Flowtech pressure relief valve

Flowtech pressure relief valve

Flowtech pressure relief valve

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

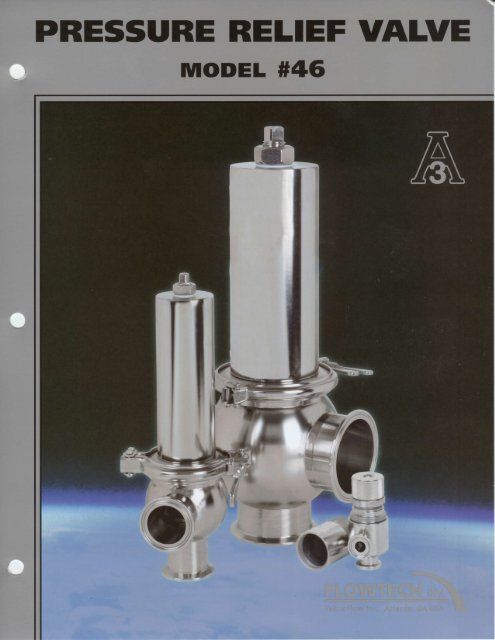

PRESSURE RELTEF VALVE<br />

MODEL #46<br />

rl<br />

ô

The newly engineered adjustable #45 Pressure Relief Valve is<br />

designed to be used in the pharmaceutical / biotech, food<br />

and beverage and chemical industries.<br />

STD <strong>pressure</strong> range<br />

Optional<br />

STD max system <strong>pressure</strong><br />

STD inside finish<br />

STD o-ring material<br />

10-105 psig<br />

up to 200 psig<br />

down to 5 psig<br />

200 psig<br />

35 Ra (0.8 micron. pm)<br />

EPDM<br />

The new #46 Pressure Relief Valve is sanitary-designed<br />

to allow the user to easily adjust <strong>pressure</strong> settings without<br />

removing the <strong>valve</strong> from the process line. An adjustment<br />

locking mechanism and stainless cap are provided for<br />

protection against accidental adjustments and for a clean and<br />

aesthetic appearance. An O-ring is positively sandwiched<br />

between the two disc members and will not come loose due<br />

to the velocity of liquid or accidental bumping or sticking.<br />

The Flowtighfu design has been proven to seal over years.<br />

Valves can be adjusted from 15 psig up to 105 psig without use<br />

of special tools. The <strong>valve</strong> body and spring chamber are<br />

connected by sanitary Tri-Clamp connection for easy disassembly<br />

without removal from the process line for service. An added<br />

feature is the external stem lifter, allowing for opening of<br />

the <strong>valve</strong> for cleaning and removal of the entire top half<br />

while still installed.<br />

All wetted #46 <strong>valve</strong> parts are in 316L stainless material.<br />

O-ring elastomers available in EPDM, Viton or PTFE<br />

encapsulated Viton.<br />

A B c Weisht<br />

stze mm In mm tn kq lbs<br />

0.5"<br />

0.75"<br />

1.0"<br />

1.5"<br />

2.0"<br />

2.5"<br />

3.0"<br />

4.O"<br />

6.0"<br />

104<br />

104<br />

285<br />

285<br />

335<br />

335<br />

414<br />

434<br />

770<br />

Sizes 1.0"- 6.0"<br />

4.' |<br />

4.' |<br />

't't.2<br />

11.2<br />

13.2<br />

13.2<br />

16.3<br />

17.1<br />

30.3<br />

30 1.2<br />

30 1.2<br />

70 2.8<br />

70 2.8<br />

89 3.5<br />

89 3.s<br />

159 6.3<br />

159 6.3<br />

138 5.4<br />

Manual operating handle<br />

I Tt'<br />

l A l<br />

I -l<br />

---[<br />

c --l<br />

Sizes 0.5"- 0.75"<br />

1 1.2<br />

1 1.2<br />

3 5.0<br />

4 7.0<br />

5 10.5<br />

6 12.0<br />

10 22.0<br />

13 29.0<br />

78 170.0<br />

)<br />

a<br />

a<br />

a<br />

a<br />

a<br />

Special springs available for <strong>pressure</strong> adjustments<br />

less than 15 psig or up to 200 psig<br />

Polish up to 15 Ra (0.4 micron, pm) and / or<br />

electropolishing<br />

Hastelloy-C and AL6XN material<br />

Elastomers of USP Class Vl material<br />

Air to Air (A-A) or Air to Spring (A-S) air-override<br />

available on 1.5" to 4.0"<br />

ANSI or DIN flanged connections<br />

Material test report available<br />

. lcps (water at ambient temp)<br />

Technical changes without notice<br />

Distributor:<br />

lrr([Dx*<br />

PorilPES ot PRodDfS<br />

PUrtlPSond PR0cEss<br />

è)<br />

6ô50, rue P.E. Lomorche<br />

St-Léonord, Québec<br />

HIP IJ7<br />

féf.: (514) 744t24<br />

l€88-88r{1224<br />

fox: (514) 74l,4121<br />

www.lnoxpumpo.com<br />

FLOWTECH<br />

Teknoflow Inc. Atlanta, GA USA<br />

1701 Spinks Drive, Marietta, Georgia 30067-8925<br />

Telephone: (770) 218-8900 Fax: F70) 218-8442<br />

www.flowtechdiv.com info@flowtechdiv.com