Goulds Models 3180/3185 Paper Stock/Process Pumps

Goulds Models 3180/3185 Paper Stock/Process Pumps

Goulds Models 3180/3185 Paper Stock/Process Pumps

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

BULLETIN 723.9<br />

February 2003<br />

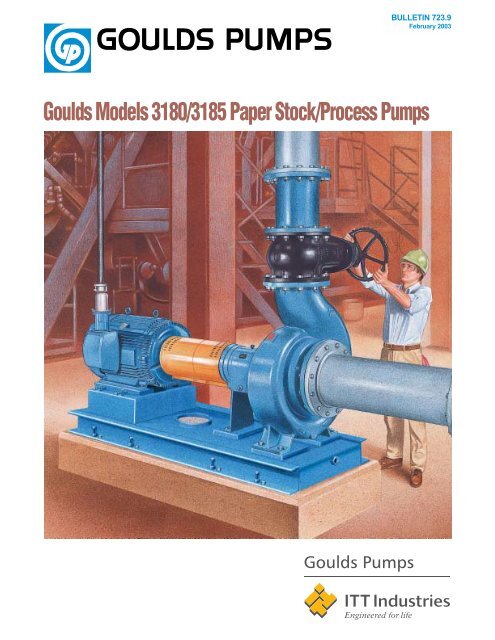

<strong>Goulds</strong> <strong>Models</strong> <strong>3180</strong>/<strong>3185</strong> <strong>Paper</strong> <strong>Stock</strong>/<strong>Process</strong> <strong>Pumps</strong>

Top: A model <strong>3180</strong><br />

installed in a North<br />

American recycle mill.<br />

Above: Model <strong>3180</strong>XL on<br />

difficult high temperature<br />

service. Spring-mounted<br />

baseplate provided to<br />

compensate for thermal<br />

expansion.<br />

Left: Cooling water pump<br />

for primary turbine at a<br />

power plant in the<br />

Middle East.<br />

World Wide Experience<br />

on <strong>Process</strong> Pumping<br />

Services<br />

When <strong>Goulds</strong> developed the <strong>3180</strong>/85 we utilized<br />

140 years of pump design experience to ensure it<br />

would have unmatched mechanical reliability.<br />

Today, installations around the world attest to its<br />

remarkable performance.<br />

The <strong>3180</strong>/85 ... the heavy duty process pump<br />

designed to handle all of your tough process<br />

pumping applications.<br />

World Class Pump Line<br />

Model <strong>3180</strong> (built to English standards)<br />

• ANSI 125/150 lb. flange drilling<br />

• Inch-dimensioned O.D. of mechanical seal sleeve<br />

• Inch-dimensioned bearing locknut<br />

• Inch-dimensioned shaft and keyway at coupling<br />

Model <strong>3185</strong> (built to Metric standards)<br />

• ISO or JIS 16 bar flange drilling<br />

• mm-dimensioned O.D. of mechanical seal sleeve<br />

• mm-dimensioned bearing locknut<br />

• mm-dimensioned shaft and keyway at coupling<br />

• International design <strong>3185</strong> pumps comply<br />

to ISO 5199 with eight sizes conforming to ISO<br />

2858 dimensions. Metric fasteners and fittings<br />

used throughout.<br />

■ Capacities to 26,000<br />

■ GPM (6000 m 3 /h)<br />

■ Heads to 410 feet (125 m)<br />

■ Temperatures to 446°F (230°C)<br />

■ Pressures to 232 PSIG (16 bar)<br />

2

<strong>Models</strong> <strong>3180</strong>/85 <strong>Paper</strong> <strong>Stock</strong>/<strong>Process</strong> <strong>Pumps</strong><br />

Heavy Duty Design Features for Handling the Toughest Services<br />

LUBRICATION<br />

FLEXIBILITY<br />

The preferred<br />

lubrication of oil is<br />

standard. No special<br />

parts required to<br />

convert to grease .<br />

SEALING FLEXIBILITY<br />

Choice of mechanical seal<br />

(illustrated), packed box or<br />

dynamic seal.<br />

TAPERBORE TM<br />

PLUS SEAL CHAMBER<br />

Wide range of sealing arrangements available<br />

to meet service conditions. Patented seal<br />

chambers improve lubrication and heat<br />

removal (cooling) of seal faces for extended<br />

seal life and pump uptime.<br />

LABYRINTH<br />

SEALS<br />

Unique <strong>Goulds</strong> design<br />

prevents premature<br />

bearing failure caused<br />

by lubricant<br />

contamination and<br />

loss of lubricant.<br />

CASING<br />

• Top centerline discharge<br />

for air handling and<br />

self-venting. Special<br />

volute design reduces<br />

radial loads.<br />

• Back pull-out design.<br />

• Foot-mounted.<br />

CONTINUOUS<br />

HIGH<br />

PERFORMANCE<br />

Original high<br />

efficiency maintained<br />

by simple external<br />

impeller adjustment<br />

resulting in long term<br />

energy savings.<br />

HEAVY DUTY<br />

SHAFT<br />

Designed for minimum<br />

deflection at maximum<br />

load. Dry shaft<br />

achieved by sealing<br />

from pumpage by<br />

O-rings at sleeve and<br />

impeller nut.<br />

RIGID FEET<br />

Large casing and<br />

bearing frame feet<br />

maintain driver<br />

alignment with high<br />

pipe loads; absorb<br />

system vibration.<br />

RENEWABLE<br />

SUCTION<br />

SIDEPLATE<br />

With open impeller<br />

design minimizes<br />

maintenance costs.<br />

Positively sealed with<br />

O-ring and gasket.<br />

OPEN IMPELLER<br />

Full back shroud and thick impeller vanes<br />

for handling slurries and stringy fibers. Large<br />

balance holes and back pump-out vanes<br />

minimize stuffing box pressure and axial<br />

thrust. Optional enclosed impeller available.<br />

3

Power Ends Designed for<br />

Maximum Reliability<br />

Power End Reliability is vital when thinking about pump mean<br />

time between failure (MTBF). To ensure maximum bearing<br />

life, the <strong>3180</strong>/85 follows three key bearing design factors:<br />

1. Bearing Design Life<br />

2. Bearing Temperature<br />

3. Bearing Environment<br />

Bearing Design Life<br />

Bearing manufacturers state that skidding, cage stresses<br />

and oil temperatures can greatly reduce the bearing life of<br />

oversized bearings. The “right” size bearing is vital to overall<br />

bearing life.<br />

Bearing Load Measured on Test<br />

Bearing Life in Hours<br />

Maximized Bearing Life<br />

Assumed<br />

• Skidding<br />

• Cage Stresses<br />

• Temperature<br />

Assumed Bearing Life<br />

Actual Bearing Life<br />

Actual<br />

<strong>Goulds</strong><br />

Bearing<br />

Sizes<br />

Undersized<br />

Bearings<br />

Oversized<br />

Bearings<br />

Bearing Size<br />

Bigger is NOT always better!<br />

Bearings are often oversized because pump designers often estimate<br />

bearing loads. <strong>Goulds</strong> measured their loads on test and chose bearing<br />

designs that would enable bearing life of 100,000 hours.<br />

Bearing Temperature<br />

Keeping the pump loads minimized and selecting<br />

the “right” bearing will keep bearing temperature<br />

under control.<br />

85˚C<br />

70˚C<br />

High<br />

Typical<br />

180˚F<br />

160˚F<br />

Bearing Temperature vs. Size<br />

60˚C<br />

140˚F<br />

Temperature<br />

The Right Size<br />

50˚C<br />

(<strong>3180</strong>/85<br />

Avg.)<br />

40˚C<br />

Low<br />

120˚F<br />

(<strong>3180</strong>/85<br />

Avg.)<br />

100˚F<br />

Bearing Size<br />

Typical bearing operating temperatures of competitor’s<br />

process pumps are between 140-160˚F. <strong>Goulds</strong> Model<br />

<strong>3180</strong>/85 bearing temperatures average only 120˚F/50˚C!<br />

6

Bearing Environment<br />

Labyrinth oil seals are standard<br />

Contamination being the second leading cause<br />

of bearing failure requires special attention.<br />

Common lip seals were not considered due to<br />

their 2,000 hour design life. After wearing out,<br />

there will be an open passage way for<br />

contamination. For this reason our <strong>3180</strong>/85 is<br />

provided with labyrinth oil seals as standard. We<br />

picked carbon filled Teflon ® since it is durable<br />

and impervious to corrosion.<br />

Labyrinth sealing paths<br />

Water exclusion test<br />

Oil containment test<br />

Dust exclusion test<br />

Design Life, X 1000h<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

Relative Life of Bearing Housing Protection Devices<br />

Single<br />

Lip Seal<br />

Magnetic<br />

Seal<br />

Bearing<br />

Lower<br />

Range<br />

Bearing<br />

Upper<br />

Range<br />

Infinite<br />

Labyrinth<br />

RIGID FRAME FOOT<br />

Heavy duty foot reduces<br />

effects of pipeloads/<br />

thermal expansion on<br />

bearing life. Bearings<br />

continue to run cool.<br />

Our labyrinth seals were put through a series of<br />

“torture” tests to see how well they would perform.<br />

Only the <strong>Goulds</strong> seal passed every test while<br />

other competitive labyrinth seals failed.<br />

LARGE OIL<br />

SIGHT GLASS<br />

The standard oil<br />

sight glass assures<br />

oil level is properly<br />

set and maintained.<br />

Condition<br />

of oil is also<br />

easily monitored.<br />

Power End Reliability is Both<br />

Designed-In and Guaranteed<br />

Bearing Design Life................❑ (>100,000 hours)<br />

Bearing Temperature..............❑ ✓(120˚F/50°C average)<br />

Bearing Environment..............❑ ✓(Superior Oil Seal design)<br />

Guarantee...............................❑ ✓(Reliability<br />

Guarantee)<br />

✓<br />

Our Guarantee<br />

<strong>Goulds</strong> <strong>Pumps</strong> backs the <strong>3180</strong>/85 power ends with an<br />

unconditional guarantee against defects in workmanship<br />

and material for 3 years from date of manufacture.<br />

7

Hydraulic Coverage 50 Hz<br />

150<br />

TOTAL HEAD—METERS<br />

125<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

25<br />

20<br />

15<br />

1470 RPM<br />

3 x 6-14<br />

3 x 6-12<br />

4 x 6-19<br />

4 x 6-16<br />

6 x 10-22<br />

8 x 10-22<br />

4 x 8-19<br />

10 x 12-22<br />

6 x 10-19<br />

12 x 14-22<br />

8 x 10-19<br />

6 x 8-16<br />

10 x 12-19<br />

6 x 10-16<br />

12 x 14-19<br />

4 x 6-14<br />

8 x 10-16<br />

6 x 8-14<br />

10 x 12-16<br />

8 x 8-14<br />

14 x 14-16<br />

10 x 10-14<br />

4 x 6-12<br />

6 x 8-12 8 x 8-12<br />

12 x 12-14<br />

10<br />

7<br />

30 50 80 100 150 200 300 500 700 1000 2000 3000 4000<br />

CAPACITY—m 3/h<br />

TOTAL HEAD—METERS<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

15<br />

10<br />

7<br />

960 RPM<br />

6 x 10-25<br />

6 x 10-22<br />

8 x 12-25<br />

10 x 14-25<br />

8 x 10-22<br />

4 x 6-19<br />

4 x 8-19<br />

6 x 10-19<br />

10 x 12-22<br />

8 x 10-19 12 x 14-22 20 x 20-25<br />

4 x 6-16<br />

14 x 16-22<br />

10 x 12-19<br />

6 x 8-16<br />

6 x 10-16<br />

3 x 6-14<br />

12 x 14-19<br />

4 x 6-14<br />

8 x 10-16<br />

16 x 16-19 18 x 18-22<br />

6 x 8-14<br />

10 x 12-16<br />

20 x 20-25<br />

8 x 8-14<br />

(740 RPM)<br />

3 x 6-12<br />

14 x 14-16 18 x 18-22<br />

(740 RPM)<br />

10 x 10-14<br />

6 x 8-12<br />

4 x 6-12<br />

8 x 8-12 12 x 12-14<br />

5<br />

3<br />

20 30 40 50 70 100 200 300 500 700 1000 2000 3000 5000 7000<br />

CAPACITY—m 3/h<br />

10

Hydraulic Coverage 60 Hz<br />

500<br />

400<br />

1780 RPM<br />

4 x 6-19<br />

300<br />

250<br />

4 x 6-16<br />

4 x 8-19<br />

6 x 10-19<br />

8 x 10-19<br />

TOTAL HEAD—FEET<br />

200<br />

150<br />

100<br />

80<br />

3 x 6-14<br />

3 x 6-12<br />

6 x 8-16<br />

6 x 10-16<br />

8 x 10-16<br />

10 x 12-16<br />

4 x 6-14 6 x 8-14<br />

8 x 8-14<br />

10 x 10-14<br />

4 x 6-12<br />

6 x 8-12<br />

8 x 8-12<br />

12 x12-14<br />

60<br />

40<br />

150 200 300 400 500 700 1000 2000 3000 5000 7000 10000<br />

CAPACITY—GPM<br />

350<br />

300<br />

250<br />

200<br />

1180 RPM<br />

6 x 10-22<br />

6 x 10-25<br />

8 x 12-25<br />

10 x 14-25<br />

TOTAL HEAD—FEET<br />

150<br />

100<br />

70<br />

50<br />

40<br />

30<br />

3 x 6-14<br />

3 x 6-12<br />

4 x 6-19<br />

4 x 6-16<br />

4 x 6-14<br />

6 x 8-14<br />

4 x 8-19<br />

6 x 10-19<br />

6 x 8-16<br />

8 x 8-14<br />

4 x 6-12 6 x 8-12 8 x 8-12<br />

6 x 10-16<br />

8 x 10-16<br />

8 x 10-22<br />

10 x 12-22<br />

12 x 14-22<br />

8 x 10-19<br />

10 x 12-19<br />

10 x 10-14<br />

10 x 12-16<br />

12 x 12-14<br />

14 x 14-16<br />

12 x 14-19<br />

14 x 16-22<br />

16 x 16-19<br />

16 x 16-19<br />

(885 RPM)<br />

18 x 18-22<br />

(885 RPM)<br />

18 x 18-22<br />

20 x 20-25<br />

(885 RPM)<br />

20<br />

15<br />

100 200 300 400 500 700 1000 1500 2000 3000 5000 10000 20000 30000<br />

CAPACITY—GPM<br />

11

Parts List and Materials of Construction<br />

Material<br />

Item<br />

All Iron/<br />

All Iron/<br />

Number<br />

Part Name<br />

SS Impeller<br />

SS Impeller,<br />

SS Sideplate<br />

All 316SS All 317SS All CD4MCu<br />

100 Casing Cast Iron Cast Iron 316SS 317SS CD4MCu<br />

101 Impeller 316SS 316SS 316SS 317SS CD4MCu<br />

105 Lantern Ring Teflon ®<br />

106 Packing Teflon ® Impregnated Fibers<br />

107 Gland 316SS<br />

112 Thrust Bearing (Duplex Angular Contact)<br />

122 Shaft Carbon Steel (4340)<br />

126 Shaft Sleeve 316SS 316SS 316SS 317SS CD4MCu<br />

127 Case Wear Ring (Enclosed Impeller) 316SS 316SS 316SS 317SS CD4MCu<br />

134A Bearing Housing Cast Iron<br />

136 Bearing Locknut and Lockwasher Steel<br />

159 Seal Chamber (Mechanical Seal) Cast Iron Cast Iron 316SS 317SS CD4MCu<br />

176 Suction Sideplate (Open Impeller) Cast Iron 316SS 316SS 317SS CD4MCu<br />

184 Stuffing Box Cover (Packed Box) Cast Iron Cast Iron 316SS 317SS CD4MCu<br />

184A Stuffing Box Cover (Dynamic Seal Option) 316SS 316SS 316SS 317SS CD4MCu<br />

202 Impeller Wear Ring (Enclosed Impeller) 316SS 316SS 316SS 317SS CD4MCu<br />

228 Bearing Frame Cast Iron<br />

262 Repeller (Dynamic Seal Option) 316SS 316SS 316SS 317SS CD4MCu<br />

304 Impeller Nut 316SS 316SS 316SS 317SS CD4MCu<br />

332A Labyrinth Seal, Outboard Carbon-Filled Teflon ® with Viton ® O-Ring<br />

333A Labyrinth Seal, Inboard Carbon-Filled Teflon ® with Viton ® O-Ring<br />

351 Casing Gasket Aramid Fiber with EPDM Rubber<br />

353 Mechanical Seal As Required<br />

358 Casing Drain Plug Carbon Steel Carbon Steel 316SS 317SS Alloy 20<br />

360P Sideplate-to-Casing Gasket Aramid Fiber with EPDM Rubber<br />

409 Radial Bearing (Cylindrical Roller)<br />

412A O-ring, Impeller Teflon ®<br />

412C O-ring, Sideplate-to-Casing Viton ®<br />

412F O-ring, Sleeve Teflon ®<br />

444 Backplate (Dynamic Seal Option) 316SS 316SS 316SS 317SS CD4MCu<br />

496 O-ring, Bearing Housing Buna<br />

748 Casing Lug Ductile Iron<br />

Materials of Construction<br />

Approximate Equivalent Standards<br />

Material ASTM DIN JIS ISO<br />

Ductile Iron A536 Gr 60-40-18 0.7043<br />

Cast Iron A48 Class 30B 0.6020<br />

316SS A743 CF-8M 1.4408<br />

317SS A743 CG-8M 1.4448<br />

CD4MCu A743 CD4MCu 1.4517<br />

Alloy 20 A743 CN-7M 1.4536<br />

G5502<br />

FCD40<br />

G5501<br />

FC20<br />

G5121<br />

SCS14<br />

R1083/400-12<br />

DR185/Gr200<br />

12

Dimensions Model <strong>3180</strong><br />

All dimensions in inches. Not to be used for construction.<br />

SP A B<br />

DISCHARGE<br />

X<br />

SUCTION<br />

D<br />

DIMENSIONS—ENGLISH (INCHES)<br />

Group Size Discharge Suction D X B A<br />

SP<br />

(minimum)<br />

Pump Weight–<br />

Pounds<br />

3X6–12 3 6 9.84 12.40 4.92 20.87 5.51 368<br />

4X6–12 4 6 9.84 13.98 5.51 20.87 5.51 389<br />

6X8–12 6 8 11.02 14.76 6.30 20.87 5.51 520<br />

S 8X8–12 8 8 12.40 16.73 7.87 20.87 5.51 650<br />

3X6–14 3 6 9.84 12.40 4.94 20.87 5.51 468<br />

4X6–14 4 6 11.02 13.98 5.51 20.87 5.51 503<br />

4X6–16 4 6 12.40 15.75 5.51 20.87 5.51 566<br />

M<br />

L<br />

XL<br />

6X8–14 6 8 12.40 15.75 6.30 26.38 7.09 545<br />

8X8–14 8 8 12.40 17.72 7.09 26.38 7.09 620<br />

10X10–14 10 10 13.98 18.70 8.86 26.38 7.09 773<br />

12X12–14 12 12 16.73 22.05 9.84 26.38 7.09 922<br />

6X8–16 6 8 12.40 17.72 6.30 26.38 7.09 626<br />

4X6–19 4 6 12.40 16.73 6.30 26.38 7.09 672<br />

6X10–16 6 10 13.98 19.69 7.09 29.53 7.09 821<br />

8X10–16 8 10 16.73 19.69 8.86 29.53 7.09 913<br />

10X12–16 10 12 16.73 23.62 10.43 29.53 7.09 1077<br />

14X14–16 14 14 19.69 26.38 11.04 29.53 7.09 1336<br />

4X8–19 4 8 13.98 17.72 6.30 29.53 7.09 700<br />

6X10–19 6 10 13.98 19.69 7.09 29.53 7.09 926<br />

8X10–19 8 10 16.73 22.05 7.87 29.53 7.09 994<br />

10X12–19 10 12 16.73 23.62 9.84 29.53 7.09 1133<br />

6X10–22 6 10 16.73 22.05 7.09 29.53 7.09 1087<br />

8X10–22 8 10 16.73 23.62 8.86 29.53 7.09 1198<br />

12X14–19 12 14 19.69 26.38 11.02 32.68 9.84 1538<br />

16X16–19 16 16 22.05 29.53 11.81 33.46 9.84 1846<br />

10X12–22 10 12 19.69 26.38 8.86 32.68 9.84 1451<br />

12X14–22 12 14 22.05 26.38 10.43 32.68 9.84 1682<br />

14X16–22 14 16 24.80 29.53 13.19 32.68 9.84 2018<br />

18X18–22 18 18 24.80 33.46 13.98 33.46 9.84 2321<br />

6X10–25 6 10 16.73 22.05 7.87 32.68 9.84 1389<br />

8X12–25 8 12 19.69 24.80 8.86 32.68 9.84 1515<br />

10X14–25 10 14 22.05 29.53 9.84 32.68 9.84 1688<br />

20X20–25 20 20 29.53 39.37 15.75 33.46 9.84 2681<br />

14

Dimensions Model <strong>3185</strong><br />

All dimensions in mm. Not to be used for construction.<br />

A F<br />

X DN 1<br />

H 2<br />

DN 2<br />

H 1<br />

DIMENSIONS—METRIC (mm)<br />

Group Size<br />

Discharge Suction<br />

DN<br />

H 1 H 2 A F<br />

1 DN 2<br />

X<br />

(minimum)<br />

Pump<br />

Weight–kg<br />

3X6–12* 80 150 250 315 125 530 140 167<br />

4X6–12* 100 150 250 355 140 530 140 176<br />

6X8–12* 150 200 280 375 160 530 140 236<br />

S 8X8–12 200 200 315 425 200 530 140 295<br />

3X6–14* 80 150 250 315 125 530 140 212<br />

4X6–14* 100 150 280 355 140 530 140 228<br />

4X6–16* 100 150 315 400 140 530 140 257<br />

6X8–14* 150 200 315 400 160 670 180 247<br />

8X8–14 200 200 315 450 180 670 180 281<br />

M<br />

10X10–14 250 250 355 475 225 670 180 351<br />

12X12–14 300 300 425 560 250 670 180 418<br />

6X8–16* 150 200 315 450 160 670 180 284<br />

4X6–19 100 150 315 425 160 670 180 305<br />

6X10–16 150 250 355 500 180 750 180 372<br />

8X10–16 200 250 425 500 225 750 180 414<br />

10X12–16 250 300 425 600 265 750 180 489<br />

14X14–16 350 350 500 670 180 750 180 606<br />

L<br />

4X8–19 100 200 355 450 160 750 180 318<br />

6X10–19 150 250 355 500 180 750 180 420<br />

8X10–19 200 250 425 560 200 750 180 451<br />

10X12–19 250 300 425 600 250 750 180 514<br />

6X10–22 150 250 425 560 180 750 180 493<br />

8X10–22 200 250 425 600 225 750 180 543<br />

12X14–19 300 350 500 670 280 830 250 698<br />

16X16–19 400 400 560 750 300 850 250 837<br />

10X12–22 250 300 500 670 225 830 250 658<br />

12X14–22 300 350 560 670 265 830 250 763<br />

XL<br />

14X16–22 350 400 630 750 335 830 250 915<br />

18X18–22 450 450 630 850 355 850 250 1053<br />

6X10–25 150 250 425 560 200 830 250 630<br />

8X12–25 200 300 500 630 225 830 250 687<br />

10X14–25 250 300 560 750 250 830 250 766<br />

20X20–25 500 500 750 1000 400 850 250 1216<br />

*Pump dimensions per ISO 2858 (125 mm flanges are not used).<br />

15

Modular Interchangeability<br />

Size Casing Sideplate/Impeller Stuffing Box Power End*<br />

3x6–12▲<br />

4x6–12▲<br />

6x8–12<br />

8x8–12<br />

3x6–14▲<br />

4x6–14▲<br />

4x6–16▲<br />

S Group<br />

6x8–14▲<br />

8x8–14▲<br />

10x10–14▲<br />

12x12–14<br />

6x8–16▲<br />

4x6–19▲<br />

M Group<br />

6x10–16▲<br />

8x10–16▲<br />

10x12–16▲<br />

14x14–16▲<br />

4x8–19▲<br />

6x10–19▲<br />

8x10–19▲<br />

10x12–19▲<br />

6x10–22▲<br />

8x10–22▲<br />

L Group<br />

12x14–19▲<br />

16x16–19<br />

10x12–22▲<br />

12x14–22▲<br />

14x16–22▲<br />

18x18–22<br />

6x10–25▲<br />

8x12–25▲<br />

10x14–25▲<br />

20x20–25<br />

XL Group<br />

*Shafts for <strong>Models</strong> <strong>3180</strong> and <strong>3185</strong> are not interchangeable.<br />

Sleeves for mechanical seals on the <strong>3180</strong> and <strong>3185</strong> are not interchangeable.<br />

▲ Available with enclosed impeller.<br />

16

Construction Details <strong>3180</strong> (English Dimensions) and <strong>3185</strong> (Metric Dimensions)<br />

Temperature<br />

Limits<br />

Shaft Diameters<br />

(English=inches,<br />

Metric=mm)<br />

S Group M Group L Group XL Group<br />

Model <strong>3180</strong> <strong>3185</strong> <strong>3180</strong> <strong>3185</strong> <strong>3180</strong> <strong>3185</strong> <strong>3180</strong> <strong>3185</strong><br />

(units) (English) (Metric) (English) (Metric) (English) (Metric) (English) (Metric)<br />

Grease Lube 355° F 180° C 355° F 180° C 355° F 180° C 355° F 180° C<br />

0il Lube w/o cooling 355° F 180° C 355° F 180° C 355° F 180° C 355° F 180° C<br />

0il lube w/cooling 445° F 230° C 445° F 230° C 445° F 230° C 445° F 230° C<br />

At Impeller 1.51 38.5 1.77 45 2.20 56 2.60 66<br />

Under Shaft Sleeve 1.97 50 2.28 58 2.68 68 3.15 80<br />

At Coupling 1.625 42 1.875 48 2.375 65 2.875 75<br />

Between Bearings 2.63 67 2.88 73 3.39 86 4.06 103<br />

Bore 3.35 85 3.74 95 4.13 105 4.72 120<br />

Depth 3.35 85 3.35 85 3.54 90 3.54 90<br />

Packed Stuffing Packing Size 1/2 12.5 1/2 12.5 1/2 12.5 1/2 12.5<br />

(English=inches, # of Packing Rings 5 5 5 5 5 5 5 5<br />

Metric=mm) Width of Lantern Ring 5/8 16 5/8 16 3/4 19 3/4 19<br />

Distance to 1st Obstruction 2.26 57 3.14 80 2.76 70 3.24 82<br />

Sleeve Diameter 2.362 60 2.756 70 3.150 80 3.738 95<br />

Seal Chamber for Bore 3.37 85.6 3.88 98.5 4.49 114 5 127<br />

mechanical seal Depth to VPE ring 1.81 46 2.40 61 2.15 54.6 2.15 54.6<br />

(English=inches, Distance to 1st Obstruction 2.89 73 3.64 93 3.46 88 3.98 101<br />

Metric=mm) Sleeve Diameter 2.375 60 2.75 70 3.25 80 3.75 95<br />

Coupling Spacing Min. req’d for back pull-out 5.5 inch 140 mm 7.09 inch 180 mm 7.09 inch 180 mm 9.84 inch 240 mm<br />

Ease of Maintenance<br />

• High strength Casing Lugs to secure cover to casing.<br />

• Lugs swing away without removal during disassembly. Prevents<br />

lost or misplaced Lugs and Casing Bolts.<br />

• Lug can be used as jacking bolt to assist in pump disassembly.<br />

• Large opening on each side of adapter for easy access to<br />

Seal and Gland.<br />

Model 3181/86<br />

for High Pressure/Temperature<br />

Services<br />

• Centerline mounted<br />

• Same hydraulics as <strong>3180</strong>/85<br />

• Power End components are<br />

interchangeable with <strong>3180</strong>/85<br />

17

Pick Your Perfect <strong>Process</strong> Pump<br />

No one in the industry offers the broad range<br />

of process pumps that <strong>Goulds</strong> does!<br />

Whether it’s for pumping severe corrosives, abrasive<br />

slurries, fibrous/stringy solids, high temperature<br />

liquids, hazardous fluids, low flow or high capacity<br />

services – <strong>Goulds</strong> has a perfect, reliable solution.<br />

The <strong>Goulds</strong> selection of pump solutions<br />

includes horizontal and vertical configurations<br />

in a range of alloy and non-metallic<br />

constructions, sealed and sealless.<br />

The Pulp and <strong>Paper</strong> Industry has the widest range of applications of any industry. <strong>Goulds</strong> wide range of products ensures<br />

that we have the right pump for virtually every application.<br />

Mill Area<br />

Mill Area<br />

Bleach Chemical<br />

<strong>Paper</strong> Power<br />

Bleach Chemical<br />

Pump Type Model Woodyard Pulp Mill Plant Recovery Recycle Machine House<br />

Pump Type Model Woodyard Pulp Mill Plant Recovery Recycle<br />

<strong>Paper</strong> <strong>Stock</strong><br />

Medium<br />

Consistency<br />

Chemical<br />

<strong>Process</strong><br />

Recessed<br />

Impeller<br />

Double<br />

Suction<br />

3175<br />

<strong>3180</strong>/85<br />

3181/86<br />

3500<br />

3501<br />

3196<br />

LF3196<br />

IC<br />

CV3196<br />

HS<br />

3410/3409<br />

3415/3420<br />

3796<br />

Sealless<br />

High Temp/Press<br />

Multi-Stage<br />

Axial Flow<br />

Slurry<br />

Submersible<br />

Vertical<br />

3298<br />

3296<br />

3700<br />

3310H<br />

3355<br />

3600<br />

3316<br />

AF<br />

JC<br />

SRL<br />

HSU<br />

JCU<br />

VHS<br />

Self-Priming &<br />

Pump<br />

Trash Hog<br />

Solids Handling<br />

3171<br />

Prime Line<br />

Vertical VIT<br />

Turbine VIC<br />

<strong>Paper</strong><br />

Machine<br />

Power<br />

House<br />

Visit our website at www.gouldspumps.com<br />

Form B723.9 2/03<br />

© 2003 <strong>Goulds</strong> <strong>Pumps</strong>, Incorporated<br />

A subsidiary of ITT Industries, Inc.