Woolworths Vendor Capability News - Woolworths wowlink

Woolworths Vendor Capability News - Woolworths wowlink

Woolworths Vendor Capability News - Woolworths wowlink

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Issue 4 December 2010<br />

<strong>Woolworths</strong> <strong>Vendor</strong> <strong>Capability</strong> <strong>News</strong><br />

Merry Christmas To All Of Our Trade Partners<br />

With the busiest time of year upon us we extend our warmest wishes for a safe and happy<br />

festive season to all of our Trade Partners and their families. We also thank our Trade<br />

Partners for their efforts in improving their level of logistics conformance into our <strong>Woolworths</strong><br />

DC’s. In the last six weeks total conformance has shown positive signs which is a credit to<br />

everyone in the supply chain.<br />

Congratulations To Our Crossword Prize Winner… FAVCO! Thanks to<br />

Last months crossword was very popular and thank you to all Trade Partners who submitted<br />

entries, but there can only be one winner. We congratulate Michael Wilson from Favco<br />

based in Queensland who was the correct entry drawn out of the barrel and is the recipient of<br />

the free onsite GS1 Pallet Label Assessment Service.<br />

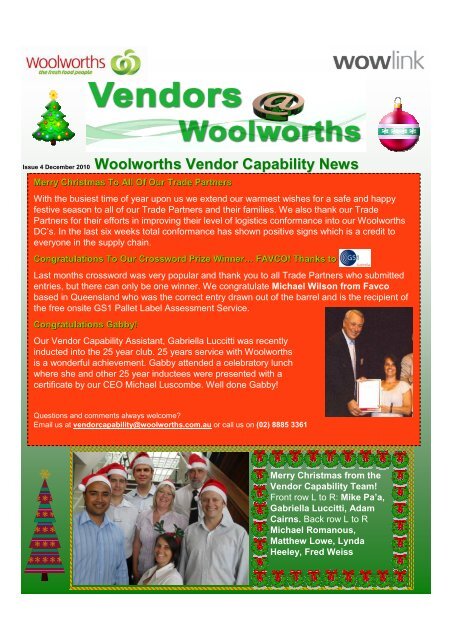

Congratulations Gabby!<br />

Our <strong>Vendor</strong> <strong>Capability</strong> Assistant, Gabriella Luccitti was recently<br />

inducted into the 25 year club. 25 years service with <strong>Woolworths</strong><br />

is a wonderful achievement. Gabby attended a celebratory lunch<br />

where she and other 25 year inductees were presented with a<br />

certificate by our CEO Michael Luscombe. Well done Gabby!<br />

Questions and comments always welcome<br />

Email us at vendorcapability@woolworths.com.au or call us on (02) 8885 3361<br />

Merry Christmas from the<br />

<strong>Vendor</strong> <strong>Capability</strong> Team!<br />

Front row L to R: Mike Pa’a,<br />

Gabriella Luccitti, Adam<br />

Cairns. Back row L to R<br />

Michael Romanous,<br />

Matthew Lowe, Lynda<br />

Heeley, Fred Weiss

Understanding Non-Conformances<br />

Pallet Issues: Plastic Wrapping / ‘Dags’<br />

Many Trade Partners nominate Plastic Wrapping / Dags as the non-conformance<br />

that is the most difficult to eliminate. This may be due to the fact that Plastic<br />

Wrapping / Dags can occur in transit or can occur after the pallet has been wrapped<br />

and left the site… But they are preventable.<br />

Most dags are caused by the forklift tines piercing the stretch wrap, creating a dag.<br />

This is why our specifications state that if you are wrapping pallets, the stretch wrap<br />

is to cover the top 1/3 of the pallet only. This enables forklifts to access the pallet<br />

without creating dags, but still secure the wrapped cartons to the pallet.<br />

The easiest way to ensure your stretch wrap covers the<br />

top 1/3 of the pallet each and every time is to install a<br />

roller bar device at the base of your wrapping machine<br />

(shown right).<br />

When the stretch wrap moves over the roller, it delivers<br />

the additional benefit of roping the stock to the pallet.<br />

This adds strength to the base of the wrap and prevents<br />

the wrapping extending down more than the top 1/3.<br />

Roller bar in use<br />

Total Pallet Issue Non-Conformance Last 13 Weeks<br />

Poorly wrapped pallet<br />

A4 Loose<br />

Paper/Non<br />

WOW Label<br />

6%<br />

Incorrect<br />

Temperature<br />

Damage 1%<br />

0% OverHang /<br />

Load Shifted<br />

14% 13%<br />

Plastic<br />

Wrapping /<br />

'Dags'<br />

70%<br />

Pallet Damaged<br />

10%<br />

Of 9,151 Pallet Issue<br />

Non-Conformances Reported…<br />

Well wrapped pallet

Plastic Wrapping / Dags: DC Impacts<br />

How Does a Piece of Stray Plastic Impact Our Distribution Centres<br />

es<br />

In our automated sites, pallets move along conveyors on the way to the high bay<br />

warehouse storage. During this process they are subjected to a series of checks, one<br />

of which is ensuring that no foreign object is protruding from the pallet. This is where<br />

Plastic Wrapping / Dags cause issues.<br />

Pallet Profile Scanner<br />

Dags<br />

Dags<br />

The Pallet Profile Scanners detect any object<br />

protruding from the pallet, for example:<br />

• Overhanging cartons<br />

• Loose plastic wrapping (dags)<br />

• Nails<br />

• Pallet boards<br />

If the pallet shows any signs of a foreign object it<br />

is rejected from entering the high bay warehouse<br />

causing our staff to re-work the pallet.<br />

Pallet Profile Scanner<br />

Rejecting a Pallet<br />

In extreme cases, dags can become caught on racking<br />

and cause significant damage to plant and equipment. It<br />

is for this reason we ask that the ends of stretch wrap be<br />

tucked in or taped down.<br />

The pictures below show how in extreme cases dags<br />

can occur and cause damage when retrieved by the<br />

crane, even though the pallet initially passed through the<br />

pallet profile scanner.<br />

Extreme Dag<br />

Damage to Plant and Equipment

Keeping Things M ving<br />

This Christmas<br />

Christmas time is easily the busiest time of year for everyone<br />

connected to the Retail industry. Follow these tips to allow us to<br />

turn your trucks around as fast as possible!<br />

• Ensure the driver has been inducted at the site to which they are<br />

delivering<br />

• Ensure all loads are secured correctly with gates, boards, straps<br />

etc<br />

• Keep paperwork simple… and correct!<br />

Avoid multiple invoices, 1 invoice per Purchase Order<br />

will make checking off your deliveries easier<br />

No packing slips or drivers run sheets are accepted<br />

No excessively sealed envelopes<br />

Accuracy and integrity<br />

• Ensure the driver has the Purchase Order numbers ready when<br />

arriving at the gatehouse & quotes ALL PO’s<br />

• Remember; No child under the age of 15 permitted on site<br />

• No speeding on site, safety at all times<br />

• Plan for additional transport if expecting increased volumes over<br />

the Christmas period<br />

• Ensure new staff or hired labour are trained on <strong>Woolworths</strong><br />

requirements… Have they seen the <strong>Vendor</strong> <strong>Capability</strong> DVD<br />

• Arrive within the ‘on time’ booking window!<br />

NOTE: All new drivers or transport companies can pre-arrange site inductions with<br />

the DC prior to deliveries by contacting the relevant DC in advance

Some of our most critical Christmas lines are chilled products such as Hams,<br />

Turkeys, Custards and Creams. With the warmer weather approaching it is important<br />

that our Trade Partners are focussed on maintaining cold chain integrity.<br />

• Do - Service the units on your trucks as correct temperature<br />

is the number one priority! 4 degrees max for chiller, minus 18<br />

degrees for freezer<br />

• Do - Arrive within your booking window at the DC (up to 60<br />

mins prior or 30 mins after your booking time)<br />

• Do - Remember maximum pallet height is 1.2 metres (some<br />

exceptions, milk etc)<br />

• Do - Temperature probes should be maintained and calibrated<br />

regularly to eliminate rejection for being over temperature<br />

Probe in use<br />

• Don’t - Mix frozen or chilled stock with ambient stock on a<br />

truck<br />

• Don’t - Open doors until the receiving staff have asked you to<br />

do so. Don’t break the cold chain!<br />

• Don’t - Mix Use by Dates on a pallet… only one Use by Date<br />

per line item, per pallet<br />

• Don’t turn off refrigeration unit when parked

The Five Minute National<br />

Ti Hi Audit!<br />

Check your Ti Hi settings nationally to make sure your pallet configurations are correct…<br />

- Login to <strong>wowlink</strong> and go to Supply Chain Reports – Replenishment<br />

and run the Product DC Details report<br />

- When the data has refreshed, export to Excel<br />

as ‘Data Only (XLS)’<br />

- When the export is complete, select ‘Open’<br />

- Copy and paste the data into a new Excel sheet<br />

- Delete rows 1 to 7<br />

- Click on a single cell within the sheet and on the menu bar click on<br />

Data, scroll down and select PivotTable and PivotChart Report<br />

- Select PivotTable, and click Finish. You will be presented with a blank<br />

canvas… Drag and drop the fields as shown below…<br />

Opportunity<br />

You will end up with a ref by DC table showing all Ti Hi’s for <strong>Woolworths</strong> DC’s<br />

nationally. Any Ti Hi that is different across our sites should be investigated as<br />

there could be logistical efficiencies available!<br />

If you need help with these steps, call us and we can walk you through it Ph (02) 8885 3361<br />

Need <strong>wowlink</strong> Send an email to <strong>wowlink</strong>_admin@woolworths.com.au

You may recall in our first newsletter we encouraged our <strong>Vendor</strong>s to submit and<br />

share ideas that would help other suppliers, and in turn help us all… This is a<br />

fantastic idea that Linfox at Erskine Park use to make sure their SSCC Labels are in<br />

the correct position on each and every pallet. Linfox are the 3PL for Proctor &<br />

Gamble operating the Erskine Park DC. We thank P&G & Linfox Erskine Park for<br />

sharing this idea with the <strong>Vendor</strong> community and hope this helps put an end to<br />

SSCC Label Position Incorrect issues.<br />

800mm<br />

400mm<br />

A solution to your Non-Conformance of SSCC Label Position Incorrect is the humble<br />

broom handle shown here in use at the Linfox wrapping station. The broom handle<br />

simply has red electrical tape applied up until the 400mm SSCC zone starts, then<br />

green tape up to 800mm high with yellow tape right in the sweet spot 600mm high.<br />

The broom handle is then finished off with red tape to the top. A simple but effective<br />

tool.<br />

The second requirement of the SSCC Label Position requires the label to be placed<br />

between 50mm and 100mm in from the right hand edge of the pallet. This distance is<br />

slightly less than the width of an SSCC Label (portrait orientation is 105mm). Use<br />

this as a guide only, but if you have a different way of ensuring the SSCC Label is in<br />

the correct position, let us know and we’ll share it in next months newsletter!

<strong>Vendor</strong>s @ <strong>Woolworths</strong><br />

<strong>Vendor</strong> Q & A<br />

Our December Q & A is with Kraft Foods Ian Bell<br />

Q: Ian, what steps does Kraft Foods take to ensure<br />

their operation is ready for Christmas volumes into<br />

<strong>Woolworths</strong> DC's<br />

A: Kraft Foods Confectionery start pre-planning<br />

Christmas lines with <strong>Woolworths</strong> approximately six<br />

months in advance. We work closely with <strong>Woolworths</strong><br />

Replenishment to agree when stock needs to be in DC,<br />

when it will be shipped to store, and build delivery plans<br />

around those dates. Given that a lot of our Christmas<br />

volume goes through the <strong>Woolworths</strong> cold storage<br />

DC's, space constraints mean it is essential we work<br />

together to ensure product flows into and out of the<br />

DC's smoothly.<br />

Q: You've recently undergone a change of warehouse facility, what were the main<br />

compliance challenges during that transition<br />

A: As part of our DC transition, the compliance checks and processes have migrated further up the<br />

supply chain. Previously the key compliance requirements were corrected when receiving our own<br />

stock within the DC to meet the same crane tolerances at the <strong>Woolworths</strong> automated sites. With our<br />

new DC, we are more reliant on getting everything right at the manufacturing sites.<br />

Q: What advice would you give to other Trade Partners who are experiencing circumstances<br />

outside those of their normal operation to ensure their conformance levels stay high<br />

A: Spend time at your DC receiving and despatch points to identify the issues, then use that<br />

knowledge to re-train in the right areas. It's essential to push the compliance as far back through<br />

the supply chain as possible, as it is not feasible to correct everything at point of despatch.<br />

Q: How do you think our Trade Partners can use the <strong>Vendor</strong> <strong>Capability</strong> Team to improve<br />

their operations compliance<br />

A: Develop a close working relationship with the <strong>Vendor</strong> <strong>Capability</strong> team and draw upon their<br />

knowledge to better understand compliance opportunities. Take advantage of this knowledge by<br />

having them conduct site audits - these will provide you with comprehensive feedback on how well<br />

you are really doing, and help you to target the remedial actions necessary.<br />

I N V E R T E D T W O<br />

A F N A B N<br />

T F G A T E H O U S E<br />

I N I T I A T E D<br />

P O C G Y<br />

N I E V E R Y O N E<br />

A E V D S<br />

L A N G U A G E O N C E<br />

L T G R U A<br />

Y N E W Y E A R L<br />

A O A<br />

W O W L I N K T<br />

E E F I F T E E N<br />

Last months crossword: Answers<br />

Wishing all of our Trade Partners and<br />

their families a very Merry Christmas<br />

Warm Regards,<br />

<strong>Vendor</strong> <strong>Capability</strong> Team