPERATURE METER<br />

1 – PANASONIC VP-9623P AC VOLTMETER<br />

14 – VOLT/DECIBEL METERS, (1) TRIO VT-104, (8) KENWOOD VT-121, (3) KENWOOD<br />

VT-171, (1) KENWOOD VT-181, (1) HEWLETT-PACKARD 400F<br />

43 – OSCILLATORS, (1) KIKUSUI ORC11 RC, (36) ONSOKU OG-242S SPEAKER TEST,<br />

(3) ONSOKU OG-242RA SPEAKER TEST, (2) ONSOKU OG-53J NOISE<br />

4 – OSCILLOSCOPES, (1) BK PRECISION 2615A, (1) HITACHI V-302F, (1) TEKTRONIX<br />

TDS 210 2-CHANNEL, (1) TENMA 72-3055<br />

1 – FISHER PERMASCOPE<br />

20 – ONSOKU POLARITY CHECKERS<br />

8 – LISTEN MICROPHONE POWER SUPPLY SETS<br />

3 – TRIPP LITE PR-60 POWER SUPPLIES<br />

7 – MATSUAGA SVC-128.3 AUTOMATIC VOLTAGE REGULATORS<br />

1 – NIKON SMZ-2B STEREOSCOPE, With Light Source<br />

1 – BRUEL & KJAER 4913 STROBOSCOPE<br />

1 – HEWLETT-PACKARD 3488A SWITCH CONTROL UNIT<br />

1 – ONKYO ATS-1 AUTOMATIC IMPEDANCE TESTER<br />

1 – KIKUSUI TOS7010L INSULATION TESTER<br />

1 – SPECTROMETRY 5842 TIME DELAY CONTROL UNIT<br />

2 – SHIMADZU DIGITAL LAB SCALES<br />

1 – YOKOGAWA 2755 WHEATSTONE BRIDGE<br />

1 – KUNSTKOPF KU100 DUMMY HEAD<br />

Meters, Testers, Probes, Etc.<br />

STEREO EQUIPMENT<br />

10 – CROWN AMPLIFIERS, (4) MICRO-TECH 1200, (5) CROWN K2, (1) MCINTOSH MC502<br />

1 – ONKYO A-809 STEREO AMPLIFIER<br />

13 – STEREO POWER AMPLIFIERS, (4) MCINTOSH DIGITAL, (8) NAD 214, (1) ONKYO<br />

INTEGRA M508<br />

1 – ONKYO GRAND INTEGRA P-308 STEREO PREAMPLIFIER<br />

2 – STEREO DUAL CASSETTE DECKS, (1) PIONEER CT-W604RS, (1) ONKYO TA-W450<br />

2 – ONKYO STEREO CASSETTE DECKS, (1) INTEGRA TA-2090, (1) INTEGRA TA-2800<br />

1 – ONKYO DX-V500 CD/CDV/LD COMPATIBLE PLAYER<br />

3 – ONKYO COMPACT DISC PLAYERS, (1) DX-C200, (1) DX-6800, (1) DX-5500<br />

1 – ONKYO INTEGRA T9090II FM STEREO TUNER<br />

2 – ONKYO TUNER AMPLIFIERS, (1) TX-905, (1) TX-SV525 AUDIO/VIDEO CONTROL<br />

3 – VCRs, (1) SONY SLV-675HF, (1) ZENITH VR4156, (1) TOSHIBA M-648<br />

1 – OMNI DRIVE LOUDSPEAKER MANAGEMENT SYSTEM<br />

ZENITH STC201214 PORTABLE<br />

ULTRASONIC CLEANER<br />

MITUTOYO MODEL B504B<br />

3-AXIS BRIDGE-TYPE CMM<br />

HARSHAW 21 SALT SPRAY<br />

ENVIRONMENTAL TEST CHAMBER<br />

TO 1999<br />

MICRO-VU VECTOR 12X12 BRIDGE-TYPE VIDEO<br />

MEASURING SYSTEM AND<br />

FARO ARM ANTHRO CAM MODEL S12-05<br />

PORTABLE PRECISION MEASURING SYSTEM<br />

PARTIAL VIEW OF ELECTRONIC TEST &<br />

STEREO EQUIPMENT<br />

PAGE 5

Toolroom • Shop • Material Handling Equipment<br />

1997<br />

CLAUSING-COLCHESTER 15” X 52” C.C.<br />

QUICK CHANGE GEARED HEAD LATHE<br />

DELTA CRANE SYSTEMS 5-TON X 34’ SPAN SINGLE-GIRDER<br />

TOP-RUNNING BRIDGE CRANE<br />

1999<br />

GENIE MODEL GS-1930<br />

500-LB. CAPACITY ELECTRIC<br />

SELF-PROPELLED<br />

WORK PLATFORM<br />

For your appraisal needs, please<br />

contact one of DoveBid’s valuation<br />

professionals at 800.665.1043<br />

®<br />

TOOLROOM MACHINERY<br />

1 – CLAUSING-COLCHESTER 15” X 52” C.C. QUICK CHANGE<br />

GEARED HEAD LATHE, S/N LTR50SILFV/3680 A# 00838, Spindle<br />

Speeds 25 to 2000 RPM, Threads .0015 to .040 IPR, Feeds 2 to 72<br />

TPI, Hole Thru Spindle 2-1/4”, Taper Attachment, Thread Chasing Dial,<br />

Coolant System<br />

1 – BRIDGEPORT SERIES I 2-HP VARIABLE SPEED VERTICAL<br />

MILLING MACHINE, S/N BR230434 (1985), Table Size 9” X 42”,<br />

Spindle Speeds 60 to 4200 RPM, Power Feed Table, Bijur Lubrication,<br />

Acu-Rite III 2-Axis Digital Readout<br />

1 – STARTRITE MODEL 24V 24” VERTICAL CONTOUR METAL<br />

CUTTING BAND SAW, S/N 114013 A# 00845, Table Size 21” X 21”,<br />

Blade Speeds 67 to 3840 FPM, Blade Welder/Grinder<br />

1 – ROPER WHITNEY MODEL U416 4’ X 16-GA CAPACITY HAND<br />

BOX & PAN BRAKE, S/N 2928-11-96 (1996) A# 00846<br />

1 – CRAFTSMAN CONTRACTOR SERIES 10” TILTING ARBOR TABLE<br />

SAW, Table Size 27” X 44”, Exact-1-RIP 3024 Rip Fence, 3-HP Motor<br />

1 – CYCLONE MODEL 4826 26” X 48” SAND BLAST CABINET,<br />

S/N 9101, With Dust Collector<br />

MACHINE ACCESSORIES<br />

2 – ROTARY TABLES, PHASE II 12” PRECISION TILTING, MEDA 8”<br />

3 – MACHINE VISES, (1) LIANG J 6” PRECISION, (1) 6”, (1) 4”TILTING<br />

R-8 Collets, Collets, Drill Chucks, Tool Posts, Centers, Etc.<br />

SHOP & FACTORY<br />

1 – NOBLES SPEED SCRUB 2701 WALK-BEHIND ELECTRIC FLOOR<br />

MACHINE, S/N SS27100006148DQ, 24-Volt<br />

8 – BETTER PACK MODEL 55L ELECTRIC TAPE SHOOTERS<br />

6 – PORTABLE SCREW GUNS, (2) WEBER MODEL HSP 31-ZSB-242,<br />

S/Ns 1102750.07, 1102750.06, (4) DIXON MODEL 750, S/Ns 115,<br />

116, 117, 118, All With Vibratory Bowl Feeders<br />

LARGE QUANTITY OF SOLCON H10S ELECTRIC NUT RUNNERS<br />

LARGE QUANTITY OF HAK-631 & HAK-937 DIGITAL ELECTRIC<br />

SOLDERING UNITS<br />

Bench Vises, Benches, Hand Tools, Power Tools, Supply Cabinets, Safety<br />

Cabinets, Hand Trucks, Dollies, Shop Carts, Belt Conveyor, Roller<br />

Conveyor, Skate Conveyor, Lockers, Tables, Shelving, Racks, Fans, Pallet<br />

Trucks, Foremans Desks, Shop Furniture, Tape Shooters, Metro Racks,<br />

Shop Vacs, Banding Outfits, Tote Pans, Air Hose, Shop Stools, Worklights,<br />

Platform Scales, Safety Ladders, Man Lift, Work Platforms, Small Parts<br />

Cabinets, Hot Melt Equipment, Time Clocks, Glue & Paint Pressure Pots,<br />

Safety Cans, Tool Boxes, Etc.<br />

BRIDGE CRANE<br />

1 – DELTA CRANE SYSTEMS 5-TON X 34’ SPAN SINGLE-GIRDER<br />

TOP-RUNNING BRIDGE CRANE, S/N 6834 (1997), 6-Way Pendant Control,<br />

R&M Spacemaster II 5-Ton Electric Chain Hoist<br />

FORKLIFTS<br />

1 – CATERPILLAR 2EC25-50 5000-LB. CAP. ELECTRIC FORKLIFT TRUCK, S/N<br />

A2EC260886, Side Shift, Lift 190”, Solid Tires, Overhead Guard, 36-Volt<br />

4 – NISSAN CYM02L208-40 3700-LB. CAP. ELECTRIC FORKLIFT TRUCKS,<br />

S/Ns CYM02-001258 (#5), -001268 (#4), -001231 (#3) (ALL 1988), -004765<br />

(#2) (1994), Side Shift, Lift 187”, Solid Tires, Overhead Guard, 36-Volt<br />

5 – CROWN 4500-LB. CAPACITY ELECTRIC REACH-TYPE STAND-UP RIDING<br />

FORKLIFT TRUCKS (ALL 1997), (4) MODEL RR3520-45, S/Ns 1A180506<br />

(#2), 1A180539 (#3), 1A188988 (#4), 1A180536 (#1), (1) MODEL 3020-45, S/N<br />

1A55502 (#5), All With Side Shift, Lift 210”, Solid Tires, Overhead Guard, 36-Volt<br />

2 – CLARK MODEL ESM20 3675-LB. CAPACITY ELECTRIC STAND-UP RIDING<br />

FORKLIFT TRUCKS, S/Ns ESM245-0145-7827FB (#1), ESM245-0375-<br />

6955FB (#2) (BOTH 1990), Side Shift, Lift 188”, Solid Tires, Overhead Guard,<br />

S/N ESM245-0145-7827FB (Partially Disassembled)<br />

1 – CROWN SP3000 SERIES 3000-LB. NARROW AISLE ELECTRIC ORDER<br />

PICKER, S/N 1A2103 (1999), Lift 210”, Solid Tires, Overhead Guard, 36-Volt<br />

2 – LEE/PRESTO MODEL PS62-50 1500-LB. CAPACITY WALKIE-TYPE<br />

ELECTRIC DIE FORKLIFT TRUCKS, S/Ns 99802-01, 99802-02 (BOTH 1999),<br />

Lift 72”, Built-In Battery Charger<br />

MATERIAL HANDLING EQUIPMENT<br />

1 – GENIE MODEL GS-1930 500-LB. CAPACITY ELECTRIC SELF-PROPELLED<br />

WORK PLATFORM, S/N 16774 (1999), Platform 26” X 60”, Max. Height 19’<br />

3 – 4000-LB. CAPACITY ELECTRIC WALKIE-TYPE PALLET TRUCKS,<br />

(1) DOCKSTOCKER MODEL DSW400, S/N D4W-96-00190 (1996), 24-Volt,<br />

(2) PRIMEMOVER MODEL PX-40-W488C, S/Ns 181769, 181767, 12-Volt<br />

20 – CROWN, LIFTRITE, BLUE GIANT & BARRETT 5000-LB. CAPACITY<br />

HYDRAULIC PALLET TRUCKS<br />

4 – JAPANESE MODEL LC-20C 200-KG CAPACITY MANUAL LIFT CARTS<br />

1 – MAC TRAC 16”W X 7’L INCLINED MOTORIZED BELT CONVEYOR,<br />

S/N 1297C102897-004-001-01 (1997), Vari-Speed Control, 1/4-HP Motor<br />

9 – 36-VOLT BATTERY CHARGERS, (3) EXIDE SYSTEM 3000 TYPE F,<br />

S/Ns MC11796, MA10350, TO600907-1, (2) KW BATTERY LIFEGUARD<br />

FERRORESONANT, S/Ns K11029, N/A, (1) HOBART ACCU-CHARGER,<br />

S/N 071999, (2) GENERAL SERIES 7000 PLUS, S/Ns X09301, V149588,<br />

(1) GNB FER CHARGER 100, S/N 9500167F<br />

3 – BATTERY HANDLING SYSTEMS BATTERY & CHARGER RACKS<br />

1 – BATTERY HANDLING SYSTEMS MODEL BTC-24MPR HYDRAULIC<br />

BATTERY HANDLER, S/N MR29187<br />

TO 1999<br />

LEE/PRESTO 1500-LB. DIE FORKLIFT TRUCKS AND<br />

PARTIAL VIEW OF PALLET TRUCKS<br />

PAGE 6<br />

TO 1999<br />

3 OF 4 NISSAN CYM02L208-40 3700-LB. CAPACITY ELECTRIC FORKLIFT TRUCKS,<br />

CROWN 4500-LB. ELECTRIC REACH-TYPE STAND-UP RIDING FORKLIFT TRUCKS AND<br />

CROWN SP3000 SERIES 3000-LB. CAP. NARROW AISLE ELECTRIC ORDER PICKER

Plant Support • Computer • Office Equipment<br />

1 OF 2 LANTECH STRETCH-TYPE<br />

PALLET WRAPPERS<br />

PARTIAL VIEW OF 170 SECTIONS OF<br />

INTERLAKE ADJUSTABLE PALLET RACKING<br />

1997<br />

INGERSOLL-RAND MODEL SSR-XF250<br />

250-HP ROTARY SCREW AIR COMPRESSOR<br />

PALLET WRAPPERS<br />

2 – LANTECH STRETCH-TYPE PALLET<br />

WRAPPERS, (1) Q300, S/N QM004886,<br />

Prod. Speed 35 Loads/Hour, Programmable<br />

Controls, Drive-On Ramp, (1) LAN-WRAP-<br />

PER, S/N V1175, Both With Platform Size 65”<br />

Diameter, Max. Load Weight 4000-Lbs., Max.<br />

Load Size 52”L X 52”W X 8”H, 3/4-HP Motor<br />

SCALES<br />

5 – GENERAL ELECTRIC SYSTEMS FREEDOM<br />

II/B 100-LB. CAP. DIGITAL PORTABLE<br />

PLATFORM SCALES, S/Ns 401146B,<br />

401147B, 401148B, 401149B, 401150B<br />

18 – GSE SCALE SYSTEMS MODEL 550<br />

50 X .005-KG CAPACITY PORTABLE<br />

DIGITAL PLATFORM SCALES<br />

1 – YAMATO ED1-312 32-KG CAPACITY<br />

DIGITAL PLATFORM SCALE, S/N N/A<br />

1 – OHAUS MODEL 15S 25-LB./10-KG<br />

BENCH-TOP DIGITAL SCALE, S/N JA21764,<br />

Platform Size 12” X 12”<br />

PALLET RACKING<br />

170 – SECTIONS OF INTERLAKE STEEL<br />

ADJUSTABLE PALLET RACKING, 9’W X<br />

3-1/2’D X 15’H, Wire Decking (Late Delivery -<br />

Date to be announced during the auction)<br />

TRASH COMPACTOR<br />

1 – J.V. MFG. MOD. CCR-02 HYDRAULIC<br />

TRASH COMPACTOR, S/N CP6303 (1999),<br />

10-HP Hydraulic Unit<br />

AIR COMPRESSORS<br />

1 – INGERSOLL-RAND MOD. SSR-XF250<br />

250-HP ROTARY SCREW AIR<br />

COMPRESSOR, S/N DE1147U97259<br />

(1997), Ingersoll-Rand Intellisys System,<br />

Heat Exchanger, Sound Enclosure<br />

2 – INGERSOLL-RAND ROTARY SCREW<br />

AIR COMPRESSOSRS, (1) XF-100<br />

100-HP, S/N D8936U8913 (1989), (1)<br />

XF-50 50-HP, S/N D6373U886 (1988),<br />

Both With Heat Exchanger, Sound Enclosure<br />

1 – SPEEDAIRE MODEL 5Z404A 5-HP<br />

HORIZONTAL TANK-MOUNTED AIR<br />

COMPRESSOR, S/N 100792L-032768<br />

1 – INGERSOLL-RAND MODEL TM1125<br />

THERMAL MASS REFRIGERATED<br />

COMPRESSED AIR DRYER, S/N<br />

97KTM505 (1997), Ingersoll-Rand<br />

Intellisys System, Sound Enclosure<br />

1 – 650-GALLON VERT. AIR RECEIVING<br />

TANK, S/N 282221<br />

MISCELLANEOUS<br />

1 – VERTICAL HYDRAULIC BALER, Bale<br />

Size 60” X 30” X 40”, Top-Mounted<br />

Hydraulic Unit<br />

1 – 55-GAL. HYD. DRUM COMPACTOR.<br />

1 – GRAYMILLS HANDI-KLEEN PH522-A<br />

HEATED RECIRCULATING PARTS<br />

WASHER, S/N 18FY9, Tank 30” X 23” X<br />

16”D, Variable Temp. Control, 1/4-HP<br />

1 – LEG-MOUNTED OVERHEAD CONE<br />

DRYER, SA# 00800, With (3) Carts<br />

COMPUTER EQUIPMENT<br />

1 – DELL POWEREDGE 2300 450-MHZ DUAL<br />

PENTIUM III XEON FILE SERVER, 1024-MB,<br />

72-GB Hard Drive, 40X CD ROM Drive, 40-GB DLT<br />

Tape Drive<br />

1 – DELL POWEREDGE PENTIUM III FILE SERVERS,<br />

(1) 6300 450-MHZ, 1024-MB, 54-GB Hard Drive,<br />

40X CD ROM Drive, 40-GB DLT Tape Drive,<br />

(1) 4400 400-MHZ, 128-MB, 18-GB Hard Drive,<br />

24X CD ROM Drive<br />

1 – COMPAQ PROLIANT 4500 166-MHZ DUAL<br />

PENTIUM FILE SERVER, 256-MB, 12-GB Hard<br />

Drive, 20-GB DLT Tape Drive<br />

1 – INFOTEL ULTRA 266-MHZ PENTIUM II FILE<br />

SERVER, 128-MB, 24-GB Disk Drive, 16X CD ROM<br />

1 – PIONEX HAL-9000 200-MHZ PENTIUM FILE<br />

SERVER, 128-MB, 4.2 GB-Hard Drive, 16X CD ROM<br />

2 – DELL POWEREDGE FILE SERVERS, 2200, 2500<br />

2 – CODENT 2-LINE INKJET PRINTERS, S/Ns 1888, 1596<br />

4 – ZEBRA MODEL Z105 LABEL PRINTERS, S/Ns<br />

6027913, 6117126, 75735-1 (1999), 6109718<br />

1 – CALCOMP MODEL 4036 DIGITAL PLOTTER<br />

OVER (40) COMPUTERS & (30) PRINTERS<br />

Workstations, Disk Drives, Switches, Hubs, UPSs, Etc.<br />

1997<br />

INGERSOLL-RAND TM1125<br />

THERMAL MASS<br />

COMPRESSED AIR DRYER<br />

OFFICE EQUIPMENT<br />

4 – COPIERS, TOSHIBA 1710, CANON NP6050, SAVIN 9013Z, CANON IMAGERUNNER 330S<br />

2 – FAX MACHINES, XEROX 470-CX, PANASONIC KX-FP101<br />

1 – REPRO-TECHNOLOGY BLUELINER 1000 BLUEPRINT MACHINE<br />

1 – PANASONIC & INTER-TEL DIGITAL PHONE SYSTEM<br />

Electronic Marker Boards, Desks, Credenzas, Workstations, Chairs, Conference Tables, Lateral Files,<br />

File Cabinets, Blueprint Files, Supply Cabinets, Bookcases, Modular Office Cubicles, Office Dividers,<br />

Lobby & Lunchroom Furniture, Etc.<br />

Industrial Real Estate<br />

For Sale Through Private Negotiations Only<br />

Land Area: 19.1 acres (Additional Parcel 5.74 acres)<br />

Building Area: 127,800 sq. ft. Total<br />

55,200 sq. ft. Air-Conditioned Manufacturing Area,<br />

60,960 sq. ft. Warehouse Area,<br />

11,640 sq. ft. Air-Conditioned Office Area<br />

• Pre-Engineered Steel Frame With Metal Exterior Walls<br />

• Year Built: 1988 Original Construction<br />

• Zoned I-3 (Additional Parcel Agriculture)<br />

• 14’ to 20’ Ceiling Heights<br />

• Varco-Pruden Standing Seam System Roof<br />

• 2000-Amp, 400/277-Volt, 3-Phase Power<br />

• 6” Concrete Floor • (7) Docks<br />

• 300+ Car Parking • (2) Drive-Ins<br />

• Wet Sprinkler System<br />

For additional information, please contact Patrick B. Lindley, SIOR<br />

Colliers Turley Martin Tucker Company • Phone: (317) 639-0457<br />

PAGE 7