Download PDF - EEEGR

Download PDF - EEEGR

Download PDF - EEEGR

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

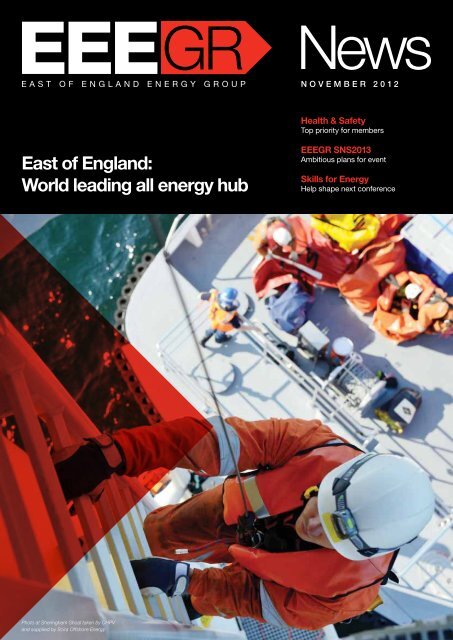

News<br />

NOVEMBER 2012<br />

Health & Safety<br />

Top priority for members<br />

East of England:<br />

World leading all energy hub<br />

<strong>EEEGR</strong> SNS2013<br />

Ambitious plans for event<br />

Skills for Energy<br />

Help shape next conference<br />

Photo at Sheringham Shoal taken by CHPV<br />

and supplied by Scira Offshore Energy

WELCOME<br />

Contents<br />

November 2012<br />

HEALTH & SAFETY<br />

03.........Oilennium revitalises Seajacks’ training<br />

Crown Estate's safety message<br />

04-05...Bartech's expansion driven by H&S<br />

New occupational health clinic<br />

06-07...Triple success for supersafe SSI<br />

08.........SafeHouse plans regional growth<br />

09.........Health of offshore workers vital<br />

ALL <strong>EEEGR</strong><br />

13.........Supply chain roadshow success<br />

14-15....Ambitious plans for SNS2013<br />

<strong>EEEGR</strong> chairman steps down<br />

<strong>EEEGR</strong> MEMBERS<br />

17..........Sheringham Shoal's royal launch<br />

18-19....Calorex paints master art class<br />

20.........Clipper South delivers first gas<br />

21.........New base for Fendercare<br />

22-31....What other members are up to<br />

SKILLS FOR ENERGY<br />

33.........Military in the Energy sector<br />

34-35...Promising start for UEA students<br />

Coming soon –<br />

<strong>EEEGR</strong> events<br />

november 2012<br />

22nd – Decommissioning Special<br />

Interest Group:<br />

OrbisEnergy, Lowestoft<br />

29th – Offshore Europe Launch Event:<br />

Beacon Innovation Centre,<br />

Gorleston<br />

december 2012<br />

13th – <strong>EEEGR</strong> Christmas Ball:<br />

Ocean Room, Gorleston<br />

januARY 2013<br />

18th – <strong>EEEGR</strong> Breakfast Club:<br />

TBC<br />

FEBRuARY 2013<br />

TBC – Nuclear Special Interest Group<br />

MARCH 2013<br />

5th – Platform for Innovation:<br />

Norfolk Showground, Norwich<br />

5th – <strong>EEEGR</strong> Gala Dinner:<br />

Norfolk Showground, Norwich<br />

6th – SNS2013 - The Sea of<br />

Opportunity:<br />

Norfolk Showground, Norwich<br />

22nd – <strong>EEEGR</strong> Breakfast Club:<br />

TBC<br />

MAY 2013<br />

17th – <strong>EEEGR</strong> Breakfast Club:<br />

TBC<br />

Next issue:<br />

the global gateway<br />

In the next issue we'll be focusing on the<br />

East of England as a global gateway in the<br />

energy world.<br />

We want to emphasise the world-class<br />

capabilities of our regional supply chain to<br />

export products, services and expertise<br />

around the world.<br />

At the same time, our assets and<br />

resources are attracting international<br />

companies who want to do business in a<br />

thriving region with potential spanning many<br />

decades ahead.<br />

We feature examples of such news in<br />

every issue but for the February 2013 edition,<br />

we'll be demonstrating the strength and<br />

value of our region within the global market.<br />

Let's hear your stories of international<br />

success whether it is selling abroad or<br />

encouraging overseas business into our<br />

region. No more than 300 words, please,<br />

and with a relevant good quality picture<br />

where possible.<br />

February will also have a full preview of<br />

our SNS 2013 Conference and Exhibition at<br />

the Norfolk Showground which will also be<br />

flying the flag for the excellence of our region<br />

and its supply chain.<br />

www.eeegr.com<br />

Visit our website to keep up-to-date with<br />

the latest energy stories and events, and<br />

to download this and previous versions of<br />

<strong>EEEGR</strong> News.<br />

Editorial deadline is Friday January 18th.<br />

Email: news@eeegr.com<br />

Contact<br />

<strong>EEEGR</strong> (East of England Energy Group)<br />

Now representing more than 380 members<br />

T: 01493 446535<br />

F: 01493 446536<br />

E: info@eeegr.com<br />

www.eeegr.com<br />

Front cover image: Safety tops every criteria list in<br />

the energy world. Photo at Sheringham Shoal by<br />

CHPV and supplied by Scira Offshore Energy.<br />

Designed and produced by TMS Media<br />

www.tms-media.co.uk<br />

The publisher cannot accept responsibility for<br />

accuracy, legality or reliability of information in this<br />

publication although the utmost care is taken.<br />

Opinions expressed by contributors are not<br />

necessarily those of <strong>EEEGR</strong>.<br />

<strong>EEEGR</strong> News is printed on 80% recycled paper<br />

02 – NOVEMBER 2012

HEALTH & SAFETY<br />

Safer than houses!<br />

C Simon Gray, <strong>EEEGR</strong> chief executive<br />

It would be obvious to say that three top priorities<br />

for the energy sector are - safety, safety<br />

and safety.<br />

AREVA's Andrew Fox put it as simply at<br />

the <strong>EEEGR</strong> 2012 Conference when he said<br />

supply chain businesses were assessed on<br />

quality, cost, delivery and safety. “But safety<br />

is everything.”<br />

Health is inextricably linked with safety.<br />

Unhealthy, unfit personnel can make dangerous<br />

mistakes or decisions. Lack of attention to<br />

safety can lead to catastrophe.<br />

Our high risk energy sector has a remarkable<br />

record for safety. But that is not enough.<br />

We must always strive to improve.<br />

That's why this issue has a special focus<br />

on H&S; the many companies involved in a<br />

whole range of aspects - the new initiatives,<br />

the training, the protection, the supervision<br />

and the equipment.<br />

It forms a critical element to our supply<br />

chain and one, without which, our industry<br />

could not operate.<br />

Oilennium revitalises<br />

Seajacks’ training<br />

C Samantha O’Hara, Oilennium<br />

C 01508 522 700<br />

C sam@oilennium.co.uk<br />

C www.oilennium.com<br />

Oilennium Ltd has successfully completed<br />

a series of customised eLearning training<br />

programmes for Seajacks, the Great<br />

Yarmouth-based operator of purpose-built,<br />

self-propelled jack-up vessels.<br />

Initially, Seajacks asked Oilennium to<br />

provide effective, cost-effective training for its<br />

employees.<br />

The first requirement was to help enhance<br />

the company’s health and safety training<br />

programme and the primary objective was to<br />

revitalise Seajacks’ existing programme by<br />

offering a more dynamic, interactive training<br />

experience.<br />

To achieve that, Oilennium provided<br />

Seajacks with access to a wide range of<br />

health and safety courses through its Learning<br />

Management System (LMS), an online<br />

user-friendly system that features interactive<br />

training tools.<br />

These courses, currently being taken<br />

by 150 employees around the world, provide<br />

training in confined space entry, task-based<br />

risk assessment, COSHH, manual handling,<br />

lifting operations, and noise awareness.<br />

Bespoke programmes were devised<br />

for Seajacks featuring lively animations and<br />

meaningful graphics that provide delegates<br />

with a clearer, more immediate understanding<br />

of the subject matter.<br />

Delegates demonstrate what they’ve<br />

learned through a series of knowledge checks<br />

and a final exam.<br />

“The health and safety courses proved<br />

to be so popular and effective, we decided<br />

to bring Oilennium in to revitalise our vessel<br />

induction video for the harsh environment<br />

installation vessel Seajacks Kraken,” said<br />

Max Paterson, sales and marketing manager<br />

for Seajacks.<br />

“Their work on the Kraken vessel video<br />

was so impressive, we decided to have<br />

Oilennium develop bespoke videos for two<br />

more vessels: the Seajacks Leviathan and the<br />

Seajacks Zaratan. Since we began training<br />

our employees via the new safety training and<br />

vessel induction programmes, there has been<br />

a marked improvement in employee appreciation<br />

of safety, and of the unique characteristics<br />

of each vessel.”<br />

Kevin Keable, managing director of<br />

Norfolk-based Oilennium, added: “Developing<br />

a culture that is vigilant and truly dedicated<br />

to best practices in HSE requires hard work,<br />

dedication and sheer persistence”.<br />

Above: Seajacks retained Oilennium to revitalise its<br />

vessel induction video for the harsh environment<br />

installation vessel Seajacks Kraken.<br />

New focus as<br />

windpower reaches<br />

deeper waters<br />

C 020 7851 5311<br />

C www.thecrownestate.co.uk<br />

As the offshore wind industry moves truly<br />

‘offshore’ into deeper waters - now similar to<br />

the southern sector oil & gas developments -<br />

the focus on health & safety has dramatically<br />

intensified to ensure that projects can be<br />

delivered safely.<br />

The Crown Estate’s health and safety<br />

champion Peter Hodgetts said: “Now, after<br />

more than 12 years of offshore wind, we are<br />

continuing to learn vital lessons even as we<br />

move further offshore. Deeper water creates<br />

changes in our risk profile but we can learn<br />

from other sectors, including oil & gas.<br />

“The Crown Estate is championing many<br />

of these initiatives with a range of strategic<br />

workstreams which reflect areas that concern<br />

our development partners. We also<br />

reward good practice through our Health &<br />

Safety Award.”<br />

A unique element of the offshore wind<br />

sector is the very large number of vessels<br />

utilised throughout the lifecycle, numbering<br />

up to 35 or 40 vessels on site during the<br />

construction phase, requiring rigorous marine<br />

co-ordination.<br />

Recently published by The Crown Estate<br />

was a Vessel Safety Guideline designed to<br />

support developers in selecting vessels ‘fit<br />

for purpose’ through the development phase<br />

and a further guideline is planned to address<br />

vessels that will be used during the<br />

construction phase.<br />

Its Safer by Design workshops brought<br />

together a large cross-section of industry<br />

experts to discuss lessons learned as well as<br />

looking ahead at the factors that will influence<br />

the whole lifecycle of projects.<br />

“An important step is that the industry<br />

is now moving from a ‘day trip’ scenario to<br />

a format similar to the oil & gas sector with<br />

personnel living offshore for extended periods<br />

and this brings another range of factors that<br />

must be managed and the industry is rolling<br />

out the first offshore wind training courses,”<br />

said Mr Hodgetts.<br />

NOVEMBER 2012 – 03

HEALTH & SAFETY<br />

Bartech Marine’s<br />

expansion driven by<br />

health & safety<br />

C Paul Douglas<br />

C 01206 384677<br />

C pdouglas@bartechmarine.com<br />

C www.bartechmarine.com<br />

As Bartech Marine Engineering enters its<br />

25th anniversary year, it remains committed<br />

to its founding principles of supplying both<br />

high quality products and service that’s built<br />

on a vision of ‘Providing Safety Through<br />

Mechanical Excellence’.<br />

It is a first port of call for global companies<br />

needing mechanical equipment for<br />

marine, offshore and industrial engines.<br />

With success have come many new<br />

opportunities. In recent months, Bartech has<br />

supplied fuel pipes for the boats that shuttled<br />

spectators to and from Olympic venues, and<br />

it has been appointed one of only five UK<br />

service dealers for global engine manufacturer<br />

MTU.<br />

As the company has grown, Bartech’s<br />

insistence on the highest standards of<br />

health & safety has allowed it to take new<br />

demands in its stride. It uses RBS’s Mentor<br />

consultancy service to ensure its H&S provision<br />

goes far beyond simple compliance with<br />

the regulations.<br />

Top & centre:<br />

Safety’s always first<br />

for Bartech Marine<br />

The result is a company that has H&S<br />

underpinning all aspects of its work. Its design<br />

and manufacturing of fuel pipes conforms<br />

to SOLAS (Safety of Life at Sea) and the<br />

company is proactive in reducing the risk of<br />

engine fires — 66% of all marine fires start<br />

in the engine room, and most of them can<br />

be avoided. Bartech also offers a 24-hour<br />

response window in which to reach clients’<br />

vessels, assets and sites, but they undertake<br />

full risk assessments and compile method<br />

statements every time.<br />

When it comes to offshore work, all staff<br />

undertake specialised training, while in the<br />

factory there are regular H&S meetings and<br />

internal poster campaigns. Now it is moving<br />

into much larger new premises in Colchester,<br />

Bartech will be training employees to use new<br />

cranes and lifting equipment and will update<br />

its H&S policies to meet the demands of its<br />

new building and operations.<br />

Director Paul Bleck said: “We put our<br />

people first and we’re determined to create a<br />

healthy, safe environment for all. If you only<br />

pay lip service to health & safety you not<br />

only endanger your employees and reputation,<br />

but you miss out on a whole range of<br />

benefits such as better motivation, staff<br />

retention and productivity.”<br />

New occupational<br />

health clinic for East<br />

of England<br />

C 01603 274460<br />

C info-norwich@abermed.com<br />

C www.abermed.com<br />

Abermed/International SOS Medical Services<br />

NEU opened a new occupational health clinic<br />

in Norwich last month.<br />

Located at Norwich Research Park, it is<br />

part of a thriving science and innovation business<br />

park that is continuing to put Norwich on<br />

the map as a centre of research and scientific<br />

excellence.<br />

The clinic is easily accessible with good<br />

transport links to locations across East Anglia<br />

and it is based within a newly furbished unit<br />

and offers a full range of occupational health<br />

services from medical assessments, occupational<br />

health consultations, travel health<br />

services to seasonal flu vaccinations.<br />

Occupational health is sometimes mistakenly<br />

taken to be simply to provide advice<br />

once an individual is sick or there is a medical<br />

problem impacting on work. At its simplest<br />

04 – NOVEMBER 2012<br />

this can be thought of as ensuring a good fit<br />

between an individual’s medical capability<br />

and the work they do – ensuring that work<br />

does not cause harm, and the individual’s<br />

health does not adversely impact on work.<br />

Prevention is always better than cure –<br />

avoiding problems or fixing them before they<br />

become serious is usually easier, more effective<br />

and cheaper than waiting until health<br />

problems start to occur.<br />

In occupational health, prevention<br />

focuses on health screening, surveillance<br />

and health promotion. These services seek<br />

to encourage awareness and early action to<br />

control identified health problems or risks<br />

and to monitor health over time to reduce risk<br />

of deterioration. A good occupational health<br />

provider will work pro-actively with a business<br />

to help identify risk factors in the work<br />

or workplace and support risk reduction to<br />

avoid harm to workers.<br />

Effective occupational health is a part<br />

of good business management and has a<br />

significant contribution to make to help a<br />

business deliver high performance and effective<br />

cost control.<br />

Above: Abermed/International SOS<br />

Medical Services NEU<br />

Right: A Tideland Syncrolan light<br />

station with an MLED-180 15 NM<br />

main light and an MLED-150 10 NM<br />

secondary light.

Altor’s new course<br />

to handle offshore<br />

conflicts<br />

C Altor Risk Group<br />

C 01224 588442<br />

C enquiries@altor-risk-group.com<br />

C www.altor-risk-group.com<br />

Tom Marchbank<br />

A global risk management group specialising in<br />

offshore crisis resolution is to pass on its extensive<br />

expertise in bringing peaceful solutions to<br />

conflict situations.<br />

Altor Risk Group, which has a new<br />

emergency response hub for the oil and gas<br />

industry in Aberdeen, launched a three day<br />

crisis intervention skills and protester response<br />

course targeted at those working offshore.<br />

The training will be led by former police<br />

negotiators experienced in dealing with<br />

hundreds of such situations and aims to raise<br />

awareness of ways to successfully resolve<br />

flashpoint situations.<br />

Setting of strategy, suicide intervention,<br />

communication skills, use of force, demands,<br />

deadlines and threats, working with an intermediary,<br />

influencing behaviour, protestor response<br />

and police expectations will all be covered.<br />

The event culminates in a half-day exercise<br />

where delegates put their newly acquired skills<br />

to the test in a mock emergency situation.<br />

Former police officer Tom Marchbank is<br />

a project manager at Altor and developed the<br />

Offshore Crisis Intervention Skills Course after<br />

identifying a shortage of knowledge among<br />

those offshore who might have to deal directly<br />

with a person in crisis.<br />

“ SADLY, SOME TRAGIC INCIDENTS<br />

MAY HAVE BEEN PREVENTED IF<br />

THERE HAD BEEN APPROPRIATE<br />

INTERVENTION. ”<br />

He said: “There is an acknowledgement<br />

from companies that incidents had occurred on<br />

their installations in the past. Sadly, some tragic<br />

incidents may have been prevented if there had<br />

been appropriate intervention.<br />

“The Emergency Preparedness Offshore<br />

Liaison Group (EPOL) agreed there needs to be<br />

suitable personnel trained to deal with people<br />

in an emotional crisis offshore until support<br />

can be obtained from the police. This is not<br />

confined to the oil & gas industry but equally<br />

applies to vessels where either passengers or<br />

crew may be affected.”<br />

Established in July 2010 by Jim Walker,<br />

the Altor Risk Group provides a complete risk<br />

management service<br />

Mr Walker said: “Major events in the North<br />

Sea and Gulf of Mexico have underlined the<br />

importance of planning for and testing various<br />

scenarios to ensure that an organisation is well<br />

equipped to deal with any potential situation.”<br />

Tideland warning<br />

systems for Gudrun<br />

platform<br />

Aibel AS of Norway has chosen Tideland<br />

Signal to supply a comprehensive package<br />

of Syncrolan LED light stations for the new<br />

Gudrun development in the Norwegian sector<br />

of the North Sea.<br />

The Tideland LED warning systems to be<br />

installed on the Gudrun platform comprise a<br />

main Syncrolan light station with a range of<br />

15 NM, two subsidiary lights, battery banks, a<br />

central alarm and monitor panel and intermediate<br />

structures. All the principal equipment is<br />

ATEX certified for use in Zone 1 (Cat 2) hazardous<br />

areas.<br />

The equipment will be built by Dabbrook<br />

in Great Yarmouth and Dabbrook technicians<br />

will commission the system offshore.<br />

Tideland's Syncrolan light stations<br />

combine an MLED-180-HI EX main light and<br />

a MLED-150 EX secondary light wired to an<br />

Exe junction box and mounted on a stainless<br />

steel pedestal. The subsidiary beacons are<br />

Tideland MLED-150 EX units with a range of<br />

10NM, also wired to an Exe junction box and<br />

mounted on a stainless steel bracket.<br />

Tideland’s MLED-180Hi and MLED-150<br />

lantern offers minimal maintenance requirements<br />

and an expected service life in excess<br />

of 25 years on station in the most demanding<br />

environments. Long-life LEDs and high-integrity<br />

electronics are employed to maximise<br />

reliability and minimise maintenance.<br />

Gudrun is located in the central Norwegian<br />

North Sea, about 55km north of Sleipner A,<br />

to which it will transport partially stabilised oil<br />

and gas. The NOK 21 billion field development,<br />

licensed jointly to Statoil as operator (75%)<br />

and GdF Suez (25%), will centre on a jacketsupported<br />

production platform with process<br />

facilities for partial stabilisation of oil and gas.<br />

Due to come on stream in 2014, the platform<br />

will have 16 well slots and the plan calls for<br />

seven production wells.<br />

NOVEMBER 2012 – 05

HEALTH & SAFETY<br />

Business in triplicate<br />

for supersafe SSI<br />

C Margaret Jessop<br />

C 01493 659411<br />

C Margaret.Jessop@ssiuk.net<br />

C www.survivalsystemsinternational.com<br />

Survival Systems International UK (SSI) has<br />

completed the refurbishment of three 50-man<br />

lifeboat capsules from the Global Sante Fe<br />

Galaxy rig at its UK base at Great Yarmouth.<br />

All three were transported together by<br />

road from Scotland to be worked on simultaneously<br />

in Norfolk while the North Sea rig was<br />

being revamped in the Nigg fabrication yard<br />

on the Cromarty Firth.<br />

It’s another feather in the cap for a company<br />

which reminds its workforce daily that<br />

more than 2000 lives have been saved to date<br />

using SSI equipment.<br />

“We were delighted to be given the work<br />

by Transocean, the world’s largest drilling<br />

contractor, and even happier to report that<br />

we finished on schedule within a tight<br />

deadline,” said Andy Dickson, SSI UK’s<br />

operations manager.<br />

“It’s meant the workshop has been<br />

particularly busy with all three capsules being<br />

worked on alongside another major contract.”<br />

Every component from each of the<br />

capsules was thoroughly checked through<br />

SSI’s ‘traffic light’ assessment – green for<br />

OK, yellow for potential refurbishment and<br />

red for replacement. Safety testing was also<br />

incorporated into the six-week project.<br />

“It was ideal for us to get the job as the<br />

capsules were all built by our parent company<br />

in the United States so we were very familiar<br />

with their design, equipment and layout,”<br />

said Andy.<br />

The GSF Galaxy, a harsh environment<br />

deepwater jack-up platform, was undergoing<br />

a three-month refurbishment, the first oil rig<br />

for nine years at the Nigg yard.<br />

Risks involved in<br />

driving to work<br />

C Mike Weatherstone<br />

C 01508 488181<br />

C info@drivexcel.co.uk<br />

C www.drivexcel.co.uk<br />

It's worth reminding everyone of Health & Safety<br />

Executive rules relating to driving at work.<br />

Essentially, an employer requiring anyone<br />

to drive, however rarely and even if driving is<br />

not normally part of their work, has a legal duty<br />

to complete a risk assessment and keep it<br />

under review.<br />

This applies equally to directors and<br />

sub-contractors, but excludes commuting<br />

unless the employee is travelling from their<br />

home to a location not their usual place of<br />

work. It applies to company vehicles and those<br />

owned by the employee.<br />

If there are fewer than five employees the<br />

employer is not required to record anything, but<br />

it is probably unwise not to do so.<br />

There is no obligation to use an outside<br />

person to risk assess but, should disaster<br />

strike, clearly the employer must be able to<br />

demonstrate they were competent to do it<br />

06 – NOVEMBER 2012<br />

Top: Triple triumph for<br />

Great Yarmouth’s Survival<br />

Systems International<br />

Top right: Surface<br />

workers keep in touch<br />

with personnel working<br />

underground 500m away<br />

themselves. This may be very difficult if one<br />

ordinary driver with no special background or<br />

expertise is risk assessing another.<br />

If an employer fails to risk assess and a<br />

serious accident occurs, a charge of corporate<br />

manslaughter against the director and/or<br />

manager responsible can result. The law<br />

allows for lengthy jail terms and closure of the<br />

company on conviction, so this is not a duty to<br />

be lightly ignored.<br />

<strong>EEEGR</strong> member Drivexcel, based near<br />

Norwich and run by ex-traffic police officer<br />

Mike Weatherstone, specialises in low-cost “on<br />

the road” driver risk assessment for cars, vans<br />

and HGV to Class1 and covers the whole of the<br />

UK. Combined with a mini-police advanced<br />

driving course, eco-driving and speeding<br />

point avoidance tips, employees enjoy them<br />

immensely and always take away something<br />

new which may save their life.<br />

Drivexcel

Fern’s FRX-1 proves a<br />

hit in Romania<br />

C Jennifer Cushion<br />

C 01502 560800<br />

C jennifer@FernCom.com<br />

C www.FernCom.com<br />

A Suffolk company’s pioneering two-way<br />

radio communications system is proving vital<br />

in making life safer for people working deep<br />

underground or in other hazardous areas by<br />

ensuring they can maintain contact.<br />

The latest test for Fern Communications<br />

Ltd saw its FRX-1 Portable Radio Repeater<br />

dramatically enhance communications<br />

for personnel carrying out inspections in<br />

underground sewage and water systems in<br />

Romania.<br />

In trials carried out on behalf of water and<br />

wastewater management company Apa Nova<br />

in central Bucharest, the FRX-1 was placed in<br />

strategic locations where the radio signal is<br />

normally disrupted, causing a breakdown in<br />

communications between personnel inspecting<br />

and surveying tunnels and pipelines. With<br />

the FRX-1 in place, radio 'black spots' were<br />

eliminated.<br />

Normally, Apa Nova personnel working<br />

in the 150ft deep tunnel lose the radio signal<br />

completely not long after entering it. But with<br />

the FRX-1 in operation, they could, for the<br />

first time, maintain radio signal and<br />

“ WITH THE FRX-1 IN PLACE,<br />

RADIO 'BLACK SPOTS'<br />

WERE ELIMINATED. ”<br />

communication with co-workers located<br />

above ground 500m away.<br />

“It was very impressive,” said Raluca<br />

Niculae, economist and project manager for<br />

Centrul pentru Servicii de Radiocomunicatii<br />

(CSR). “For Apa Nova, this trial demonstrated<br />

that maintaining quality communications<br />

with personnel who are carrying out critical<br />

inspection of the sewage network and tunnels<br />

is possible.”<br />

Apa Nova has now purchased the<br />

FRX-1 as a standard component of its radio<br />

communications kit for personnel working<br />

underground, the first time the system has<br />

been adopted for use in Romania.<br />

A major oil and gas operator in Romania is<br />

also in discussions with CSR about field trials<br />

with the FRX-1 in the Carpathian Mountain<br />

tunnels and on oil rigs in the Black Sea.<br />

During recent years, Fern’s radio repeaters<br />

have been successfully trialled by Technip<br />

in the Gulf of Mexico, QServ in Scotland, and<br />

Qatargas, offshore Qatar. Staff at Thetford<br />

Power Station in Norfolk also use Fern's<br />

system during planned shutdowns.<br />

Centre: Going down: The FRX-1<br />

Radio Repeater goes on trial with the<br />

Apa Nova inspectors watched by<br />

(centre) Clive Cushion, Fern technical<br />

director, and Raluca Niculae, of CSR.<br />

Above: Fugro’s offshore survey<br />

training team<br />

Fugro Survey’s success<br />

in RoSPA Awards<br />

C Eric Robertson<br />

C 01224 257500<br />

C e.robertson@fugro.com<br />

C www.fugrosurvey.co.uk<br />

Fugro Survey Limited has been recognised<br />

for its excellent approach to the prevention<br />

of accidents and ill health in the RoSPA<br />

Occupational Health and Safety Awards 2012.<br />

The Order of Distinction is the highest<br />

merit of continuous HSE performance excellence<br />

as it is awarded only after 15 consecutive<br />

gold awards are achieved.<br />

The award scheme recognises commitment<br />

to accident and ill health prevention<br />

and is open to businesses and organisations<br />

of all types and sizes from across the UK<br />

and overseas. It looks not just at accident<br />

records, but also entrants’ overarching health<br />

and safety management systems, including<br />

important practices such as strong leadership<br />

and workforce involvement.<br />

David Rawlins, awards manager at<br />

RoSPA, said: “We congratulate Fugro Survey<br />

on its success and encourage it, and all our<br />

other winners, to remain committed to safety<br />

and health, an approach that is well recognised<br />

to be good for workers and the bottom line.”<br />

Alistair Sutherland, QHSE manager for<br />

Fugro, which has bases in Aberdeen and<br />

Great Yarmouth, said: “The award from RoSPA<br />

is testament to the considerable commitment<br />

and effort made by everyone in our workforce<br />

towards the provision of a safe and healthy<br />

working environment over many years.”<br />

There was more good news from Fugro<br />

Academy which has celebrated delivering<br />

1,000 instructor-led training courses since its<br />

creation in 2006, benefiting more than 7,600<br />

staff and representing about 35,000 days<br />

of training.<br />

Courses are developed to support<br />

the training and development of Fugro’s<br />

surveyors, engineers, geophysicists and data<br />

processors.<br />

They are designed and delivered by<br />

experienced professionals who pass on their<br />

knowledge and experience to colleagues.<br />

As well as classroom training courses,<br />

Fugro Academy also provides a wide range<br />

of online courses to staff covering health and<br />

safety, surveying, human resource development,<br />

office software applications, leadership<br />

and management and interpersonal skills.<br />

NOVEMBER 2012 – 07

HOT<br />

WORK<br />

Needs a SafeHouse Habitat<br />

The ONLY Internationally<br />

ATEX Accredited ‘Hot Work’ Habitat<br />

SafeHouse Habitats<br />

plans regional growth<br />

C Andrew Cossey C acossey@safehouseltd.com<br />

C www.safehousehabitats.com<br />

SafeHouse Habitats Ltd, Dundee-based international safety<br />

engineering services company, has opened a new office in Great<br />

Yarmouth to further develop its interests in the region.<br />

The company has long-term plans to create further job<br />

opportunities in and around the East of England and further afield<br />

as local business develops.<br />

Its new office at Great Yarmouth’s Gapton Hall industrial<br />

estate will help meet the growing demand for its services in the<br />

southern offshore sector and onshore petrochemical & gas plants.<br />

Established ten years ago, SafeHouse has experienced<br />

significant growth and development in recent times; employing<br />

around 80 staff, with further representation via subsidiaries,<br />

partners and agents across the globe.<br />

Providing services to oil, gas & petrochemical industries,<br />

its pressurised habitats are used to perform hot work (cutting,<br />

welding, grinding etc.) in areas having a potentially hazardous<br />

atmosphere due to the presence of hydrocarbons.<br />

Performing hot work in these areas is extremely dangerous<br />

for workers and the surrounding environment as the heat and<br />

sparks generated can ignite hydrocarbons, leading to potentially<br />

catastrophic explosive chain reactions.<br />

The habitat system provides an isolated atmosphere by<br />

generating an internal pressure greater than the external, preventing<br />

the ingress of hydrocarbons while stopping the egress of hot<br />

sparks etc. This system effectively controls and reduces risks,<br />

while providing further options to operators and contractors for<br />

maintenance work and project planning.<br />

Andrew Cossey, business development/operations engineer<br />

for SafeHouse in Great Yarmouth, said: “Our aim is to progressively<br />

develop our services as far as is practicable so that we can<br />

provide the safest possible working environment for personnel<br />

carrying out hot work in industry.”<br />

Better news on H&S offshore<br />

C oilandgasuk.co.uk<br />

NOW OPEN<br />

GREAT YARMOUTH OFFICE<br />

TEL: 01493 658564<br />

Oil & Gas UK's first ever Health & Safety Report launched earlier<br />

this year reported a number of recent major improvements to<br />

offshore safety in the UK oil and gas industry.<br />

It also recorded an overview of the various safety-related<br />

projects being carried out across the industry; an explanation<br />

of how the safety agenda is being effectively managed by Oil &<br />

Gas UK and its members; and a look ahead to the future.<br />

On safety performance, the report finds:<br />

C Despite being a major hazard industry, in terms of non-fatal<br />

accidents the sector is the third-best performer in the UK, with<br />

only finance/business and education performing better.<br />

C A noticeable and steady reduction in the incidence of overthree<br />

day injuries, reaching an all time low in 2010/11.<br />

C Two years into a three-year programme to reduce hydrocarbon<br />

releases (HCRs) by 50%, there has already been a 40%<br />

reduction in major and significant releases.<br />

C Major and significant hydrocarbon releases in 2011/2012 at<br />

an all time low.<br />

Oil & Gas UK's Robert Paterson later welcomed publication<br />

of the Health & Safety Executive’s 2011/2012 Offshore Safety<br />

Statistics Bulletin whose findings matched its own report.<br />

08 – NOVEMBER 2012

HEALTH & SAFETY<br />

Health of offshore<br />

workers is great asset<br />

C 0870 0505 3456<br />

C www.rsoh.co.uk<br />

Patricia Douglas<br />

Much more can still be done to look after<br />

the physical and mental health of offshore<br />

employees on an ongoing basis, according<br />

to leading company RS Occupational Health.<br />

Statistics show that whilst accidental<br />

death offshore is now rare (only one incident<br />

in UK waters in the last five years), there were<br />

five ill-health related deaths on installations in<br />

the Northern North Sea last year – all caused<br />

by heart attack or stroke in the over 50s age<br />

group. The Southern Sector is unlikely to be<br />

any different.<br />

“The majority of companies correctly<br />

view employees as their greatest asset, so<br />

addressing their overall health and wellbeing<br />

is vital,” explains RS Occupational<br />

Health business development manager,<br />

Patricia Douglas.<br />

“There are many things that employers<br />

can do to help promote a culture of health that<br />

could assist in reducing illness and ultimately<br />

enhance productivity.<br />

“Health and wellbeing campaigns can<br />

offer early identification of potential employee<br />

health issues and provide potential solutions<br />

through informed lifestyle choices: employers<br />

can offer individual lifestyle assessments,<br />

cholesterol checks, lunch and learns on<br />

health-related topics, run team fitness challenges<br />

and a great deal more.”<br />

She added: “Employers should also<br />

remain alert to mental health issues which<br />

are one of the most common reasons for<br />

referrals to occupational health physicians.<br />

Recent UK research shows that one in four<br />

people will experience some mental health<br />

problem in the course of a year but just four<br />

in ten say they would feel confident disclosing<br />

a mental health problem to their employer.<br />

Stress awareness training is only one of many<br />

options to consider.”<br />

RS Occupational Health operates from<br />

bases in Great Yarmouth, Inverness and<br />

Aberdeen and holds the contract to administer<br />

the registration of oil and gas doctors,<br />

worldwide, on behalf of Oil & Gas UK.<br />

Established in 1999, the company employs<br />

50 people.<br />

Charity initiative by<br />

AID Rope Access<br />

C Simon Page<br />

C 01953 454383<br />

C simon@aidropeaccess.com<br />

C www.aidropeaccess.com<br />

AID Rope Access launched its charity Rope<br />

Aid in September to help people gain access<br />

to industry related skills, primarily within the<br />

rope access, work at height, renewable and<br />

oil & gas sectors.<br />

The charity is aimed at individuals who<br />

have been unable to progress socially and/or<br />

professionally due to disadvantage from low<br />

income, unemployment, previous offending<br />

or educational exclusion.<br />

Access Inspection Development (AID)<br />

was founded in 1998 by Tjebbe Roestenburg<br />

who - having spent 20 years as a commercial<br />

saturation diver in the oil industry - transferred<br />

his skills to the working at height industry,<br />

forming AID Rope Access Ltd.<br />

As a training facility, the company hosts a<br />

fully functional 25m tower at Great Yarmouth<br />

which is constantly being upgraded to meet<br />

changes in demand. AID is also in the process<br />

of developing a new training facility on<br />

the outskirts of Norwich near to the A11.<br />

AID delivers approved training in IRATAapproved<br />

rope access, work at height,<br />

rescue, SCAPE offshore evacuation system,<br />

ladder safety, confined space, drops awareness,<br />

rooftop safety and competent person<br />

PPE equipment inspection.<br />

Initially, Rope Aid will support people in<br />

the East of England - with plans to spread<br />

across the UK and, in time, to Africa. The aim<br />

is to put back into communities where our<br />

industries have prospered.<br />

Rope Aid does not intend to throw money<br />

at people, but rather provide the necessary<br />

skills that will, eventually, give individuals the<br />

ability to help themselves by improving their<br />

employment prospects.<br />

To date, ‘Rope Aid’ has meetings<br />

arranged with other support organisations<br />

in order to find the best possible route to<br />

the people that are in the greatest need of<br />

our help, and to identify the most suitable<br />

candidates. There are plans for a sponsored<br />

bike-ride in July 2013 and a cross-channel<br />

canoe event in the summer, to raise money<br />

for Rope Aid and to enhance its profile.<br />

New marine wireless<br />

headset systems<br />

C David Ash<br />

C 01621 853003<br />

C david@mantsbrite.com<br />

C www.mantsbrite.com<br />

Effective communication between skipper<br />

and crew plays an important role in the safe<br />

passage of vessels of all types and sizes,<br />

and a new range of products from specialist<br />

electronic navigation and communication<br />

distributor Mantsbrite will make on-board<br />

communication much more effective.<br />

The David Clark Company has pioneered<br />

air and space crew equipment design and<br />

manufacture for over 70 years, and its new<br />

Marine Wireless Headset Communication<br />

Systems provide maximum mobility and clear<br />

communication without crew members being<br />

tethered to the vessel.<br />

Mantsbrite has chosen the BMEA conference<br />

and exhibition to launch these systems<br />

to the UK and Ireland marine industry, and<br />

managing director David Ash believes wireless<br />

headsets will quickly prove very popular, saying:<br />

“They are ideal for a wide variety of work<br />

boats, barges, tugs, and ferries as well as<br />

harbour patrol, coast guard and pilot vessels.<br />

“David Clarke headsets have been in use<br />

in the aviation industry for many years, and<br />

have a great reputation for clarity and reliability,<br />

and I am delighted that Mantsbrite is now able<br />

to offer them to the marine sector.”<br />

Providing crisp clear communication over<br />

a 100m range, the wireless headset systems<br />

offer totally hands-free communication using<br />

lightweight battery packs with up to 24 hours<br />

use between re-charges. The stylish, yet rugged<br />

headset systems are manufactured using<br />

marine grade components, and the range features<br />

versions which are specifically designed<br />

to be worn under protective hard hats.<br />

They will shortly be available from<br />

Mantsbrite's 175-strong UK and Ireland dealer<br />

network to which it already supplies navigation<br />

and communication products from manufacturers<br />

including AMEC, ComNav, Cristec, ENAG,<br />

Interphase Technologies, Koden Electronics,<br />

Lorenz, Navicom and North Invent.<br />

NOVEMBER 2012 – 09

HEALTH & SAFETY<br />

Staff can pave way to<br />

a safer workplace<br />

C Step Change in Safety<br />

C 01224 577271<br />

C les@stepchangeinsafety.net<br />

C www.stepchangeinsafety.net<br />

Step Change in Safety, an organisation<br />

dedicated to improving safety in the UK oil and<br />

gas industry, has launched a ground-breaking<br />

suite of guidance which promises to transform<br />

the way companies interact with staff and<br />

improve safety at worksites.<br />

The Workforce Engagement Toolkit is<br />

the first of its kind and has been designed to<br />

help companies measure workforce engagement<br />

at individual worksites, identify areas of<br />

improvement and provide practical guidance<br />

on how to achieve them.<br />

The toolkit will help companies enhance<br />

their 'safety culture' at worksites by helping<br />

foster a culture where the workforce is encouraged<br />

to actively lead efforts to improve safety<br />

performance.<br />

The toolkit contains a unique worksite<br />

survey, which can be completed online or on<br />

paper by every employee at a worksite, with all<br />

input confidential.<br />

The answers can help determine the level<br />

of workforce engagement at a site. Questions<br />

include, for example, how visible workers<br />

think leaders are, how much they feel they are<br />

encouraged to participate in safety and how<br />

well they think leaders communicate and act<br />

on safety issues.<br />

Data is submitted directly to Step<br />

Change and a summary report is then issued<br />

back to the worksite to help resolve areas<br />

of strength and weakness and develop<br />

improvement plans.<br />

Step Change in Safety team leader<br />

Les Linklater said: “Improving workforce<br />

engagement is crucial to Step Change's longterm<br />

vision of making the UK the safest place<br />

to work in the worldwide oil and gas industry.<br />

“The workforce has to feel able and<br />

willing to challenge and participate fully- which<br />

means influential people such as supervisors,<br />

site leaders and senior managers have to be<br />

visible, communicate effectively, encourage<br />

involvement and provide support creating a<br />

culture of engagement in health and safety.”<br />

Find out more at:<br />

www.stepchangeinsafety.net/about/workgroups/WorkforceEngagementToolkit.cfm<br />

10 – NOVEMBER 2012

Far Left: Les Linklater<br />

Left: Ready for the TDW<br />

ILI run, achieved in less<br />

that 21 hours<br />

TDW’s rapid inline<br />

inspection for<br />

Perenco pipeline<br />

C Dean Ellis<br />

C 01793 603 600<br />

C dean.ellis@tdwilliamson.com<br />

T.D. Williamson (TDW) successfully completed<br />

the inline inspection (ILI) of a key North<br />

Sea pipeline on behalf of Perenco UK.<br />

It was carried out on the 24-inch line<br />

that links the Trent platform with the Bacton<br />

Terminal pipeline. TDW conducted this intelligent<br />

inspection and associated pipeline<br />

service operation as part of Perenco’s strategic<br />

programme to ensure the integrity of its<br />

pipelines and assets.<br />

The pipeline inspection was carried out<br />

to comply with Health, Safety & Environment<br />

(HSE) obligations.<br />

“We are a solutions provider,” said Dean<br />

Ellis, senior ILI field technician for TDW. “Our<br />

ability to offer the full range of services that<br />

Perenco required meant that we could create<br />

a custom solution, and carry out the kind of<br />

efficient and seamless operation that is only<br />

possible when all services are concentrated<br />

under one roof.”<br />

“ WE ARE A SOLUTIONS PROVIDER.<br />

OUR ABILITY TO OFFER THE<br />

FULL RANGE OF SERVICES THAT<br />

PERENCO REQUIRED MEANT<br />

THAT WE COULD CREATE A<br />

CUSTOM SOLUTION. ”<br />

TDW’s team was tasked with identifying<br />

and responding to Perenco’s precise needs<br />

and devised a comprehensive plan after a<br />

site visit. It included progressive pigging,<br />

KALIPER ® 360 geometry inspection, 24-inch<br />

gas magnetic flux leakage (GMFL) inspection,<br />

ILI reporting, fitness-for-purpose, run comparison,<br />

corrosion growth analysis reports,<br />

and other services.<br />

“We are very pleased with TDW’s ability<br />

to successfully deliver the total project,<br />

despite the challenges imposed upon them,”<br />

said Stephen Southgate, integrity & fabric<br />

maintenance superintendent for Perenco UK.<br />

In spite of working in high winds, driving<br />

rain, sleet and snow, the offshore phase,<br />

during which all site work was carried out,<br />

was completed in just 23 days. Support<br />

and equipment were supplied by the TDW<br />

operations and projects team based at the<br />

company’s facility in Swindon, England.<br />

The ILI run - from launch to trap - was<br />

achieved in less than 21 hours. No metallic<br />

components were brought in, and only a<br />

small quantity of viscous black residue was<br />

produced. The gauge plate showed no signs<br />

of any deflection at any point around its<br />

circumference.<br />

It makes sense to<br />

get staff on board<br />

C www.britanniaits.com<br />

C 0800 0149016<br />

The Health and Safety executive press<br />

reported 27 major cases of so-called neglect in<br />

September with firms fined tens of thousands<br />

of pounds for staff accidents that should, and<br />

probably could, have been prevented.<br />

According to the HSE, major injuries<br />

within the offshore industry have fallen from<br />

41 to 36 over the period 2011/12 at a time<br />

when staffing levels have increased by 5%<br />

to 29,058. The figures show a rate of 130.77<br />

per 100,000 workers, the second lowest rate<br />

in ten years - suggesting that the offshore<br />

industry takes heath and safety extremely<br />

seriously.<br />

Involving staff in health and safety planning<br />

and training them to deliver is beneficial<br />

for everyone concerned. It gives the business<br />

an element of protection against claims and<br />

can often contribute to cheaper insurance<br />

cover. The staff are educated on right practices<br />

and can see a contribution to their career<br />

development. Customers of the firm will know<br />

they are dealing with a competent company<br />

and in many industries the customer will insist<br />

on evidence of training staff to comply.<br />

Colin Wright, managing director of<br />

Britannia Safety and Training, started<br />

the company 12 years ago after a career<br />

in construction.<br />

“Our business has grown to employ 20<br />

trainers across two purpose-built centres<br />

through our vision of offering off-site or onsite<br />

training with individuals or groups, he said.<br />

“My vision, when I started the business,<br />

was to deliver a common sense approach to<br />

the health and safety of staff in the workplace,<br />

whilst ticking all the boxes. Once staff explore<br />

the reasons for working in the proper fashion<br />

they are much more motivated and inclined to<br />

practice it in the workplace.<br />

“ OUR BUSINESS HAS GROWN TO<br />

EMPLOY 20 TRAINERS ACROSS<br />

TWO PURPOSE-BUILT CENTRES<br />

THROUGH OUR VISION OF OFFERING<br />

OFF-SITE OR ONSITE TRAINING WITH<br />

INDIVIduALS OR GROUPS. ”<br />

“Having worked in a manual industry I<br />

appreciate how tough working conditions can<br />

be and I can empathise with many of those<br />

we work with. We also know how to speak<br />

the language to get messages and a better<br />

understanding across”.<br />

Britannia already works with major<br />

players in the offshore industry including<br />

CLS Offshore, Petrofac, Haliburton, UK PN,<br />

EDF and SLP and has a range of over 100<br />

accredited courses on offer.<br />

It started life offering health and safety<br />

for the construction industry but has since<br />

branched out, with experienced trainers delivering<br />

a broad range of courses for all sectors.<br />

NOVEMBER 2012 – 11

12 – NOVEMBER 2012

ALL <strong>EEEGR</strong><br />

Supply Chain Development Programme<br />

Right: John Balch<br />

(second left) and<br />

Johnathan Reynolds<br />

(right) from the Nautilus<br />

Associates team<br />

Roadshow steers<br />

supply chain to success<br />

C 01493 446535<br />

C supplychain@eeegr.com<br />

The <strong>EEEGR</strong> Supply Chain Development<br />

Programme goes from strength to strength,<br />

boosted by the hugely successful roadshow<br />

which has been taking the message across the<br />

region over the last two months.<br />

Part-funded by the European Regional<br />

Development Fund, the programme gives<br />

SMEs a chance to meet with industry and<br />

business development specialists who can<br />

offer guidance, assistance and contacts<br />

to help grow within an ever developing<br />

energy industry.<br />

“The Supply Chain Roadshow meant<br />

we could take the initiative out to businesses<br />

rather than expect them to come to us,” said<br />

Nikki Collings, <strong>EEEGR</strong>'s membership and<br />

marketing manager. “It's a format I'm sure we<br />

will use again.<br />

“There has been tremendous interest<br />

both from companies looking to get involved<br />

in the energy sector and those already there<br />

and looking for new opportunities.”<br />

Nearly 200 people attended the series<br />

of roadshows which visited locations across<br />

Norfolk, Suffolk, Essex and Cambridgeshire.<br />

<strong>EEEGR</strong> is working with a specialist team<br />

from energy industry consultants Nautilus<br />

Associates who have the insight and expertise<br />

to help deliver growth within individual businesses<br />

and across the supply network.<br />

“We’re offering the tools and support to<br />

help companies win those contracts,” said<br />

Nautilus director Johnathan Reynolds.<br />

“Many are aware of the vision, of the big<br />

picture of billions of pounds to be invested<br />

into our region. But they must also recognise<br />

the harsh realities of a tough and competitive<br />

business world and the state of the economy.<br />

“They will need resilience, thorough<br />

preparation and great determination. Everyone<br />

is aware of what’s on the horizon but it’s not<br />

being constructed yet. Someone likened it to<br />

waiting for the delivery of an order which has<br />

not yet been placed.”<br />

The free consultancy can include a highlevel<br />

strategic review with additional focused<br />

attention on strategic planning, funding and<br />

finance, marketing and operations.<br />

By the end of September, through the<br />

Supply Chain Development Programme,<br />

<strong>EEEGR</strong> had:<br />

C Supported 102 companies<br />

C Helped create 191 jobs<br />

C Helped to safeguard 27 jobs<br />

C Helped 7 business start-ups<br />

Programme<br />

boosts AJ Woods<br />

AJ Woods Engineering Limited, a marine<br />

engineering company heavily involved in<br />

the wind energy and construction industry,<br />

contacted <strong>EEEGR</strong> for growth support consultancy<br />

from the Supply Chain Development<br />

Programme.<br />

The Harwich based firm, currently<br />

involved in the construction of the Greater<br />

Gabbard Wind Farm, was also commissioned<br />

for the reworks of the Seajacks<br />

Leviathan blade rack in which it assisted in<br />

the design adaptation to enable significant<br />

improvements in loading time and safety.<br />

Through the programme, the company<br />

sought high-level property expertise and<br />

consultancy to help it search for suitably<br />

located facilities to meet expansion requirements<br />

in Lowestoft and incubation advice<br />

for the newly purchased Miranda Renewable<br />

Energy Centre in Harwich.<br />

Jason Wells, Nautilus Associates’<br />

chartered surveyor, conducted a detailed<br />

property search and site analysis for the<br />

AJ Woods directors. Directors Tony Woods<br />

and Robert Day were shown sites around<br />

Lowestoft that were not being marketed<br />

through agencies, and were amazed at the<br />

quality of space and facilities on offer.<br />

The directors also received incubation<br />

consultancy from John Balch concerning<br />

their newly purchased building along the<br />

quayside in Harwich - Miranda Renewable<br />

Energy Centre. The centre is now attracting<br />

tenants and occupancy levels are increasing.<br />

“The support we received from Nautilus<br />

Associates has been invaluable in the<br />

search for locations and facilities; their local<br />

knowledge will be key in ensuring we are<br />

strategically located so we can deliver efficiently<br />

to our clients,” said Mr Day, business<br />

development manager.<br />

Support for PDS<br />

Recruitment<br />

PDS Recruitment, a specialised recruitment<br />

agency, accessed high-level consultancy support<br />

through the Supply Chain Development<br />

Programme.<br />

The Beccles-based agency, seeking to<br />

raise its profile in the energy industry, was<br />

looking to develop a full and robust marketing<br />

strategy to reposition itself as the main recruitment<br />

contractor of choice within the sector.<br />

Through the programme, it sought<br />

high-level marketing expertise and consultancy<br />

to help gain market share and to<br />

increase turnover.<br />

A full marketing strategy and rebranding<br />

report was completed by senior marketing<br />

consultant, Julie Broadley, and as a result PDS<br />

has since updated its website and business is<br />

heading for growth.<br />

NOVEMBER 2012 – 13

ALL <strong>EEEGR</strong><br />

International flavour<br />

for SNS 2013<br />

<strong>EEEGR</strong>'s SNS conference moves to the Norfolk<br />

Showground for the first time in 2013 with ambitions<br />

to make the biggest ever impact on the<br />

national and international energy scene.<br />

The two-day event will have space for up to<br />

90 exhibition stands and is expected to attract<br />

500 delegates.<br />

“Although the emphasis remains on<br />

the potential of the East of England and the<br />

opportunities for our supply chain, we no longer<br />

see this as a regional event but as a national<br />

conference held in our region,” said <strong>EEEGR</strong><br />

chief executive Simon Gray.<br />

“It is an opportunity to showcase our skills<br />

and assets to the rest of the country and beyond<br />

and our speakers will reflect the growing international<br />

significance of the East of England to<br />

the energy world.”<br />

Among key speakers already announced<br />

is Gareth Lewis, head of development at<br />

Forewind, who will be talking about developing<br />

the world’s largest offshore wind project at<br />

Dogger Bank and the lessons learned.<br />

Windpower and the oil & gas sectors<br />

will again be the principal focus of the Sea of<br />

Opportunity Conference on March 5th and 6th.<br />

The first day will play host to ‘Platform for<br />

Innovation’ supported by DECC (Department<br />

of Energy and Climate Change). Speakers will<br />

discuss the innovation and technology available<br />

to help the supply chain tackle arising issues in<br />

the offshore wind and oil & gas sectors.<br />

In the evening, there will be a gala<br />

dinner with a principal guest speaker and the<br />

<strong>EEEGR</strong> member of the year and special<br />

recognition awards.<br />

The following day will see a full line-up of<br />

leading specialist guest speakers across the<br />

SNS industry. The exhibition will run throughout.<br />

“Using the impressive redeveloped premises<br />

at the Norfolk Showground will double the<br />

space available to us and take the conference<br />

and exhibition to a new level at the very hub of<br />

the regional energy sector,” said Mr Gray. “We<br />

believe it will bring invaluable expertise, ideas<br />

and information to our members and everyone<br />

else involved in the SNS energy business.”<br />

The growth and changes mean that the<br />

<strong>EEEGR</strong> Energy Innovation Awards will now<br />

move forward to accompany the <strong>EEEGR</strong> 2013<br />

all energy conference in summer instead of the<br />

SNS event.<br />

Alan Barlow<br />

<strong>EEEGR</strong> chairman<br />

set to move on<br />

Alan Barlow is stepping down as chairman of<br />

<strong>EEEGR</strong>, the East of England Energy Group,<br />

after a two-year stint helping steer the<br />

association through a period of change and<br />

development.<br />

He became the first executive chairman<br />

of the 380-member group in 2010 and the<br />

formal announcement of his departure came<br />

at the organisation’s Annual General Meeting.<br />

“It was a two-year fixed contract and I'm<br />

delighted we have achieved so much in that<br />

time frame,” said Mr Barlow.<br />

“I'm grateful that <strong>EEEGR</strong> allowed me<br />

to put something back into industry after<br />

completing 25 years of work in international<br />

business, with much of it being in the<br />

energy sector.<br />

14 – NOVEMBER 2012<br />

“I look forward to retaining contact with<br />

<strong>EEEGR</strong> and follow its invaluable work for the<br />

region's energy sector with great interest as<br />

I concentrate my efforts on my charity work.<br />

I firmly believe that <strong>EEEGR</strong> is eminently placed<br />

to assist industry and the public sector to bring<br />

forward successfully over £30bn of investment<br />

opportunities in the sector across the region”.<br />

During his time in post, Alan has helped<br />

to achieve significant funding for the group<br />

through the European Regional Development<br />

Fund (ERDF). The funding has enabled <strong>EEEGR</strong><br />

to expand its vital work in supporting the<br />

development of the energy supply chain.<br />

Alan has also been instrumental in<br />

developing a wider political, international and<br />

influential role for the group with a new initiative<br />

launched in the House of Commons; and a longterm<br />

business plan. He was closely involved in<br />

the formation of NSEA (the Norfolk and Suffolk<br />

Energy Alliance) to introduce a dedicated<br />

programme of inward investment promotion<br />

and related public relations campaign for the<br />

region as a world-leading all-energy hub.<br />

<strong>EEEGR</strong> chief executive Simon Gray<br />

added: “I'd like to thank Alan for his commitment<br />

and endeavour for <strong>EEEGR</strong> and wish him<br />

well in future. I'm grateful for his support during<br />

the time I have been settling into my new role.”<br />

Former chairman Mark Goodall said:<br />

“Over the last two years, Alan has provided<br />

<strong>EEEGR</strong> with excellent leadership in his role as<br />

executive chairman. On behalf of the board, I<br />

would like to thank Alan for the commitment,<br />

expertise and energy he has given to the<br />

organisation and the East of England. We wish<br />

him well in continuing his charity work.”<br />

At the annual meeting, it was announced<br />

that the three people elected to the board this<br />

year were Mark Goodall, Aker Solutions area<br />

manager; Richard Jenkins, vice-president of<br />

operations for Claxton Engineering Services;<br />

and Mark Frith, technical director for Mott<br />

MacDonald.

<strong>EEEGR</strong> chief demands<br />

Government clarity on<br />

energy policy<br />

<strong>EEEGR</strong> chief executive Simon Gray has joined<br />

the growing clamour for the Government to be<br />

crystal clear on its future commitment to the<br />

UK windpower industry.<br />

He spoke out after major companies<br />

like Siemens and Areva warned that a lack of<br />

decision-making and inconsistent comments<br />

from ministers meant they would reassess the<br />

level of political risk in the UK.<br />

They are among international energy<br />

companies with plans to invest hundreds of<br />

millions of pounds on projects which will create<br />

thousands of jobs in the UK.<br />

Simon sought clarification after the latest<br />

comments from new environment secretary<br />

Owen Paterson and Tory climate change<br />

minister Greg Barker about concerns over<br />

high subsidy levels for the renewables sector.<br />

“The industry needs to know what subsidies<br />

and tariffs will apply before investors will<br />

consider business plans for the development<br />

of renewable energy sources,” he said.<br />

“All sectors of the energy industry get<br />

subsidised through one route or another. The<br />

Wind turbine<br />

manufacturer<br />

meets suppliers<br />

One of Europe’s biggest wind turbine<br />

manufacturers was expected in Lowestoft - as<br />

<strong>EEEGR</strong> News went to press - to meet potential<br />

suppliers and partners.<br />

French company AREVA was holding<br />

a meet-the-buyer event at OrbisEnergy to<br />

outline its products and plans for the UK<br />

offshore market and hold one-to-one sessions<br />

with selected companies in the regional<br />

supply chain.<br />

The event is part of <strong>EEEGR</strong>'s extensive<br />

work to support the development of the<br />

regional energy supply chain, part financed<br />

by the European Regional Development Fund.<br />

Simon Gray, <strong>EEEGR</strong> chief executive,<br />

said: “AREVA is going to be a major player<br />

in the later Round Two and Round Three UK<br />

offshore wind farms and this offered a major<br />

Far left: Simon Gray<br />

expects SNS2013 to<br />

make a big impact<br />

Left: The SNS2012 event<br />

“ ONE THING IS CLEAR, AND<br />

THAT IS WE WILL NEED<br />

TO GET OUR ELECTRICITY<br />

FROM SOMEWHERE... ”<br />

oil and gas sectors enjoy tax benefits and<br />

nuclear benefits from the decommissioning<br />

and storage of materials, so none are quite as<br />

transparent as it might first seem.<br />

“The industry can respond to any changes<br />

in government strategy if it actually has a clear<br />

understanding of the policy and associated<br />

time frames,” he added.<br />

Through NSEA, both Norfolk and Suffolk<br />

County Council already planned to seek clarity<br />

from the Government - and <strong>EEEGR</strong> was urging<br />

a much clearer and more consistent message<br />

from political leaders.<br />

“One thing is clear, and that is we will<br />

need to get our electricity from somewhere<br />

and this is particularly true if industry emerges<br />

from recession and requires more energy<br />

to grow.<br />

“We are fortunate in this region in that<br />

we have gas, offshore wind, nuclear and the<br />

potential for carbon capture and storage,” said<br />

the <strong>EEEGR</strong> chief executive, whose thoughts<br />

were reported in the Eastern Daily Press and<br />

other local media.<br />

opportunity for companies in the region to<br />

engage with them at an early stage.”<br />

AREVA was providing information on its<br />

M5000 turbine and talking about its operations<br />

and maintenance plans.<br />

Julian Brown, Areva’s head of wind in the<br />

UK, said: “We are keen to develop our position<br />

here. We have to get stuck in on the ground<br />

and do the best we can in the confidence that<br />

the government will make the right decisions<br />

for the industry in the long term.<br />

“The UK long term is the biggest market<br />

by far but it is not all happening in the next five<br />

minutes, it is happening over a period of time.<br />

We encourage companies to get to know us<br />

and meet us. Round Three is going to take 20<br />

years to build.”<br />

But he said there were opportunities for<br />

regional companies in Germany now.<br />

“There are turbines in the yard. If UK<br />

suppliers are competitive then there is business<br />

they can do now. They should come and<br />

explore the opportunities now and not wait for<br />

it to happen in the UK and the region.”<br />

Positive start for<br />

Special Interest Group<br />

More than 50 industry professionals attended<br />

the first Decommissioning Special Interest<br />

Group (SIG) launched by <strong>EEEGR</strong> and Decom<br />

North Sea.<br />

And the depth of interest is growing with<br />

around 100 people keen to follow the development<br />

of the group which is due to meet again<br />

on November 22nd.<br />

Initial responses from delegates suggested<br />

existing good all-round capability<br />

in the oil & gas industry, with multi-skilled,<br />

competent management and workforce, and<br />

both knowledge and experience of the assets<br />

in the SNS.<br />

Key weaknesses recorded included a<br />

lack of knowledge of project timescales and<br />

future resource requirements, and also a<br />

desire for greater understanding of operators’<br />

contracting strategies. It was felt that further<br />

infrastructure development would be required.<br />

Members hoped the SIG would strive<br />

to make the region a centre of excellence for<br />

decommissioning, building on its competitive<br />

and co-operative strengths.<br />

It should also become a conduit for<br />

information and knowledge flow, promote<br />

business opportunities through networking<br />

events and workgroups, and facilitate greater<br />

co-operation across the sector. Part of that<br />

could be achieved through closer engagement<br />

with organisations such as DECC and Oil &<br />

Gas UK.<br />

Meanwhile, plans are progressing to<br />

develop a nuclear industry SIG through cooperation<br />

with the Nuclear Industry Association.<br />

An event is being planned for next year.<br />

NOVEMBER 2012 – 15

16 – NOVEMBER 2012

<strong>EEEGR</strong> MEMBERS<br />

Christian Rynning-Tønnesen<br />

meets the media<br />

Crown Prince Haakon<br />

of Norway at the<br />

official opening<br />

Sheringham Shoal<br />

opened by Norway’s<br />

Crown Prince<br />

C Liz Hancock, Scira<br />

C 07557 264326<br />

C www.scira.co.uk<br />

The 317MW Sheringham Shoal Offshore<br />

Wind Farm was officially opened by His Royal<br />

Highness, Crown Prince Haakon of Norway.<br />

The ceremony was staged at Norfolk’s<br />

Holkham Hall where the Crown Prince arrived<br />

by helicopter with representatives from<br />

the windfarm’s owner companies, Statoil<br />

and Statkraft, along with Norwegian and<br />

British Ministers and Ambassadors. He was<br />

greeted by students from local high school,<br />

Alderman Peel.<br />

Holkham Hall owners Viscount and<br />

Viscountess Coke welcomed the Crown<br />

Prince, dignitaries and around 100 guests to<br />

their stately home just outside Wells-next-the-<br />

Sea, where the windfarm will have its operations<br />

and maintenance base.<br />

Sheringham Shoal is owned equally by<br />

the two Norwegian energy leaders through<br />

joint-venture company, Scira Offshore<br />

Energy Limited.<br />

Scira general manager Einar Strømsvåg<br />

said his team had worked for more than three<br />

years to prepare for the windfarm’s operation.<br />

“In late 2010 we started to recruit locally<br />

to fill all the positions necessary to operate<br />

and maintain the windfarm. Two years later<br />

Scira has, together with our contactors and<br />

partners, established an organisation of 60<br />

highly motivated people,” he said.<br />

Also speaking at the official opening<br />

were the UK Secretary of State for Energy and<br />

Climate Change, Edward Davey; Norwegian<br />

Minister of Petroleum and Energy, Ola Borten<br />

Moe; Minister of Trade and Industry, Trond<br />

Giske; and the owners’ presidents and<br />

CEOs, Helge Lund from Statoil and Christian<br />

Rynning-Tønnesen from Statkraft.<br />

The opening event included musical<br />

performances by local students, mediated<br />

interviews by BBC presenter Sonali Shah and<br />

a show entitled A Windy World by girl group<br />

The Boxettes and dancers from Cirque Bijou.<br />

Global growth prompts<br />

CIS expansion<br />

C Andy Penman<br />

C 01493 849680<br />

C andy.penman@c-i-services.com<br />

C www.c-i-services.com<br />

Increasing demand for Conductor Installation<br />

Services (CIS) has led to the company moving<br />

into a new larger global headquarters in<br />

Great Yarmouth, launching its first apprentice<br />

scheme and making two key personnel<br />

appointments overseas.<br />

The Acteon company provides conductor<br />

installation services associated with construction<br />

projects for the oil and gas industry.<br />

Great Yarmouth man Phil Borley has been<br />

promoted to the post of Middle East and North<br />

Africa operations manager, responsible for the<br />

company’s base and operations in Qatar.<br />

He launched his career in the oil and gas<br />

industry with BJ Tubular Services in 2001 in<br />

Great Yarmouth, where he worked in hammer<br />

“ PHIL AND JON WILL HELP<br />

STRENGTHEN OUR PRESENCE<br />

IN THE MORE MATURE REGIONS,<br />

AND SUCCESSFULLY PENETRATE<br />

EMERGING MARKETS. ”<br />