Flowtech pressure relief valve

Flowtech pressure relief valve

Flowtech pressure relief valve

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The newly engineered adjustable #45 Pressure Relief Valve is<br />

designed to be used in the pharmaceutical / biotech, food<br />

and beverage and chemical industries.<br />

STD <strong>pressure</strong> range<br />

Optional<br />

STD max system <strong>pressure</strong><br />

STD inside finish<br />

STD o-ring material<br />

10-105 psig<br />

up to 200 psig<br />

down to 5 psig<br />

200 psig<br />

35 Ra (0.8 micron. pm)<br />

EPDM<br />

The new #46 Pressure Relief Valve is sanitary-designed<br />

to allow the user to easily adjust <strong>pressure</strong> settings without<br />

removing the <strong>valve</strong> from the process line. An adjustment<br />

locking mechanism and stainless cap are provided for<br />

protection against accidental adjustments and for a clean and<br />

aesthetic appearance. An O-ring is positively sandwiched<br />

between the two disc members and will not come loose due<br />

to the velocity of liquid or accidental bumping or sticking.<br />

The Flowtighfu design has been proven to seal over years.<br />

Valves can be adjusted from 15 psig up to 105 psig without use<br />

of special tools. The <strong>valve</strong> body and spring chamber are<br />

connected by sanitary Tri-Clamp connection for easy disassembly<br />

without removal from the process line for service. An added<br />

feature is the external stem lifter, allowing for opening of<br />

the <strong>valve</strong> for cleaning and removal of the entire top half<br />

while still installed.<br />

All wetted #46 <strong>valve</strong> parts are in 316L stainless material.<br />

O-ring elastomers available in EPDM, Viton or PTFE<br />

encapsulated Viton.<br />

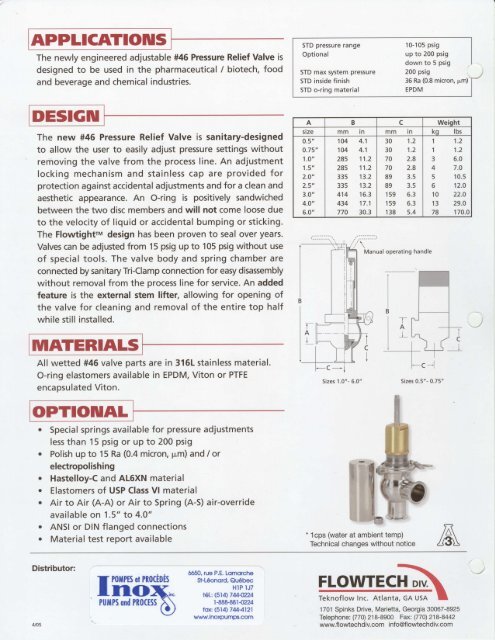

A B c Weisht<br />

stze mm In mm tn kq lbs<br />

0.5"<br />

0.75"<br />

1.0"<br />

1.5"<br />

2.0"<br />

2.5"<br />

3.0"<br />

4.O"<br />

6.0"<br />

104<br />

104<br />

285<br />

285<br />

335<br />

335<br />

414<br />

434<br />

770<br />

Sizes 1.0"- 6.0"<br />

4.' |<br />

4.' |<br />

't't.2<br />

11.2<br />

13.2<br />

13.2<br />

16.3<br />

17.1<br />

30.3<br />

30 1.2<br />

30 1.2<br />

70 2.8<br />

70 2.8<br />

89 3.5<br />

89 3.s<br />

159 6.3<br />

159 6.3<br />

138 5.4<br />

Manual operating handle<br />

I Tt'<br />

l A l<br />

I -l<br />

---[<br />

c --l<br />

Sizes 0.5"- 0.75"<br />

1 1.2<br />

1 1.2<br />

3 5.0<br />

4 7.0<br />

5 10.5<br />

6 12.0<br />

10 22.0<br />

13 29.0<br />

78 170.0<br />

)<br />

a<br />

a<br />

a<br />

a<br />

a<br />

Special springs available for <strong>pressure</strong> adjustments<br />

less than 15 psig or up to 200 psig<br />

Polish up to 15 Ra (0.4 micron, pm) and / or<br />

electropolishing<br />

Hastelloy-C and AL6XN material<br />

Elastomers of USP Class Vl material<br />

Air to Air (A-A) or Air to Spring (A-S) air-override<br />

available on 1.5" to 4.0"<br />

ANSI or DIN flanged connections<br />

Material test report available<br />

. lcps (water at ambient temp)<br />

Technical changes without notice<br />

Distributor:<br />

lrr([Dx*<br />

PorilPES ot PRodDfS<br />

PUrtlPSond PR0cEss<br />

è)<br />

6ô50, rue P.E. Lomorche<br />

St-Léonord, Québec<br />

HIP IJ7<br />

féf.: (514) 744t24<br />

l€88-88r{1224<br />

fox: (514) 74l,4121<br />

www.lnoxpumpo.com<br />

FLOWTECH<br />

Teknoflow Inc. Atlanta, GA USA<br />

1701 Spinks Drive, Marietta, Georgia 30067-8925<br />

Telephone: (770) 218-8900 Fax: F70) 218-8442<br />

www.flowtechdiv.com info@flowtechdiv.com