w w w . s c e m a g a z i n e . c o m - Supply Chain Europe

w w w . s c e m a g a z i n e . c o m - Supply Chain Europe

w w w . s c e m a g a z i n e . c o m - Supply Chain Europe

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

the model that appears to have just failed is predicted<br />

on demand that is predictable and steady or increasing.<br />

for storage in Western <strong>Europe</strong>. You might<br />

consider selling the now surplus finished<br />

goods in their country or region of origin,<br />

rather than bringing them to the West at<br />

all. Or, of course, seek another market;<br />

even in a recession, some countries are<br />

better placed than others and it may be<br />

possible, for example, to divert shipments<br />

to Latin America rather than Iberia. Of<br />

course, your downturn may have happened<br />

after your shipments have arrived. You can<br />

store these goods (with all the relevant<br />

charges and the risk of damage, decay and<br />

obsolescence) or sell on, perhaps at little or<br />

no profit, into secondary markets. (That, of<br />

course, carries its own risks; if consumers<br />

get used to finding your branded goods in<br />

low cost outlets, they may not be happy,<br />

come the upturn, when you try to reimpose<br />

your normal cost margins.)<br />

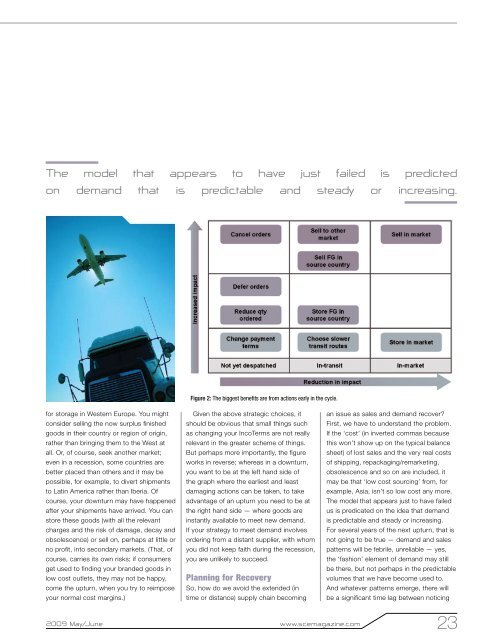

Figure 2: The biggest benefits are from actions early in the cycle.<br />

Given the above strategic choices, it<br />

should be obvious that small things such<br />

as changing your IncoTerms are not really<br />

relevant in the greater scheme of things.<br />

But perhaps more importantly, the figure<br />

works in reverse; whereas in a downturn,<br />

you want to be at the left hand side of<br />

the graph where the earliest and least<br />

damaging actions can be taken, to take<br />

advantage of an upturn you need to be at<br />

the right hand side — where goods are<br />

instantly available to meet new demand.<br />

If your strategy to meet demand involves<br />

ordering from a distant supplier, with whom<br />

you did not keep faith during the recession,<br />

you are unlikely to succeed.<br />

Planning for Recovery<br />

So, how do we avoid the extended (in<br />

time or distance) supply chain becoming<br />

an issue as sales and demand recover?<br />

First, we have to understand the problem.<br />

If the ‘cost’ (in inverted commas because<br />

this won’t show up on the typical balance<br />

sheet) of lost sales and the very real costs<br />

of shipping, repackaging/remarketing,<br />

obsolescence and so on are included, it<br />

may be that ‘low cost sourcing’ from, for<br />

example, Asia, isn’t so low cost any more.<br />

The model that appears just to have failed<br />

us is predicated on the idea that demand<br />

is predictable and steady or increasing.<br />

For several years of the next upturn, that is<br />

not going to be true — demand and sales<br />

patterns will be febrile, unreliable — yes,<br />

the ‘fashion’ element of demand may still<br />

be there, but not perhaps in the predictable<br />

volumes that we have become used to.<br />

And whatever patterns emerge, there will<br />

be a significant time lag between noticing<br />

2009 may/June www.scemagazine.com 23